A jig for controlling brazing deformation of a fuel manifold

A technology of deformation control and fuel main pipe, which is applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problem that the flatness of the end face of the nozzle cannot meet the design requirements, so as to reduce the man-hours of calibration, solve the problem of flatness, and reduce the difficulty of calibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

[0021] The present invention needs to braze and connect 24 nozzles with gas hoods to the main and auxiliary oil pipes, and ensure that the flatness of the 24 nozzles after brazing is ≤0.3mm.

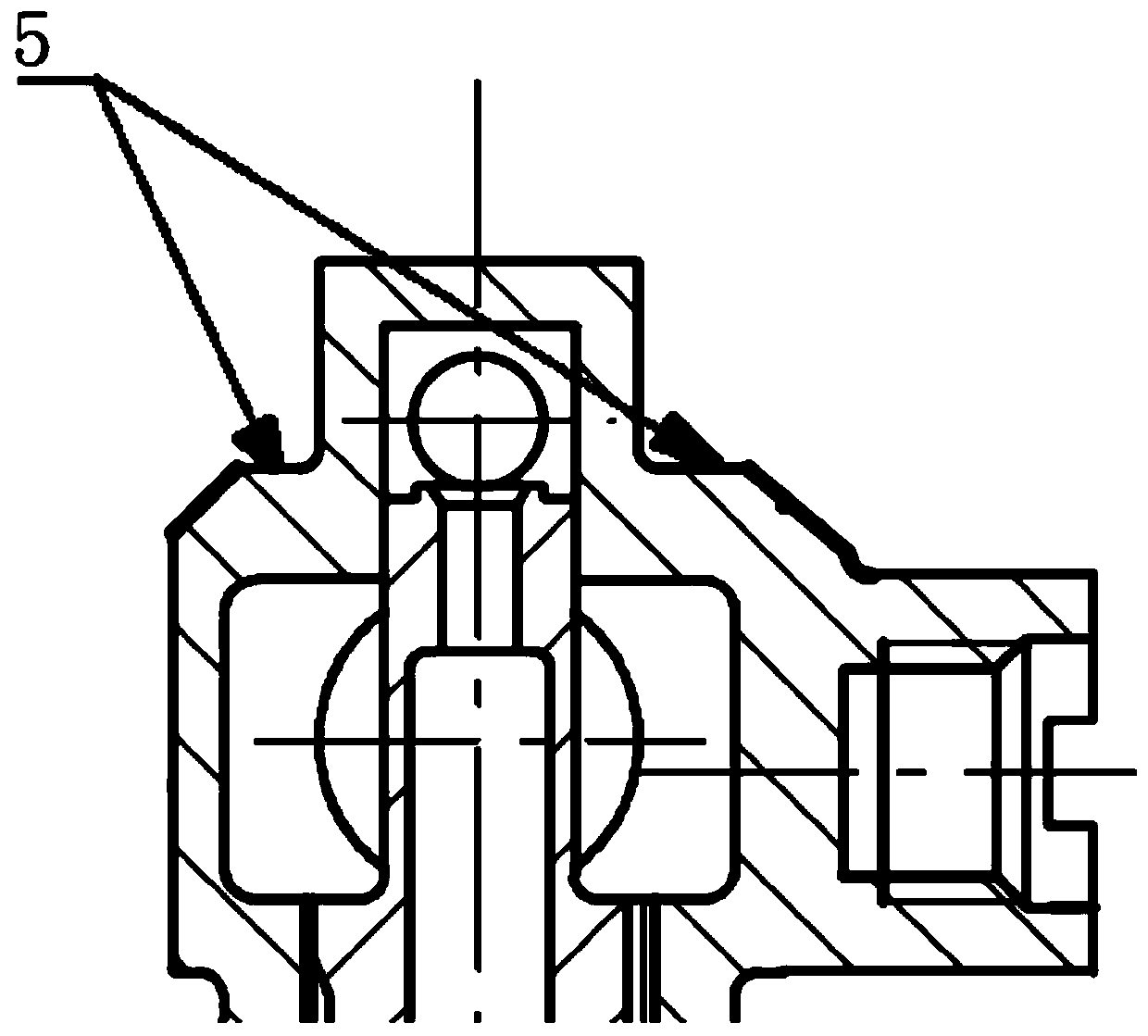

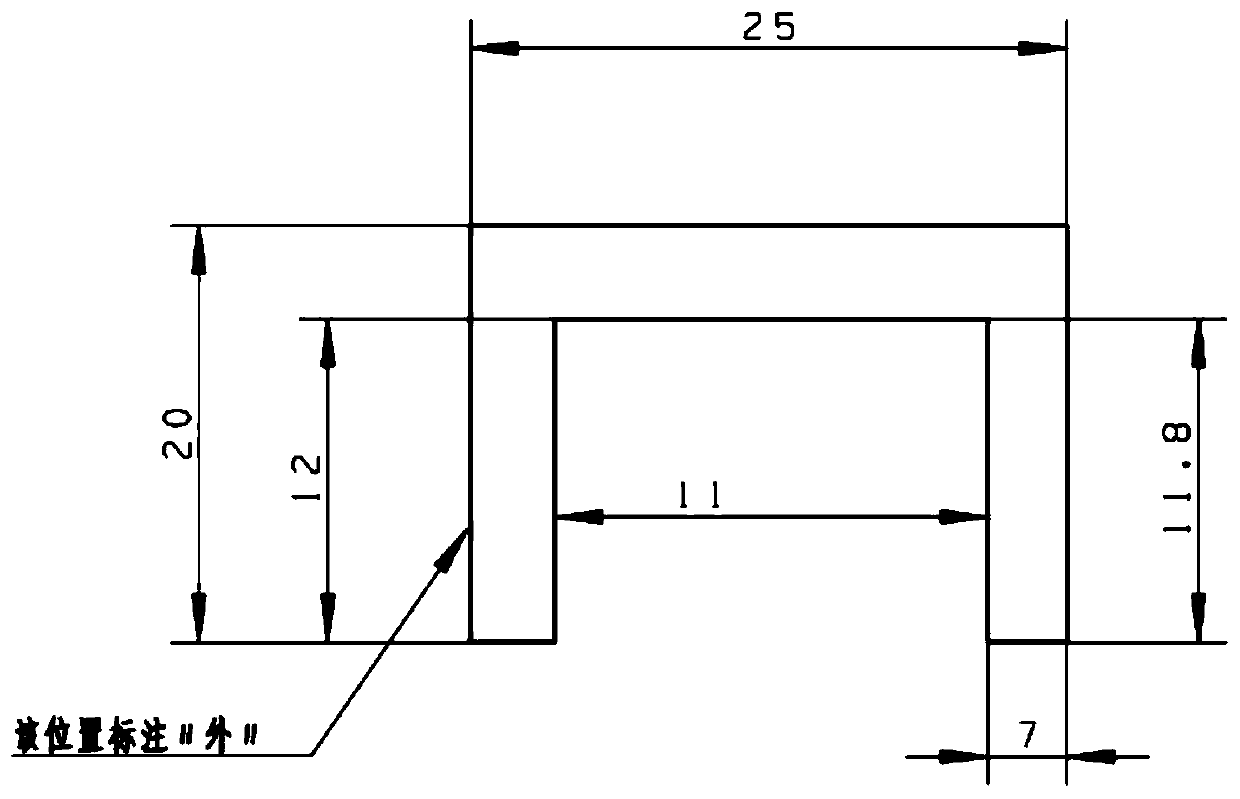

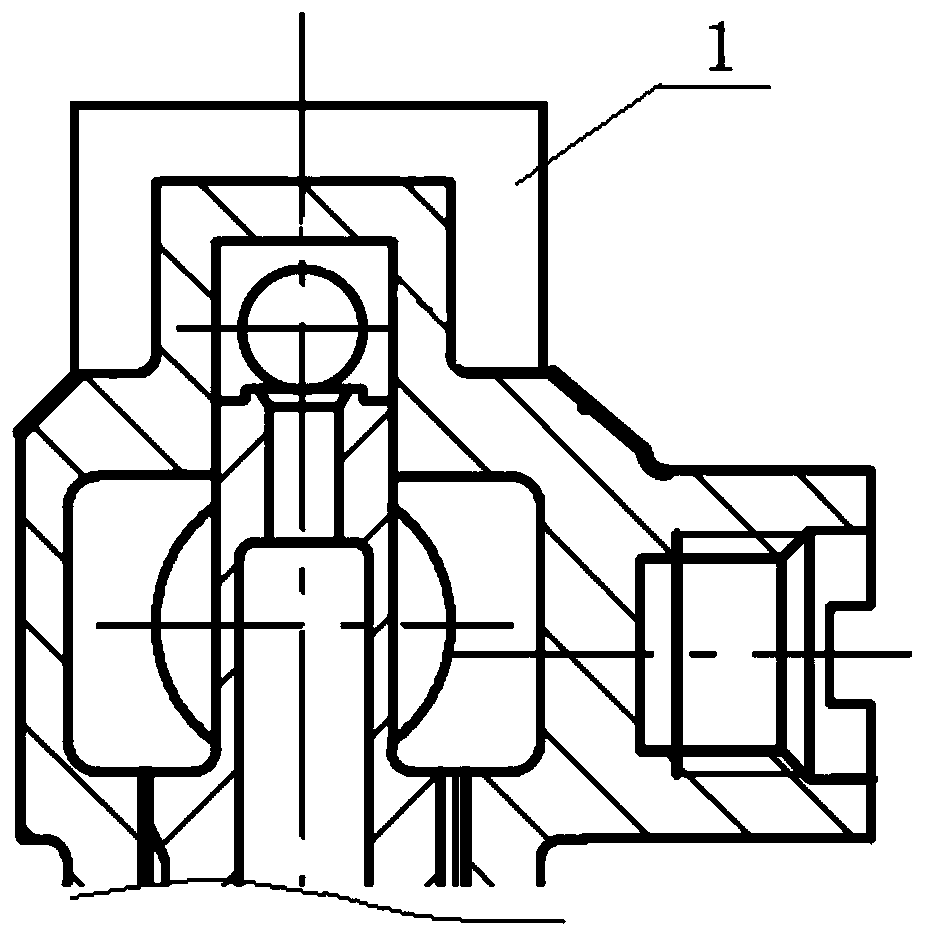

[0022] Such as figure 1 As shown, there is a pair of symmetrical shoulders 5 below the upper surface of the spout, such as figure 2 and image 3 As shown, structural part 1 is placed on the upper end surface of the spout across two shoulders. The width is 7mm, wherein the vertical side length on the outside (that is, outside the circumference of the fuel main pipe or the circumference of the annular base 2) is 12mm, and the length on the inside vertical side is 11.8mm, and the difference between the two is 0.2mm.

[0023] Such as Figure 4 As shown, 24 observation ports 3 are arranged at equa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com