A profile pulling method

A profile and vertical technology, applied in the field of metal processing, can solve the problems of poor versatility, poor flexibility, high equipment manufacturing cost, etc., achieve efficient and stable traction effect, expand traction work space, and move and walk flexibly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] In this embodiment, the following description will be made by taking the profile traction method using a vertical profile double-track traction robot as an example.

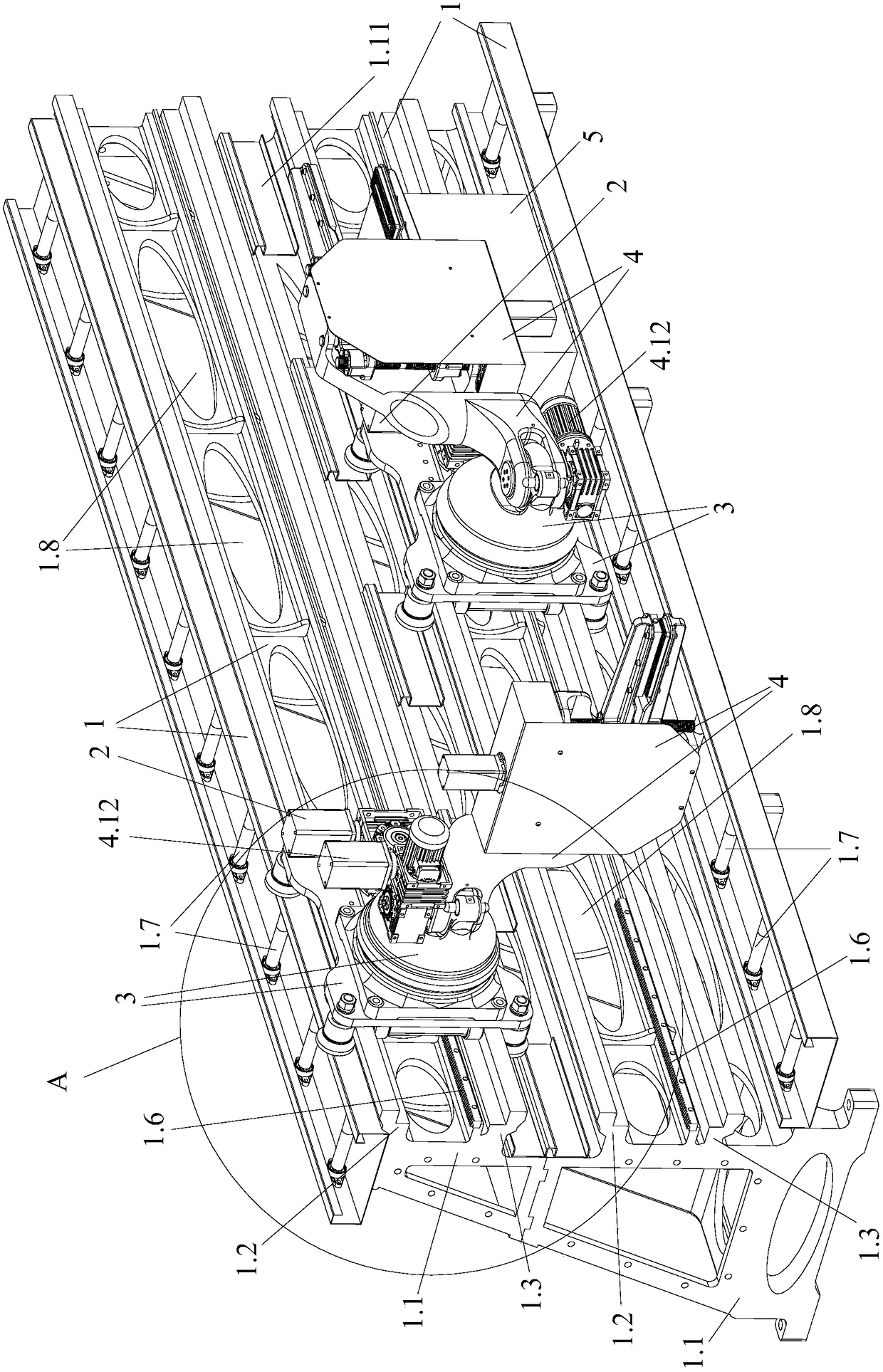

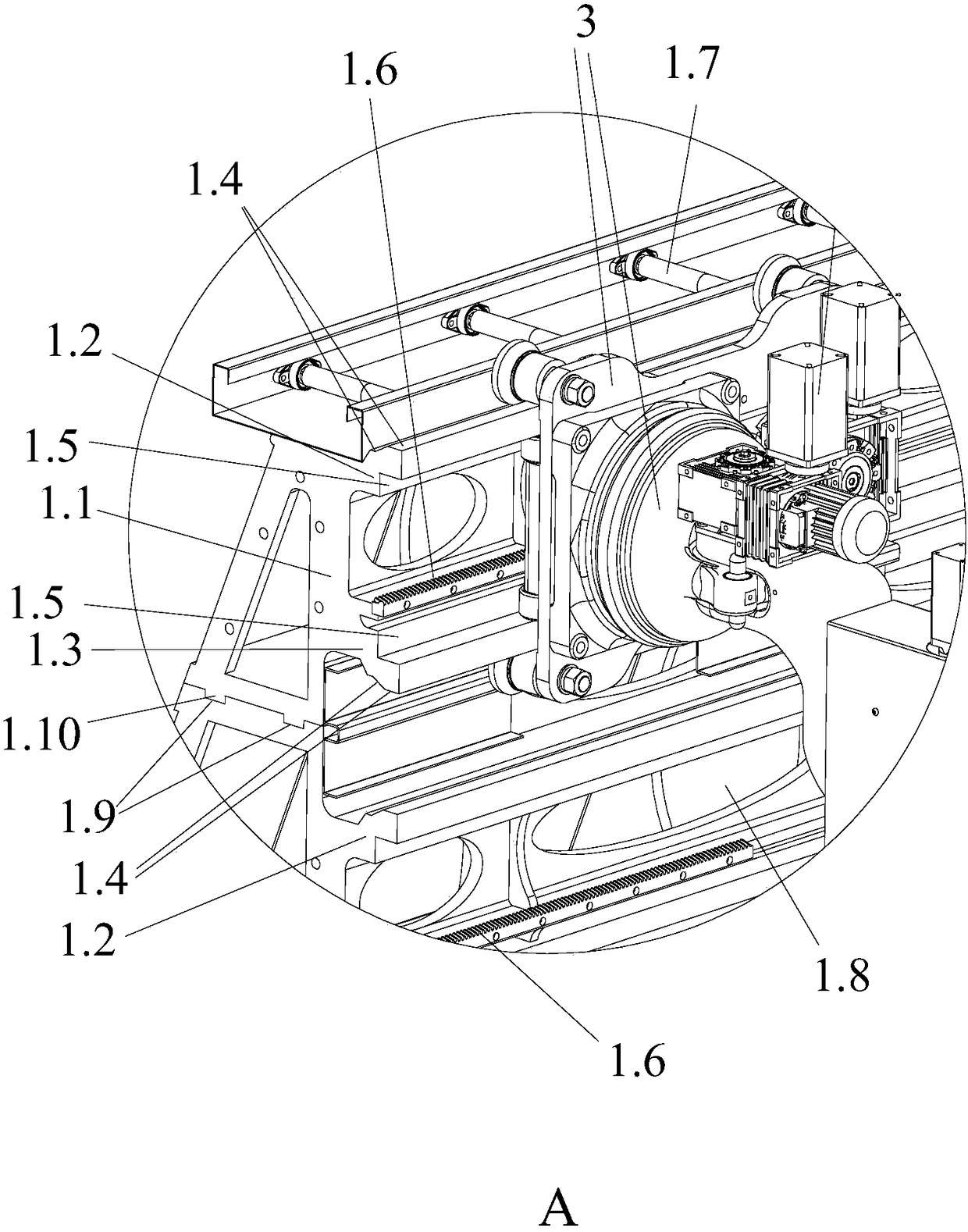

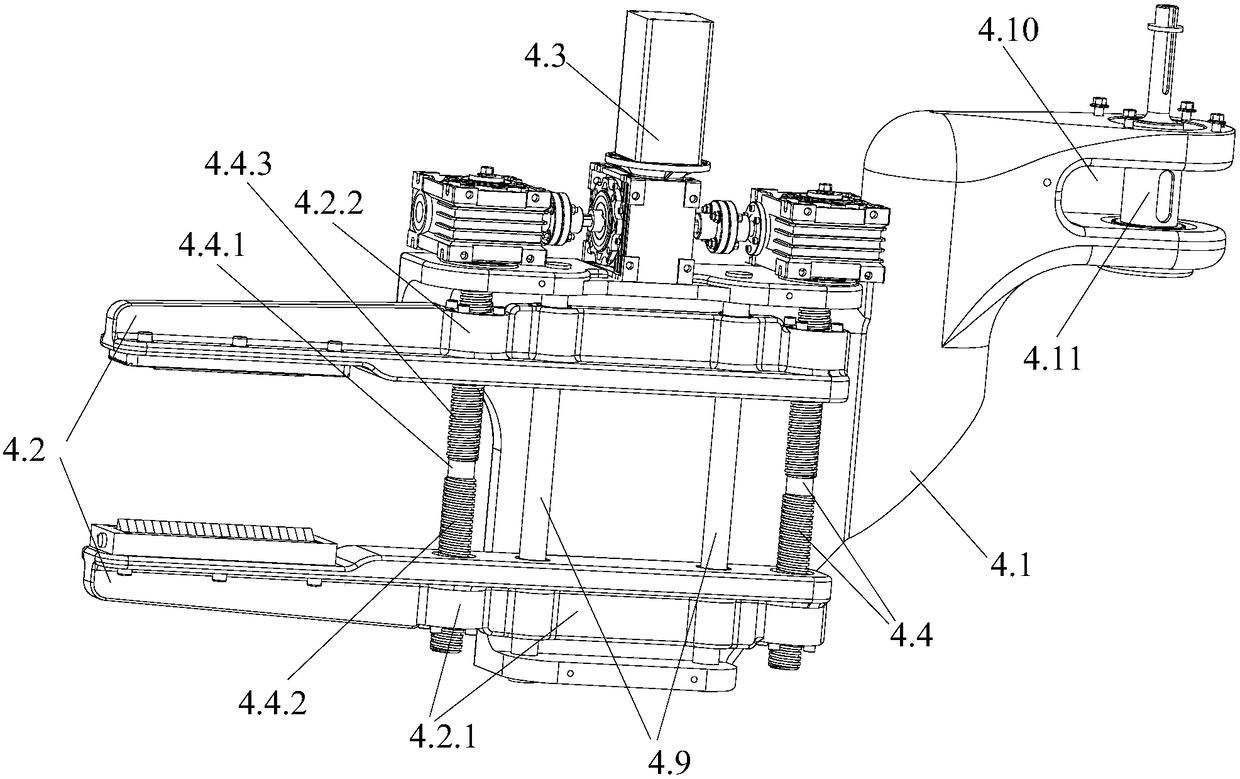

[0046] Such as Figures 1 to 7 As shown, the vertical profile double-track pulling robot of the present invention is used to pull the profile at the discharge port. The traction robot includes a control mechanism 5 and two traction units, wherein each traction unit includes a vertical walking track 1, a mechanical arm for clamping traction profiles, a transmission mechanism and a drive mechanism 2 for connecting with the transmission mechanism, Wherein, the mechanical arm is buckled on the side of the vertical walking track 1, and is slidably connected with the side of the vertical walking track 1, so that the mechanical arm is suspended on the side of the vertical walking track 1 for walking and moving; The transmission device one 3.8 on the mechanical arm and the transmission device two 1.6 on the verti...

Embodiment 2

[0067] The difference between this embodiment and the implementation is that the profile traction method of this embodiment uses a vertical traction robot to tract the profile. The vertical traction robot is composed of three or more traction units stacked and spliced. The mechanical arms of each traction unit are suspended on the vertical walking track to walk and move in a coordinated and alternate manner and avoid each other, so as to realize the traction of the profiles in a coordinated and alternate manner.

[0068] The structure of each traction unit in this embodiment is consistent with the first embodiment.

Embodiment 3

[0070] The difference between the present embodiment and the first embodiment is only that the position of the screw part 1 with a left-hand thread and the screw part 2 with a right-hand thread used in the profile pulling method of this embodiment are exchanged. In the present invention, the opening and closing movement of the first splint and the second splint can be realized as long as the screw rotation directions of the first screw and the second screw are opposite.

[0071] Other structures of this embodiment are consistent with Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com