Flue gas deep cooler for achieving gas-liquid-solid condensation and absorbing and restraining low-temperature corrosion

A low-temperature corrosion, deep cooling technology, applied in the direction of reducing greenhouse gases, climate sustainability, combustion technology mitigation, etc., can solve the problems of atmospheric visual pollution, environmental pollution, low saturated humidity of ambient air, etc., to reduce direct collision, use Long life and low smoke resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

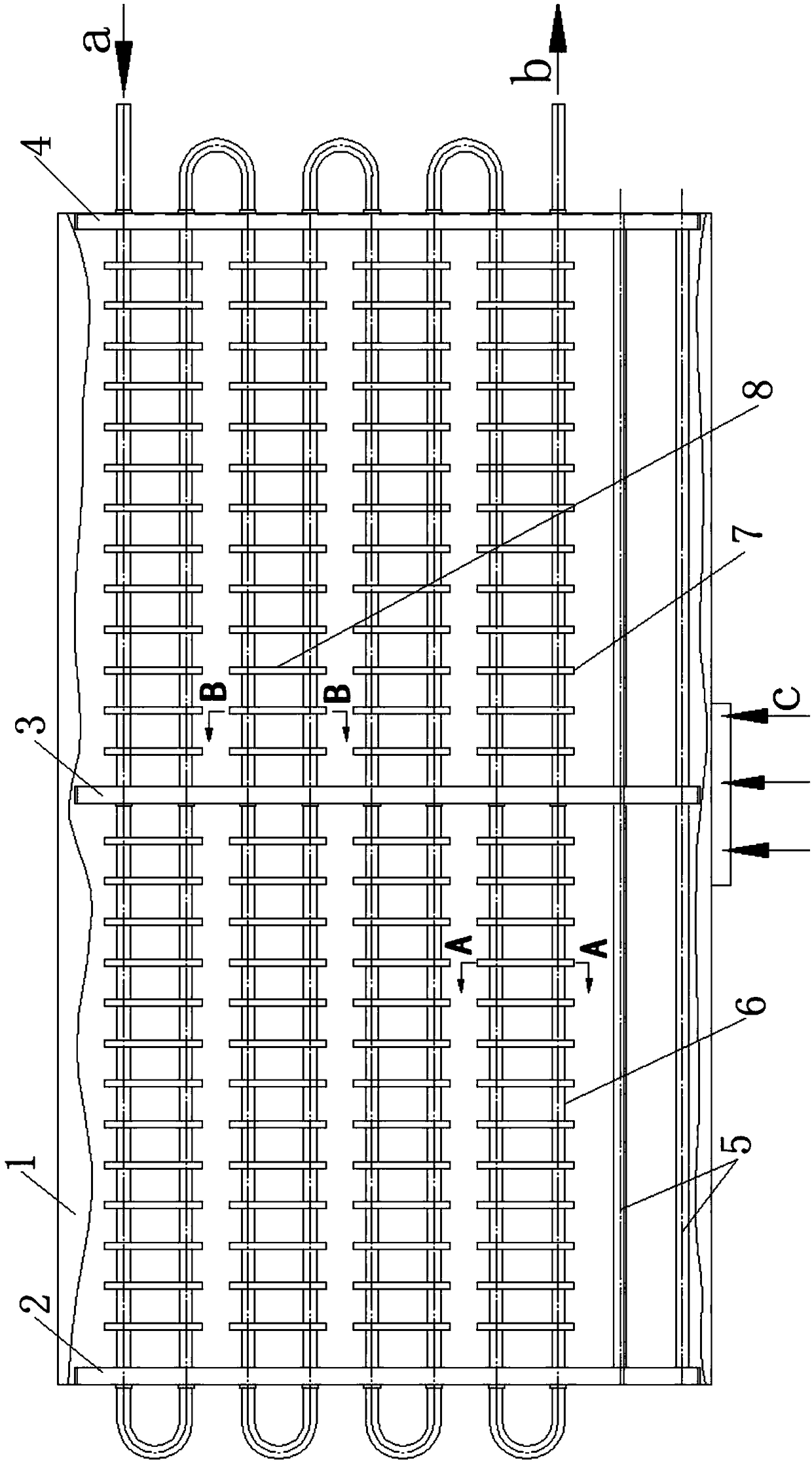

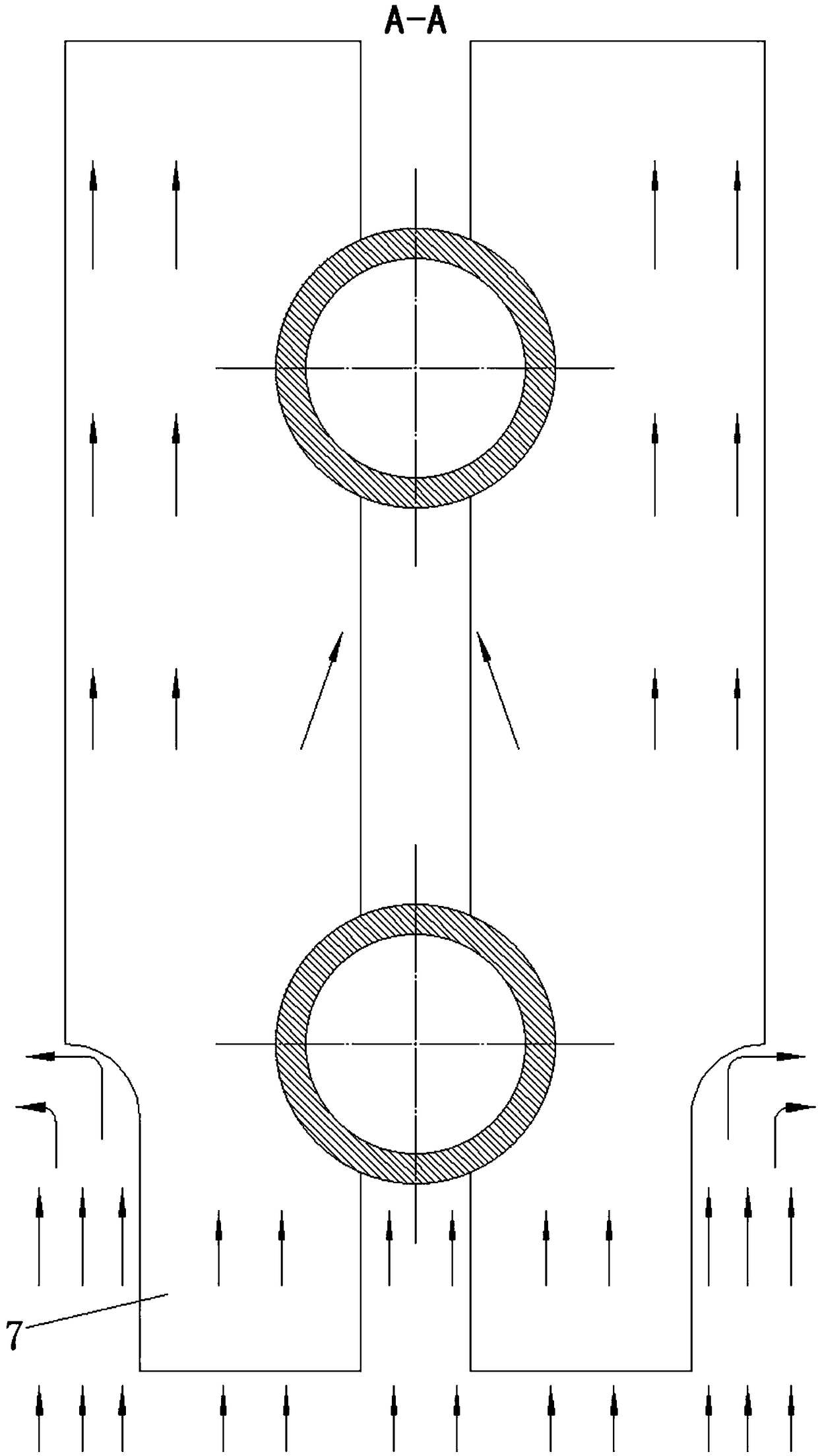

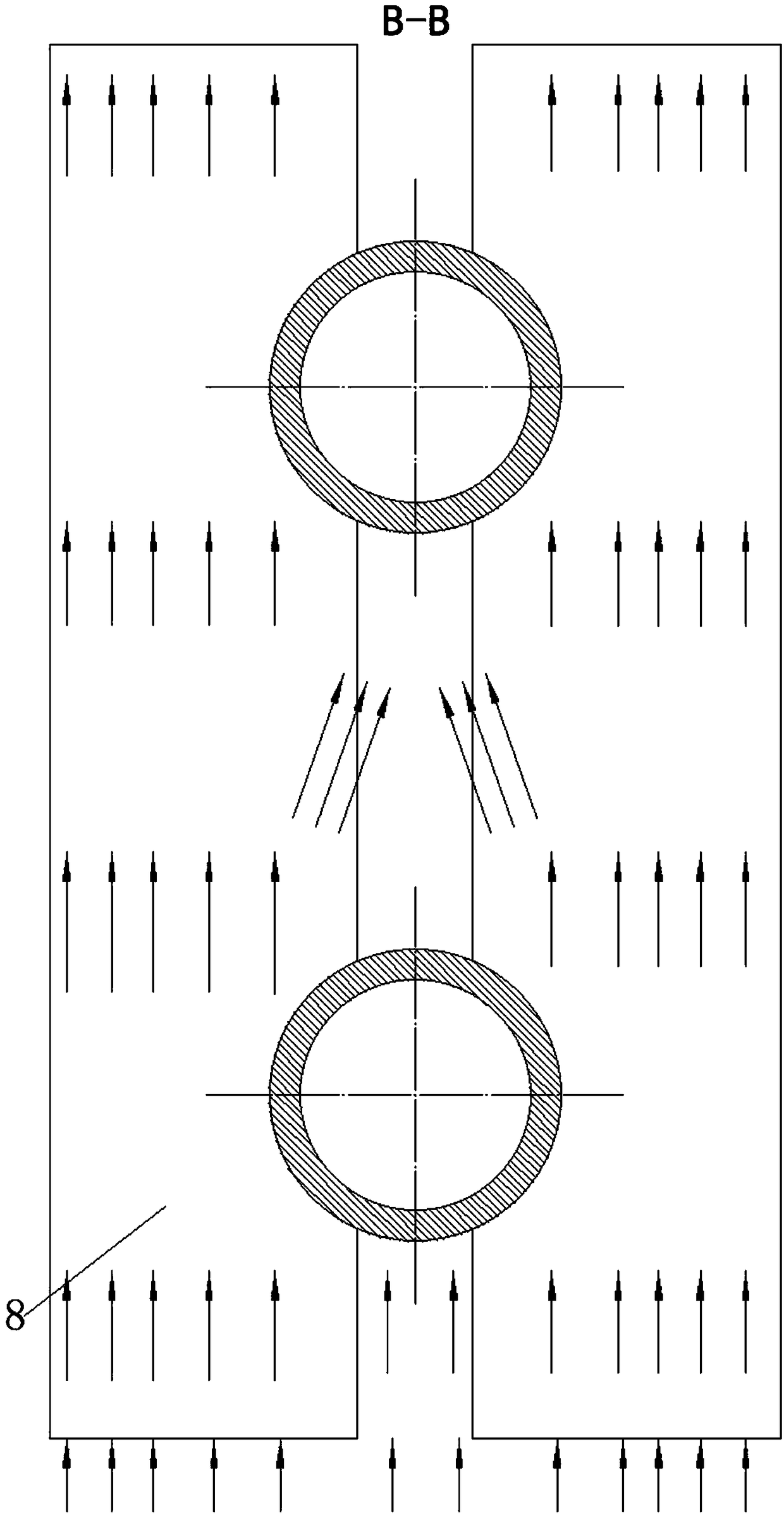

[0021] exist Figure 1 ~ Figure 3 Among them, the flue gas deep cooler of the present invention that solidifies gas and liquid and absorbs and inhibits low-temperature corrosion includes a shell 1, a left tube plate 2, a middle tube plate 3, and a right tube plate 4 installed inside the shell, located in the flue gas shock Side and installed on the left tube sheet, middle tube sheet, and right tube sheet, the anti-friction tube 5 is located above the anti-friction tube, with circulating cooling water inside and installed on the left tube sheet, middle tube sheet, and right tube sheet The curved heat exchange base pipe 6 used to resist flue gas impact, and several drainage notch slope-type impact-resistant and wear-resistant H-shaped fins 7 installed on the curved heat-exchange base pipe are located on the drainage slope type wear-resistant A plurality of H-shaped fins 8 above the H-shaped fins and installed on the curved heat exchange base tube.

[0022] The flue gas deep coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com