Method for manufacturing light-emitting diode chip

A technology for light-emitting diodes and manufacturing methods, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of optoelectronic device performance such as forward voltage, light intensity, reverse leakage current wavelength uniformity, FWHM effect, etc. The effect of internal quantum efficiency, brightness improvement, and crystal defect reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Please see Figure 1-4 , the manufacturing method of the light-emitting diode chip that embodiment one provides comprises the following steps:

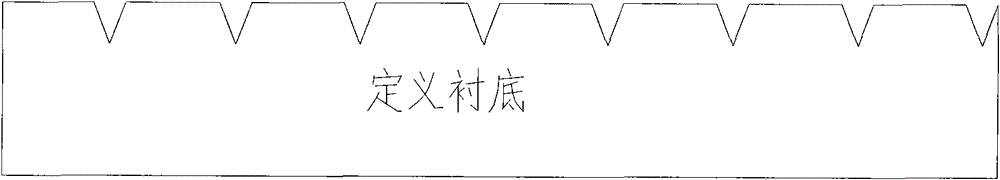

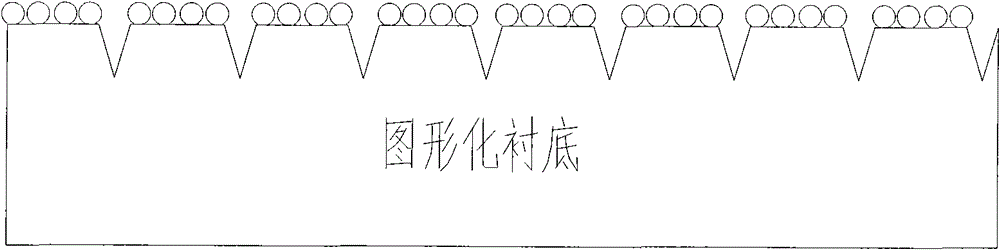

[0032] Step A, such as figure 1 , figure 2 As shown, first, aisles are formed on the surface of the growth substrate by photolithography and etching (such as plasma etching) or laser scribing, and the aisles directly divide the surface of the growth substrate into small areas with the same size as the final chip. Define the size of the chip (define the substrate), and the depth of the formed aisle is 15-50 microns; the preferred range of the general aisle depth is 15-20 microns, and the preferred aisle depth is about 20 microns. The growth substrate may be a Si substrate, a SiC substrate, a sapphire substrate, etc., and a sapphire substrate is preferred in this embodiment. The size of the growth substrate is more than 2 inches, and the beneficial effect of the present invention on large-size substrates will be more obvious....

Embodiment 2

[0041]See also Figure 1-4 , the manufacturing method of the light-emitting diode chip that embodiment 2 provides comprises the following steps:

[0042] Step A, first utilize processes such as laser scribing to form aisles on the surface of the growth substrate, and the aisles directly divide the surface of the growth substrate into small areas (defined as substrates) with the same size as the final chip, and the depth of the aisles formed is 15- 50 microns; generally, the preferred range of aisle depth is 15-20 microns, and the preferred aisle depth is about 20 microns. The growth substrate may be a SiC substrate, a sapphire substrate, etc., and a sapphire substrate is preferred in this embodiment. The size of the growth substrate is more than 2 inches, and a growth substrate of 2 inches is used in this embodiment.

[0043] Step B, cleaning the growth substrate after step A, and removing the remaining dirt in the aisle. The cleaning method can be laser cleaning, or using h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com