Method for machining complete martensitic alloy steel cold working roll after hardening and copious cooling

A cold-rolled work roll, martensite technology, applied in the direction of roll, metal rolling, metal rolling, etc., can solve the problems of complex hard cutting process, low efficiency, high cost, reduce processing difficulty and production efficiency, cutting Smooth and small bending deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for processing cold-rolled work rolls of complete martensitic alloy steel after hardening and deep cooling, comprising the steps of:

[0048] S1. Adopt CNC dual-frequency scanning quenching to precisely control the bending deformation of the cold-rolled work roll of hardened martensitic alloy steel to be cut within 2.5 / 1000mm~3 / 1000mm, that is, to control the maximum bending deformation of the work roll per 1000mm length Within 2.5 ~ 3mm;

[0049] Controlling the deformation per unit length of the work roll to be cut can effectively reduce the machining allowance, thereby reducing the processing difficulty of removing the excess martensitic hardened layer in the subsequent steps to a certain extent, thereby improving production efficiency;

[0050] S2. For the hardened martensitic alloy steel cold-rolled work roll obtained in step S1, use "a kind of machine tool for automatically centering and milling the end face, punching the center hole and covering the oute...

Embodiment 2

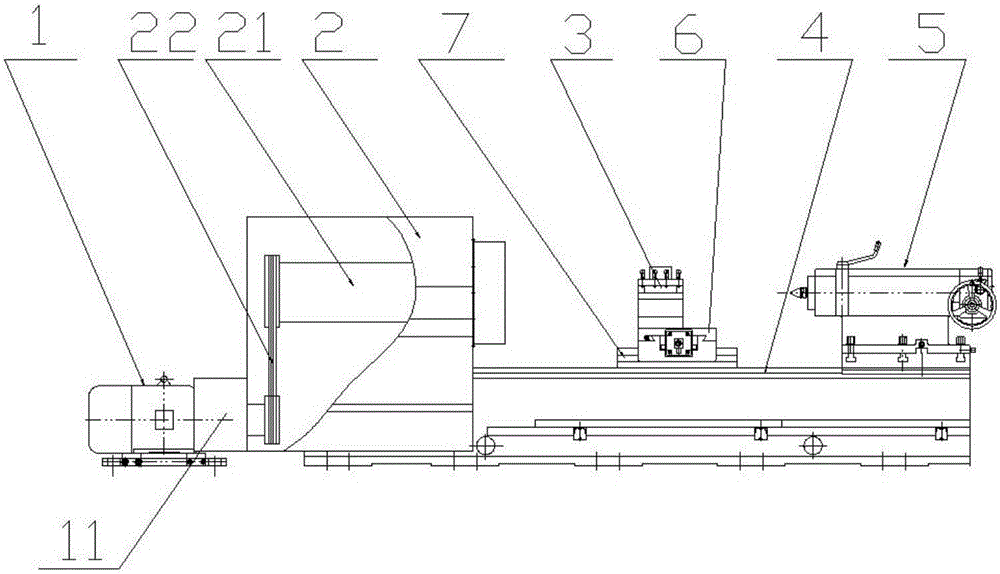

[0069] This embodiment is basically the same as Embodiment 1, the difference is: in step S3, a kind of machine tool of special configuration is improved based on a lathe with a turning diameter of 500, and its guide rail 4 adopts a three-rail structure, and the width of the three guide rails is 850mm, which greatly improves The rigidity and stability of the machine tool are improved; the large carriage 7 and the rotary tailstock 5 are respectively misplaced and arranged on the guide rail 4, the width of the middle carriage 6 is 480mm, and the electric tool holder 3 is fixedly arranged on the middle carriage 6 Above; the rotary tailstock has a built-in rotary top, the diameter of the tailstock sleeve is 220mm, and the diameter of the rotary shaft is 160mm; the main motor is equipped with an AC servo spindle motor with a power of 22KW; the width of the electric tool rest is designed to be 300mm ×300mm.

Embodiment 3

[0071]Since alloy steel cold-rolled work rolls do not form a complete martensite structure during the hardening process, there are still some residual austenite structures. This is an unavoidable technical difficulty in the heat treatment industry, and it is the cause of The source of the local spalling phenomenon; in a method of processing hardened and deep-cooled complete martensitic alloy steel cold-rolled work rolls in this embodiment, the cutting work is to be performed after the quenching treatment in step S1 and before the center hole at the two ends is re-corrected in S2 The rolls are subjected to a cryogenic process. Specifically, the hardened alloy steel cold-rolled work rolls are placed in a liquid nitrogen cold box at minus 193 degrees below zero, and then cryogenically cooled for 4 hours. Through the cryogenic process, the alloy steel is cold-rolled Part of the residual austenite structure in the matrix structure of the work roll is completely converted into marten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com