Integrated circuit packaging method

A packaging method and integrated circuit technology, applied in circuits, electrical components, electrical solid devices, etc., can solve problems such as metal stress cracking in the PAD area, and achieve the effect of solving metal cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The integrated circuit packaging method of the present invention comprises the following steps:

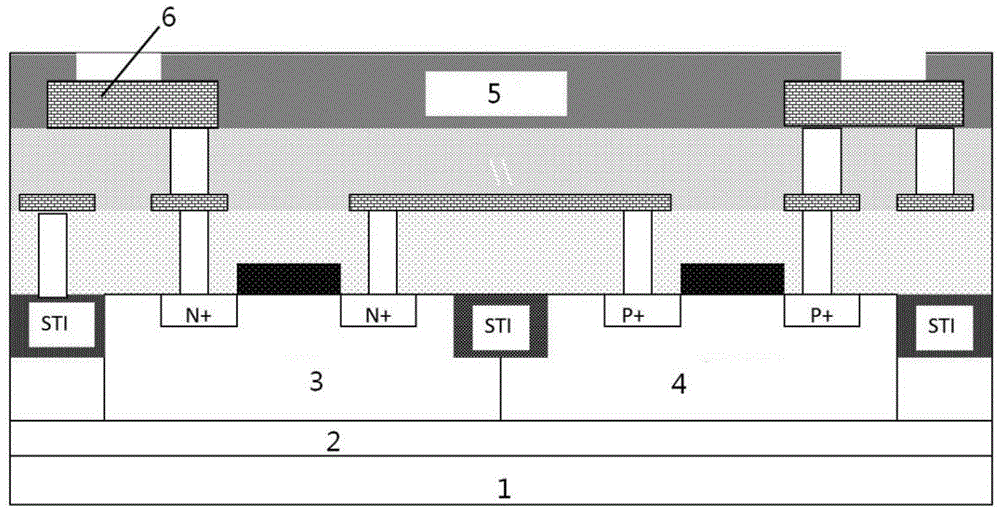

[0021] The first step is to deposit a thin layer of top layer metal on the silicon wafer with a thickness of 0.2-2.0 μm, and open the PAD window of the passivation layer by photolithography after forming the passivation layer. Such as figure 2 shown.

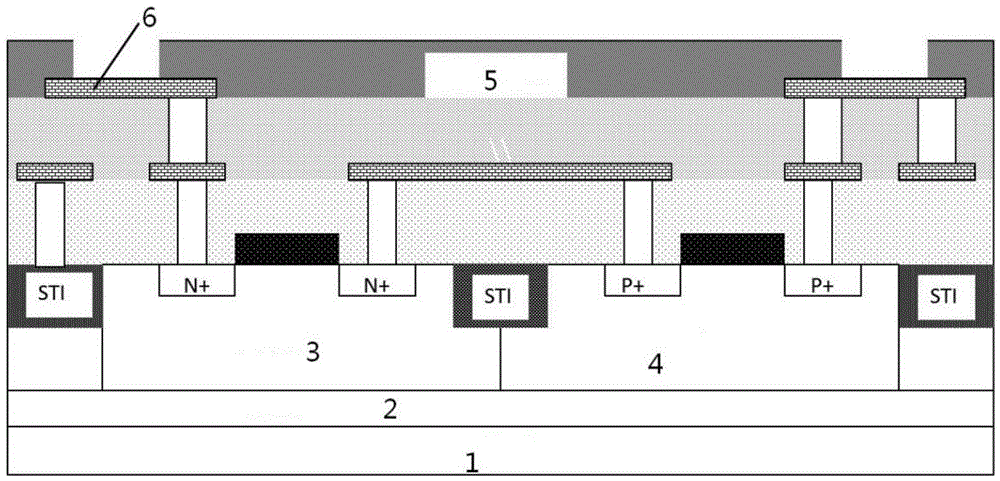

[0022] In the second step, a thicker layer of metal is deposited by CVD, with a thickness of 0.5-5.0 μm, and the material is aluminum / copper, or copper, or other materials. Such as image 3 shown.

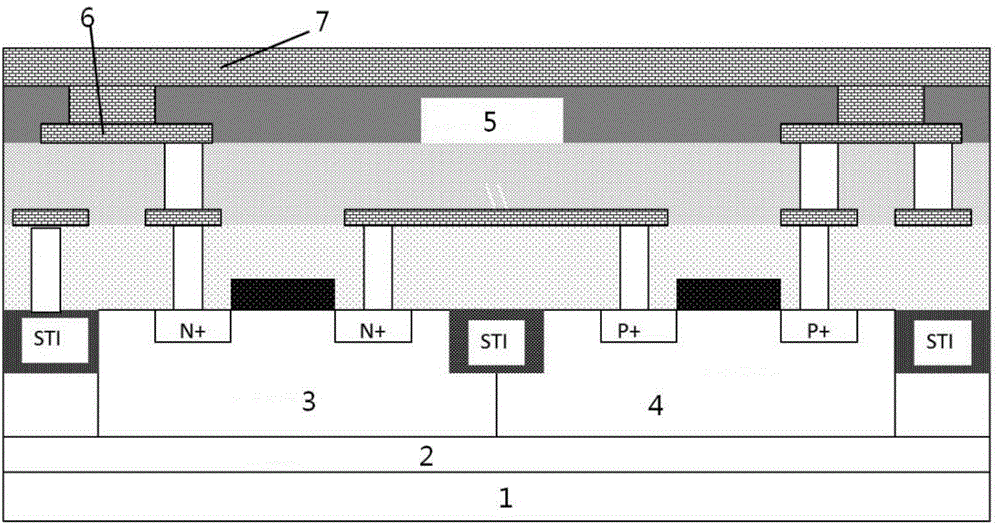

[0023] The third step is to remove the metal outside the PAD window on the passivation layer. The removal process may be a reverse etching plus CMP process, or a photolithography and etching process. If the photolithography plus etching process is used, the mask plate with the same passivation layer is used to form a photoresist with opposite characteristics to the passivation layer, that is, the positive photoresist used wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com