Lower feeding mechanism

A feeding mechanism and feeding technology, applied in the direction of cloth feeding mechanism, sewing machine components, textiles and papermaking, etc., can solve the problems of small lifting force and inability to sew perfect stitch length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

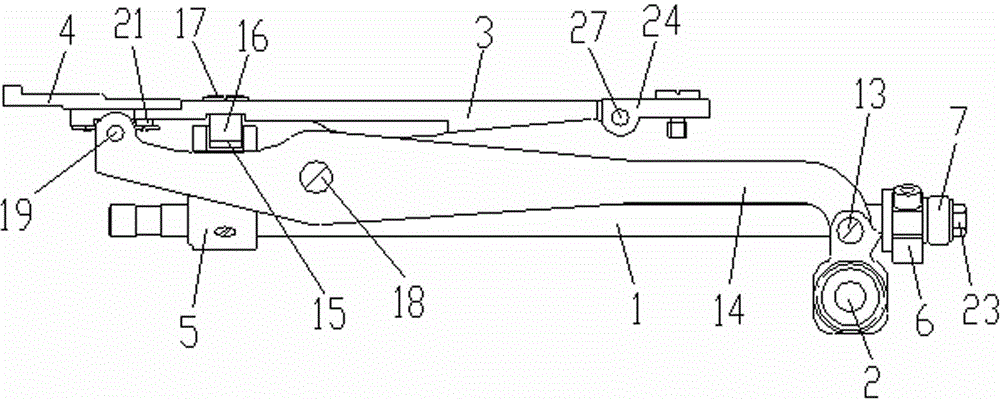

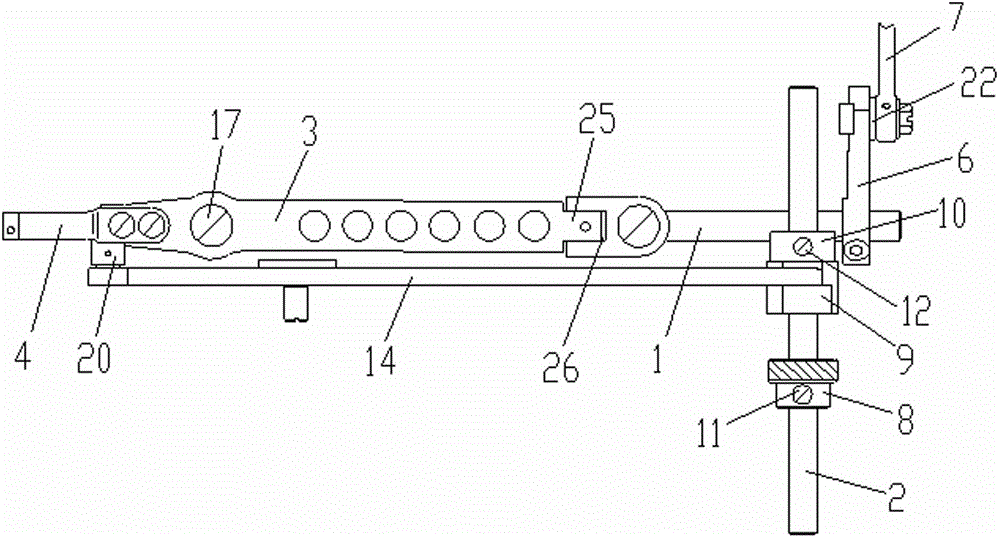

[0016] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0017] Such as figure 1 , figure 2 As shown, a lower feeding mechanism includes a feeding shaft 1, a tooth lifting shaft 2, a tooth frame 3, and a feeding tooth 4 fixed to the tooth frame 3. The two ends of the feeding shaft 1 are respectively connected with a crank 5 before feeding and a crank after feeding. 6. Before feeding, the crank 5 is connected to the tooth frame 3. After feeding, the free end of the crank 6 is connected to the feeding connecting rod 7. The tooth lifting shaft 2 is sequentially set with the tooth lifting shaft gear 8, the tooth lifting crank 9, and the tooth lifting cam 10. , the tooth lifting shaft gear 8 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com