Reciprocating four-cylinder slurry pump

A mud pump, reciprocating technology, applied in the field of reciprocating four-cylinder mud pumps, can solve the problems of easy fatigue fracture of the cam support shaft, inconvenient maintenance and replacement, and low service life of wearing parts, and achieves compact structure, easy transportation, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

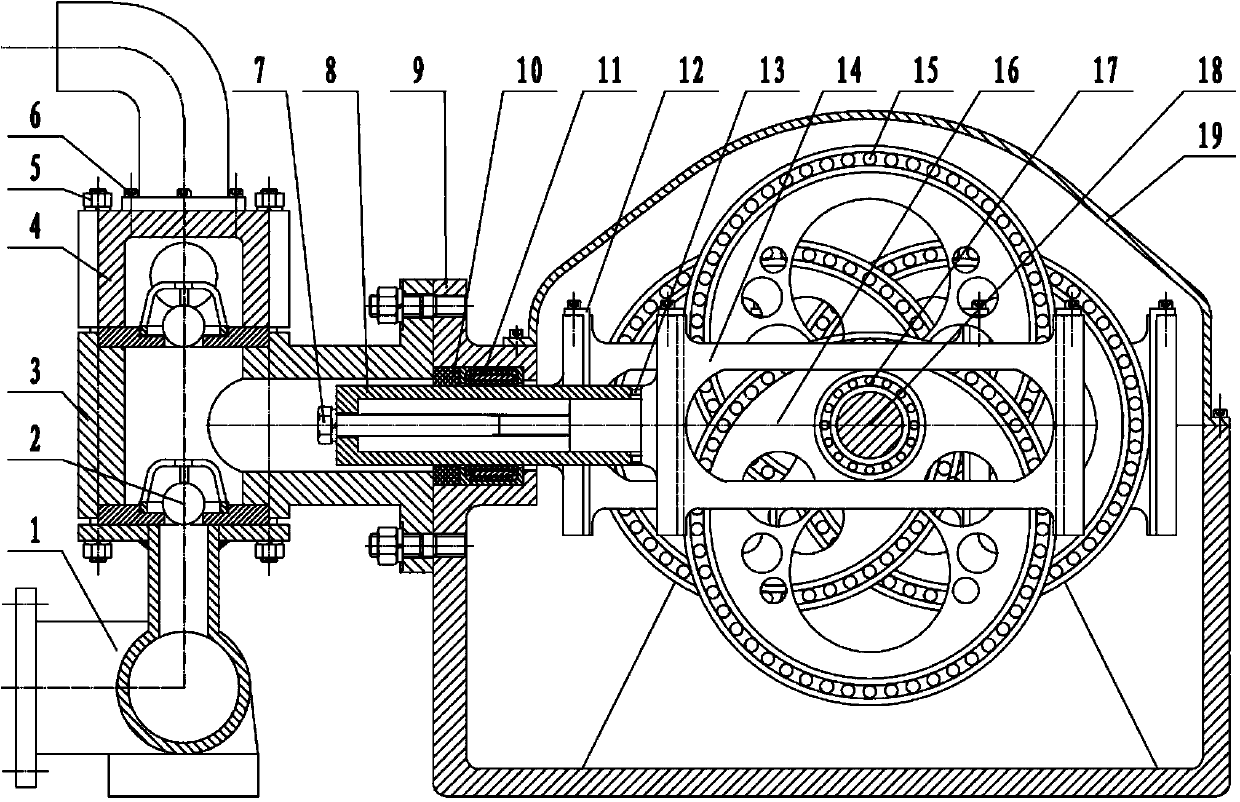

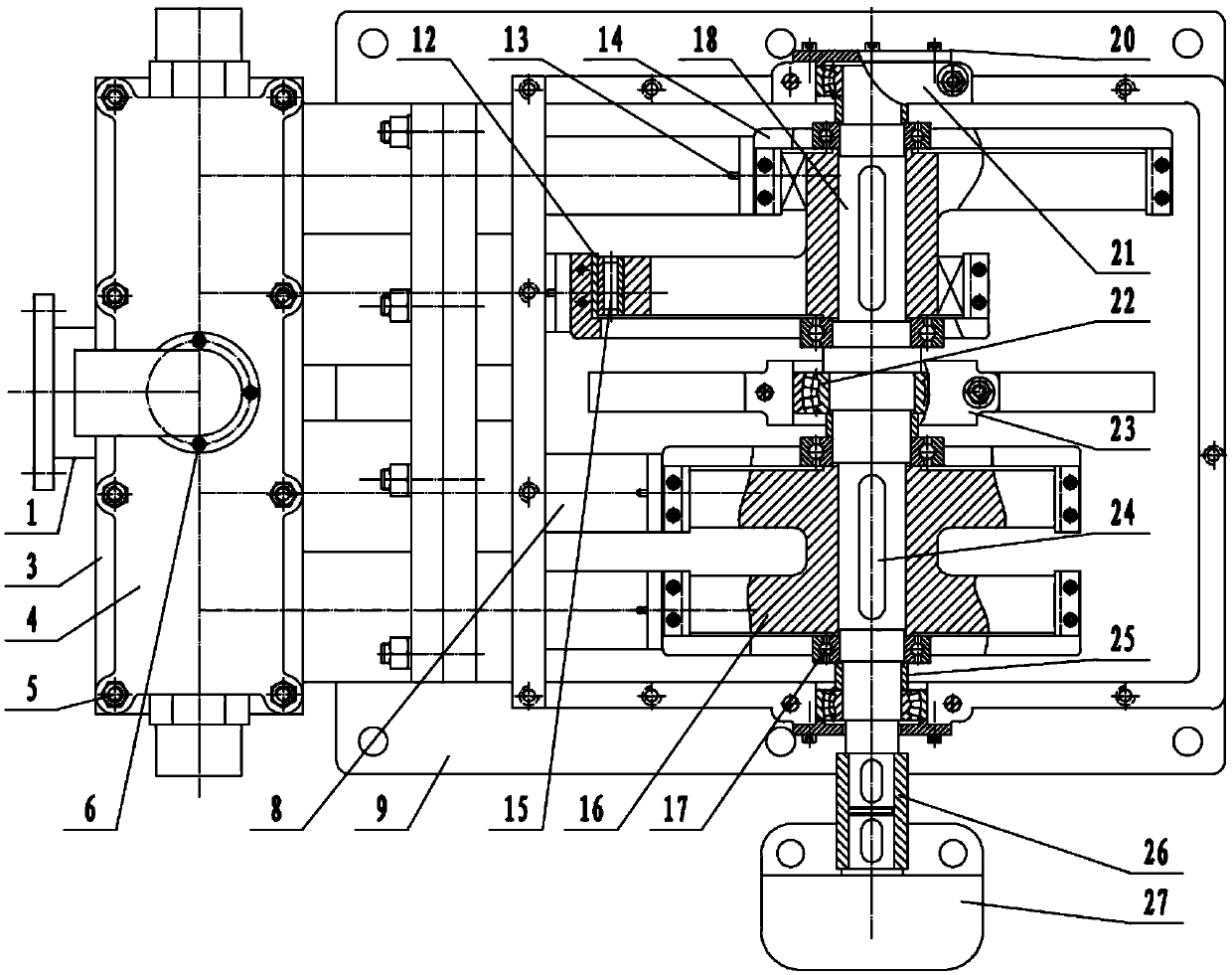

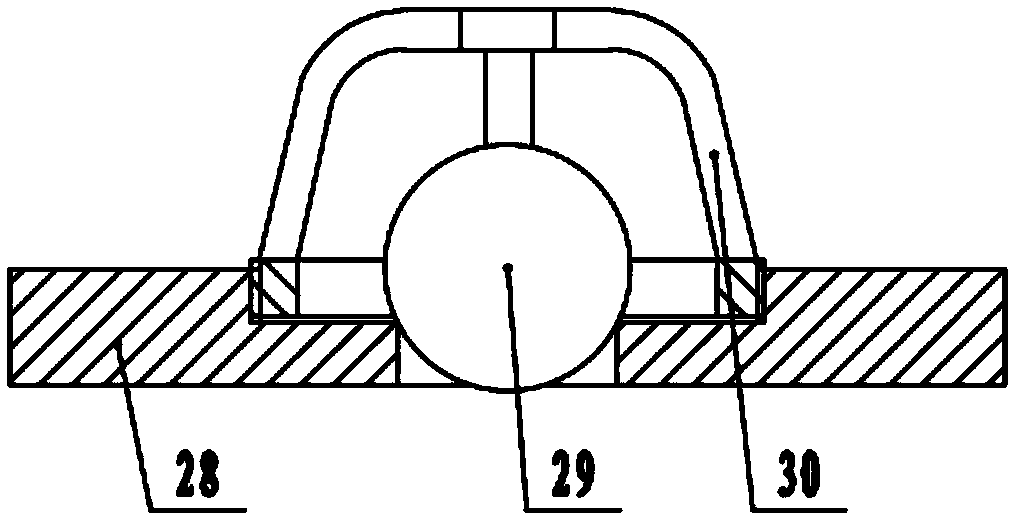

[0027] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6The structure of the reciprocating four-cylinder mud pump of the present invention is given, including a slurry suction channel 1, a steel ball check valve 2, a plunger cavity 3, a slurry discharge channel 4, a double-ended stud 5, a cylindrical head screw 6, and a bolt 7 , plunger 8, box 9, sealing ring 10, linear bearing 11, liner 12, cylindrical pin 13, flat follower 14, needle roller bearing 15, eccentric wheel cam 16, deep groove ball bearing 17, cam support Shaft 18, box cover 19, bearing end cover 20, bearing cover 21, self-aligning roller bearing 22, center bearing cover 23, key 24, sleeve 25, coupling 26, drive motor 27, ball valve seat 28, steel Ball 29, ball valve cover 30. As shown in the figure, the cam support shaft 18 is fixed in the bearing seat hole of the box body 9, and the output shaft of the drive motor 27 is connected to the cam support shaft 18 through a coupling 26 to reali...

Embodiment 2

[0036] like Figure 7 Shown: The difference between this embodiment and Example 1 is that the outer surface of the outer ring of the needle roller bearing 15 adopts a combination design of a cylindrical surface and a plane, and a static pressure oil chamber (not shown in the figure) is set up on the plane for rolling The two parallel planes on the outer surface of the outer ring of the needle bearing 15 directly cooperate with the corresponding planes of the flat bottom follower 14 to form a surface contact hydrostatic lubricated cam pair, and the liner 12 is removed, so that it is suitable for high-power and heavy-duty applications.

[0037] The operating process of the four-cylinder mud pump of the present invention is as follows: the power of the constant torque variable frequency speed regulating motor is directly input into the cam support shaft 18 through the coupling 26 to make it run, and the four eccentric wheel cams 16 on the cam support shaft 18 drive Four flat-bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com