Aluminum section online combined quenching apparatus

A technology of quenching device and aluminum profile, which is applied in the direction of quenching device, heat treatment equipment, manufacturing tools, etc., can solve the problems of unable to meet the requirements of aluminum profile cooling and quenching methods, cannot meet the water pressure requirements, and the cooling intensity is not high enough, so as to prevent Cold deformation, easy processing, and efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

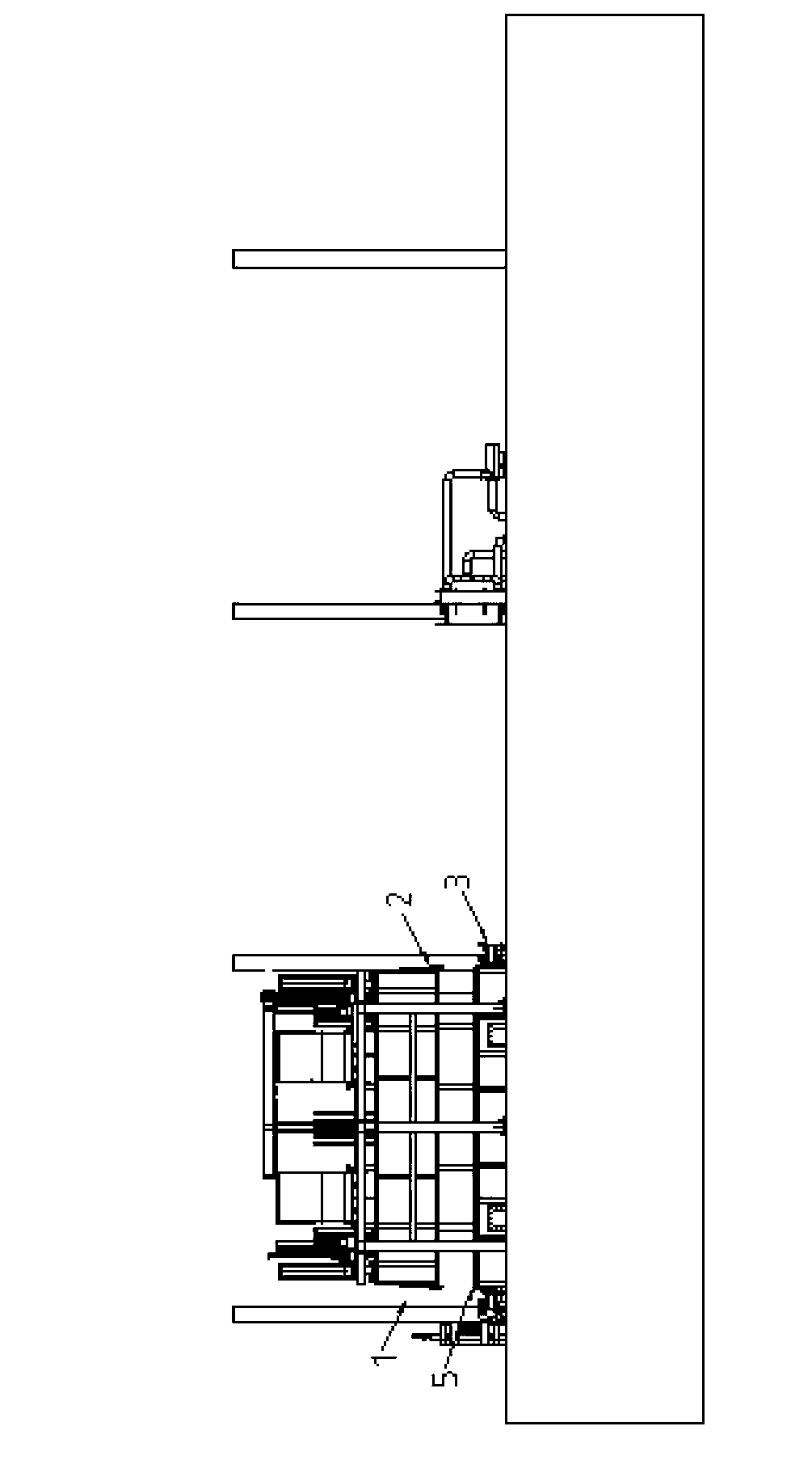

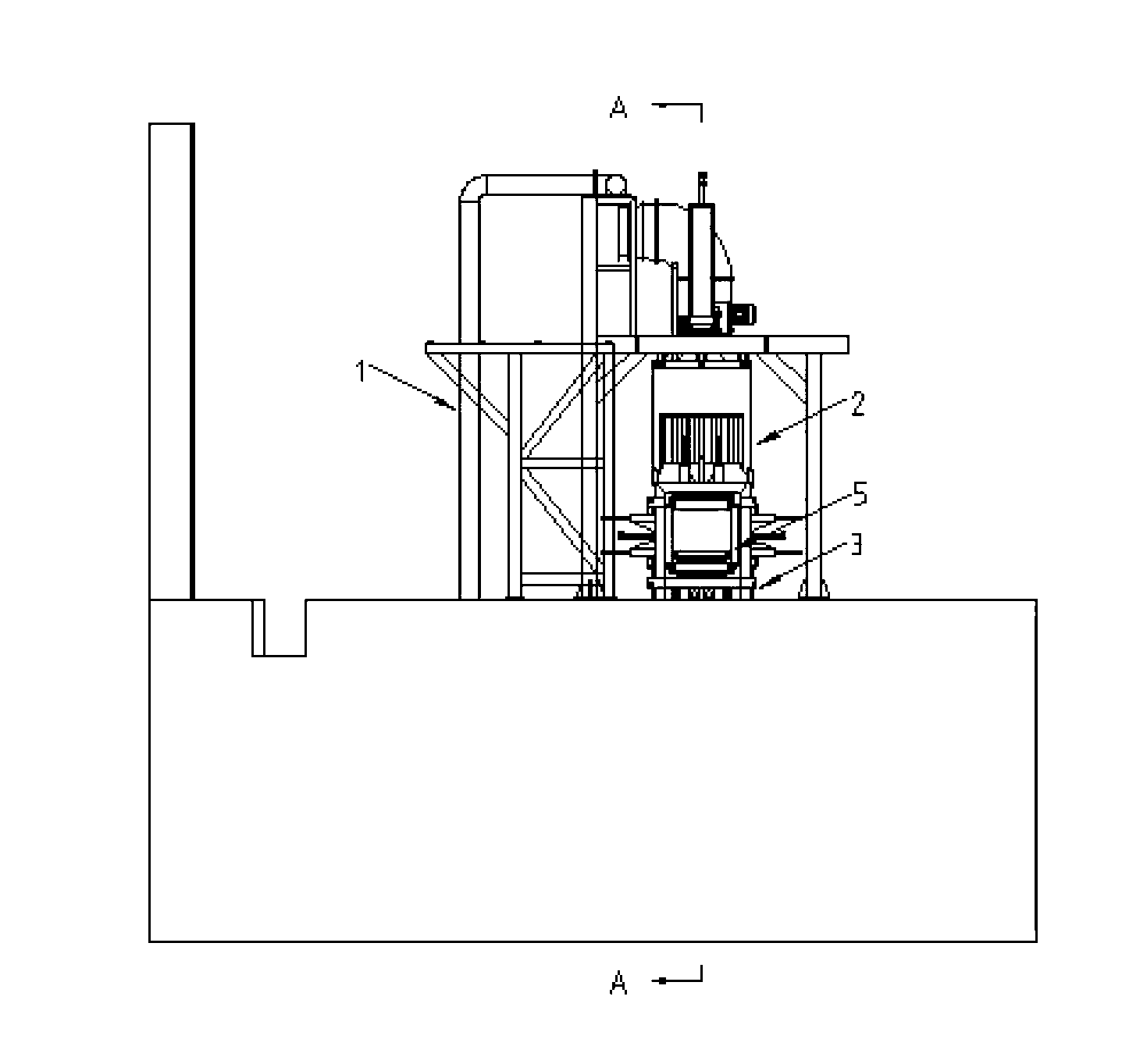

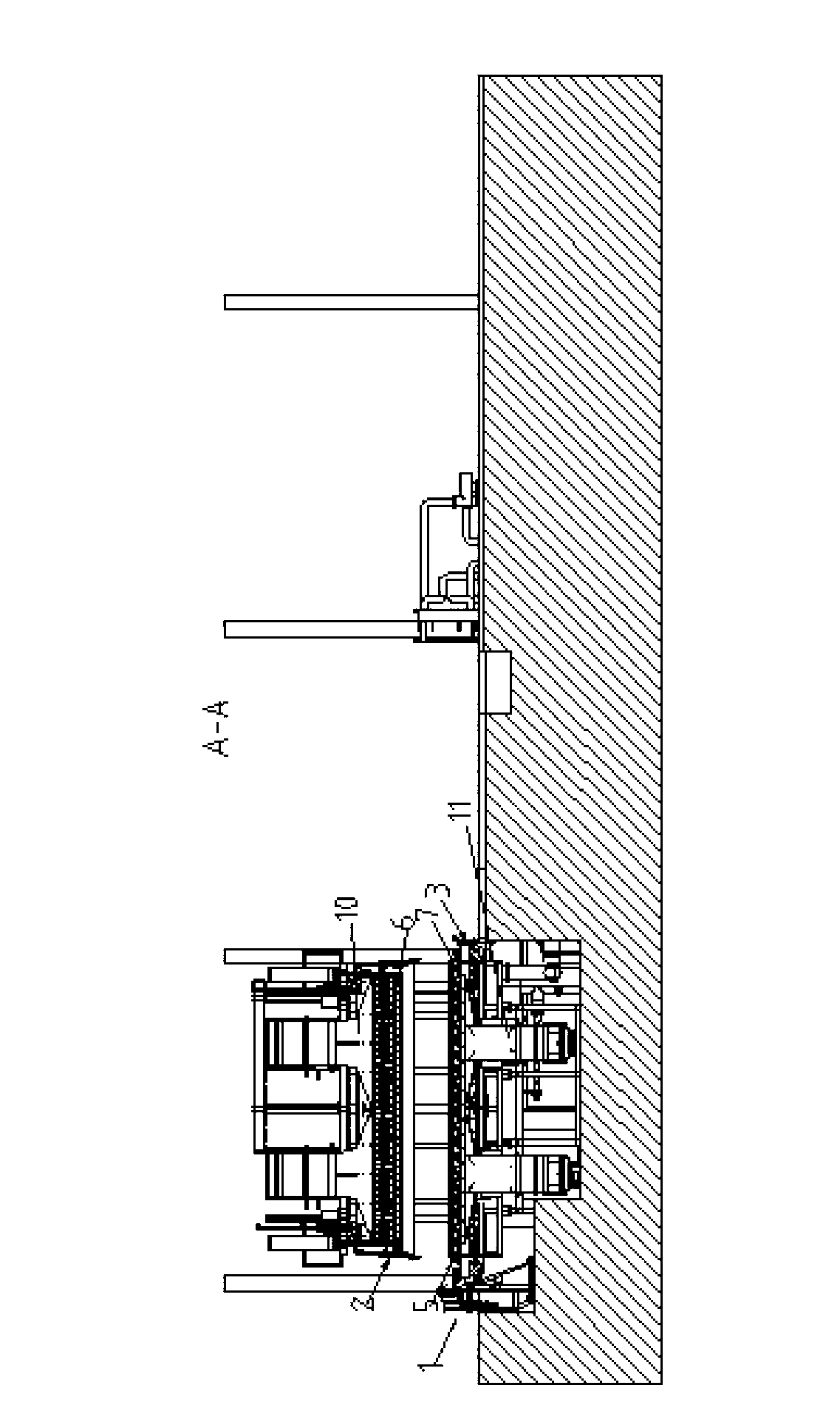

[0032]As shown in the drawings, an aluminum profile online combined quenching device includes a frame 1, an upper cooling system 2, a lower cooling system 3, and a side cooling system 4. The upper cooling system 2 is located in the lower cooling system. 3 and the two are compatible, the lower cooling system 2 is fixed on the frame 1, the upper cooling system 2 is slidably installed on the frame 1, and the lower An aluminum profile conveying device 5 is arranged between the cooling system 3 and the upper cooling system 2, and the side cooling system 4 is fixedly arranged with the upper cooling system 2, and its height is at the Between the lower water-cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com