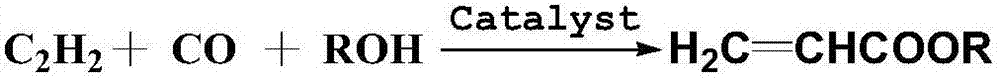

Method for carbonylation-synthesizing acrylic ester by acetylene

A technology of acrylate and chemical synthesis, which is applied in the direction of carbon monoxide or formate reaction preparation, organic chemistry, etc., can solve the problems of long reaction time, equipment corrosion, carbon deposition, etc., achieve fast reaction speed, save pretreatment time, The effect of high catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 50ml of tetrahydrofuran, 17ml of butanol, and 0.258g of nickel acetylacetonate into a 100ml autoclave, seal the autoclave, replace the air in the autoclave with 1MPa nitrogen for 3 times, fill with acetylene to saturation to 0.2MPa under stirring, then fill with CO to 4.7MPa, Raise the temperature to 230°C, maintain a stirring speed of 500r / min, and react for 60min. After the reaction, the still liquid and tail gas were analyzed, and the yield of butyl acrylate was 55.2%, and the selectivity was 89.6%.

Embodiment 2

[0034] In a 100ml autoclave, add 50ml of tetrahydrofuran, 17ml of butanol, 0.258g of nickel acetylacetonate, and 0.042g of sodium acetylacetonate, seal the autoclave, replace the air in the autoclave with 1MPa nitrogen for 3 times, fill with acetylene to saturation to 0.2MPa under stirring, and then Fill with CO to 4.7MPa, raise the temperature to 230°C, keep the stirring speed at 500r / min, and react for 45min. After the reaction, the still liquid and tail gas were analyzed, and the yield of butyl acrylate was 65.4%, and the selectivity was 99.3%.

Embodiment 3

[0036] In 100ml autoclave, add THF 50ml, butanol 17ml, Ni(OAc) 2 4H 2 O 0.249g, sodium acetylacetonate 0.042g, seal the autoclave, replace the air in the autoclave with 1MPa nitrogen for 3 times, fill with acetylene to saturation to 0.2MPa under stirring, then fill with CO to 4.7MPa, raise the temperature to 230°C, and keep at 500r / min The stirring speed was increased, and the reaction was carried out for 60 minutes. After the reaction, the still liquid and tail gas were analyzed, and the yield of butyl acrylate was 58.1%, and the selectivity was 91.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com