Elevator

A technology of elevators and machine-room-less elevators, which is applied to elevators, elevators, transportation and packaging in buildings, etc. It can solve the problems of instability, cost, and unavailability of man-made fiber ropes, so as to reduce installation time and reduce sideways The effect of supporting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

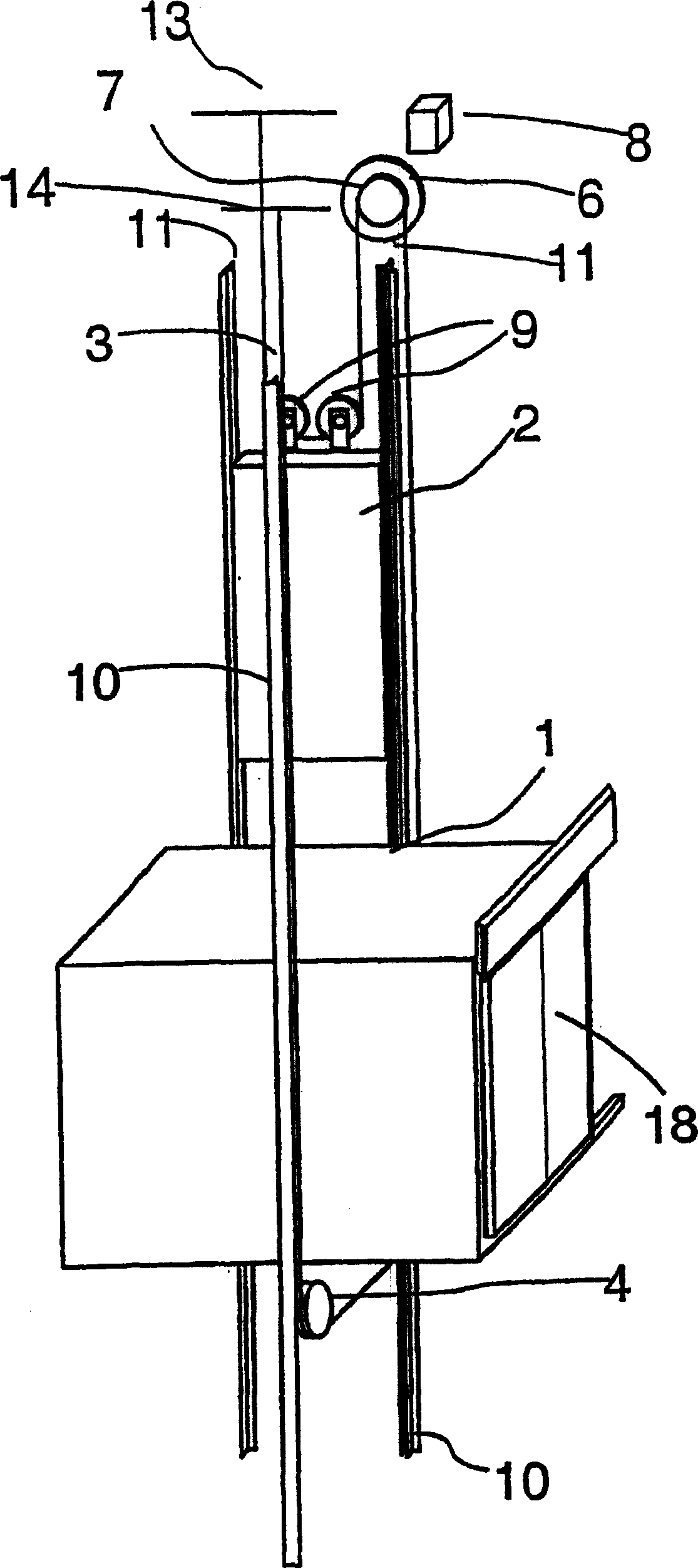

[0049] figure 1 It is a schematic diagram of the structure of an elevator. This elevator is preferably a machine-room-less elevator in which the drive machine 6 is placed in the elevator shaft. The elevator shown in the figure is a traction sheave elevator with the machine above. The running of the elevator hoisting rope 3 is as follows: one end of the rope is immovably fixed to an anchorage 13 arranged in the upper part of the shaft above the path of the counterweight 2 moving along the counterweight guide rails 11 . From this anchorage, the rope goes down and around the deflection pulleys 9 on which the counterweight is suspended, these deflection pulleys 9 are rotatably mounted on the counterweight 2, and the rope 3 then goes up to the traction sheave 7 of the driving machine 6 , bypass the traction sheave along each rope groove on the sheave. From the traction sheave 7, the rope 3 goes down to the elevator car 1 moving along the car guide rails 10, passes under the car ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com