Clamping device of numerical control machine tool

A technology of CNC machine tools and clamping device, applied in the field of CNC machine tools, can solve the problems of low degree of freedom of fixtures, increased production costs, and inability to clamp multiple workpieces at one time, and achieve a good clamping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

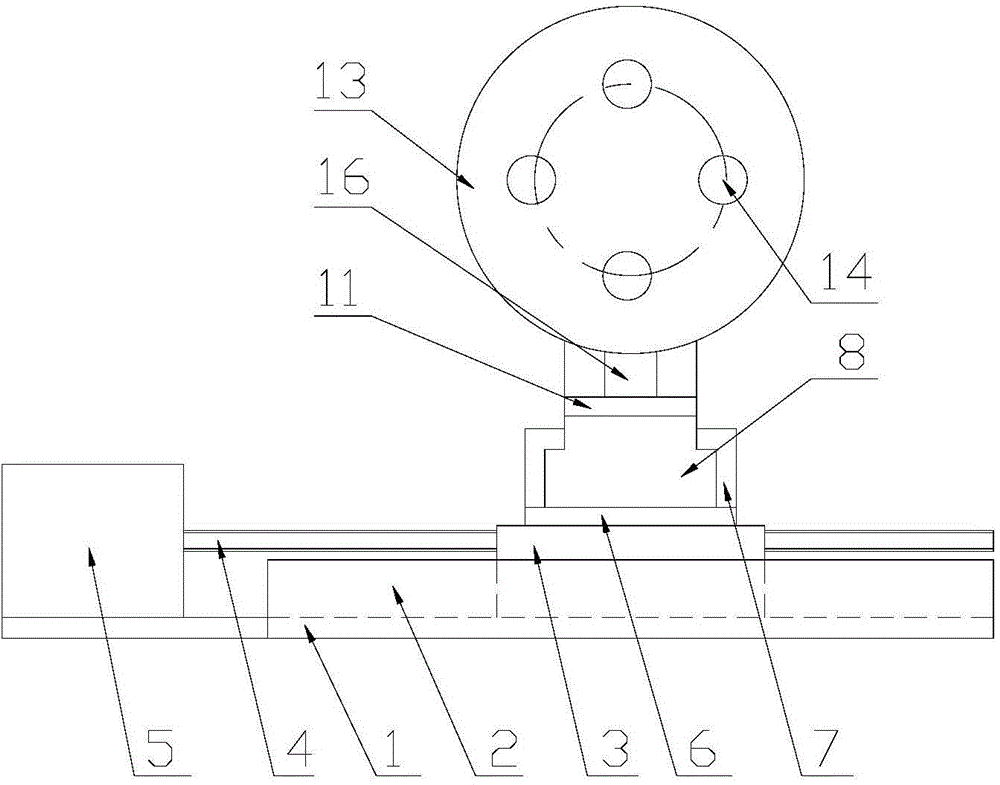

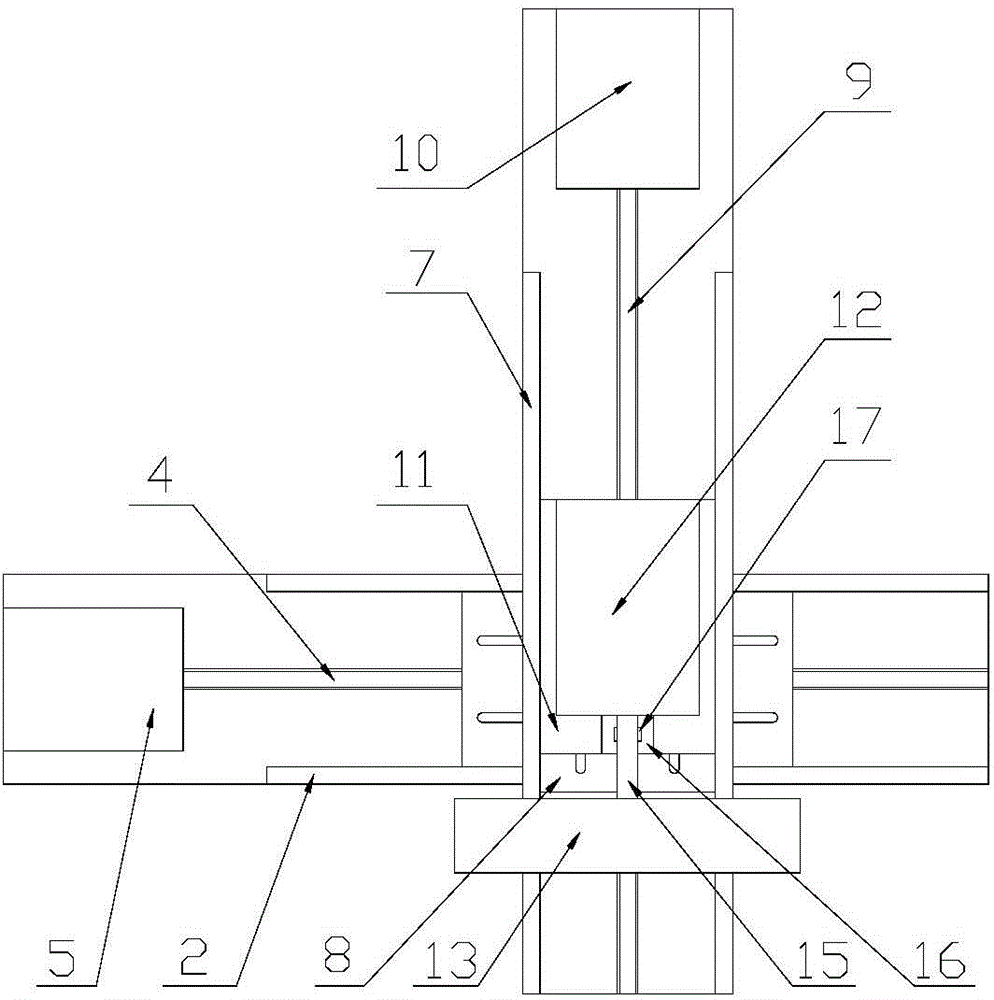

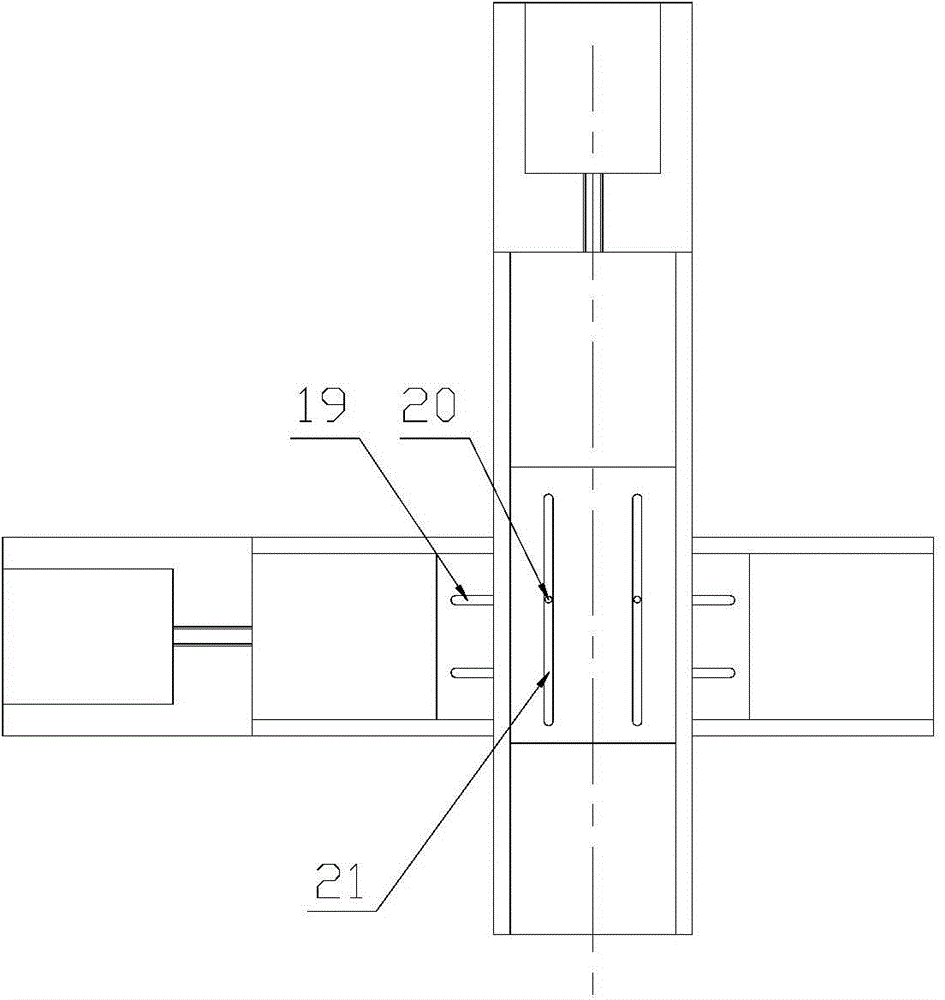

[0020] see Figure 1 to Figure 3 , is a kind of clamping device of numerical control machine tool, comprises the first base 1 that is used to be arranged on the workbench of numerical control machine tool and is rectangular plate structure, is provided with two mutually parallel first guide rails 2 on the first base 1, The first guide rail is welded and fixed on the first base 1 . The two first guide rails 2 are parallel to the two long sides of the first base 1, and the first moving plate 3 is slidably matched between the two first guide rails 2, and the inner thread of the first moving plate 3 is fitted parallel to the first The first threaded mandrel 4 of the guide rail 2 forms a first threaded mandrel nut mechanism, and the first threaded mandrel 4 is fixedly connected with the rotating shaft of the first driving motor 5 fixed on the first base 1 .

[0021] The second base 6 of rectangular plate-like structure is fixed on the first moving plate 3, the second base 6 is per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com