Adjusting roller device for glue-free film laminating machine

A technology of regulating roller and laminating machine, applied in lamination devices, layered products, lamination, etc., can solve the problems of reduced production efficiency, easy fogging, deterioration of composite effect, etc., to improve productivity and smooth film running Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

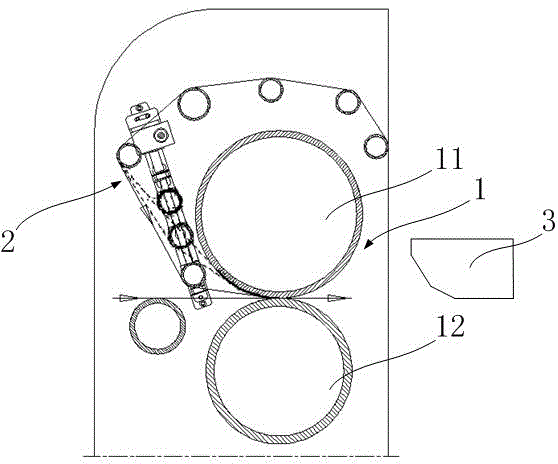

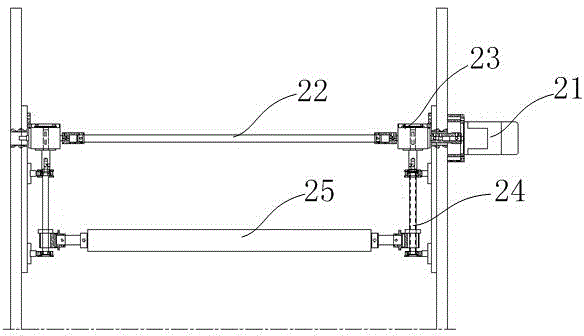

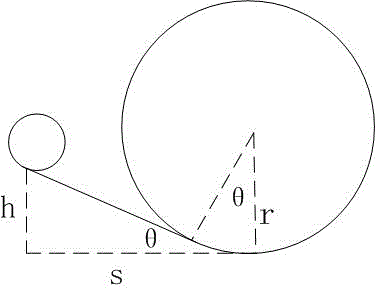

[0020] Such as figure 1 The regulating roller device of the non-adhesive laminating machine shown includes a heat pressing device 1 and a regulating roller device 2, and the heat pressing device 1 includes a relatively arranged hot steel roller 11 and a rubber roller 12, and the hot steel roller 11 It is closely attached to the roller surface of the rubber roller 12, and a heating device is arranged inside the hot steel roller 11, and the adjusting roller device 2 is arranged at the film-entry end of the thermal pressing device 1, as figure 2 As shown, it includes an AC motor 21 and a connecting shaft 22 connected to the output shaft of the AC motor 21. The connecting shaft 22 is equipped with a reducer 23, and the reducer 23 drives the ball screw 24 to rotate re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com