Circuit board processing tool for copper block brown oxidation

A technology of circuit boards and copper blocks, which is applied to printed circuits, circuit thermal parts, printed circuit manufacturing, etc., can solve the problems of tape loss, non-reusable use, and large labor investment, and achieves convenient operation, low cost, and excellent structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

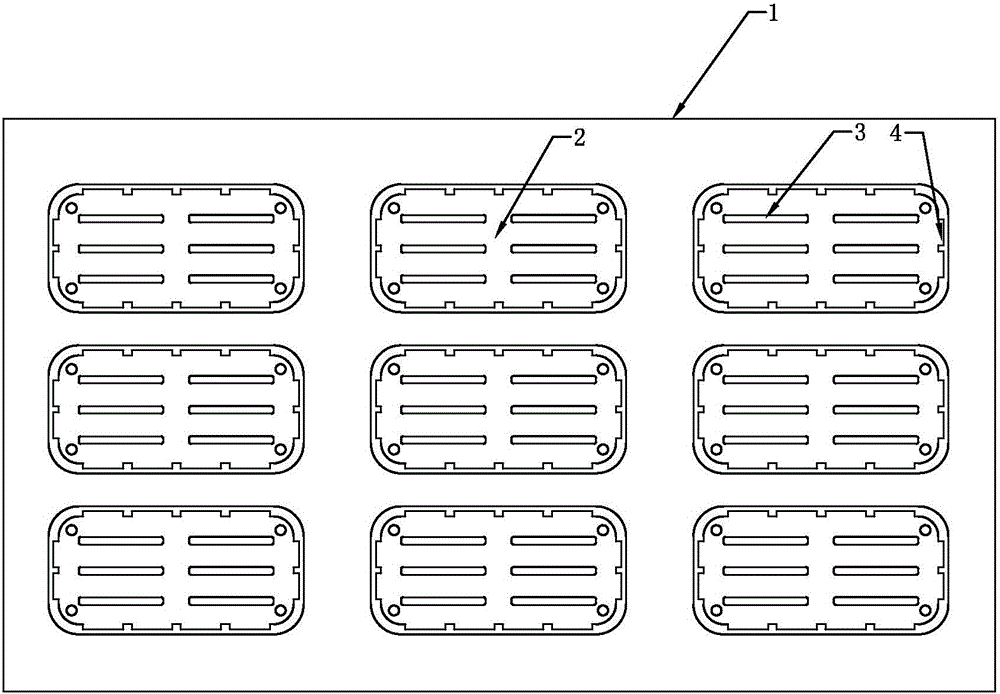

[0012] refer to figure 1 , a circuit board processing jig for browning copper blocks according to the present invention includes a supporting plate 1, and a plurality of accommodating cavities 2 for accommodating copper blocks are separated on the supporting plate 1, and the size of the accommodating cavities 2 can be determined according to the actual situation. The size of the browned copper block is designed in different specifications to meet the browning requirements of copper blocks of different sizes. The bottom of the accommodation chamber 2 is respectively provided with a plurality of through holes 3. Preferably, the through hole at the center of the bottom of the accommodation chamber 2 Hole 3 is a strip hole, and the through holes 3 at the four corners are round holes. The through hole 3 at the bottom is to facilitate the exchange and outflow of browning liquid, improve the quality of browning and avoid affecting the operation of subsequent processes. The center of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com