Combined external wall thermal insulation board, processing equipment and processing method

An external wall thermal insulation board, combined technology, applied in thermal insulation, building components, devices for coating liquid on the surface, etc., can solve the problems of unsightly buildings, easy to move the outer surface, not easy, etc., to solve the problem of a large number of gaps , reducing the effect of large voids and voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

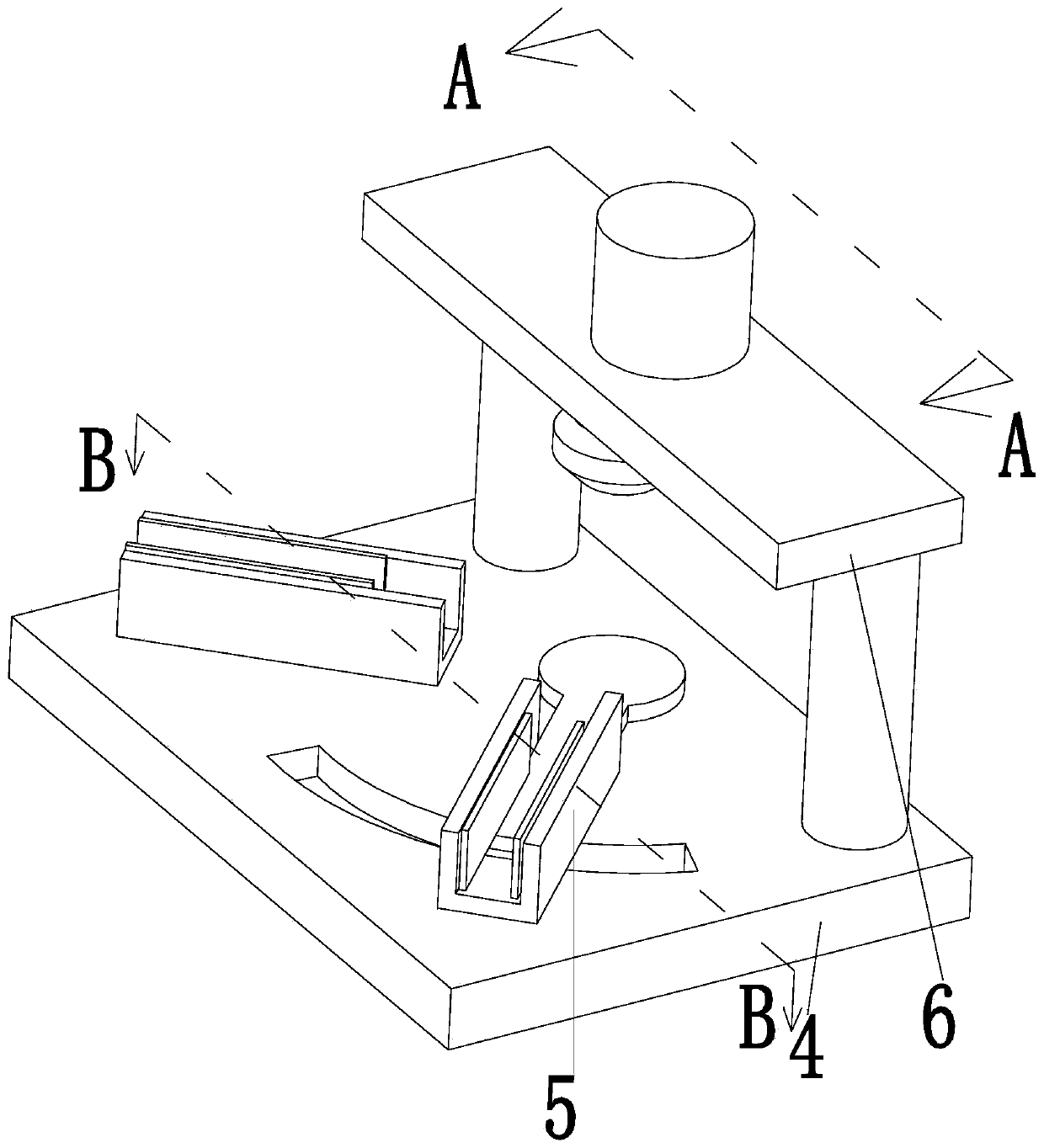

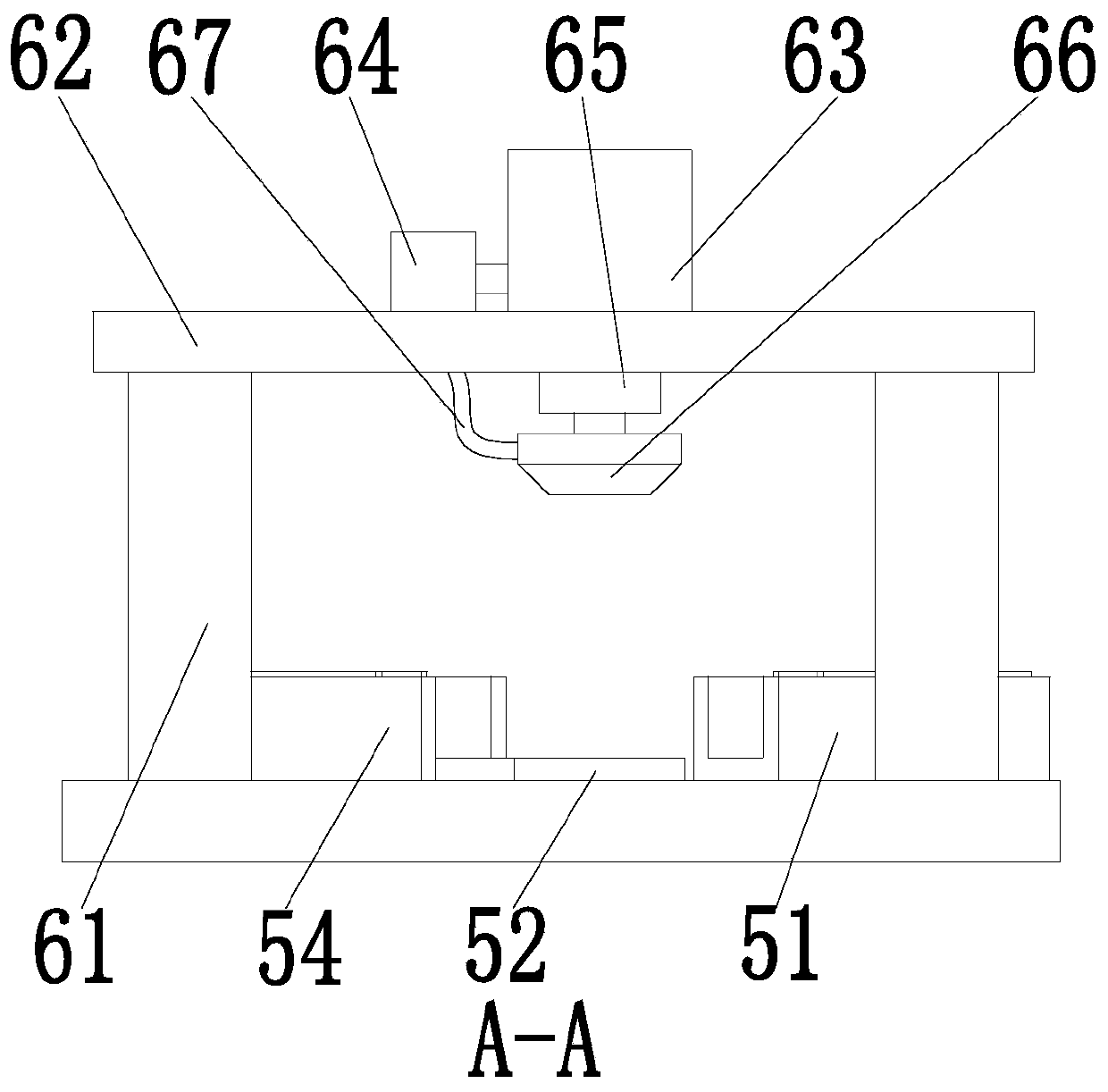

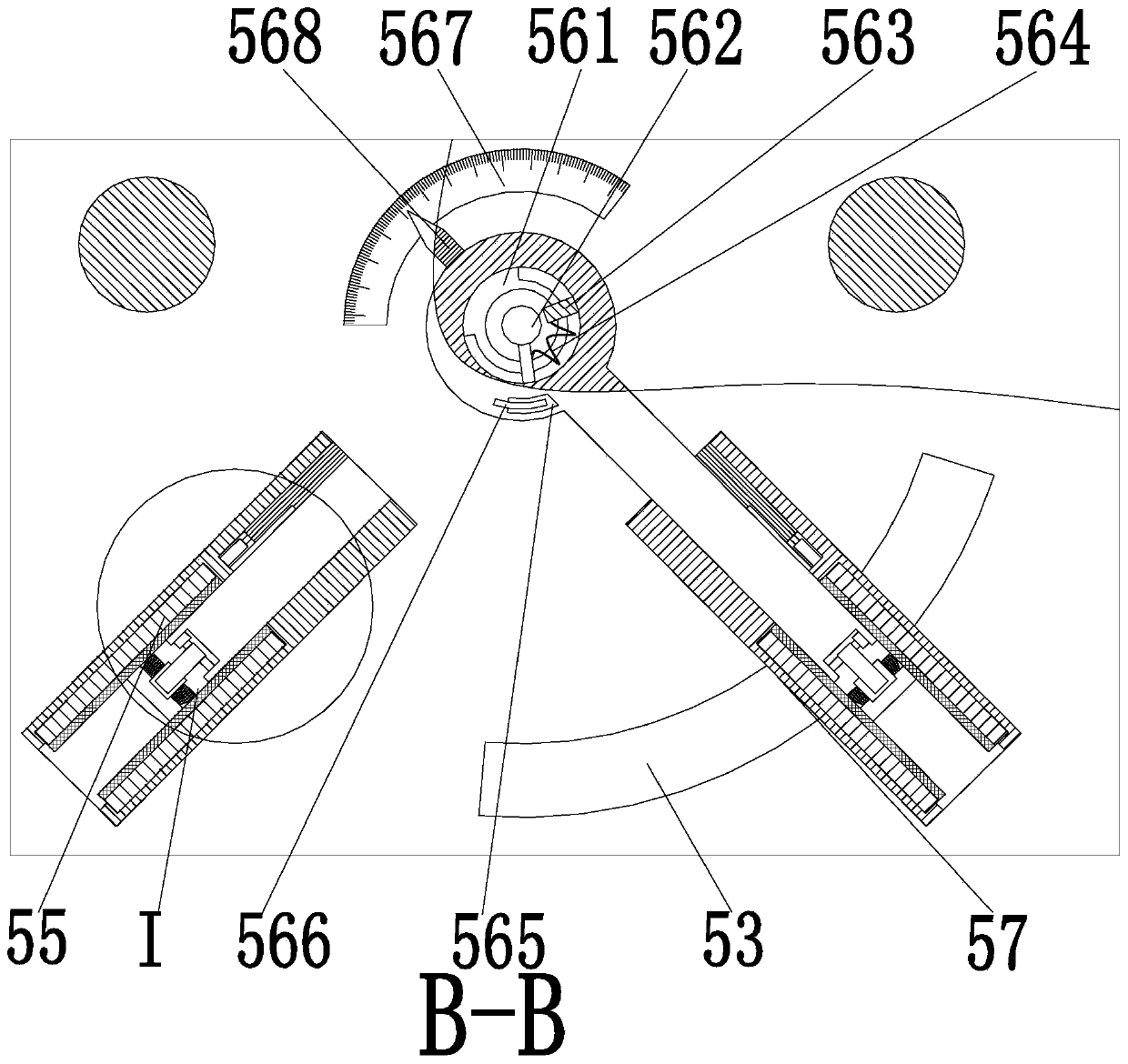

[0031] Such as Figure 1 to Figure 6 As shown, a combined external wall insulation board includes an external wall main insulation board 1, a matching insulation board 2 and a rotating column 3. The right end of the external wall main insulation board 1 is evenly provided with matching grooves from top to bottom, Rotating columns 3 are arranged between the inner walls of the upper and lower ends of the groove, and matching blocks are uniformly arranged from top to bottom at the left end of the matching insulation board 2. The matching blocks are connected to the rotating column 3 through bearings, and the matching grooves and the matching blocks are arranged at intervals; among them:

[0032] The installation process of the combined external wall insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com