Real-time detection method for clutch engaging state of loader dead axle type gearbox

A technology for real-time detection and engagement status, applied to mechanical equipment, transmission control, components with teeth, etc., to achieve rapid maintenance and prevent huge losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

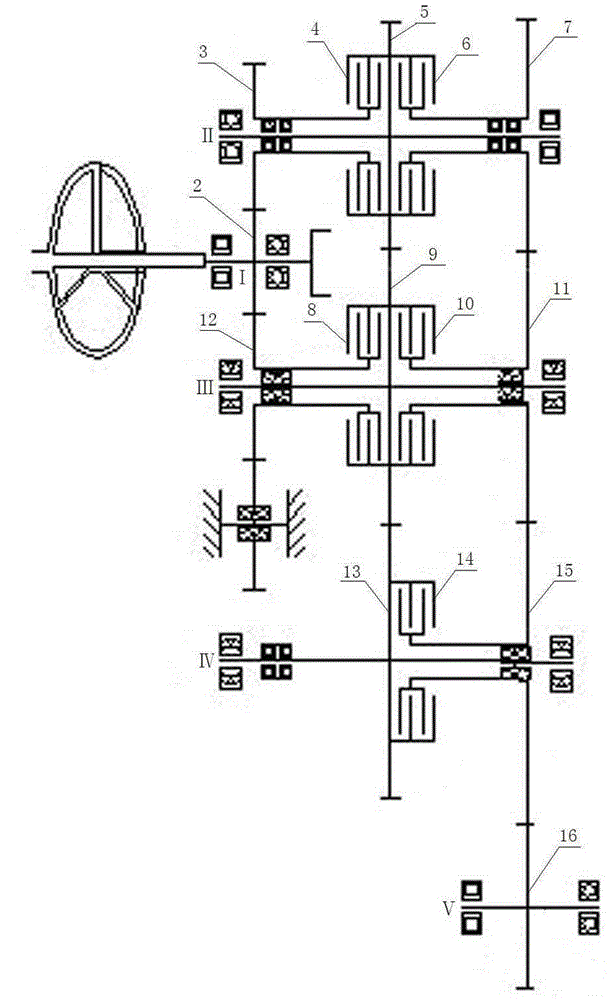

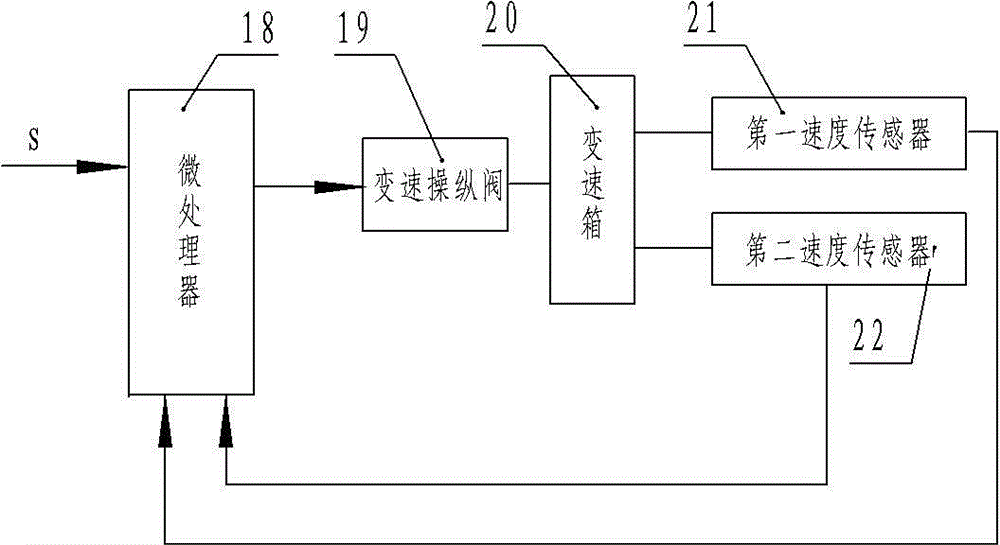

[0021] figure 2 The shown real-time detection method for the engagement state of the loader fixed-axis transmission clutch adopts a microprocessor 18 for real-time detection of the engagement state of the loader fixed-axis transmission clutch, and the signal input end of the microprocessor 18 is connected to the gear position of the loader The switch, the signal output end of the microprocessor 18 drives the gearbox 20 through the variable speed control valve 19, and the gearbox 20 includes the input shaft I of the sleeve input gear 2, the intermediate shaft of the sleeve transmission gear and the clutch, and the output shaft V of the sleeve output gear 16 , the input gear 2 is provided with a first speed sensor 21, and the output gear 16 is provided with a second speed sensor 22; connection; the intermediate shaft includes the first intermediate shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com