A kind of rolling process of aluminum alloy plate

A technology of aluminum alloy plate and process, which is applied in the direction of metal rolling, metal rolling, metal rolling frame, etc., can solve the problem of poor flatness of the plate, and achieve the effect of solving the problem of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

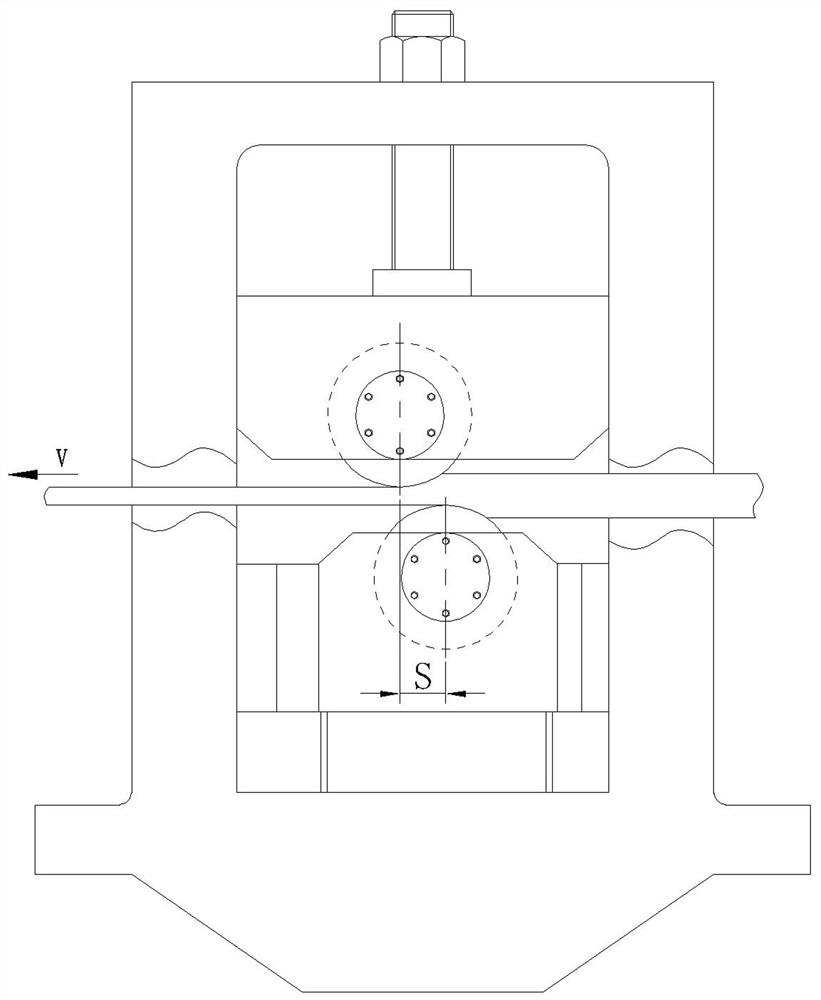

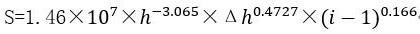

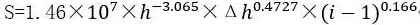

[0021] Such as figure 1 As shown, a dragon-shaped rolling mill means that the upper and lower rolls have the same roll diameter and different rotational speeds. At the same time, the axes of the upper and lower rolls are not in the same vertical plane, but the upper roll with a smaller line speed is rolled toward the rolling mill. The export direction V is offset by a certain distance, that is, the amount of dislocation S, that is, the same diameter and asymmetric different speed rolling. In this way, the rolled piece can form a forward sliding area, a rolling area and a rear sliding area in the deformation area. In the "rolling" zone, while the rolled piece bears the compressive force in the vertical direction, it also bears the shear stress in the horizontal direction, so that the rolled piece produces shear strain while being compressed. Shear strain will produce shear deformation, which is beneficial to the grain refinement of the rolled piece, and improves the microstruc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com