Multilayer stacking combined vertical type wind power generation system

A wind power generation system and combined technology, which are applied to wind turbine components, wind energy power generation, wind turbines, etc., can solve the problems of damaged tower blades, small wind volume of wind blades, and small wind area of airfoil blades. , to increase the strength and rotational torque, reduce deformation and vibration, and facilitate assembly and transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The technical solutions of the present invention will be further explained below in conjunction with the drawings and embodiments, but the following content is not intended to limit the protection scope of the present invention.

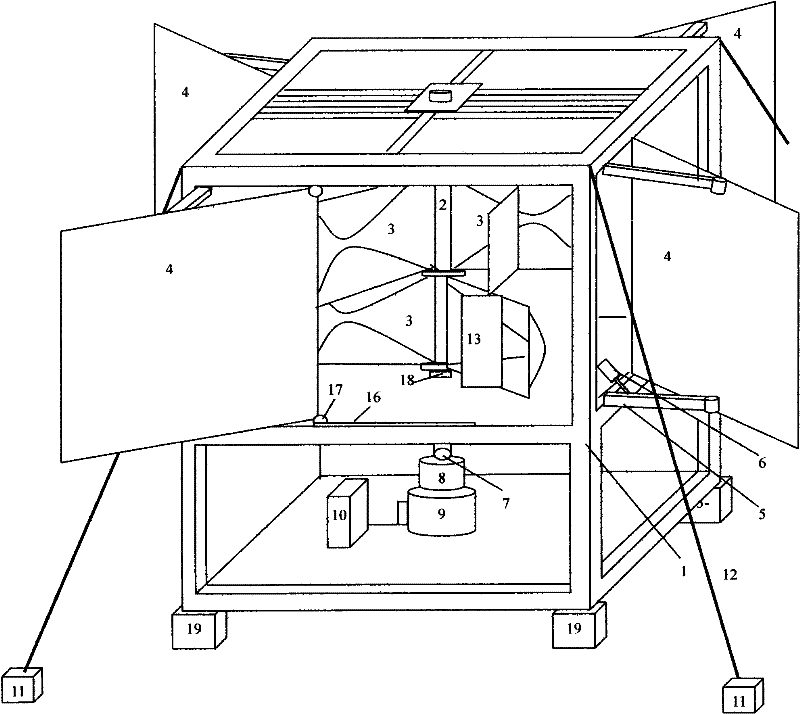

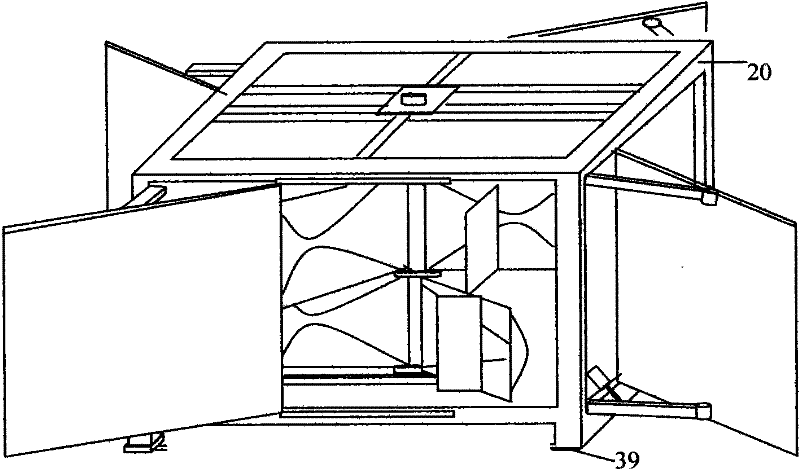

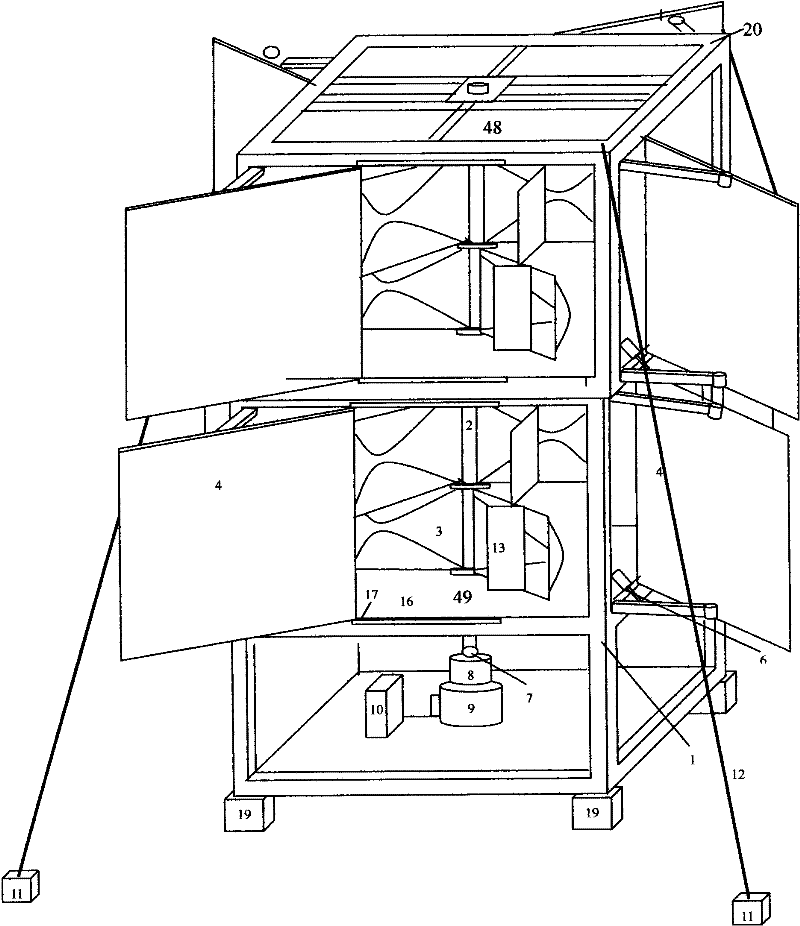

[0078] The invention provides a multi-layer superimposed combined vertical wind power generation system, comprising: a multi-section combined shaft, a multi-layer superimposed combined vertical wind power system, and a multi-layered combined frame.

[0079] The multi-layer superimposed combined vertical wind power system adopts a multi-layer box frame structure, each layer includes a multi-section machine shaft and multi-layer fan blade system, a wind collection and protection system, and a multi-winding pole-changing generator system; each layer It can be operated independently as an independent wind power system. Each layer is fixed together by each corner column, and the detachable combined coupling is used to connect the shafts of each laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com