Bicycle with linking lever and cam

A bicycle and lever technology, applied in the field of bicycles, can solve the problems of difficult adjustment and repair, high precision requirements, short service life, etc., and achieve the effect of solving the problem of crank pressure angle, good stability and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

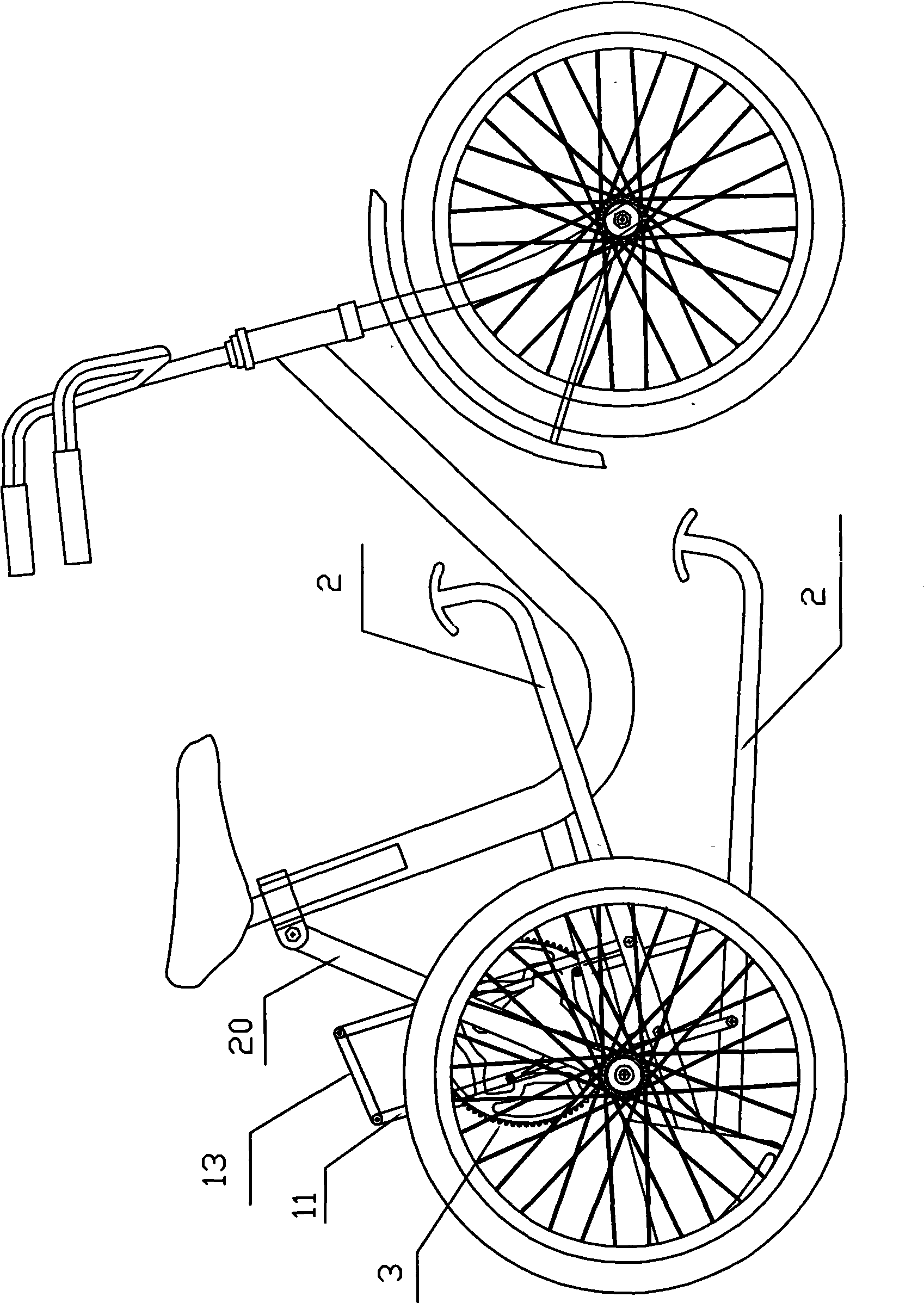

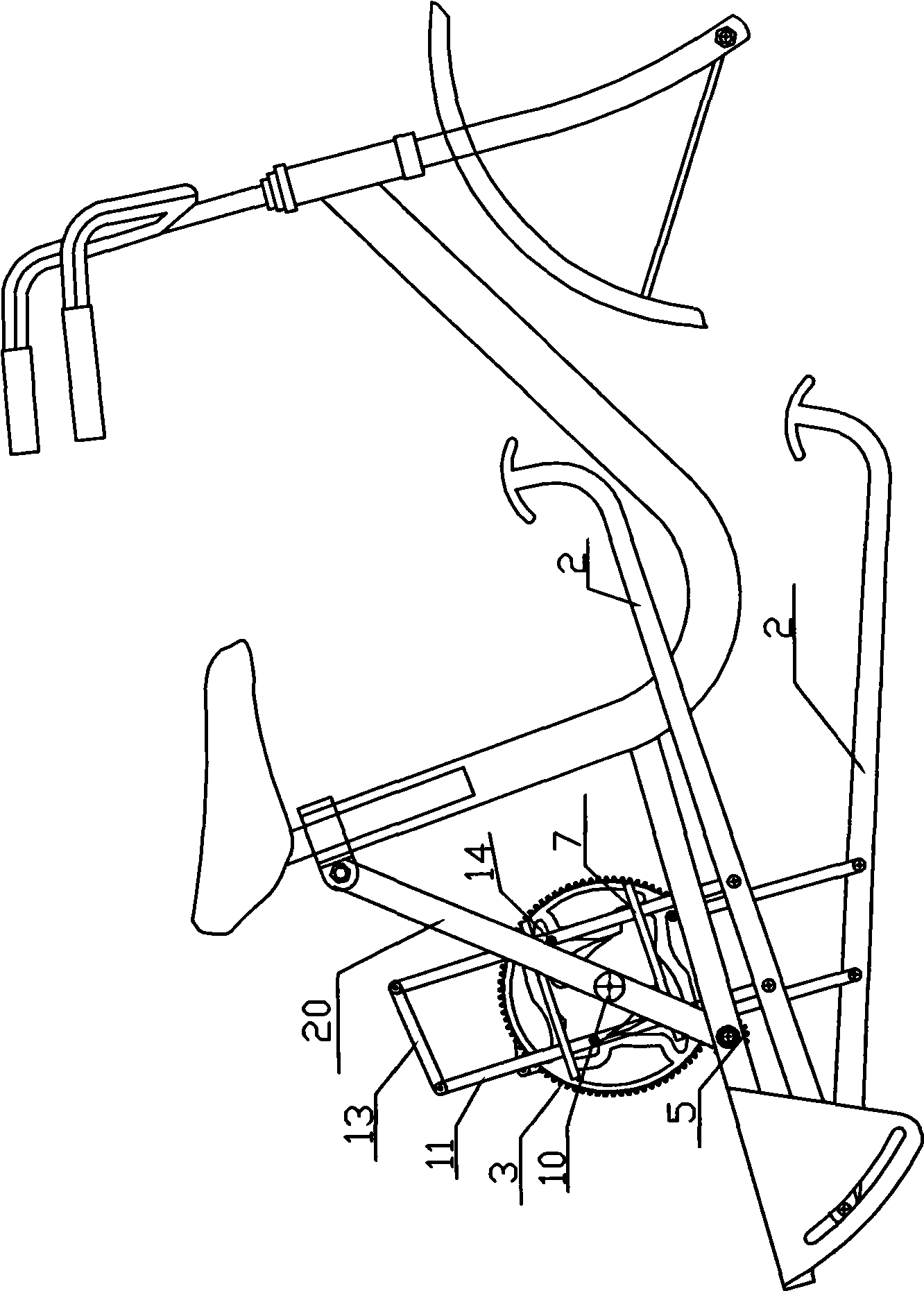

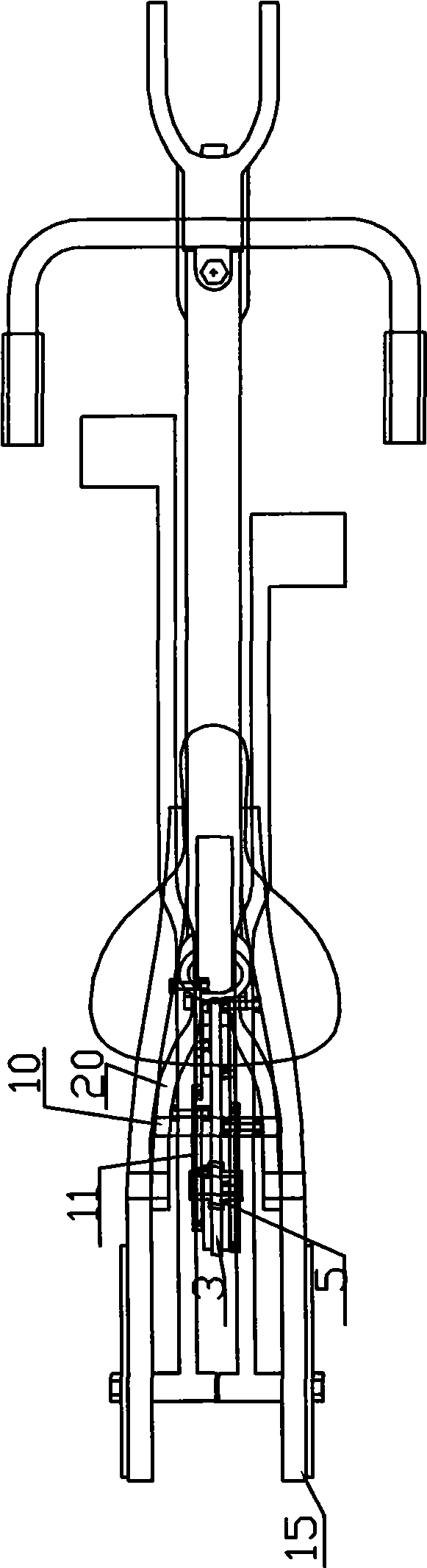

[0035] see figure 1 , figure 2 and image 3 , the invention provides a lever-cam linkage bicycle, which includes a vehicle frame, a front wheel, a rear wheel and a wheel driving device. The wheel driving device includes a lever 2, a swing rod 11, a large gear mechanism 3 and a driven gear 5 arranged on the rear wheel. One end of the lever 2 is a linear drive force application end, and the force application end is connected with a pedal. One end is movably connected to the rear support plate 15 located at the rear end of the vehicle frame, and one end of the fork 11 is hinged to the lever 2. In this embodiment, the lever 2 is provided with two fork 11, each A fork 11 middle position is provided with roller 14, and two fork on the same lever are hinged together by articulated rod 13, and lever 2 forms rolling connection by the roller 14 on the fork 11 and the profile curved surface of driving wheel.

[0036] Such as Figure 4 As shown, the large gear mechanism 3 includes a ...

no. 2 example

[0044] see Figure 7 to Figure 13 , the present invention also provides a lever-cam linkage bicycle, which includes a vehicle frame 1, a front wheel, a rear wheel and a wheel driving device. The wheel driving device includes a lever 2, a fork 11, a driving wheel, a speed change mechanism 30, and a driven gear 51 arranged on the rear wheel. One end of the lever 2 is a linear drive application end, and the application end is connected with a pedal 16. The other end of the lever is movably connected to the rear support plate 15 located at the rear end of the vehicle frame, and the lower end of the swing link 11 is hinged to the lever 2. In this embodiment, the lever 2 is provided with two swing links 11. Each swing rod 11 is provided with a roller 14 at the upper end position, and the middle and lower ends of the two swing rods 11 on the same lever are hinged together through the hinge rod 13, and the lever 2 is connected with the roller 14 on the swing rod 11. The contoured sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com