Wide-spectrum semiconductor active device and manufacturing method thereof

A technology of active devices and semiconductors, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as concentrated wavelengths, low color rendering index, and narrow half-height width of the spectrum, and achieve the effect of improving injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

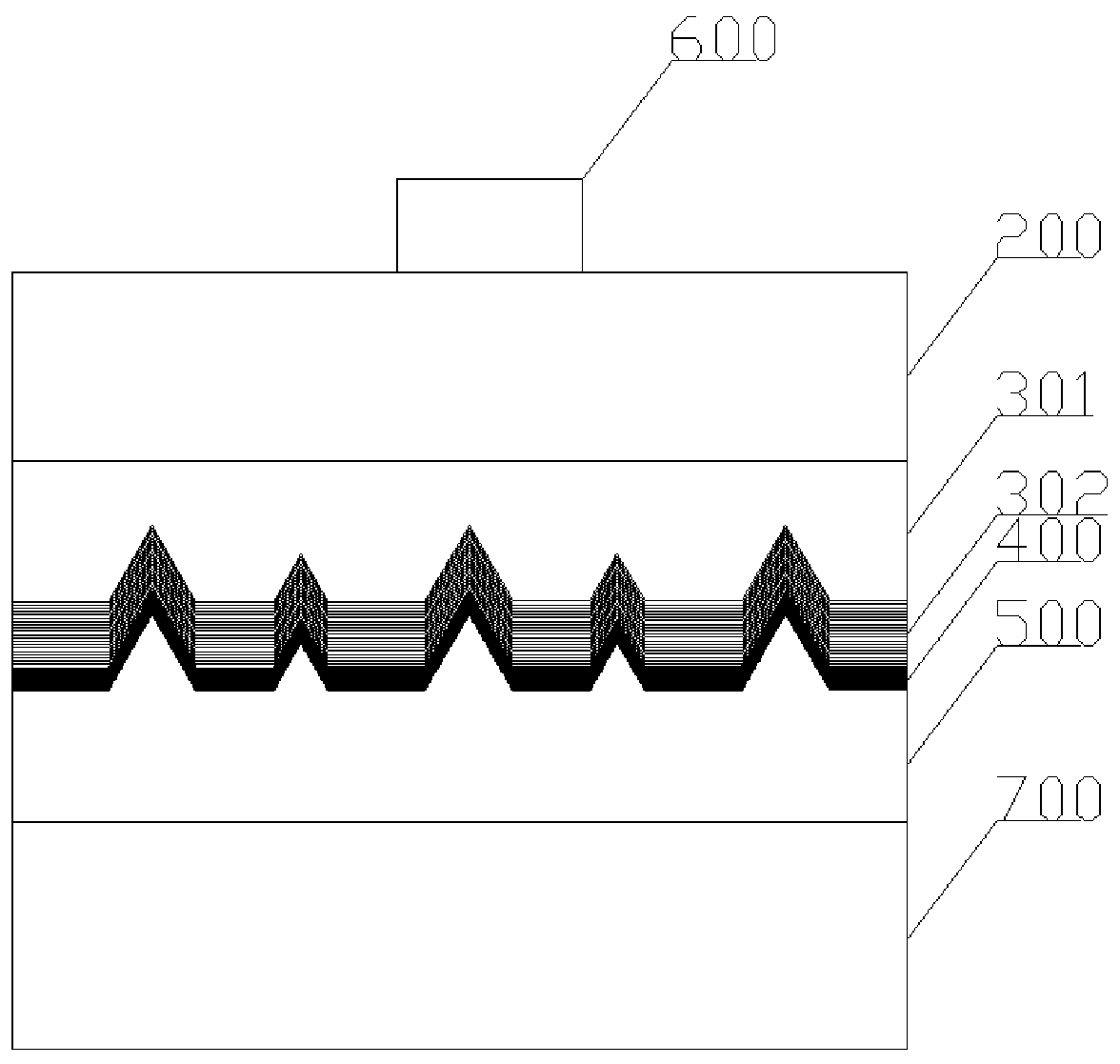

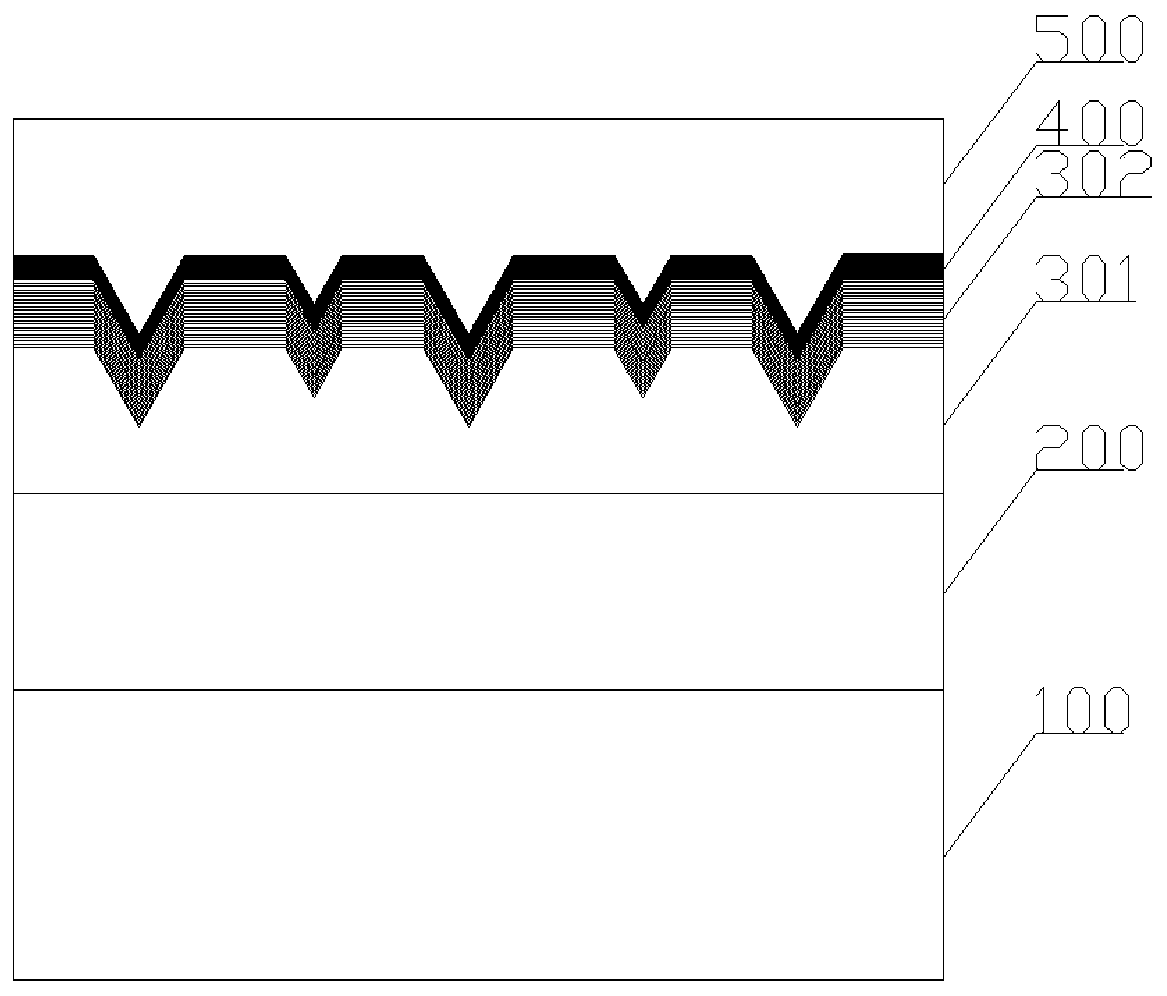

[0044] Such as Figure 5 Shown, the manufacture method of the wide-spectrum semiconductor active device provided by the present invention is specifically as follows:

[0045] Step S1, making the epitaxial structure required by the present invention. The epitaxial substrate is one of Si substrate, SiC substrate, ALN substrate, GaN substrate or Sapphire, and the epitaxial structure required by the present invention is epitaxially grown on the substrate by using epitaxial technology such as MOCVD technology or MBE technology. In this embodiment, the GaN material is epitaxially grown by MOCVD on a sapphire substrate. The thickness of the first semiconductor layer 200 is 3um˜6um, the active layer 301 , the electron blocking layer 400 and the second semiconductor layer 500 .

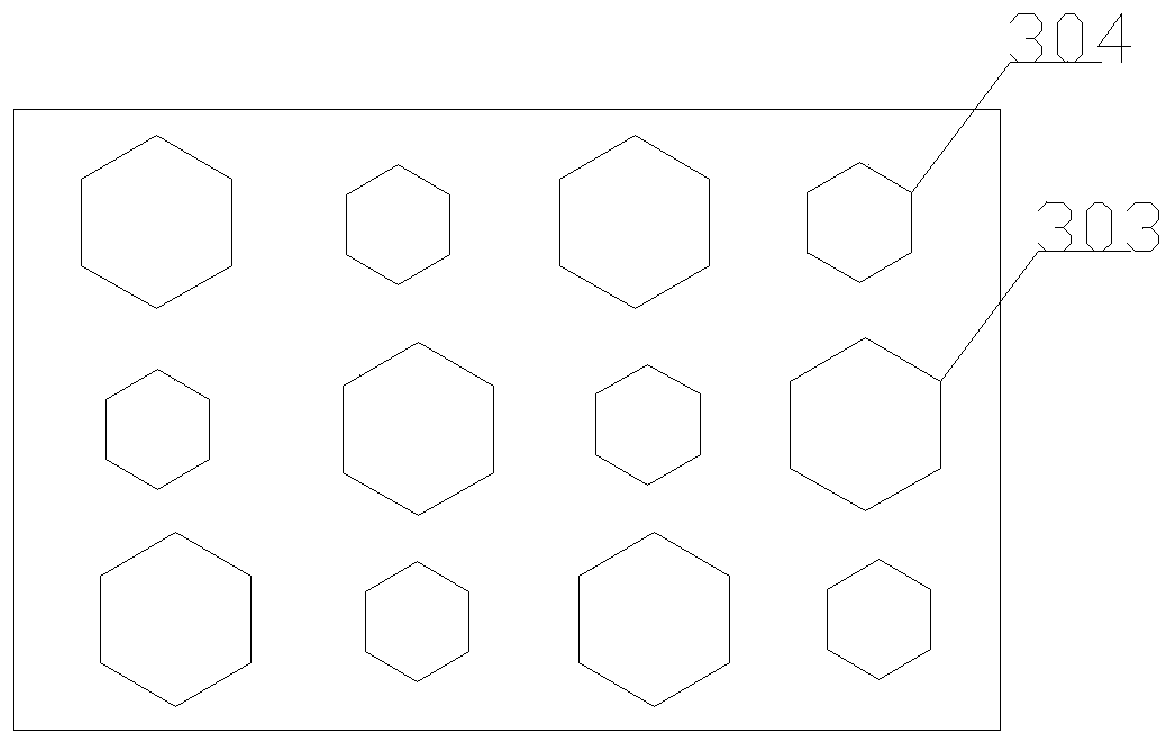

[0046] The active layer includes a two-level modulation structure 301 located 200 between the multi-quantum well structure 302 and the first semiconductor layer, and each level of modulation structure layer ...

Embodiment 2

[0053] Such as Figure 5 Shown, the manufacture method of the wide-spectrum semiconductor active device provided by the present invention is specifically as follows:

[0054] Step S1, making the epitaxial structure required by the present invention. The epitaxial substrate is one of Si substrate, SiC substrate, ALN substrate, GaN substrate or Sapphire, and the epitaxial structure required by the present invention is epitaxially grown on the substrate by using epitaxial technology such as MOCVD technology or MBE technology. In this embodiment, the GaN material is epitaxially grown by MOCVD on a sapphire substrate. The thickness of the first semiconductor layer 200 is 3um˜6um, the active layer 301 , the electron blocking layer 400 and the second semiconductor layer 500 .

[0055] The active layer includes a two-level modulation structure 301 located 200 between the multi-quantum well structure 302 and the first semiconductor layer, and each level of modulation structure layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com