Copper embedded block heat radiation substrate and manufacturing method therefor

A technology of heat-dissipating substrates and buried copper blocks, applied in circuit thermal devices, printed circuit components, etc., can solve the problems of large height deviation of copper bosses, low production efficiency, unstable quality, etc., to improve dimensional accuracy and solve easy problems. The effect of offset, improving processing efficiency and quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

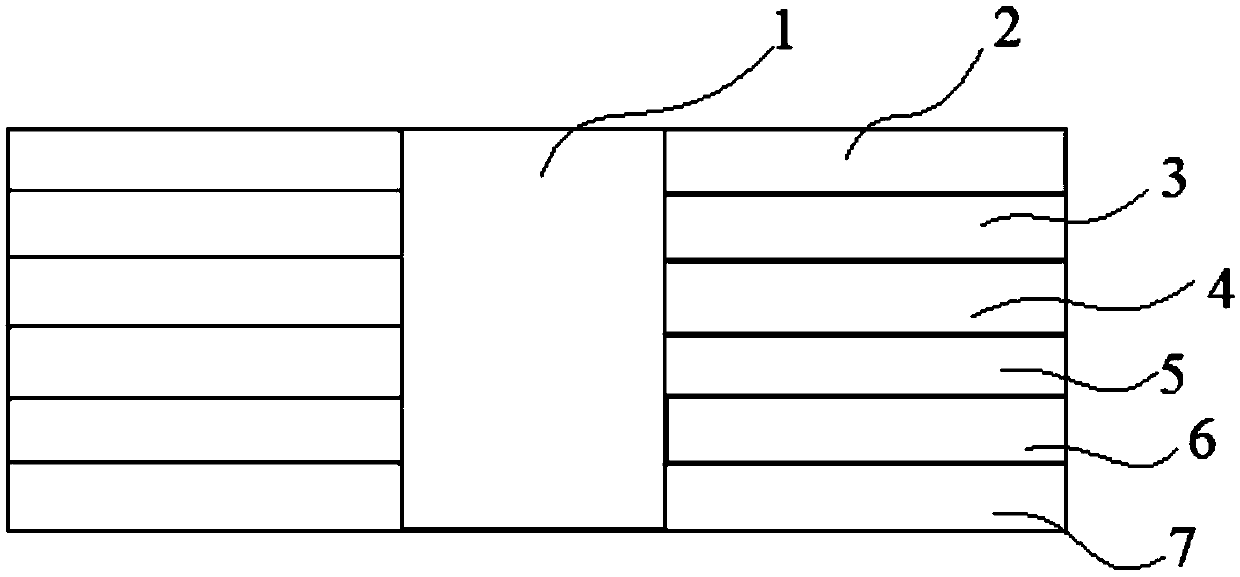

[0035] This embodiment provides a buried copper heat dissipation substrate, such as figure 1 As shown, the heat dissipation substrate includes a substrate body, and the substrate body is provided with a buried copper block through groove, and a heat dissipation copper block 1 is arranged in the buried copper block through groove, and the heat dissipation copper block 1 is a rectangular parallelepiped copper block. Its top surface and bottom surface are respectively flush with the top surface and bottom surface of the heat dissipation substrate, so that the top surface and bottom surface of the heat dissipation copper block 1 are exposed to the environment, and the heat dissipation effect is better.

[0036] Specifically, from top to bottom, the substrate body is composed of a top layer of copper foil 2, a top layer of optical core board 3, and a prepreg layer (the prepreg layer is two layers, and the first prepreg 4 is respectively from top to bottom) , the second prepreg 5), ...

Embodiment 2

[0039] This embodiment provides a buried copper heat dissipation substrate, such as figure 1As shown, the heat dissipation substrate includes a substrate body, and the substrate body is provided with a buried copper block through groove, and a heat dissipation copper block 1 is arranged in the buried copper block through groove, and the heat dissipation copper block 1 is a rectangular parallelepiped copper block. Its top surface and bottom surface are respectively flush with the top surface and bottom surface of the heat dissipation substrate, so that the top surface and bottom surface of the heat dissipation copper block 1 are exposed to the environment, and the heat dissipation effect is better.

[0040] Specifically, from top to bottom, the substrate body is composed of a top layer of copper foil 2, a top layer of optical core board 3, and a prepreg layer (the prepreg layer is two layers, and the first prepreg 4 is respectively from top to bottom) , the second prepreg 5), t...

Embodiment 3

[0043] This embodiment provides a buried copper heat dissipation substrate, such as figure 1 As shown, the heat dissipation substrate includes a substrate body, and the substrate body is provided with a buried copper block through groove, and a heat dissipation copper block 1 is arranged in the buried copper block through groove, and the heat dissipation copper block 1 is a rectangular parallelepiped copper block. Its top surface and bottom surface are respectively flush with the top surface and bottom surface of the heat dissipation substrate, so that the top surface and bottom surface of the heat dissipation copper block 1 are exposed to the environment, and the heat dissipation effect is better.

[0044] Specifically, from top to bottom, the substrate body is composed of a top layer of copper foil 2, a top layer of optical core board 3, and a prepreg layer (the prepreg layer is two layers, and the first prepreg 4 is respectively from top to bottom) , the second prepreg 5), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com