A thermal plasma array pyrolysis reactor for acetylene production from coal

A thermal plasma and plasma technology, applied in chemical instruments and methods, control/regulating processes, chemical/physical/physical-chemical processes of applying energy, etc., can solve the problems of difficult to effectively utilize high temperature and low acetylene yield, etc. Achieve the effect of reducing energy loss, high energy utilization, and reducing gas volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The method provided by the present invention will be further described below through the accompanying drawings, but the present invention is not limited thereto. Many devices are omitted in the figure, such as compressors, valves, pressure control, temperature control, etc.

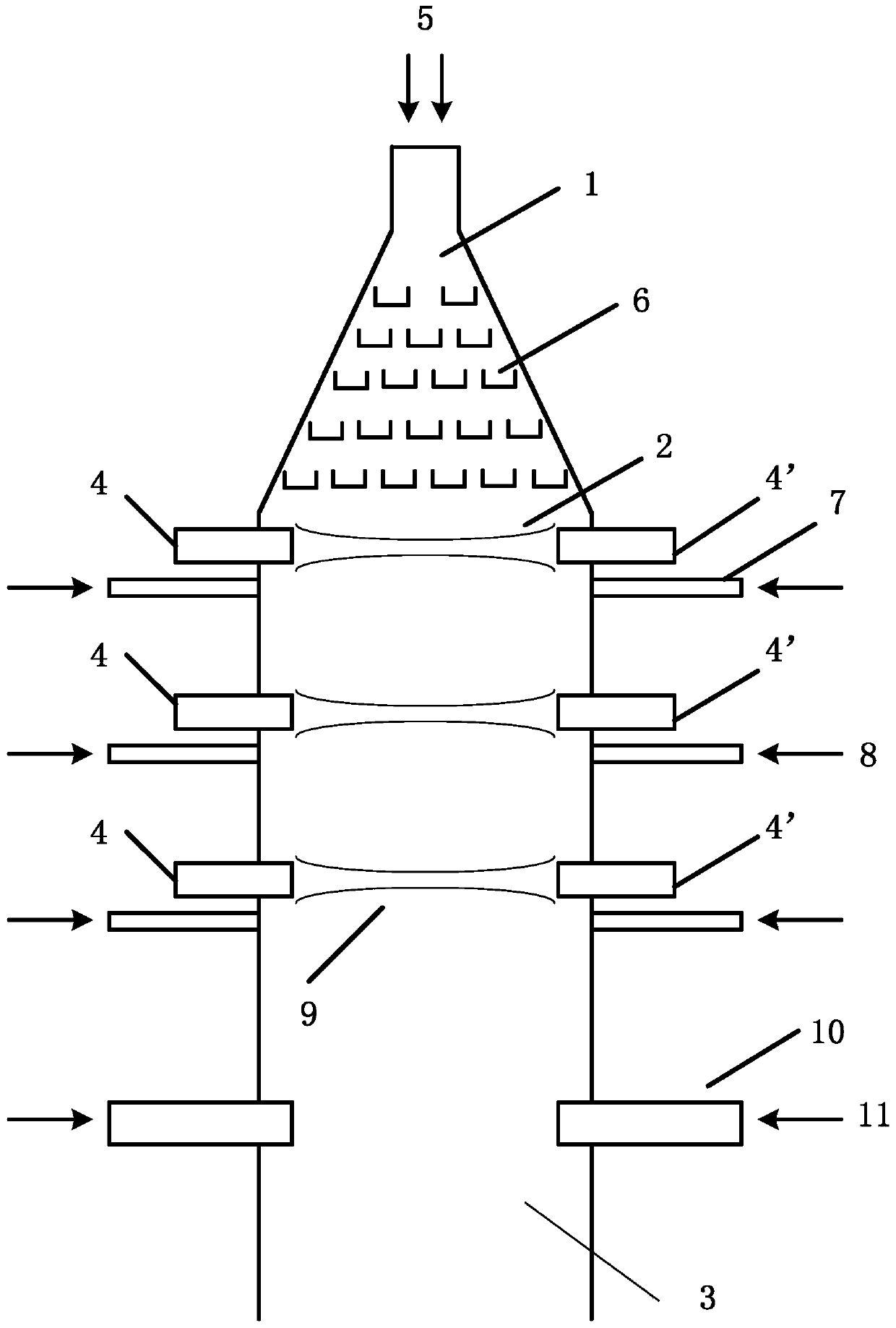

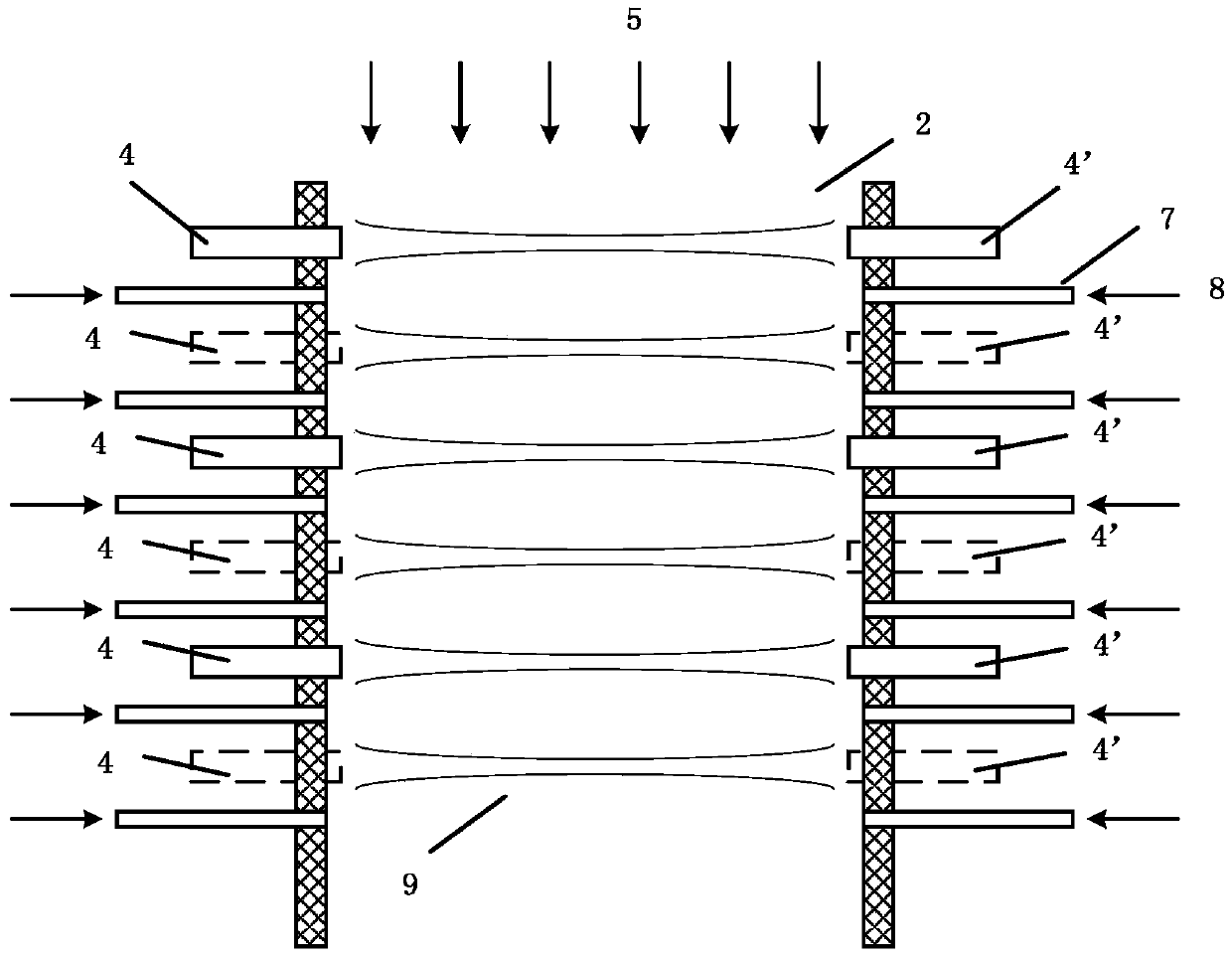

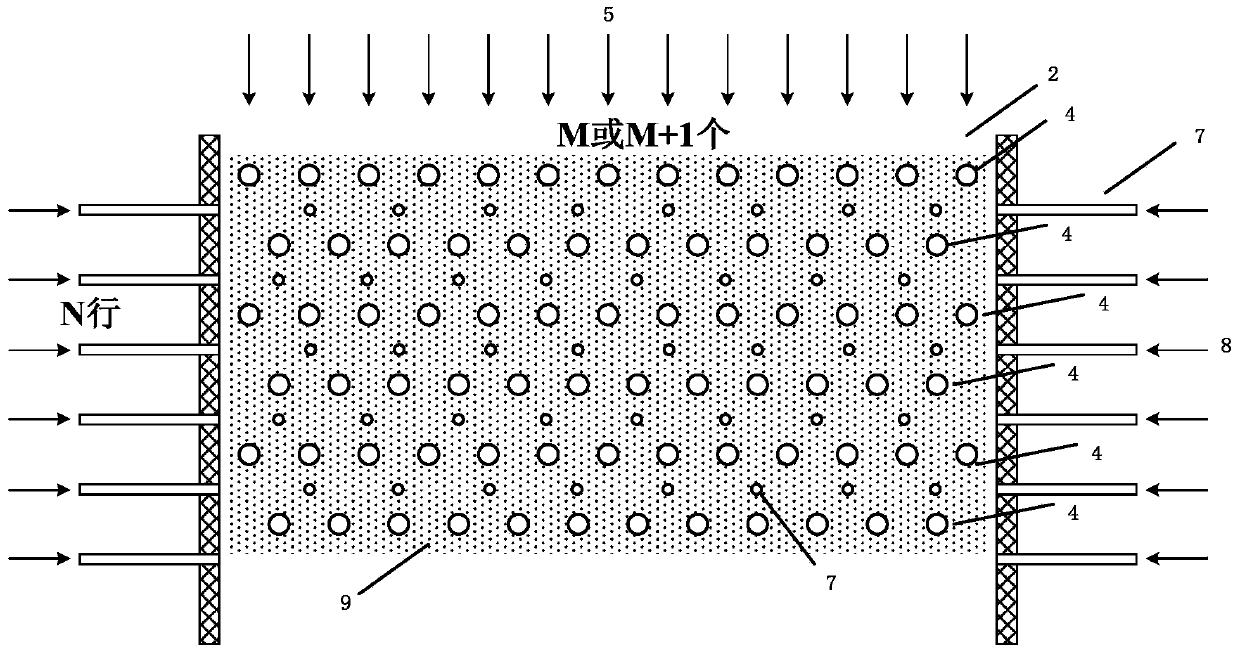

[0028] figure 1 It is a schematic diagram of a thermal plasma array pyrolysis coal-to-acetylene reactor provided by the present invention. figure 2 and image 3 A half-section diagram of the plasma array reaction section of a thermal plasma array pyrolysis coal-to-acetylene reactor provided by the present invention.

[0029] A thermal plasma array pyrolysis coal-to-acetylene reactor, comprising a coal powder pre-dispersion section 1, a plasma array reaction section 2, and a quenching section 3; figure 2 , image 3 As shown, N rows of plasma electrodes 4, 4' are arranged on the side wall of the plasma array reaction section 2, and each row includes M or M+1 plasma electrodes 4, 4', and the plas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com