Device fault pre-maintenance method based on industrial wireless technology

An equipment failure, industrial wireless technology, applied in measurement devices, instruments, signal transmission systems, etc., can solve the problems of difficult system reconfiguration, cable laying costs, high construction costs, low reliability, etc., to enhance system reliability, The effect of reducing costs and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the examples.

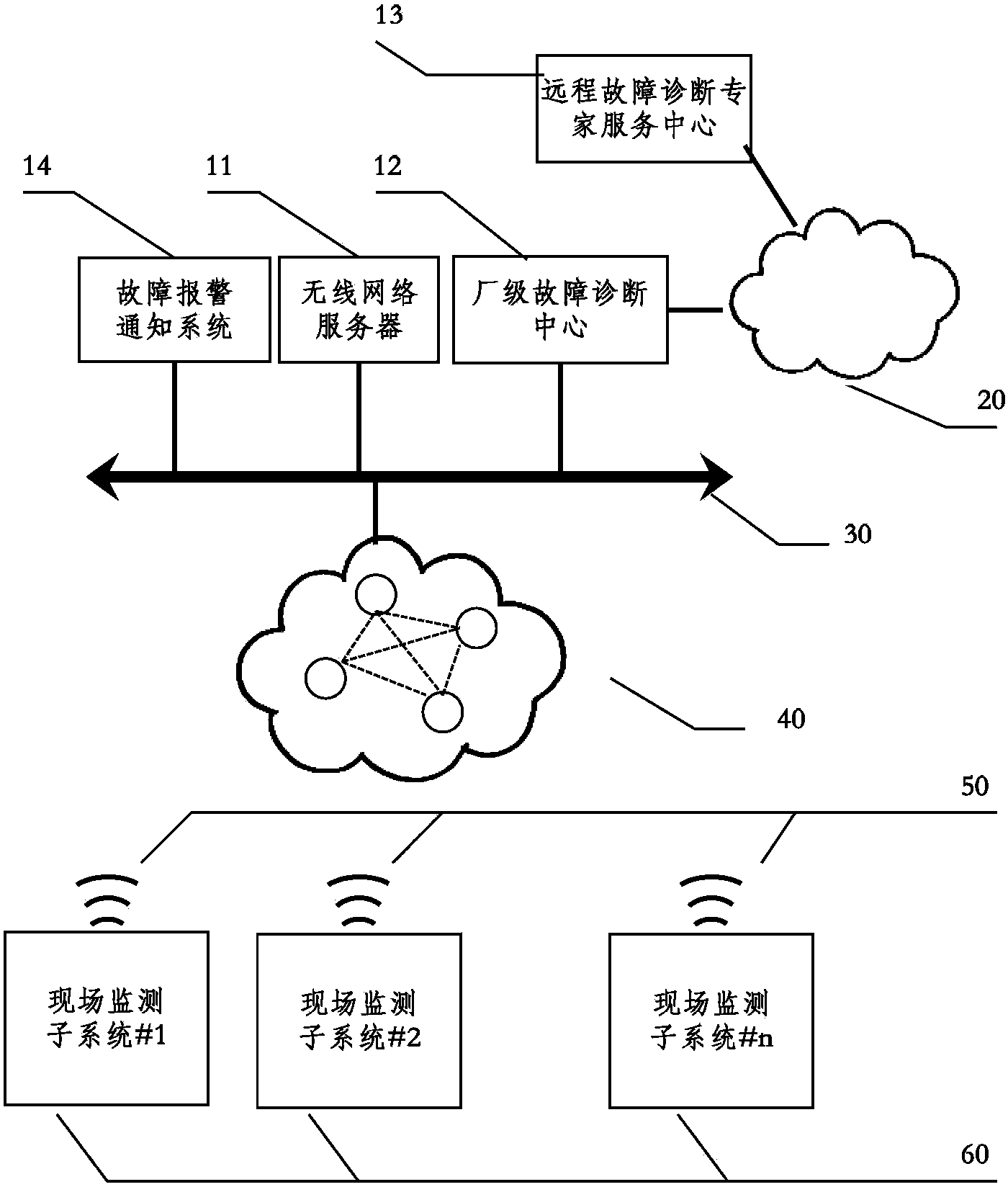

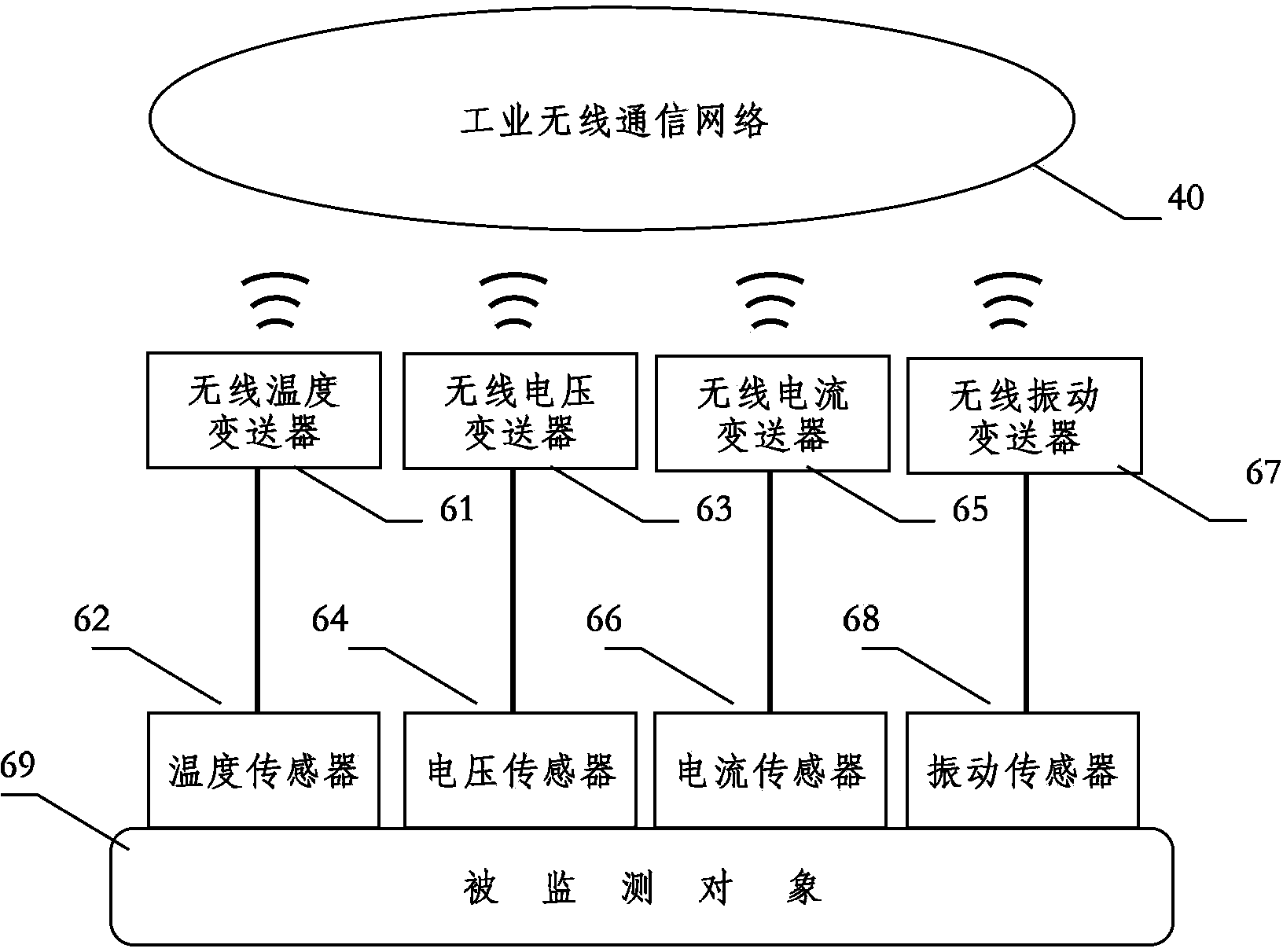

[0031] The field instrument monitors the status of the controlled object in real time, collects different data information, performs data processing and preliminary fault diagnosis locally, and then transmits the compressed data to the factory-level monitoring center through the wireless network for fault diagnosis. The local monitoring center cannot identify Faults can be submitted to the remote fault monitoring center for consultation by experts. The fault results are displayed in various ways such as local instruments and monitoring centers, and support the transmission of results by 3G network smartphones.

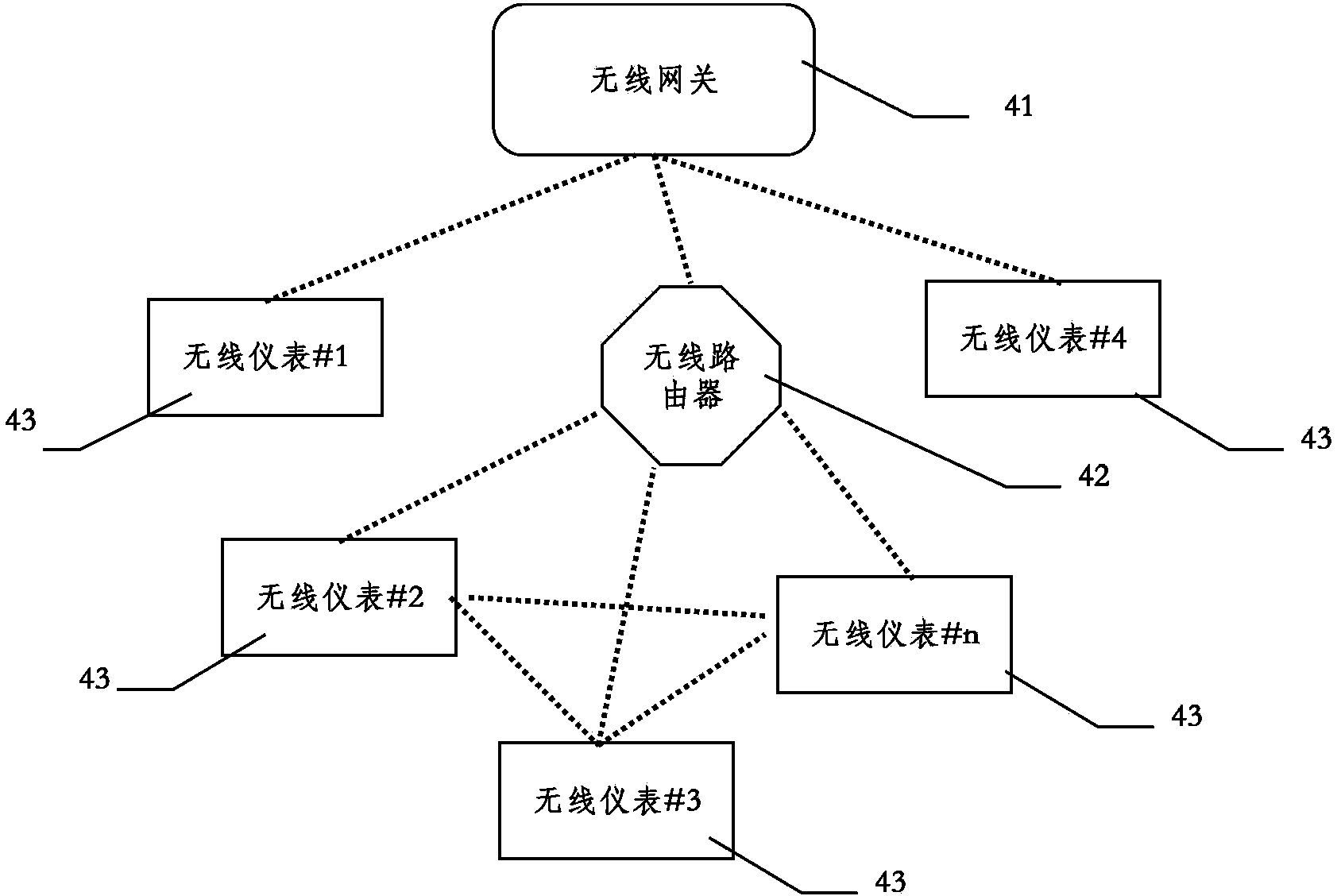

[0032] An equipment failure pre-maintenance system based on industrial wireless technology, including the composition structure of the system, the working mode of wireless instruments, the composition mode of wireless network, the factory-level fault monitoring ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com