Non-dead angle binocular solid all-directional vision sensing equipment

An omnidirectional vision, binocular stereo technology, applied in image data processing, optics, instruments, etc., can solve the problems of dead angle, unable to achieve 360°*360° range monitoring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

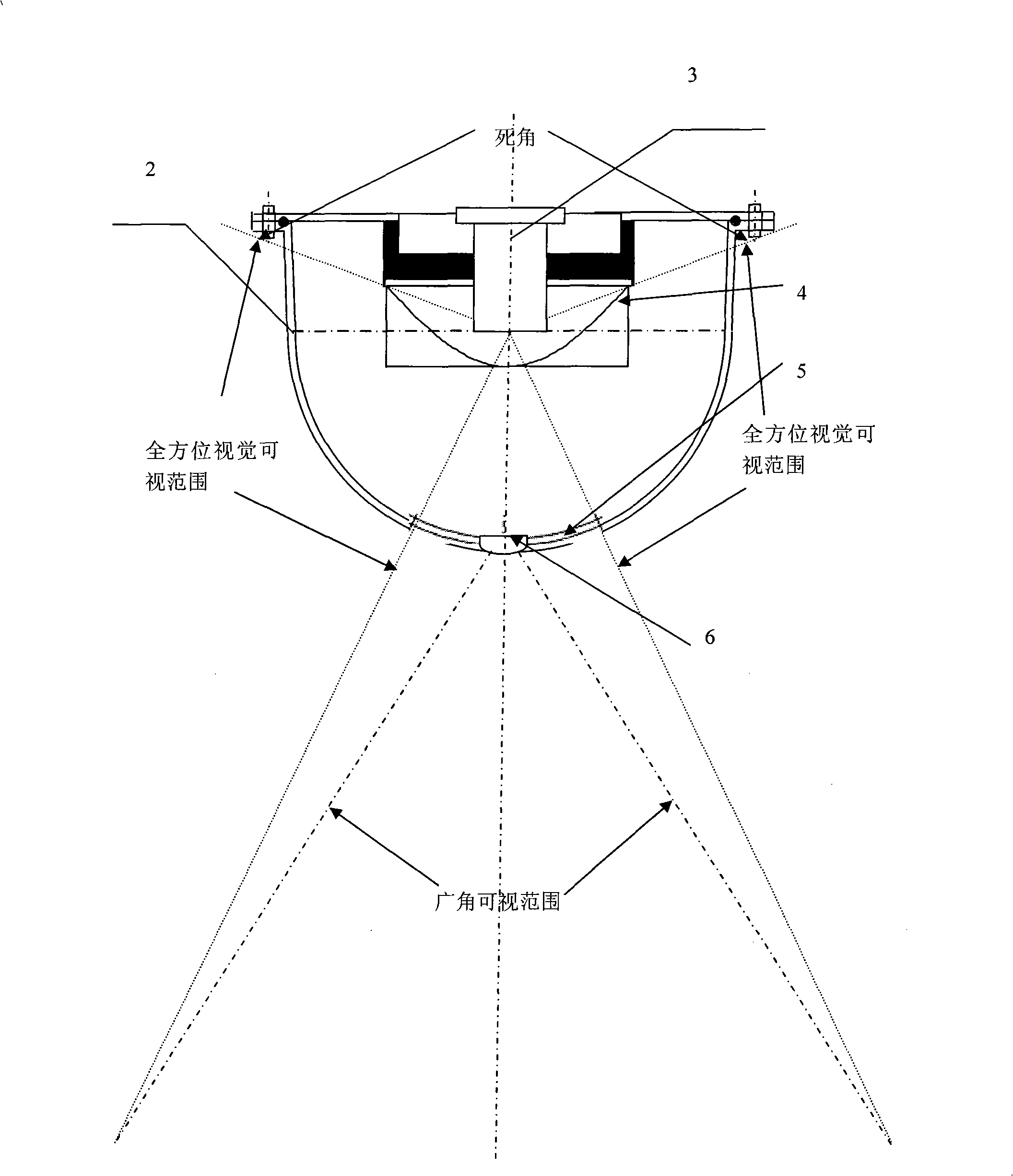

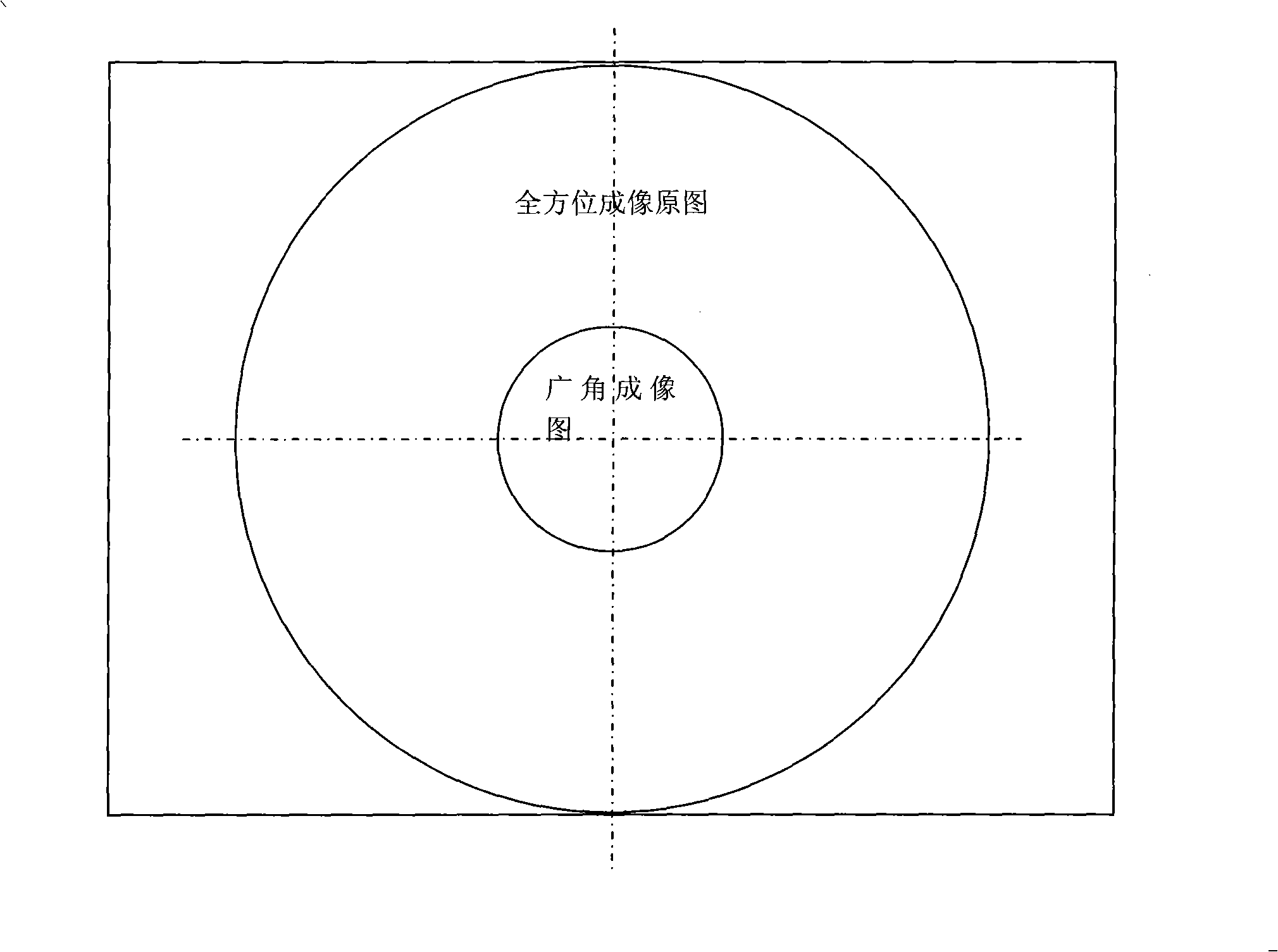

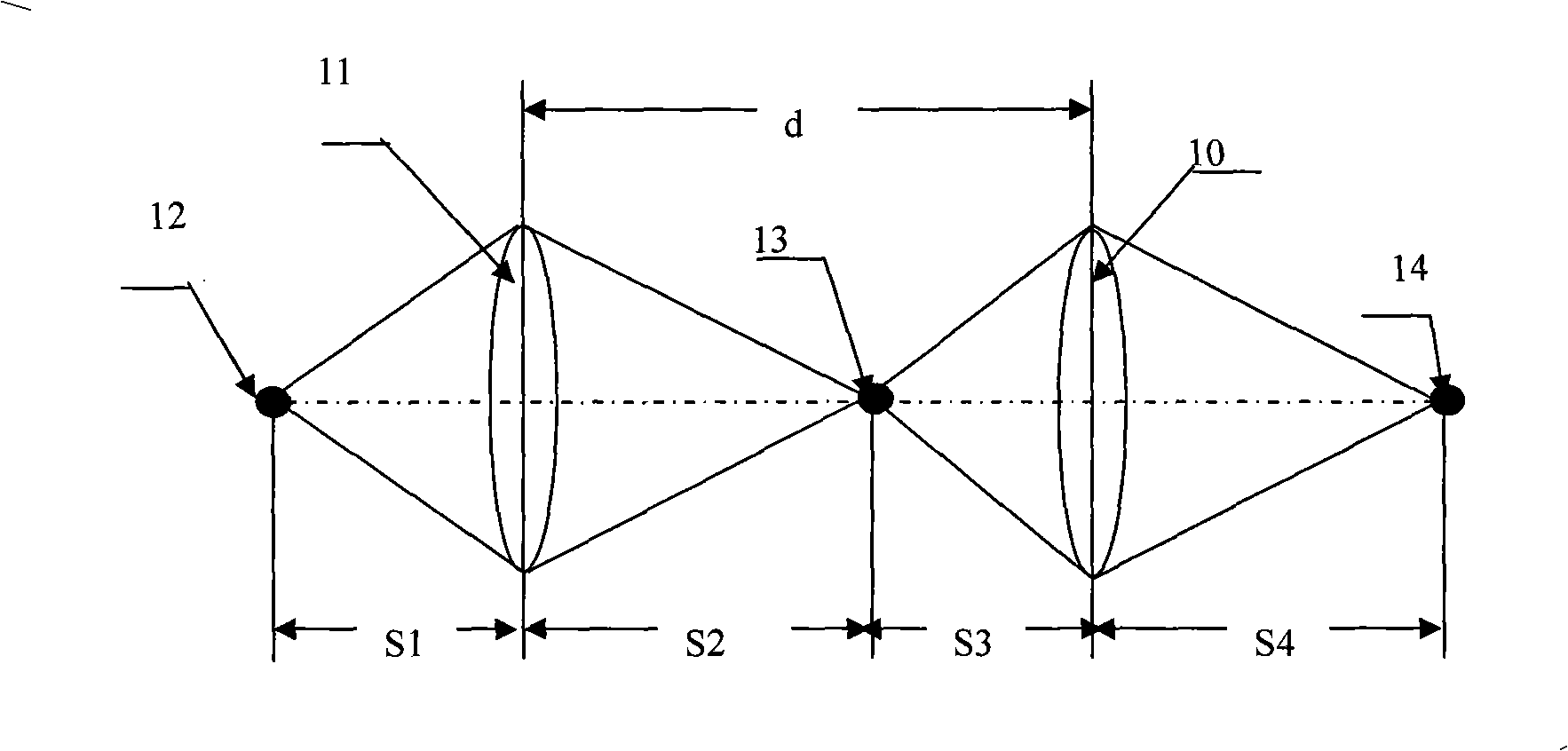

[0144] refer to Figure 1 to Figure 8 , a binocular stereo omnidirectional visual sensing device with no dead angle, which is composed of two omnidirectional vision sensors with the same average angular resolution without dead angle back-to-back assembly; Orientation Vision Sensor (ODVS), two omni-directional vision sensors with the same average angular resolution are connected with a connecting piece, and the video cable and power line of the camera are drawn out through the hole in the connecting piece, as shown in the attached Figure 4 As shown; the video lines of each ODVS camera are respectively connected to the video image reading unit, because the video acquisition information of each ODVS camera can reach 360°*240° field of view, and in the vertical (incident angle) direction It has an average angular resolution, so it can easily realize the fusion of image information between two ODVS; the video image reading unit respectively reads the video information of each ODVS...

Embodiment 2

[0202] refer to Figure 2-Figure 8 , a stereo omni-directional visual sensing device without dead angle, the rest is the same as that of embodiment 1, the difference is that in the expansion mode and splicing mode, in the video image expansion unit, the circular ring obtained by each camera is fully The azimuth image is expanded into a rectangular cylindrical panoramic image through geometric transformation, and then spliced according to the complementary mode of incident angle; since the two ODVS with the same average angular resolution are fixed back-to-back with connectors in the present invention, the two ODVS The following relationship is established between the overlapping parts of the incident angle,

[0203] φ ODVS1 =180°-φ ODVS2

[0204] Therefore, when splicing, it is necessary to first remove the overlapped portion when the overlapping portion is unfolded. In the present invention, the minimum incident angle Φmin to the incident angle is a rectangular cylindric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com