Thread rolling machine capable of machining thread ends with different lengths

A threaded end and thread rolling machine technology, applied in the field of thread rolling machines, can solve the problems of loose bolt fixing, increased production costs, and reduced processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

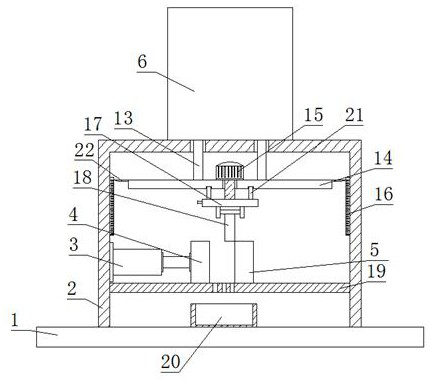

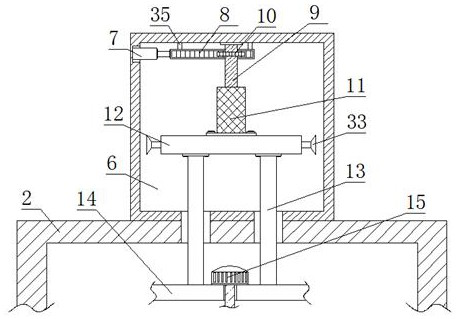

[0024] refer to Figure 1-5In this embodiment, a tooth rubbing machine capable of processing threaded ends of different lengths is proposed, including a base 1, a frame 2 is fixedly connected to the top of the base 1, and an electric push rod 3 is fixedly connected to the inner wall of one side of the frame 2, The frame 2 is fixedly connected with a placement plate 19, the top of the placement plate 19 is fixedly connected with a static tooth plate 5, the top of the placement plate 19 is slidingly connected with a movable tooth plate 4, and one end of the electric push rod 3 is connected to one end of the movable tooth plate 4. The sides are fixedly connected, and the sides where the movable tooth plate 4 and the static tooth plate 5 are close to each other are provided with tooth patterns, and the top of the frame 2 is fixedly connected with a fixed box 6, and a mounting groove is opened on the inner wall of one side of the fixed box 6. One side of the groove is fixedly conne...

Embodiment 2

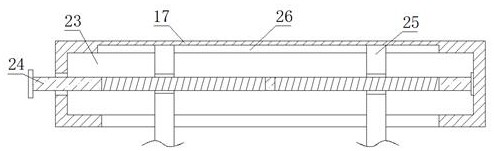

[0026] In this embodiment, the clamping assembly includes a fixed chamber 23 arranged on the fixed seat 17 , the inner wall of one side of the fixed chamber 23 is rotatably connected with a limit shaft 24 , and one end of the limit shaft 24 extends to one end of the fixed seat 17 . side and is fixedly connected with a handle, and the limit shaft 24 is symmetrically provided with two sections of opposite threads, and the two sections of opposite threads are all threaded with a clamping plate 25, and the sides of the two clamping plates 25 that are close to each other are respectively connected with the processing The two sides of the bolt 18 are closely fitted, and the two clamping plates 25 can be made close to each other by rotating the limit shaft 24, and then the processing bolt 18 can be clamped and fixed, which can prevent the processing bolt 18 from being damaged during processing. The bolt 18 is displaced, which affects the processing quality.

[0027] In this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com