Vertical type travelling mechanism for section bar traction

A walking mechanism and vertical technology, which is applied in the field of vertical profile traction walking mechanism, can solve the problems that the straightness and straightness of the traction mechanical arm cannot be guaranteed, so as to improve the stability of walking and the quality of traction processing, and expand the working space , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

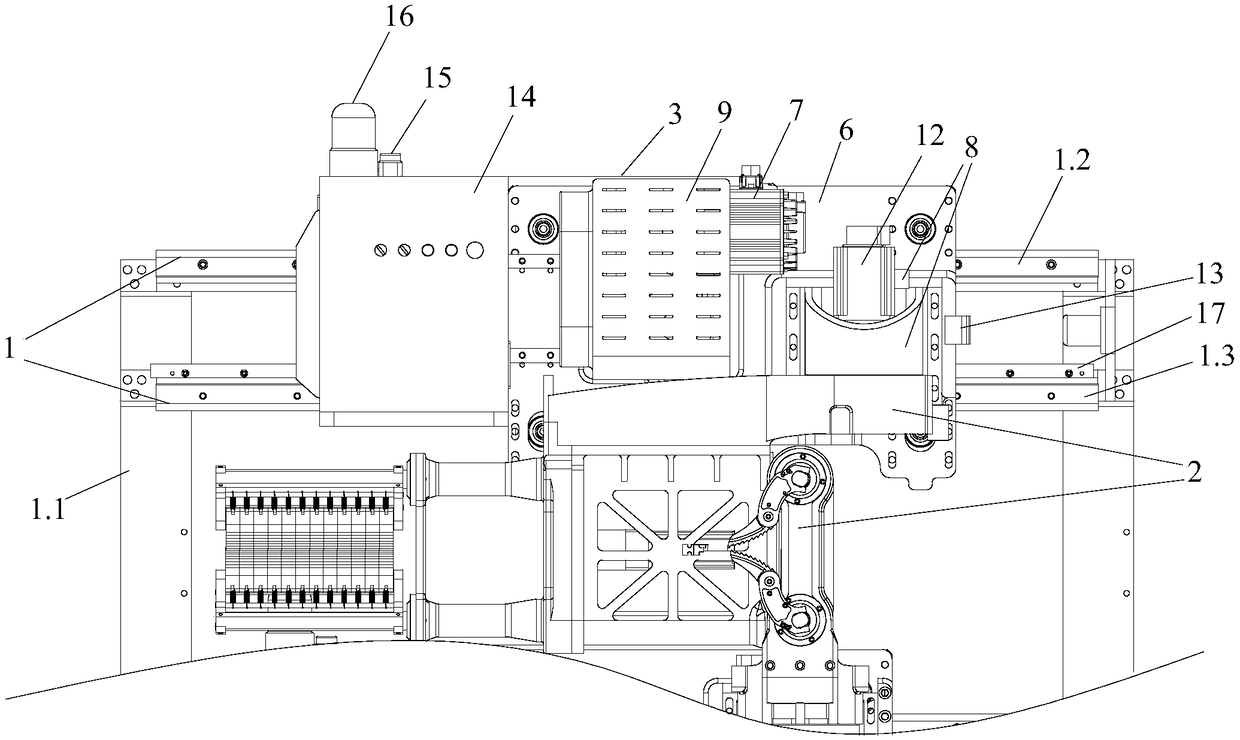

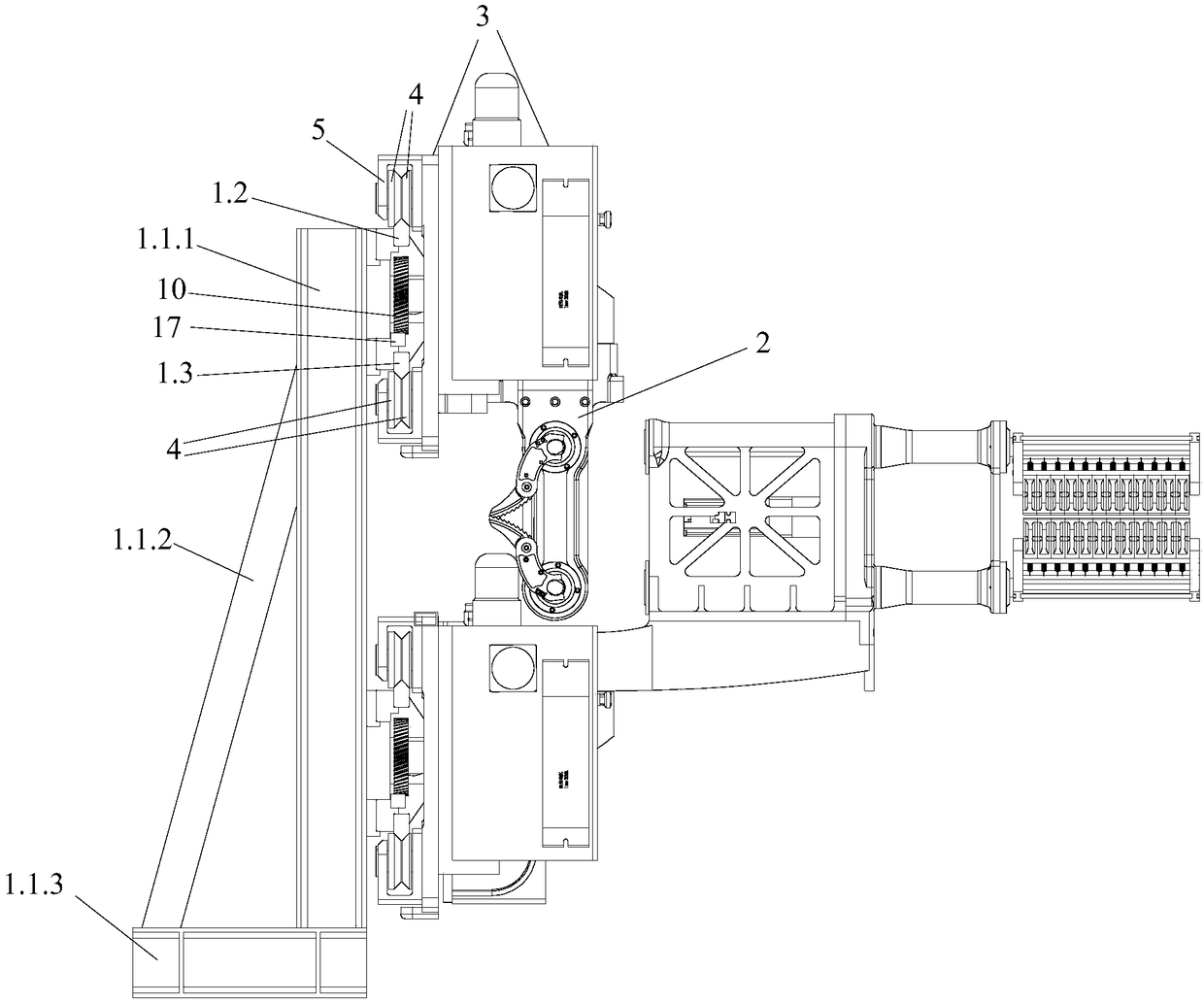

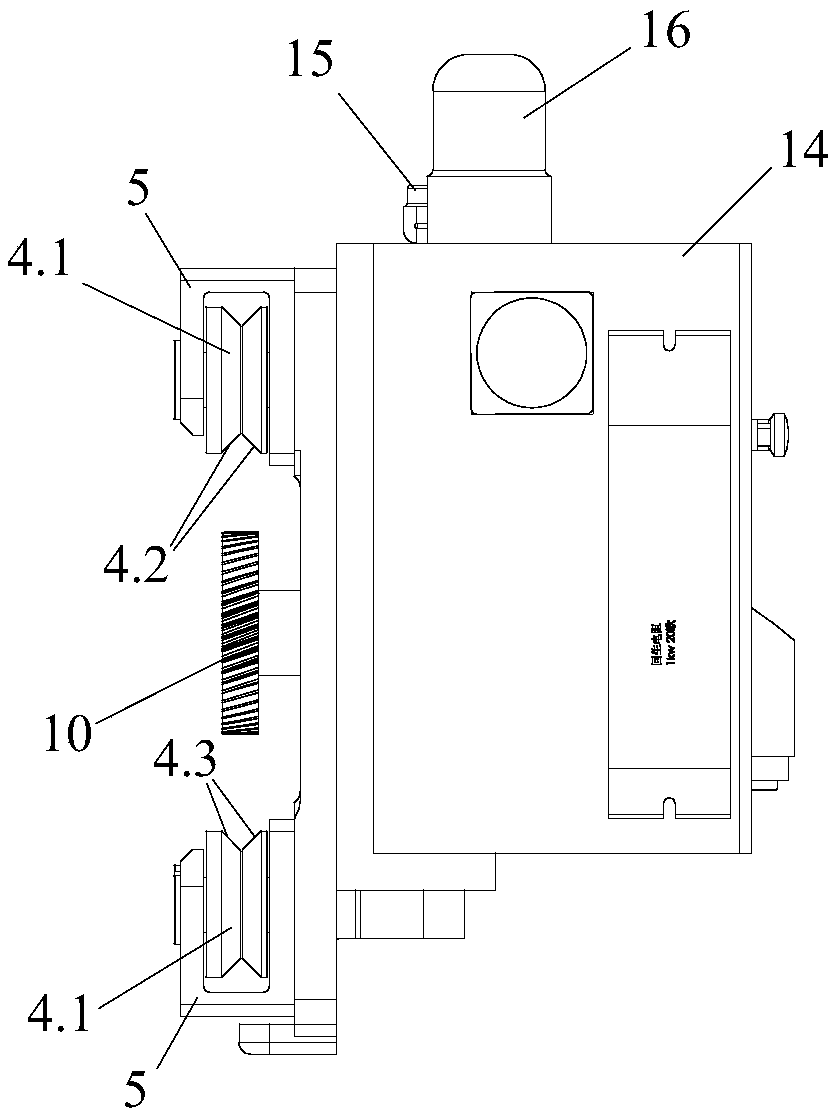

[0027] Such as Figure 1 to Figure 5 As shown, the walking mechanism of the vertical profile traction of the present invention includes a vertical walking guide rail 1 and a carriage 3 for sliding connection with the vertical walking guide rail 1 to realize the walking movement of the mechanical arm 2, wherein the vertical walking guide rail 1 includes The frame body 1.1 is formed by connecting the column 1.1.1, the support column 1.1.2 and the base 1.1.3, and the side of the frame body 1.1 is provided with slide rails along its length direction. And the carriage 3 comprises a carriage board 6, a power module 7 arranged on the carriage board 6 and a seat body 8 for installing the mechanical arm 2, wherein a sliding device is provided at the bottom of the carriage board 6, and the sliding device is used for It is clamped on the slide rail on the side of the frame body 1.1 and is slidably connected with the slide rail, so that the slide frame 3 is suspended on the side of the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com