Dynamic light source disinfection unit and disinfection cabinet applying same

A light source and dynamic technology, applied in the field of disinfection cabinets, can solve the problems of fixation, the existence of disinfection dead ends, and three-dimensional space dead ends.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

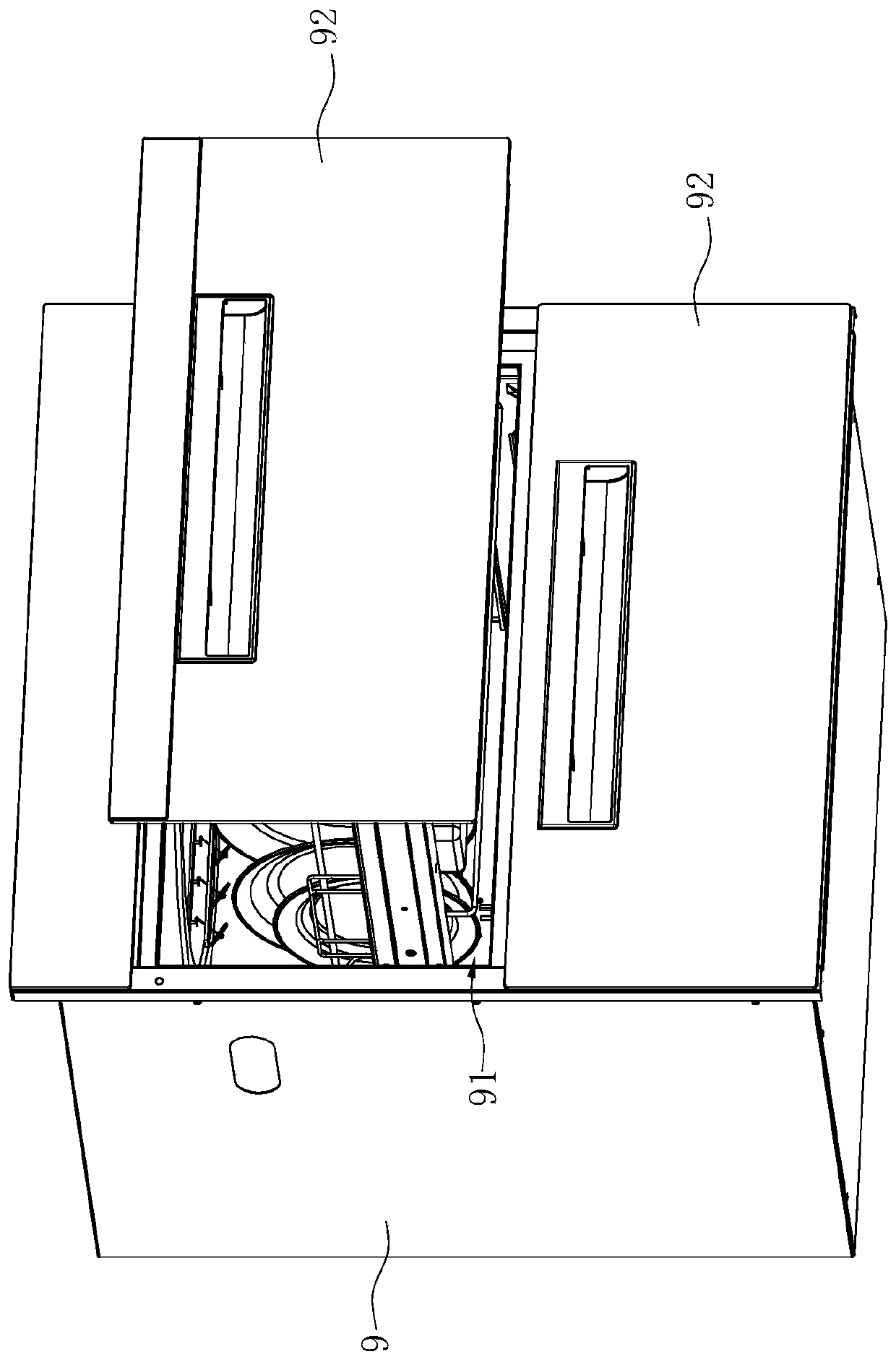

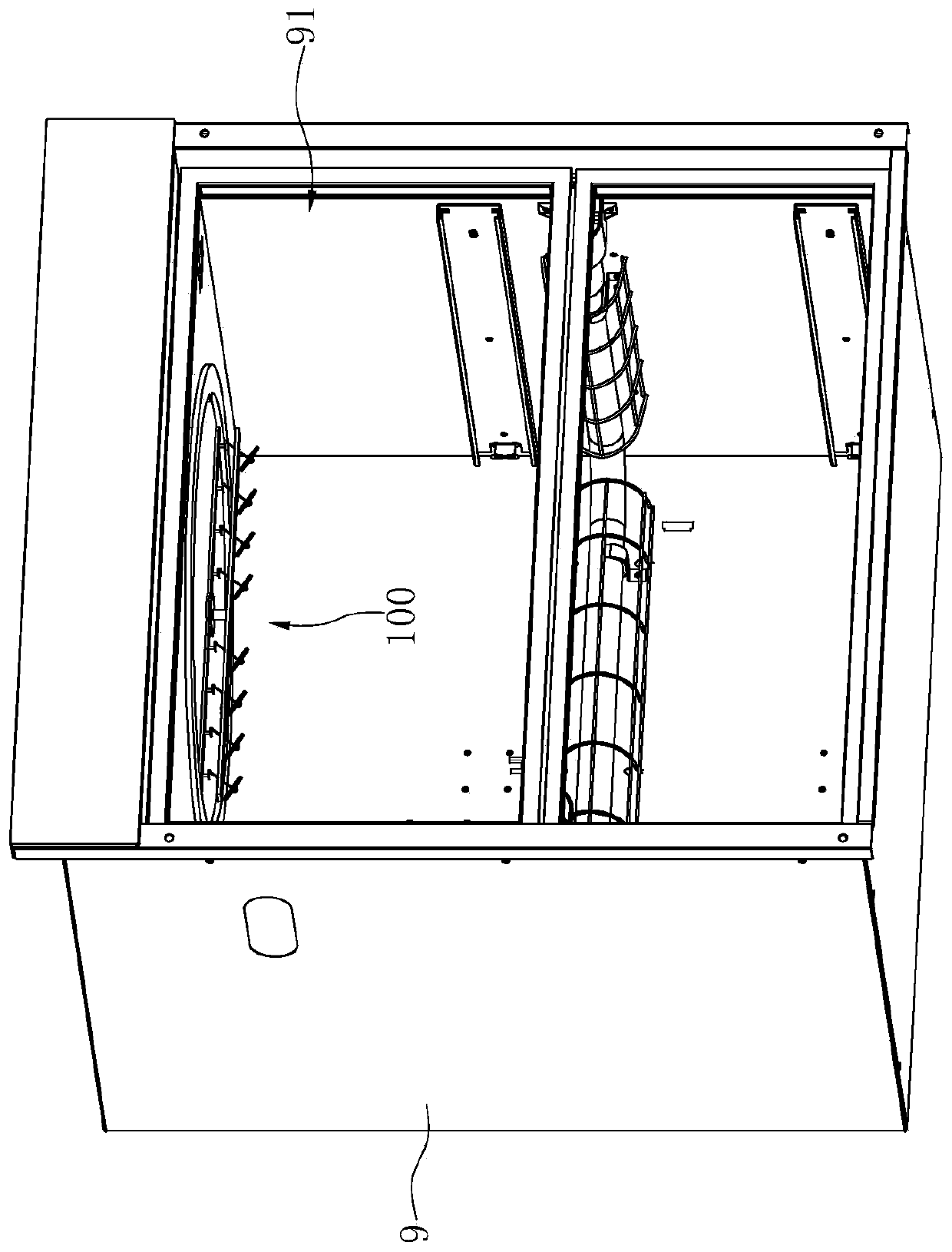

[0055] like Figure 1 to Figure 5 Shown is the first preferred embodiment of the disinfection cabinet using the dynamic light source disinfection unit of the present invention.

[0056] like figure 1 and figure 2 As shown, the disinfection cabinet includes a cabinet body 9 with a disinfection chamber 91 , a dynamic light source disinfection unit 100 disposed on the cabinet body 9 , and a drawer 92 capable of entering and exiting the disinfection chamber 91 .

[0057] Wherein, the quantity of the drawer 92 is two, and is arranged in the disinfection cavity 91 one above the other respectively.

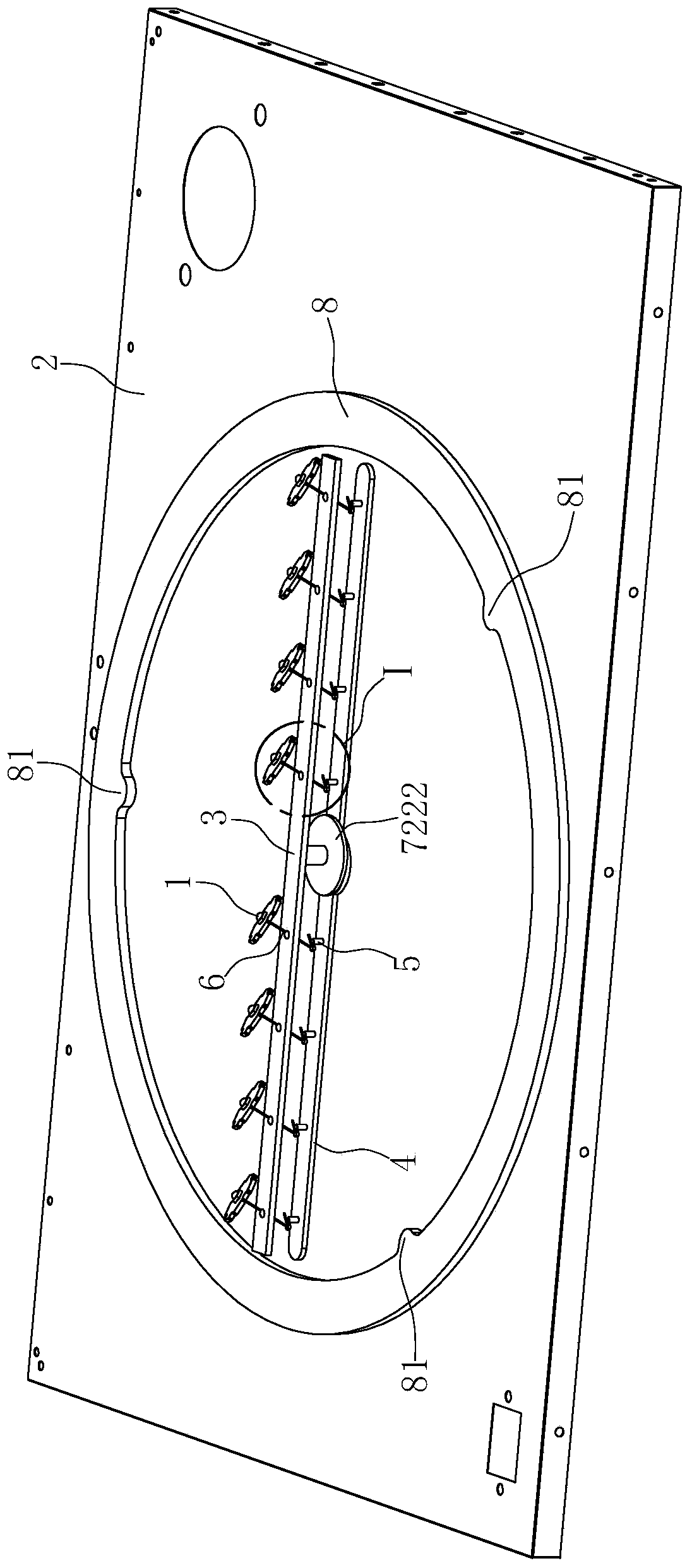

[0058] like Figure 3 to Figure 6 As shown, the dynamic light source disinfection unit 100 includes a plurality of disinfection light sources 1, a panel 2, a rotating plate 3 rotatably arranged on the panel 2, a guide strip 4 between the panel 2 and the rotating plate 3, and the disinfection light source 1 One-to-one correspondence is used to install the connecting seat 5 and the co...

Embodiment 2

[0071] like Figure 1 to Figure 5 Shown is the second preferred embodiment of the disinfection cabinet using the dynamic light source disinfection unit of the present invention. The difference with Example 1 is:

[0072] In this embodiment, the guide strip 4 is replaced by the installation strip 4', and the installation strip 4' is arranged side by side with the rotating plate 3, and both of them are arranged on the panel 2 through the rotating shaft 7221 so as to be able to rotate synchronously, without setting the support plate 7222.

[0073] Connecting seat 5 is replaced by guide gear 5 ', and this guide gear 5 ' is rotatably connected on mounting bar 4 ', and the second end of connecting rod 6 is installed in its eccentric position, and the second universal rotation ball 62 need not be set. There are two groups of guide gears 5', which are respectively located on both sides of the rotating shaft 7221. For each set of guide gears 5', the number of guide gears 5' is four, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com