Double-rotor generator and control method thereof

A generator and double-rotor technology, applied to control the direction of generators, synchronous machines, electrical components, etc. through changes in the magnetic field, can solve the problems of three-phase asynchronous generator power factor lag, etc., to improve operating efficiency, reduce vibration and noise , Enhance the effect of the air gap magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

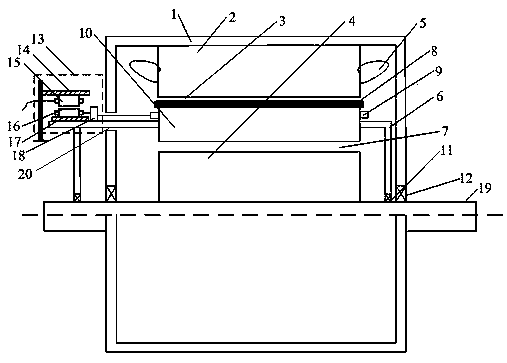

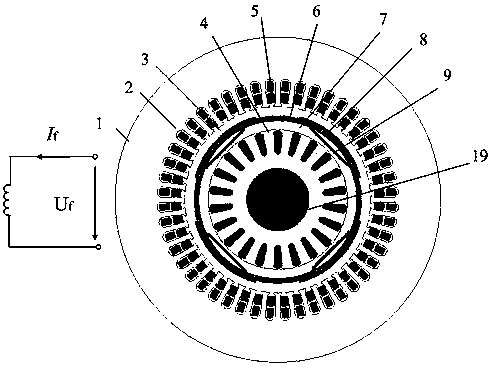

[0029] like figure 1 and figure 2 As shown, a dual-rotor generator includes a casing 1, the casing 1 is rotatably connected to a rotating shaft 19, and a stator is fixedly connected inside the casing 1, and the stator includes a stator core 2 and a stator winding 5, The stator core 2 is fixed on the casing 1, the stator winding 5 is installed in the slot of the stator core 2, the stator winding 5 is a three-phase symmetrical AC winding, and the rotating shaft 19 is fixedly connected with an inner squirrel cage The rotor 4, the inner squirrel-cage rotor 4 includes the inner squirrel-cage rotor iron core and the rotor squirrel-cage bars, the inner squirrel-cage rotor 4 is fixedly connected with the rotating shaft 19, the stator and the inner squirrel-cage rotor 4 An outer permanent magnet rotor 10 is arranged between them, the stator is arranged on the outer side of the outer permanent magnet rotor 10, the outer permanent magnet rotor 10 is rotationally connected with the rota...

Embodiment 2

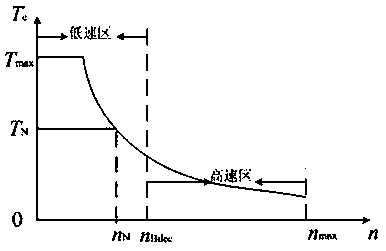

[0038] According to the characteristics and operating characteristics of the dual-rotor generator, its operating area is divided into two parts, the low-speed area and the high-speed area, such as image 3 shown.

[0039] In the low-speed area, the field-increasing control is usually used, and in the high-speed area, the field-weakening control is usually used. The operation control of the drive system can adopt the following magnetization control or field weakening control:

[0040] Magnetization control: The external permanent magnet rotor excitation winding 9 is magnetized to provide large torque and improve the short-term overload capacity of the generator. The torque detection device is used to collect real-time torque information. When the load torque is less than or equal to the generator When the rated torque is , the magnetization control is not required, that is to say, the excitation current in the field winding 9 of the outer permanent magnet rotor is I f =0; wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com