Tree-dimensional rotary knitting loom dust cleaning apparatus

A technology of dust removal device and three-dimensional rotation, which is applied in knitting, textile and paper making, etc., can solve the problems of high power consumption, occupying space and disorder, and achieve the effect of ensuring the quality of textiles, reducing power consumption and improving dust removal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following examples are further explanations and illustrations of the present invention, and do not constitute any limitation to the present invention.

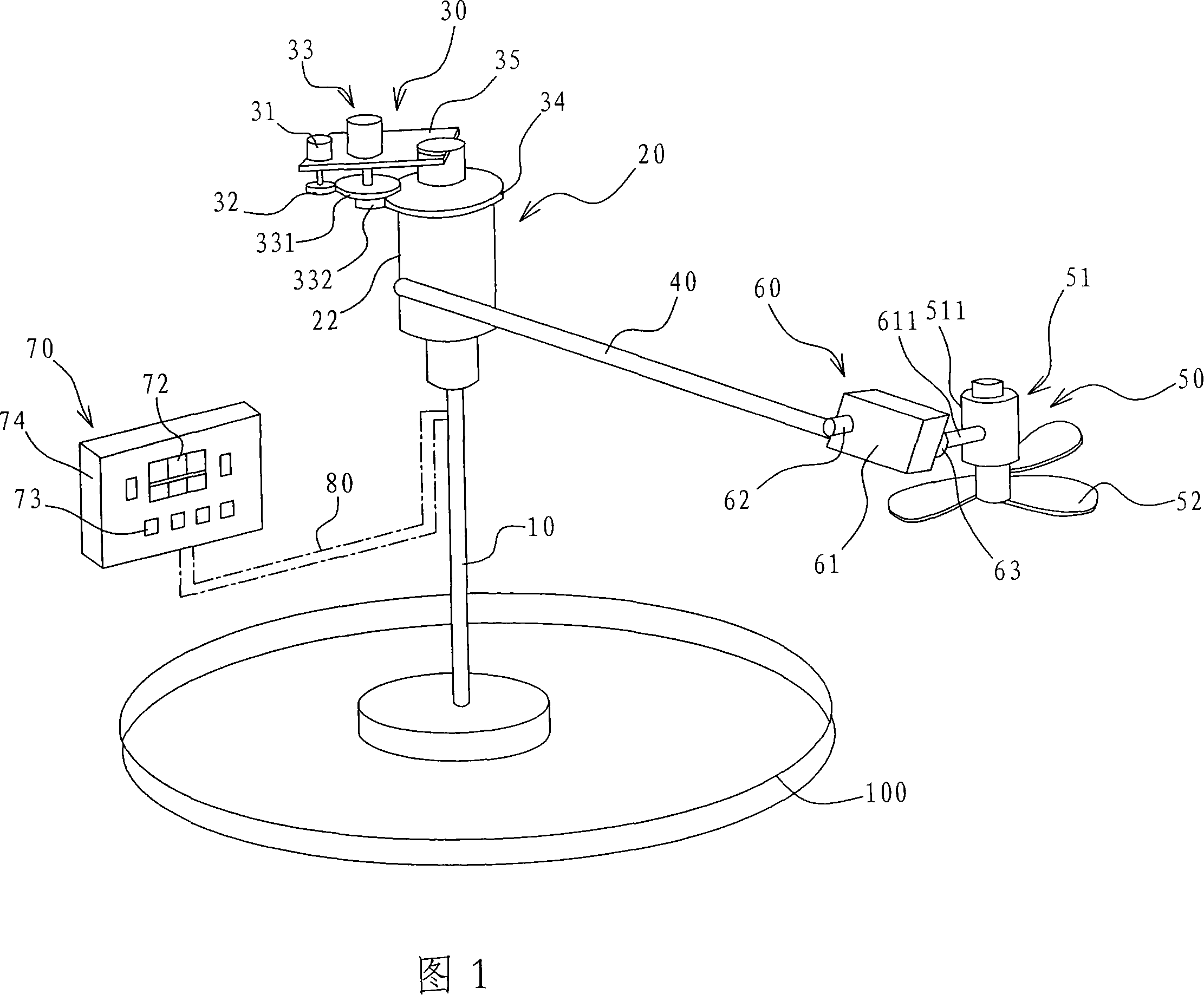

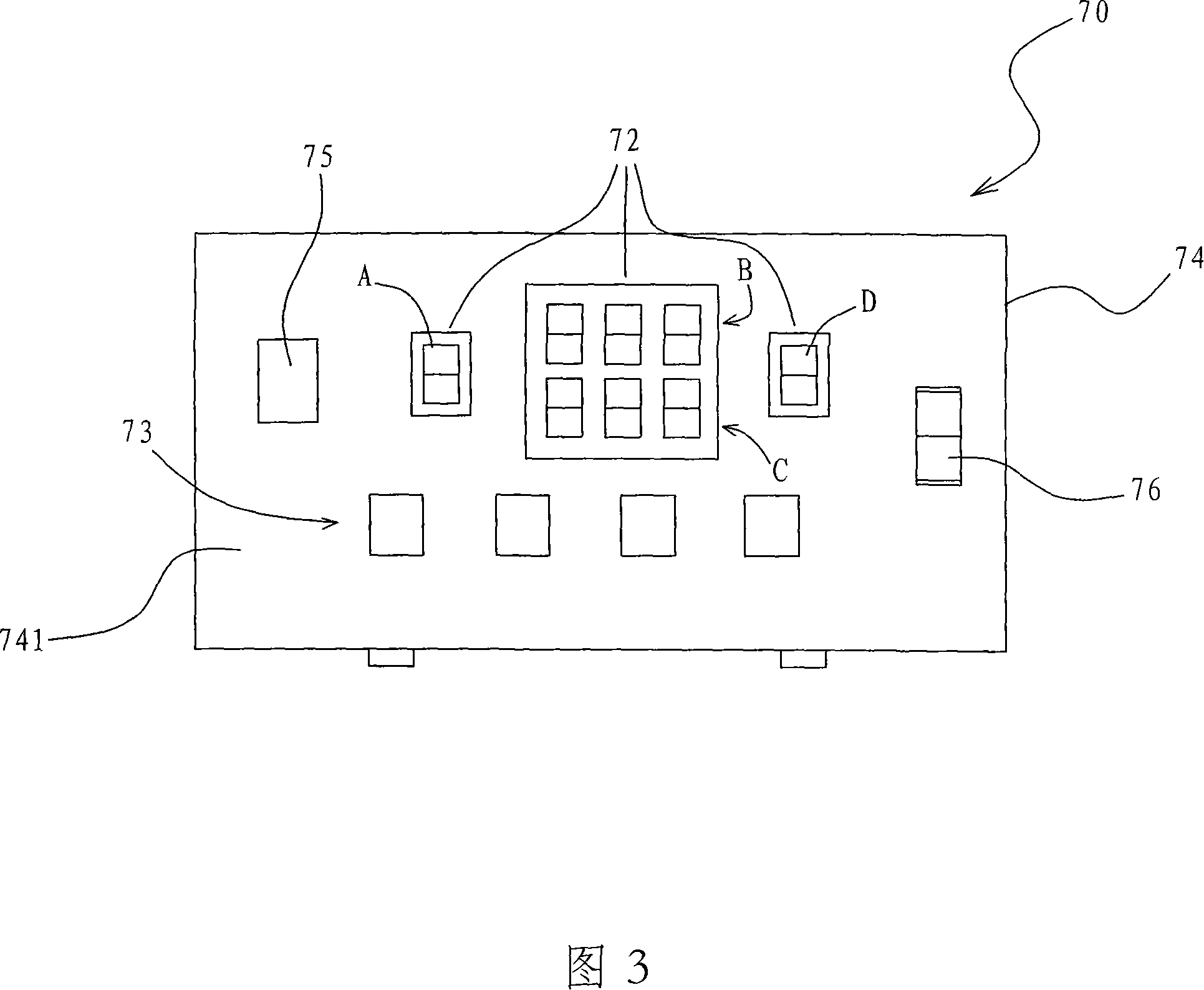

[0027] Referring to FIG. 1 , the three-dimensionally rotatable knitting machine dust removal device of the present invention includes a main rod 10 , a rotating and electrical connector 20 , a drive mechanism 30 , a fan connecting rod 40 , a fan 50 , a speed reduction mechanism 60 and a main controller 70 .

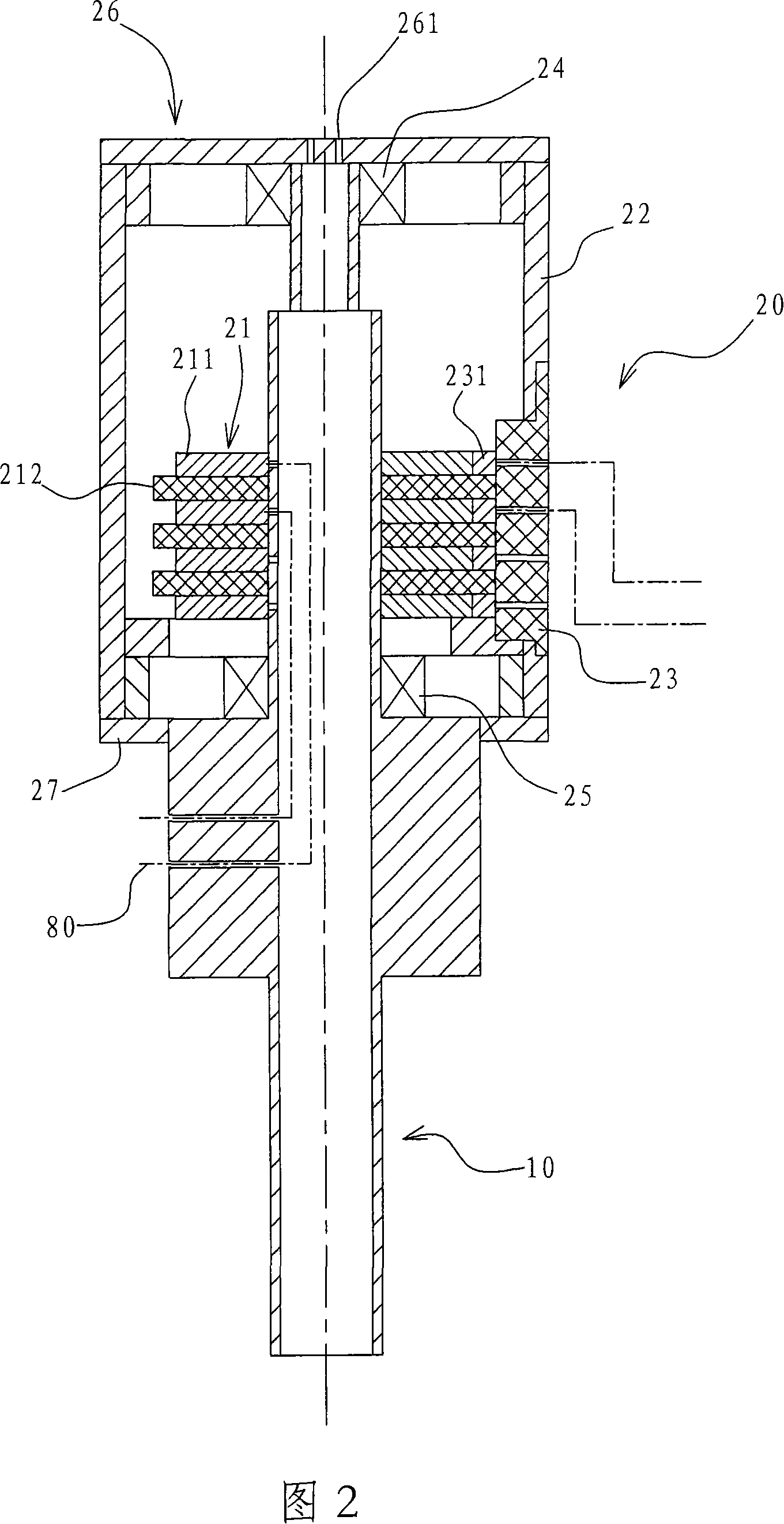

[0028] As shown in Figure 2, the main rod 10 is a hollow tubular body, the wire connecting the main controller 70 and the fan 50 can be passed inside the main rod, the main rod 10 is vertically arranged, and its lower end is fixed to the machine platform 100 , the upper end of which is equipped with a rotating and electrical connector 20 and a drive mechanism 30 .

[0029] The rotation and electrical connector 20 is a rotation connector with mechanical transmission and electrical connection, its structure is sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com