Patents

Literature

52results about How to "The lattice constant decreases" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

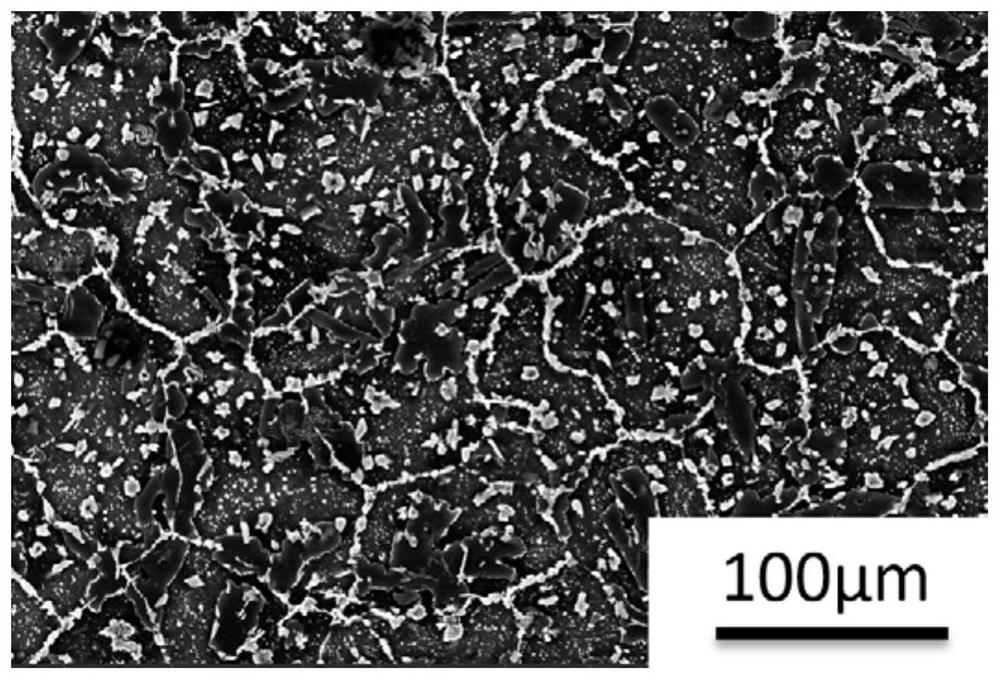

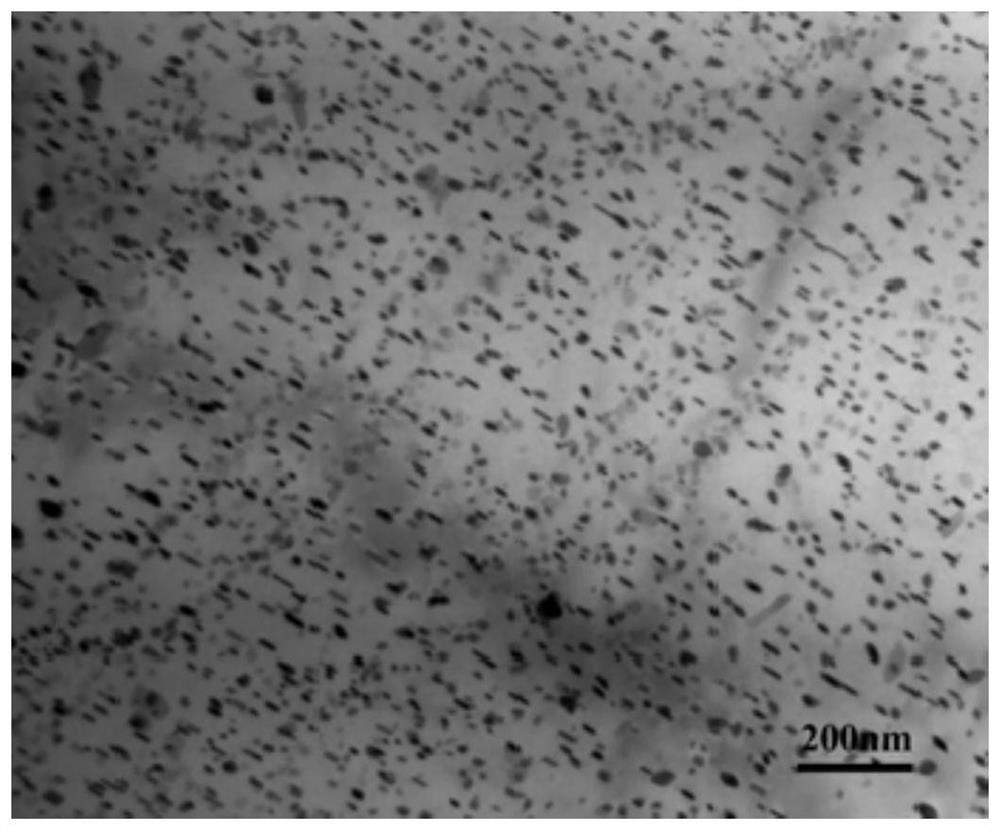

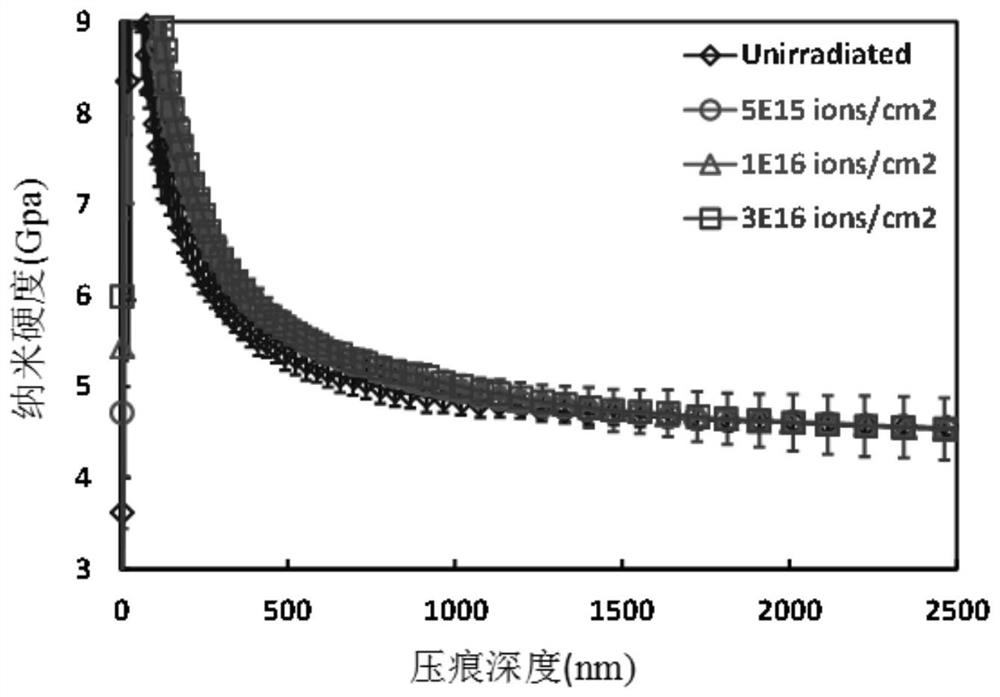

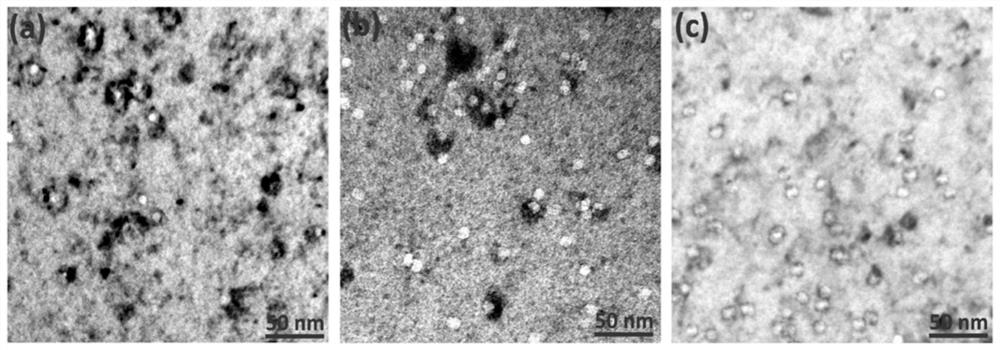

Irradiation-resistant high-entropy alloy and preparation method thereof

ActiveCN109666811AImprove high temperature performanceImprove corrosion resistanceOptical rangefindersNuclear energy generationHigh entropy alloysVolumetric Mass Density

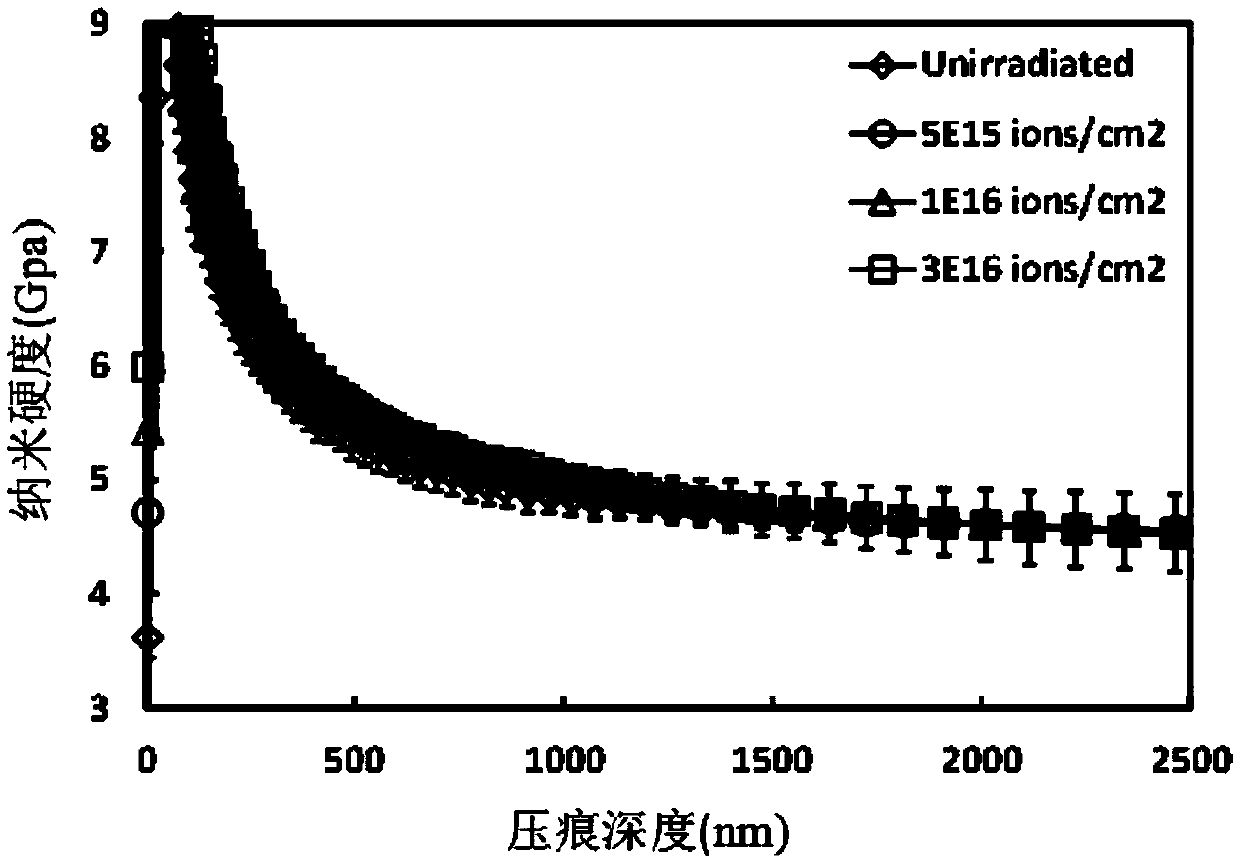

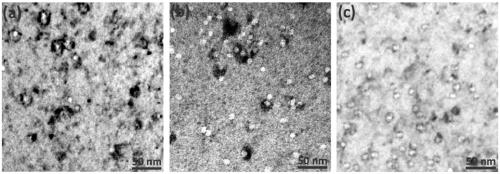

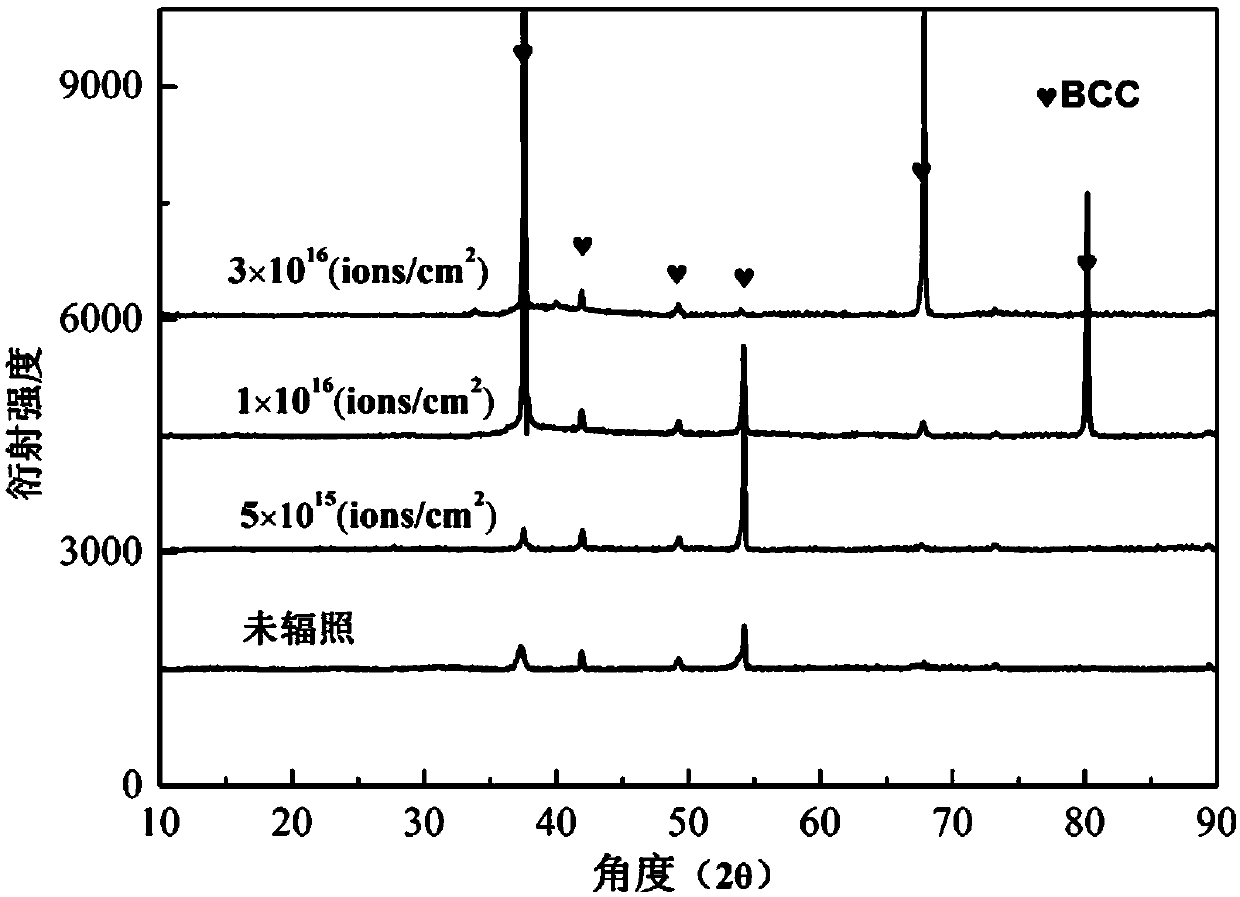

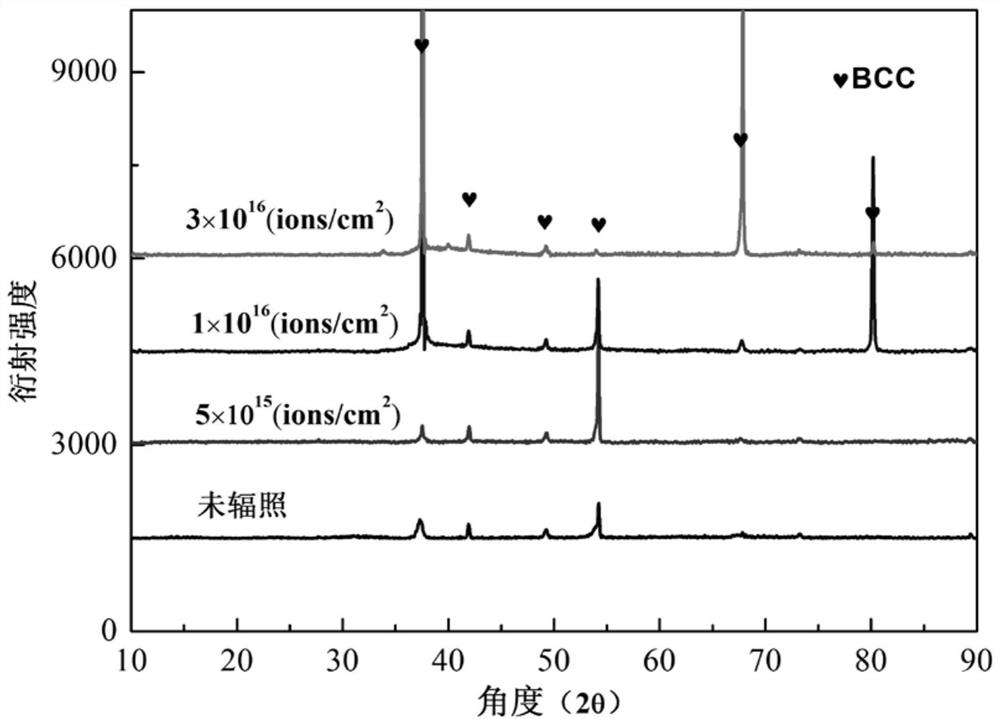

The invention provides irradiation-resistant high-entropy alloy and a preparation method thereof. The general formula of the irradiation-resistant high-entropy alloy is TiZrHfVMoTaxNby, wherein X is no more than 0.25 and no less than 0.05, y is no more than 0.5 and no less than 0.05, and x and y are molar ratio. The preparation method of the irradiation-resistant high-entropy alloy comprises the following steps: sequentially mixing Ti, Zr, Hf, V, Mo, Ta and Nb, and then adopting vacuum electromagnetic suspension induction smelting or vacuum electric arc melting to obtain the irradiation-resistant high-entropy alloy. The irradiation-resistant high-entropy alloy is excellent in performance; helium ion simulated irradiation does not generate irradiation hardening damage; on the condition thatthe helium bubble size and traditional alloy size is equivalent, the bubble density is far lower than the density of the traditional alloy, and the lattice constant after irradiation is reduced abnormally; the irradiation resistance of the irradiation-resistant high-entropy alloy is far better than that of the traditional alloy; the irradiation-resistant high-entropy alloy has excellent strengthand plasticity; the compression yield strength of the irradiation-resistant high-entropy alloy under the cast condition is as high as 1.1 Gpa, and the compression ratio and elongation exceed 50%.

Owner:DALIAN UNIV OF TECH

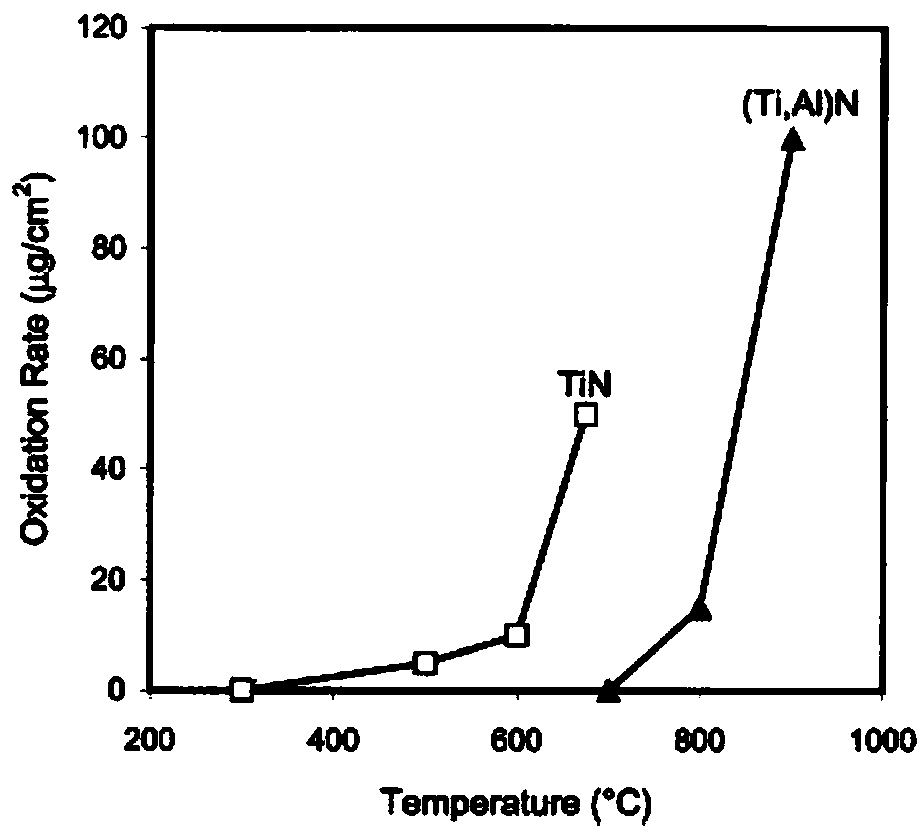

Preparation process for high-silicon super-hard PVD coating

InactiveCN104593737AWon't breakPrecise control of ingredientsVacuum evaporation coatingSputtering coatingVacuum pumpingPower flow

The invention provides a preparation process for a high-silicon super-hard PVD coating. The preparation process comprises the following steps: I, pre-processing a workpiece surface; II, clamping and loading a workpiece; III, performing vacuum-pumping on a furnace chamber; IV, heating the workpiece; V, etching and cleaning a target material and the workpiece; VI, preparing a high-silicon coating; VII, cooling the workpiece. The preparation process is used for obtaining the high-silicon super-hard PVD coating by controlling vacuum degree of a film-coating furnace chamber, bias voltage of a base body, a flow rate of nitrogen gas, target current and the like, wherein the flow rate of the reaction gas nitrogen gas (N2) ranges from 130 sccm to 210 sccm, the bias voltage of the base body ranges from 40 V to 120 V, and the vacuum degree of the furnace chamber ranges from 0.005 mbar to 0.060 mbar. By changing the element components of the coating, high silicon element content is obtained, so that the coating has characteristics of relatively high strength, hardness, wear resistance, high-temperature stability and corrosion resistance. A coating tool prepared by the process can be used for cutting a material with hardness of HRC65, and has relatively good using performances in comparison with a conventional coating.

Owner:SHANGHAI INST OF TECH

IDT/h-BN/c-BN/diamond multi-layer film structure surface acoustic wave device and its manufacture method

InactiveCN101060318ASmall difference in phase velocity VSmall velocity dispersionImpedence networksTemperature coefficientFilm structure

The disclosed IDT / h-BN / c-BN / diamond multilayer membrane structure SAW device comprises: from bottom to top, a nano-diamond membrane base prepared on mirror silicon, a nano c-BN membrane intermediate layer, a high-C-axis preferred orientated nano h-BN membrane, and an IDT. This invention can be used on condition of 2. 5GHz, high electromechanical coupling factor, smaller loss at 8w propagation, and low frequency temperature coefficient.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

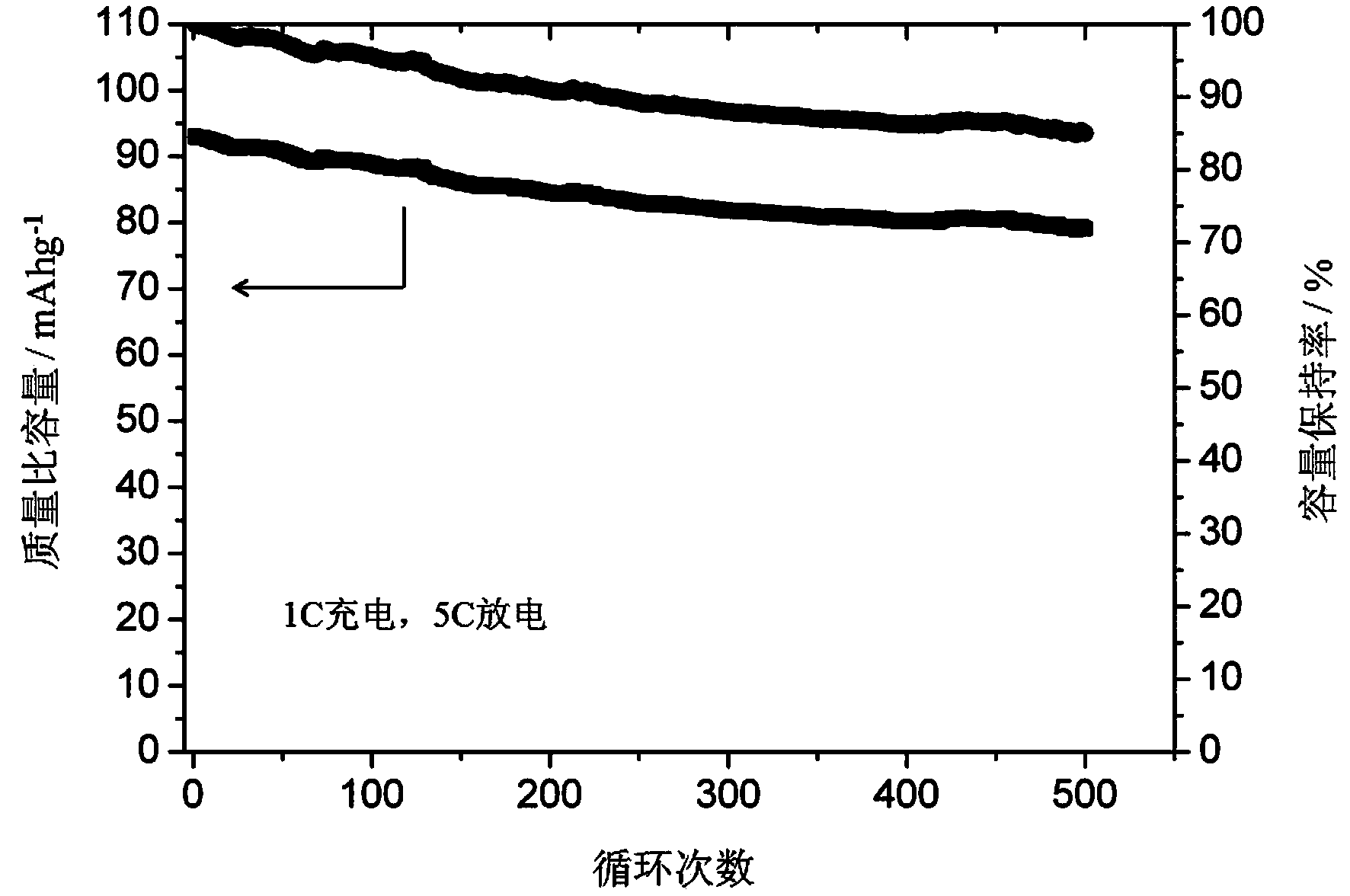

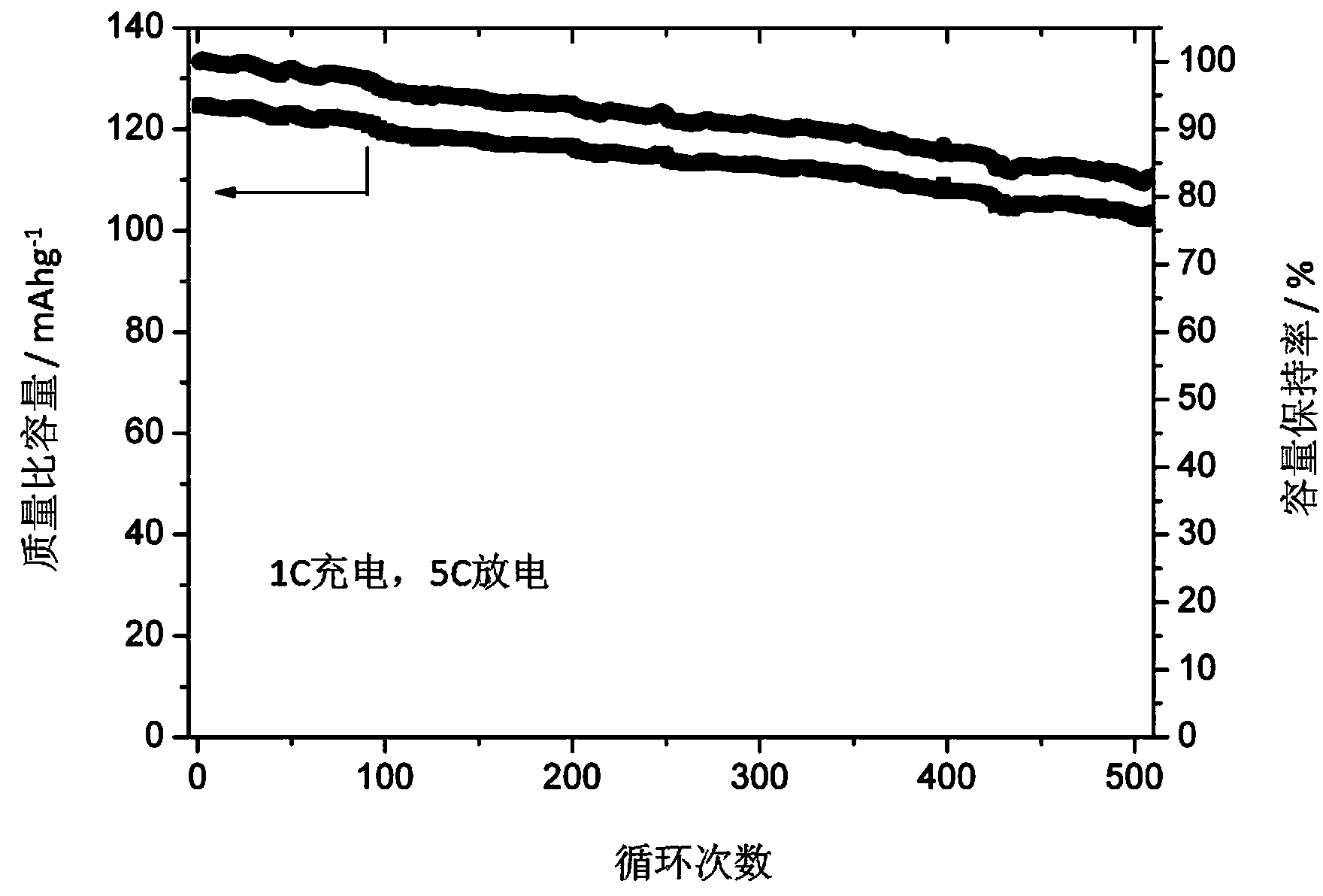

Ellipsoidal porous-structured lithium manganate or nickel lithium manganate positive electrode material and preparation method thereof

InactiveCN103367739AImprove permeabilityImproved magnification performanceCell electrodesManganateManganese

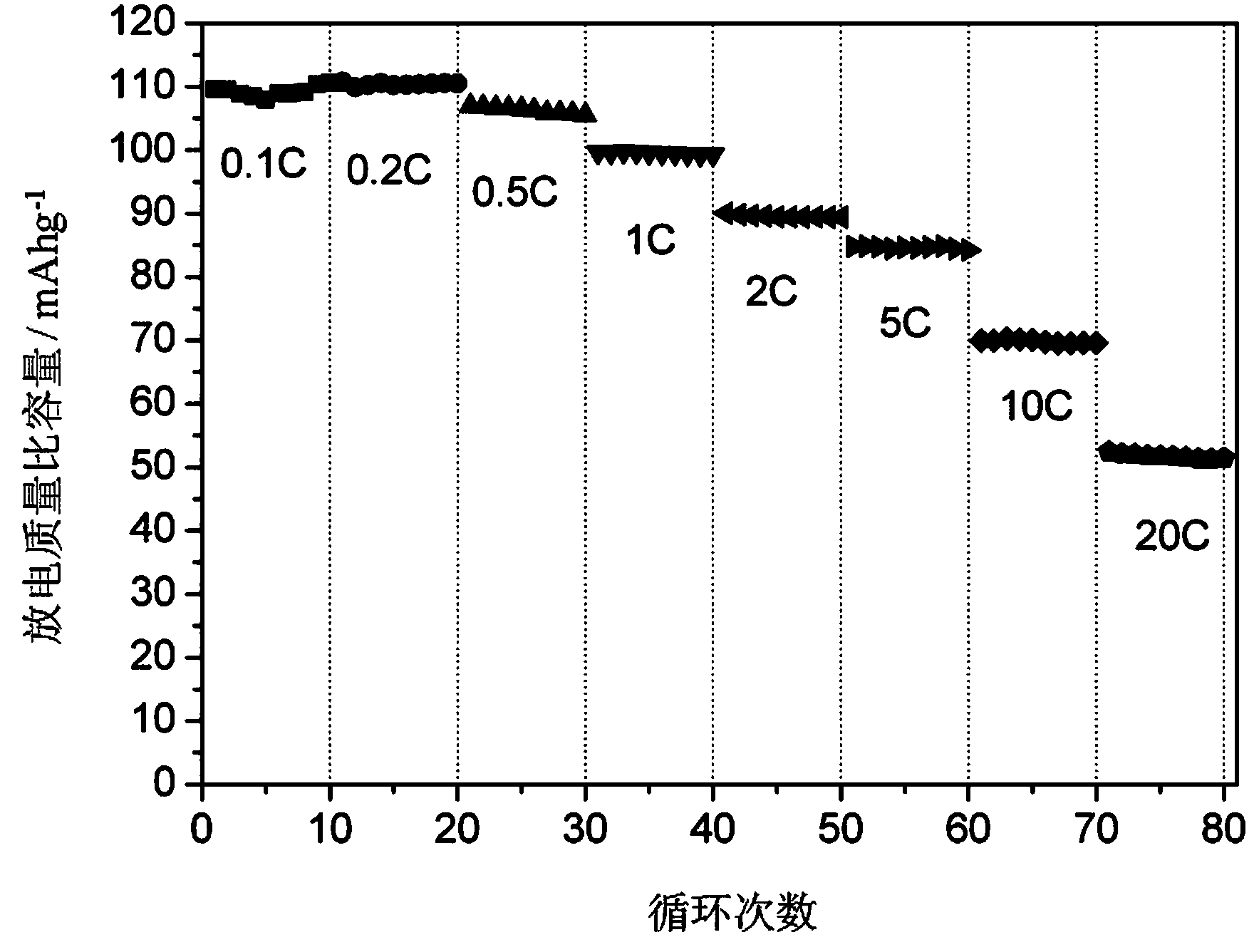

The invention discloses lithium ion battery positive electrode material and a preparation method of the material. The method comprises the steps that: (1) ellipsoidal manganese carbonate is roasted for 4-8h under a temperature of 300-400 DEG C, such that ellipsoidal manganese dioxide is obtained; (2) a lithium source or a mixture of a lithium source and a nickel source is dissolved into excessive ethanol; the mixture is added into the ellipsoidal manganese dioxide obtained in the previous step; the mixture is well mixed; the mixture is dried when ethanol is volatized; and the product is roasted for 8-20h under a temperature of 700-800 DEG C, such that ellipsoidal porous-structured lithium manganate or nickel lithium manganate is obtained. In the step (2), a molar ratio of the lithium source to the ellipsoidal manganese dioxide is that: Li:Mn=1-1.1:2, and the molar ratio of the mixture of the lithium source and the nickel source to the ellipsoidal manganese dioxide is that: Li:Ni:Mn=1-1.1:0.5:1.5. When the material provided by the invention is used as a lithium ion battery positive electrode material, performance better than that of spherical Lithium manganate can be provided.

Owner:GUILIN UNIV OF ELECTRONIC TECH

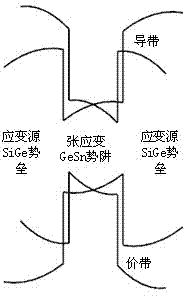

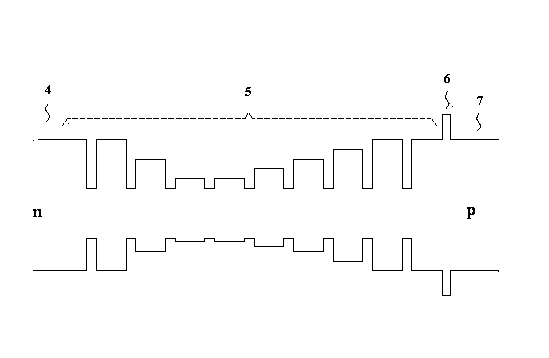

GeSn quantum well infrared illuminator with strain source

InactiveCN104300049AThe lattice constant decreasesFast and Efficient Radiative RecombinationSemiconductor devicesHeterojunctionElectron hole

The invention provides a GeSn quantum well infrared illuminator with a strain source. The structure is characterized in that a relaxation layer GeSn is arranged on a silicon substrate; strain source potential barriers n+ SiGe and p+ SiGe are arranged on the relaxation layer and grows at the peripheral region of an active region GeSn in pairs; and one end of the strain source potential barrier SiGe is a metal contact electrode. The lattice constant of the material of the strain source SiGe is smaller than that of the material of the active region GeSn, thereby forming single-axis compression strain along the z axis direction on the active region GeSn material, and forming a double-axis tensile strain along the xy plane; the strain state facilitates the GeSn material to change from an indirect band gap to a direct band gap; and through forming a heterojunction quantum well structure through the GeSn and the SiGe, fast and efficient radiative recombination of electron-hole is realized. The structure can limit electrons and holes in the well efficiently, thereby enlarging recombination rate of the electron and hole pairs, and improving luminous efficiency of an illuminator.

Owner:CHONGQING UNIV

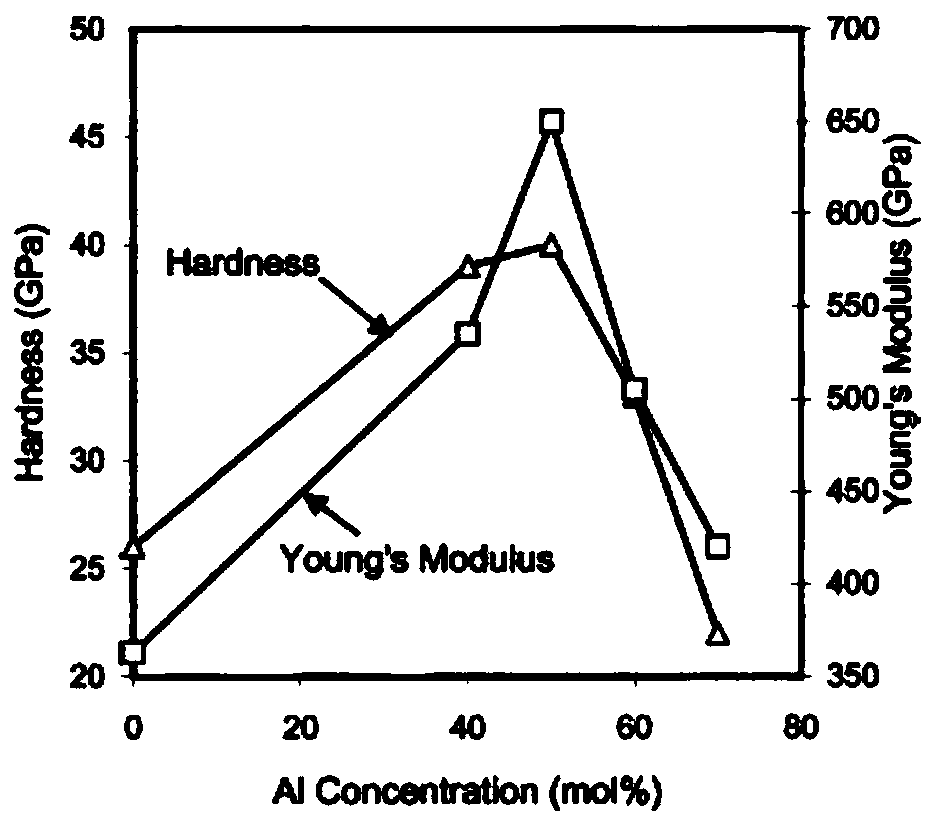

TiAlN ultra-hard composite coating provided with hardness gradient layer for supporting and preparation method of TiAlN ultra-hard composite coating

PendingCN107937876AThe lattice constant decreasesExtend your lifeVacuum evaporation coatingSputtering coatingTitanium coatingThermal fatigue

The invention discloses a TiAlN ultra-hard composite coating provided with a hardness gradient layer for supporting and a preparation method of the TiAlN ultra-hard composite coating. The TiAlN ultra-hard composite coating provided with the hardness gradient layer for supporting sequentially comprises a matrix material, an expansion layer and a deposition layer from bottom to top. The matrix material is a conductive material. The expansion layer is a plasma nitrocarburizing layer. The deposition layer is a nitrogen-aluminum-titanium coating. Through a compact TiAlN ultra-hard film, the matrixmaterial has sufficient wear resistance. The plasma nitrocarburizing layer has a hardness gradient and thus can remarkably improve the capacity to support a hard and brittle surface layer, and the bearing capacity of the TiAlN ultra-hard film is effectively improved. In addition, the residual stress value of the surface of a part is increased through nitrogen and carbon, and the fatigue resistanceof the part is made higher. Furthermore, nitride and carbide of the nitrocarburizing layer are better matched with the TiAlN film in thermophysical performance, a film / matrix interface is better fused, and thus the film has higher and more reliable bonding force and also has better thermal fatigue resistance.

Owner:NO 43 INST OF CHINA ELECTRONICS TECH GRP CETC

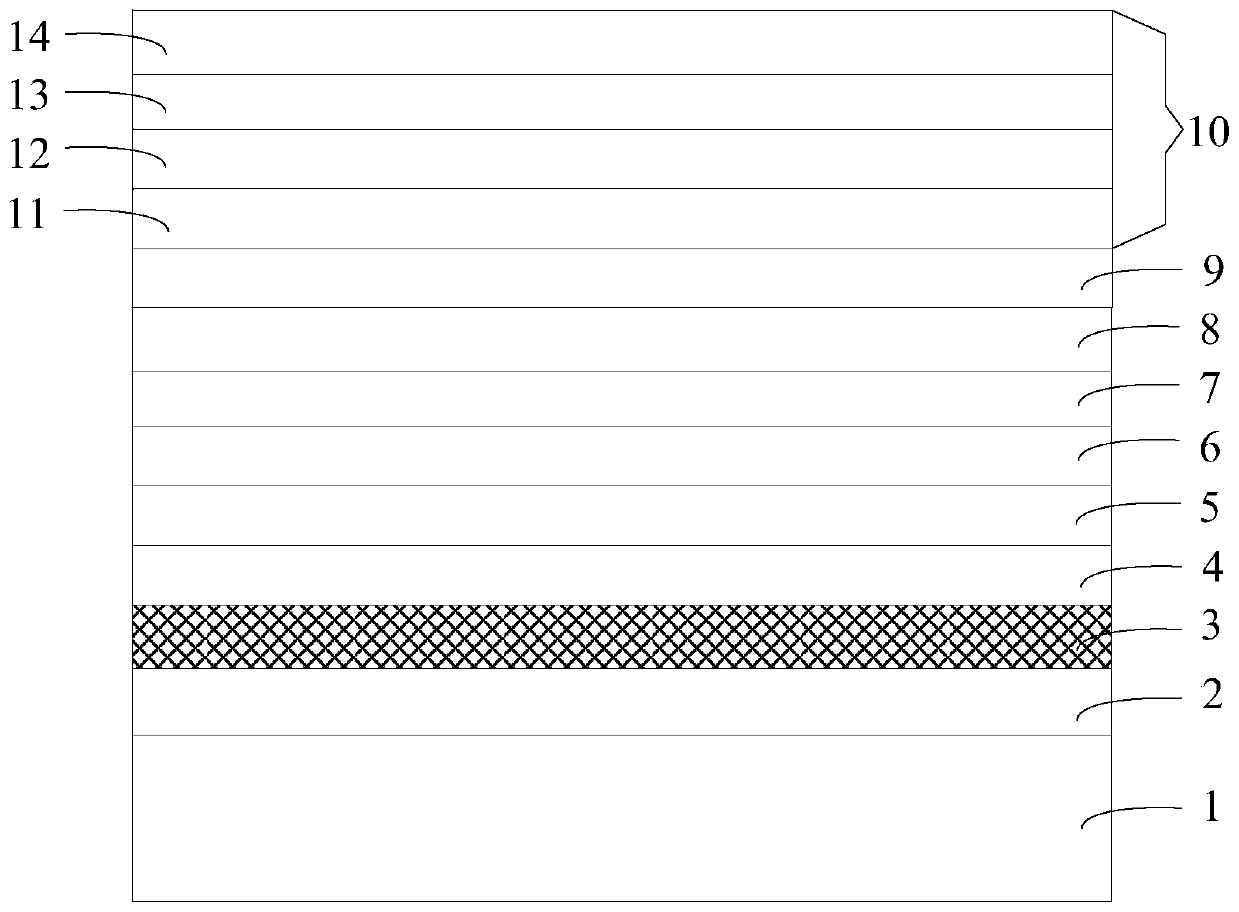

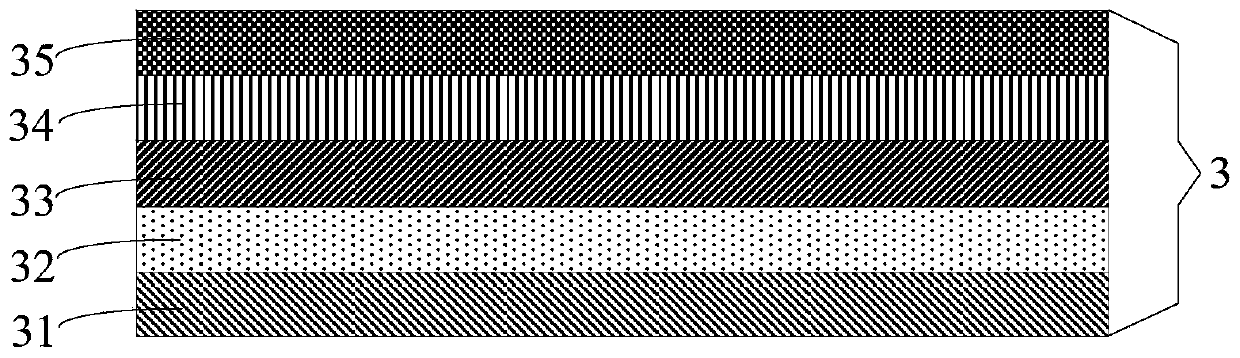

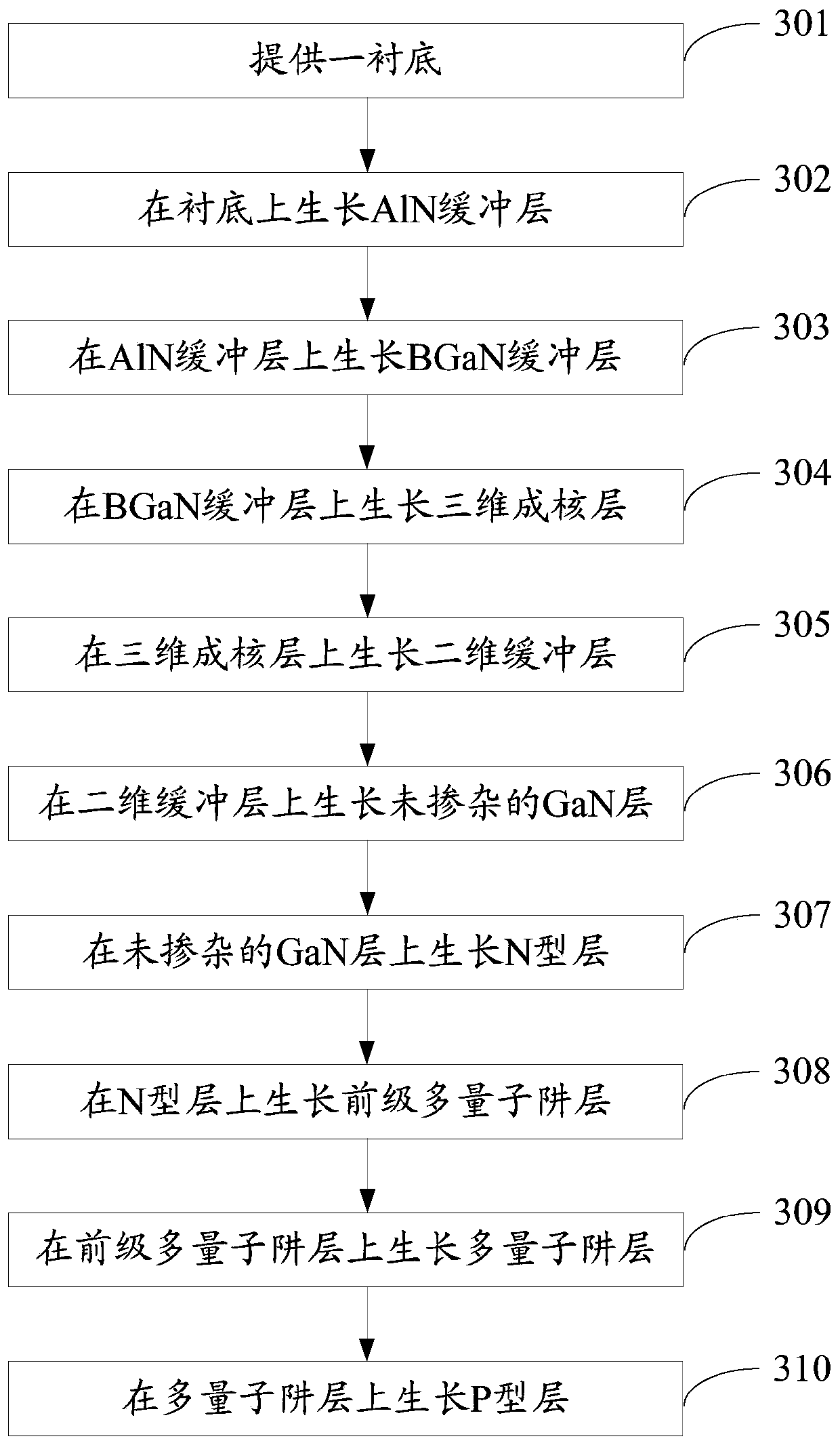

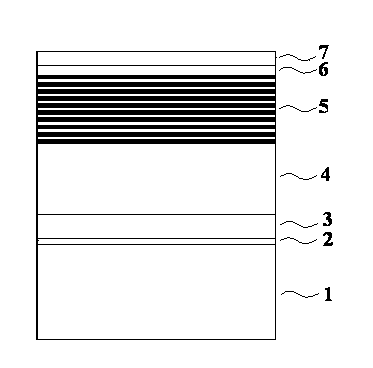

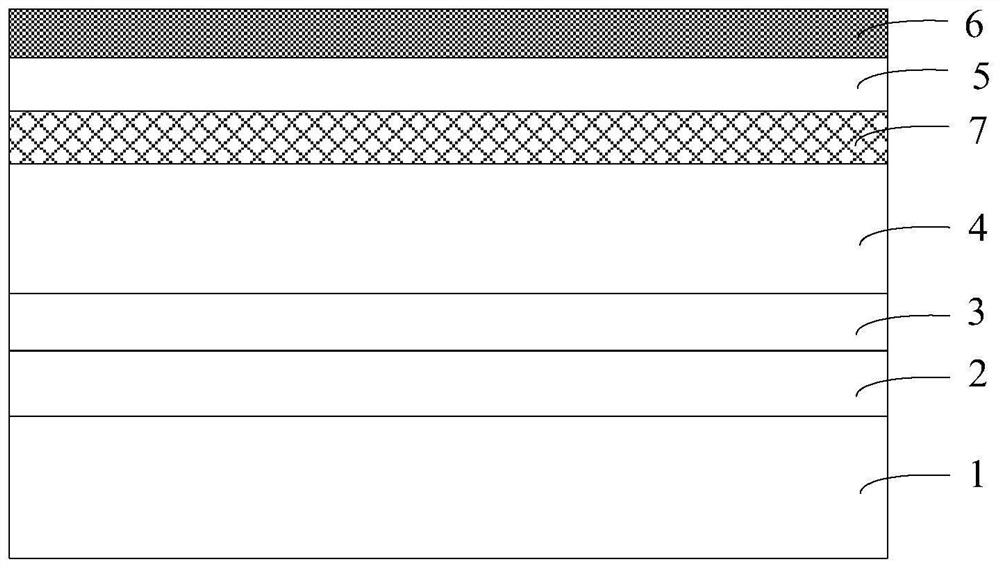

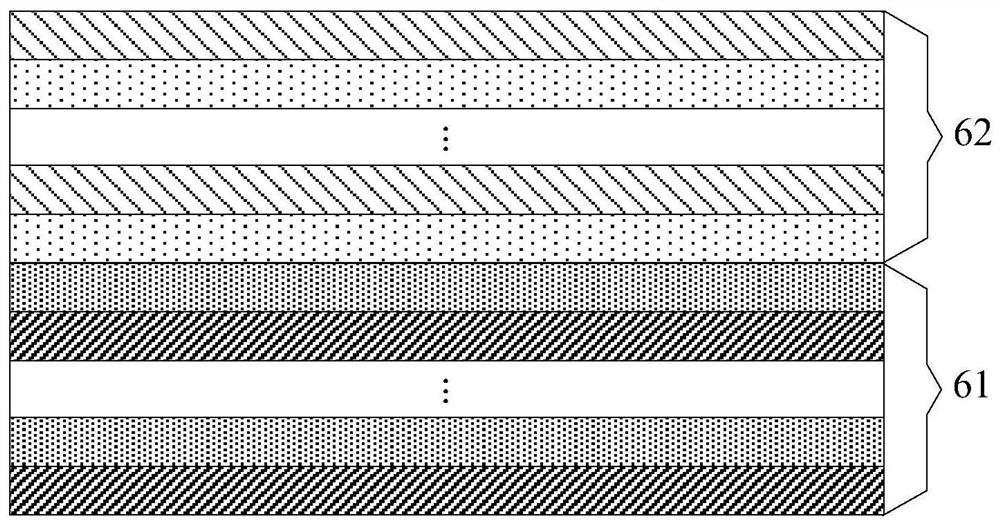

Light-emitting diode epitaxial wafer and manufacturing method thereof

ActiveCN109786527AImprove wavelength uniformityThe lattice constant decreasesSemiconductor devicesLattice mismatchQuantum well

The invention discloses a light-emitting diode epitaxial wafer and a manufacturing method thereof, and belongs to the technical field of semiconductors. The light-emitting diode epitaxial wafer comprises a substrate, and an AlN buffer layer, a three-dimensional nucleation layer, a two-dimensional recovery layer, an undoped GaN layer, an N-type layer, a multi-quantum well layer and a P-type layer which are sequentially grown on the substrate, wherein the three-dimensional nucleation layer is a GaN layer; the light-emitting diode epitaxial wafer further comprises a BGaN buffer layer arranged between the AlN buffer layer and the three-dimensional nucleation layer; and the B component in the BGaN buffer layer is gradually reduced in the stacking direction of the light-emitting diode epitaxialwafer. By virtue of the BGaN buffer layer, lattice mismatch between the AlN buffer layer and the GaN epitaxial layer can be gradually reduced, the crystal quality of the grown epitaxial layer is improved, the warping of the epitaxial layer is optimized, and the wavelength uniformity of the LED is improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

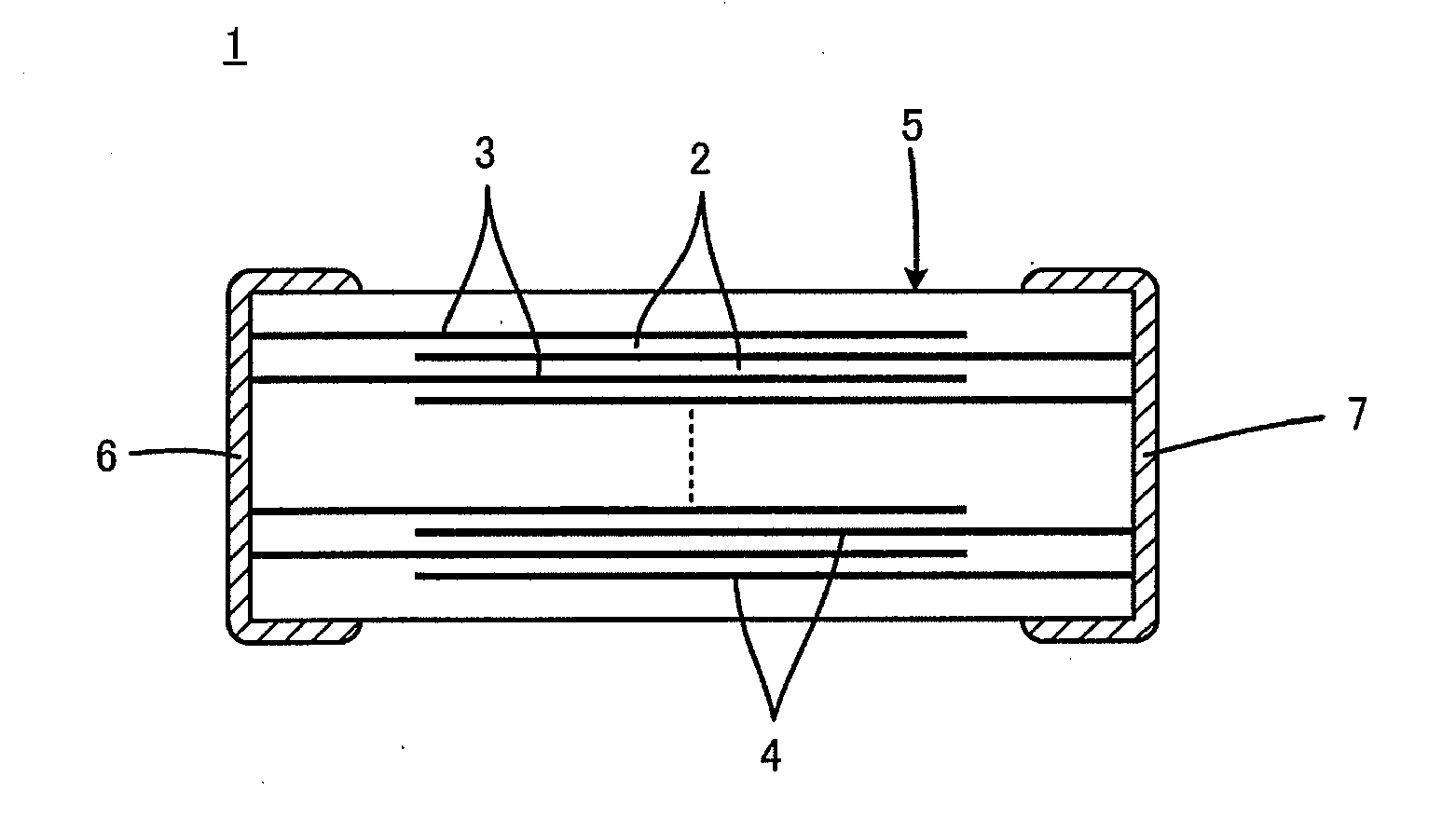

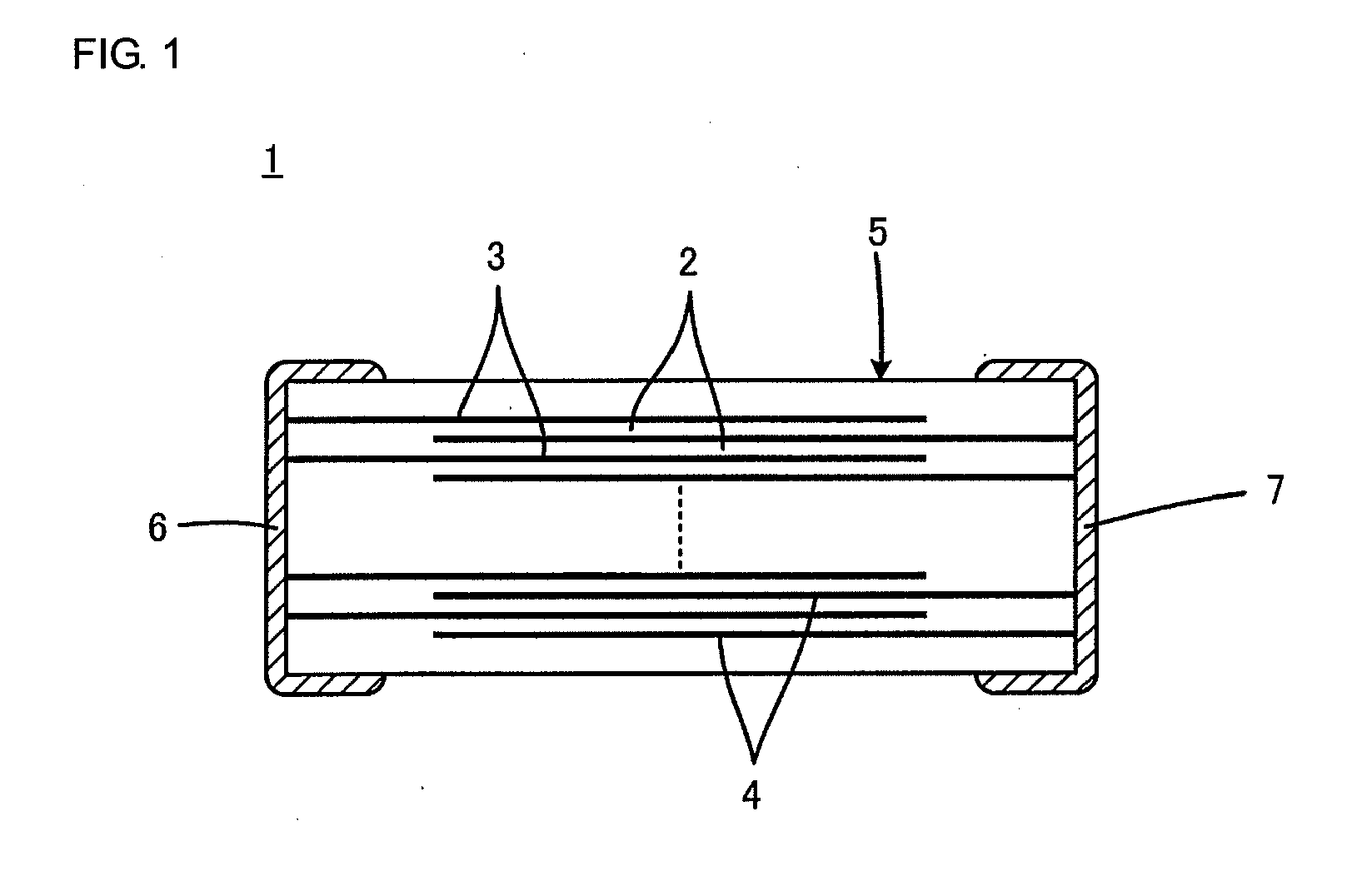

Dielectric ceramic and laminated ceramic capacitor

ActiveUS20110122541A1Improve reliabilityReduced insulation performanceFixed capacitor dielectricStacked capacitorsDielectricCeramic capacitor

A laminated ceramic capacitor which has a dielectric ceramic with a high dielectric constant and has excellent reliability against changes in temperature and mechanical shocks, even when dielectric ceramic layers are reduced in thickness employs a dielectric ceramic containing (Ba1-xCax)yTiO3 (where 0.045≦x≦0.15 and 0.98≦y≦1.05) as its main constituent and containing Re2O3 (where Re is at least one of Gd, Dy, Ho, Yb, and Y), MgO, MnO, V2O5, and SiO2 as accessory constituents, which is represented by the general formula: 100(Ba1-xCax)yTiO3+aRe2O3+bMgO+cMnO+dV2O5+eSiO2, and satisfies each of the following conditions: 0.65≦a≦1.5; 0.98≦y≦1.05; 0.15≦b≦2.0; 0.4≦c≦1.5; 0.02≦d≦0.25; and 0.2≦e≦3.0.

Owner:MURATA MFG CO LTD

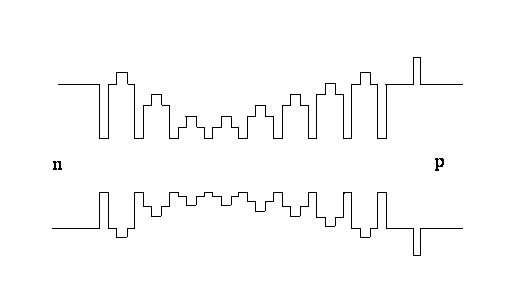

Nitride LED epitaxy structure suitable for heavy current driving

InactiveCN103855262AImprove efficiencyImprove crystal qualitySemiconductor devicesBand gapEngineering

The invention discloses a nitride LED epitaxy structure suitable for heavy current driving, and relates to the technical field of manufacturing of LED optoelectronic devices. According to the structure of the nitride LED epitaxy structure suitable for heavy current driving, a substrate sequentially comprises an n-type compound semiconductor, an active area and a p-type compound semiconductor from bottom to top, and is characterized in that the active area is formed by alternatively overlapping m quantum wells and m+1 quantum barriers, the m is any natural number, the maximum forbidden band gap of the quantum barriers is larger than the maximum forbidden band gap of the adjacent quantum wells, and the maximum forbidden band gap or film layer thickness of different quantum barriers is distributed in a gradual variation mode. Compared with the prior art, the nitride LED epitaxy structure suitable for heavy current driving can reduce or eliminate the problem of decrease of the energy efficiency of nitride LEDs under the condition of heavy current driving, and improve the quantum efficiency of devices.

Owner:TONGFANG OPTO ELECTRONICS +1

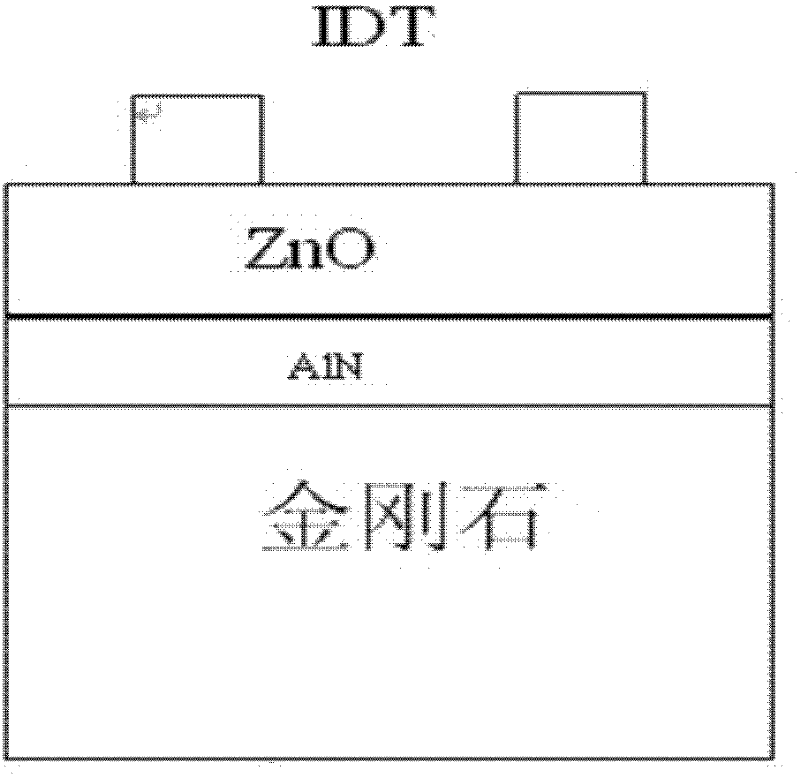

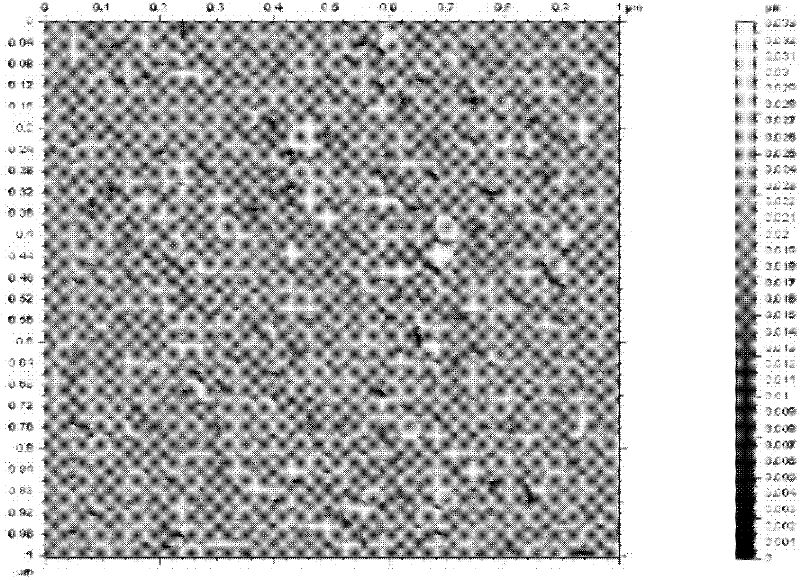

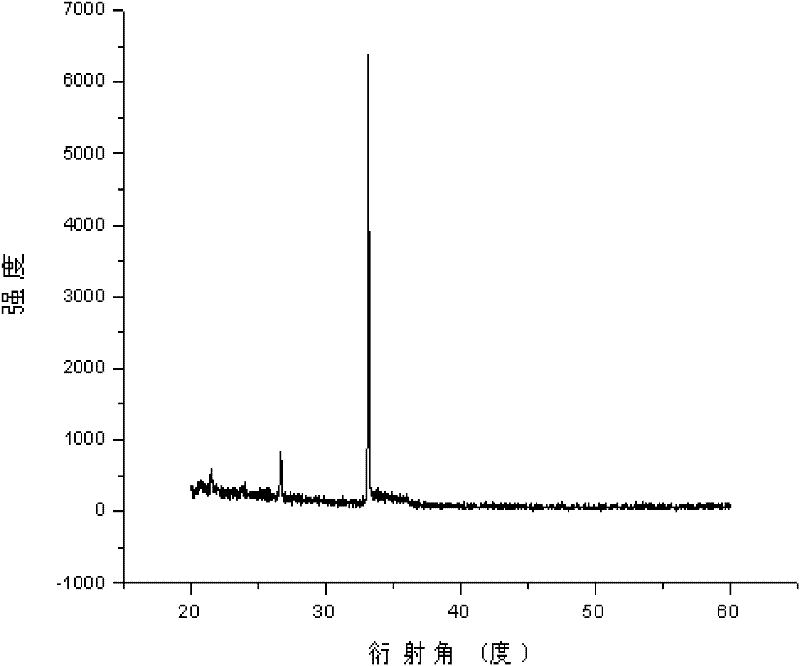

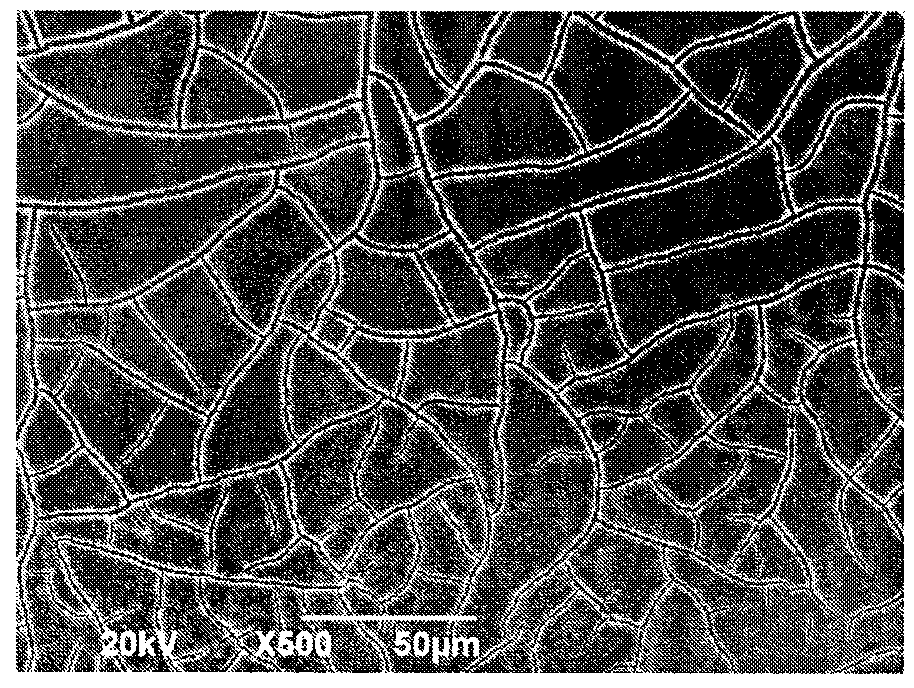

High frequency surface acoustic wave device with AlN (aluminum nitride) film as interlayer and preparation method thereof

InactiveCN102412803ASmall velocity dispersionHigh electromechanical coupling coefficientImpedence networksVacuum evaporation coatingFrequency dispersionChemical vapor deposition

The invention provides a high frequency surface acoustic wave device with an AlN (aluminum nitride) film as an interlayer. The device is characterized in that an a-axis preferred orientation AlN film is taken as a CVD (chemical vapor deposition) diamond substrate and a c-axis preferred orientation ZnO film is taken as an interlayer, the substrate and the interlayer are formed into an IDT(interdigital transducer) / ZnO / a-axis preferred orientation AlN / diamond multi-layered membrane structure and the structure is stacked with the IDT in sequence to form the high frequency surface acoustic wave device; the preparation method comprises the following steps of preparing an a-axis preferred oritention AlN film interlayer, and preparing a c-axis preferred oritentation ZnO film on the a-axis preferred orientation AlN film interlayer. The device and the preparation method provided by the invention have the following advantages that the sound velocity frequency dispersion caused by a large sound velocity gap between nanodiamond and ZnO can be solved, the application demand of the surface acoustic wave with high frequency above 4.8 GHz can be met, and moreover, the process is simple and easy to implement, and is beneficial for large-scale population and application.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

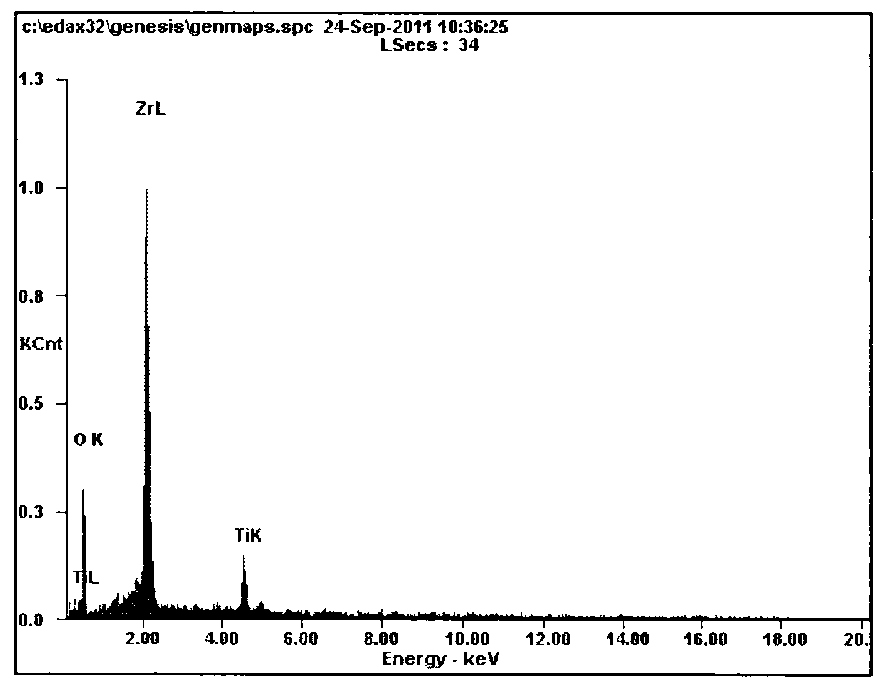

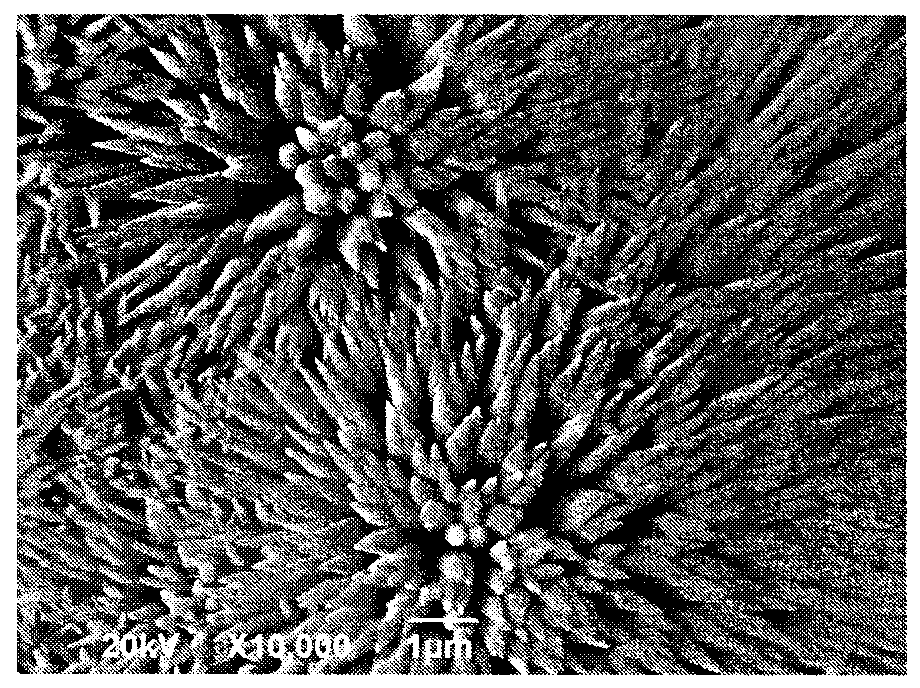

Electrochemical method for preparing fluorine-containing hydroxyapatite/zirconia transition coating on surface of medical titanium

InactiveCN103184497AAlleviate shortcomings such as thermal expansion coefficient mismatchHigh strengthImpression capsElectrolytic inorganic material coatingSolubilityApatite

The invention discloses an electrochemical method for preparing a fluorine-containing hydroxyapatite / zirconia transition coating on the surface of medical titanium. The method comprises the steps that: electro-deposition is carried in an electrolytic tank with a three-electrode system, wherein a medical titanium chip is adopted as a working electrode; a Zr(OH)4 plating is deposited in a zirconyl nitrate solution with a certain concentration and a certain pH value, wherein the deposition current is 11.1mA and the deposition time is 40s; a fluorine-containing hydroxyapatite (FHA) plating is deposited in an electrolyte which has a certain concentration and a certain pH value and which is composed of calcium nitrate, ammonium dihydrogen phosphate, and sodium fluoride, wherein the deposition current is 0.8mA and the deposition time is 3600s; and vacuum sintering is carried out under a temperature of 450 DEG C, such that the FHA / ZrO2 transition coating is obtained. According to the invention, fluorine partially substitutes hydroxyl group in apatite, fluorine ions are smaller than hydroxyl groups, and FHA lattice constant is small, such that FHA solubility is lower than HA. A coating morphology is changed from a micron-level chrysanthemum petal shape into a nano-level cone shape. With an antibacterial effect of F ions, dental caries can also be prevented. ZrO2 serves as a transition layer between the titanium substrate and the FHA coating, and the bonding strength between the FHA / ZrO2 transition coating and the Ti substrate is greatly improved. The bonding strength between the FHA / ZrO2 transition coating and the titanium substrate is high, a physiological solubility resistance is high, and antibacterial performance is good. The provided product has certain potential to be developed into an oral medical material with good development prospect.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

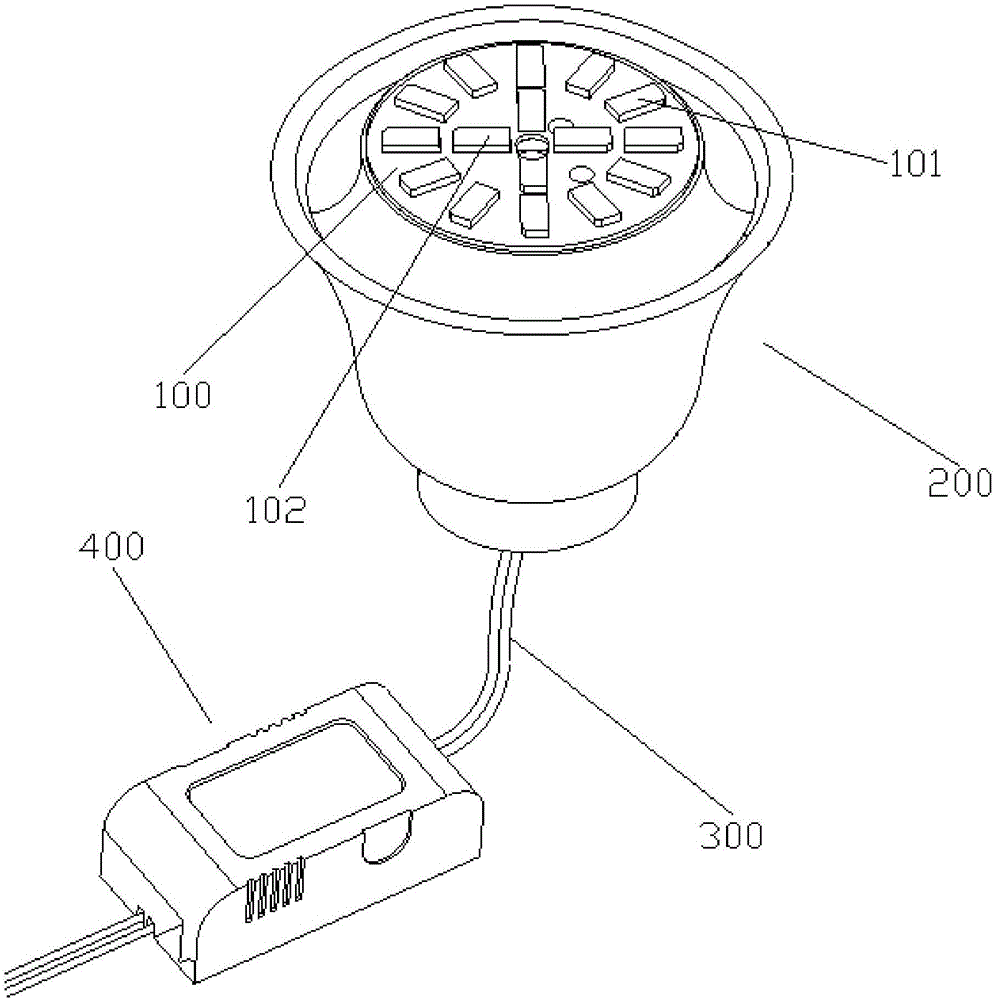

LED illuminating device and preparation method thereof

ActiveCN106764483ANot suitable for chippingIncrease productivityElectric circuit arrangementsLuminescent compositionsEngineeringLED circuit

The invention relates to an LED illuminating device and a preparation method thereof. The device is characterized by comprising an LED apparatus, an LED circuit board, a heat dissipator and a power supply controller. The LED apparatus is arranged on the LED circuit board, the LED circuit board is arranged above the heat dissipator, and the power supply controller is connected to the LED circuit board through a wire. The LED illuminating device can emit approximate natural light.

Owner:SHENZHEN YMH INTELLIGENT TECH CO LTD +1

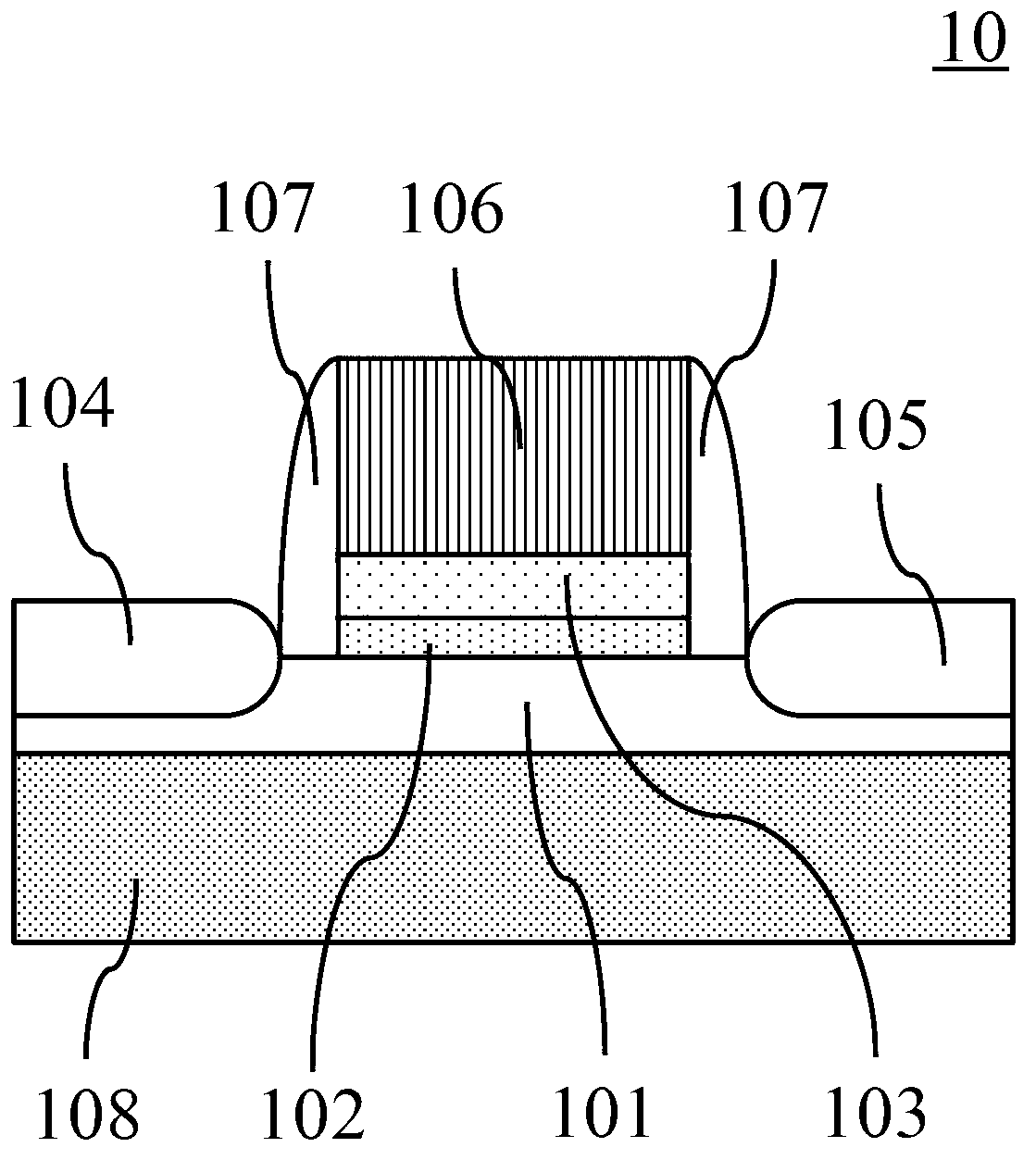

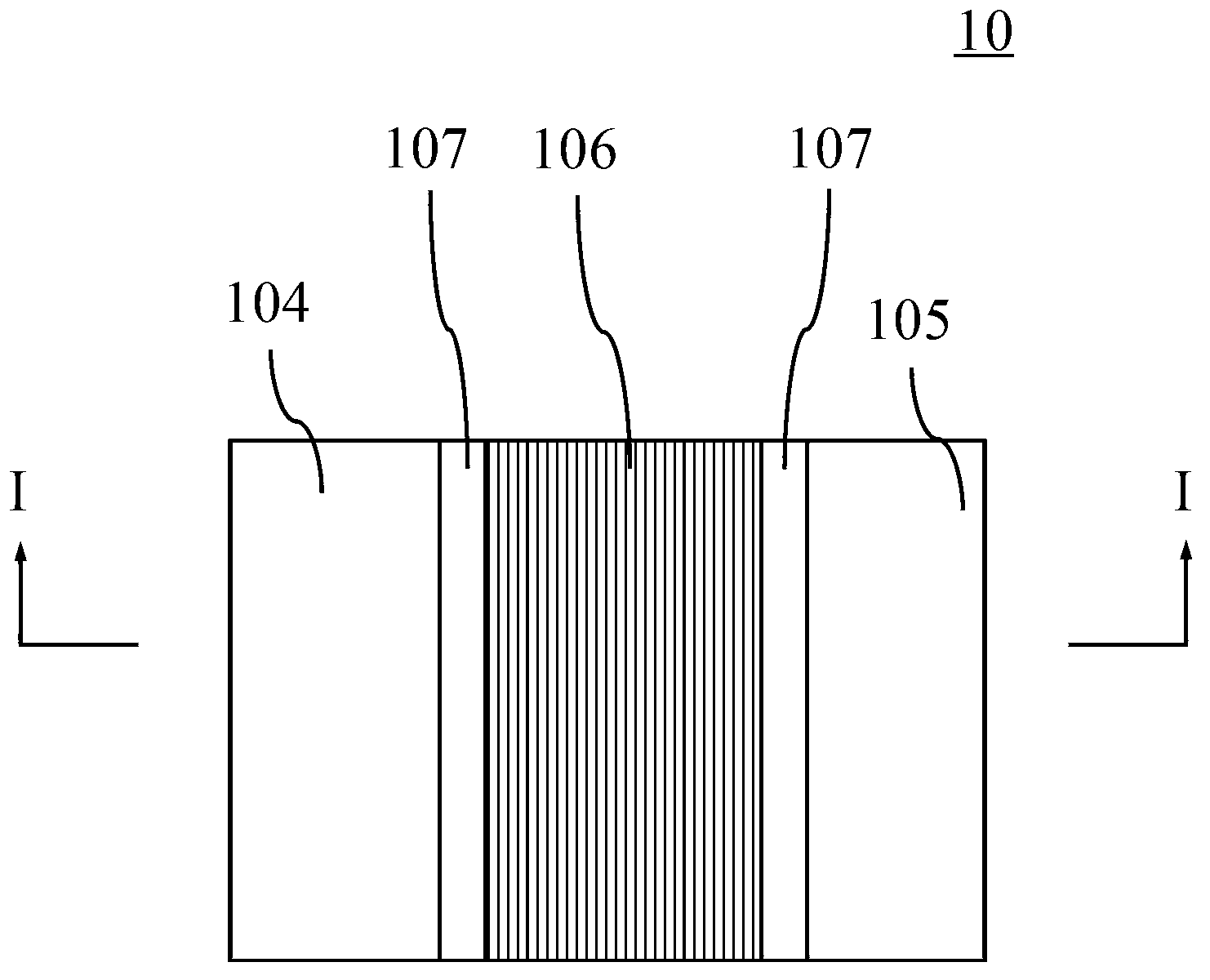

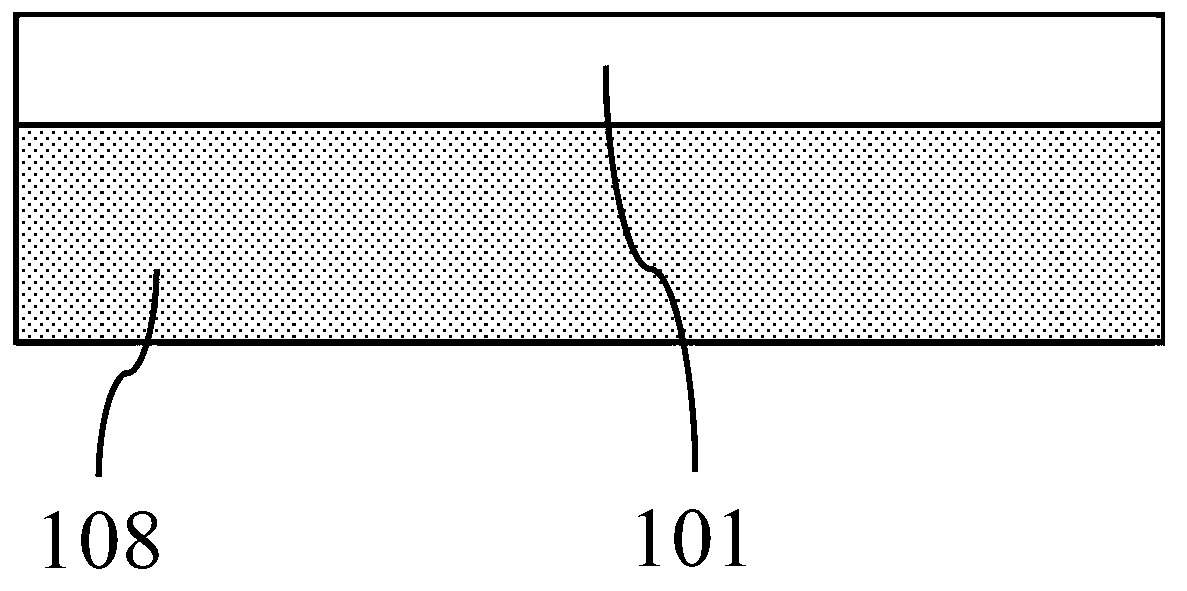

Ge channel metal-oxide-semiconductor field-effect transistor with InAlP cover layer

InactiveCN103311307AHigh hole mobilityImprove mobilitySemiconductor/solid-state device manufacturingSemiconductor devicesMOSFETValence band

The invention provides a Ge channel metal-oxide-semiconductor field-effect transistor (MOSFET) with an InAlP cover layer. The MOSFET (10) is characterized in that a Ge channel (101) is positioned on a substrate (108), the InAlP cover layer (102) is arranged above the Ge channel, an insulating dielectric film (103) is positioned between the InAlP cover layer and a gate (106), an insulating gap wall (107) separates the gate and a source / drain area (104 and 105), and an insulating gap wall separates the InAlP cover layer and the source / drain area. InAlP has a larger forbidden bandwidth than Ge, and effective band offset is formed at the positions of a conduction band and an interface valence band of Ge and InAlP so as to limit a conducting charge carrier in a Ge channel layer.

Owner:CHONGQING UNIV

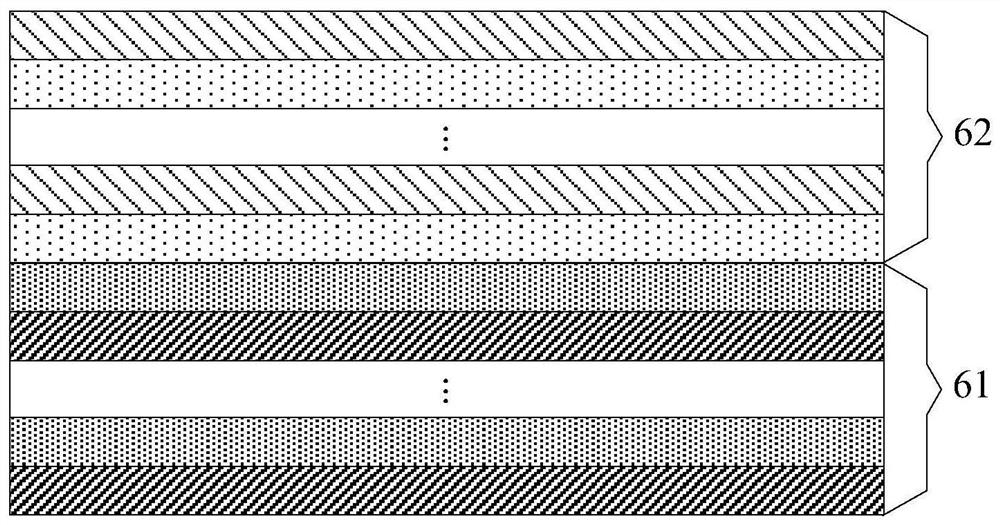

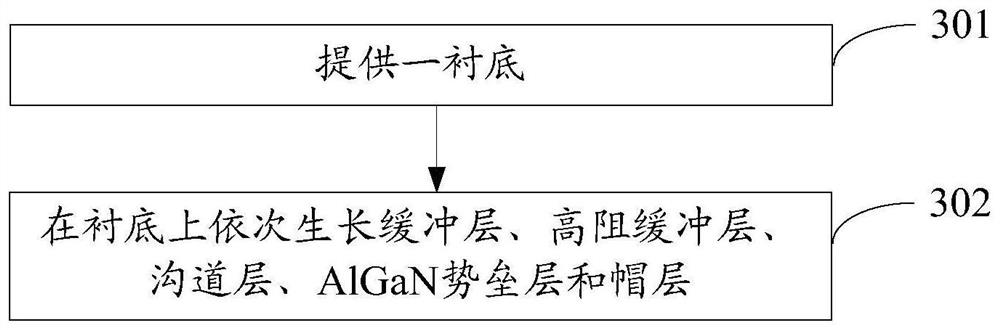

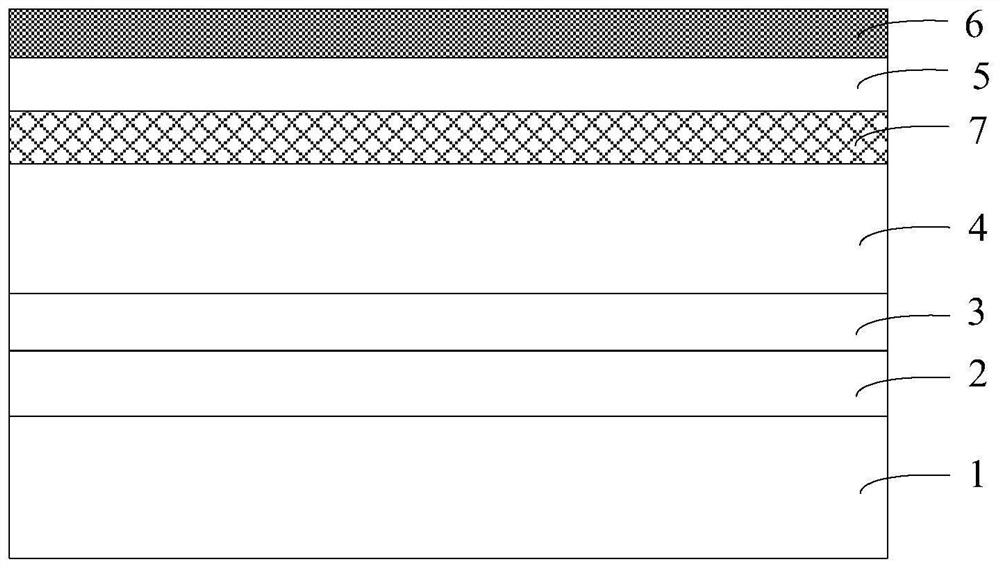

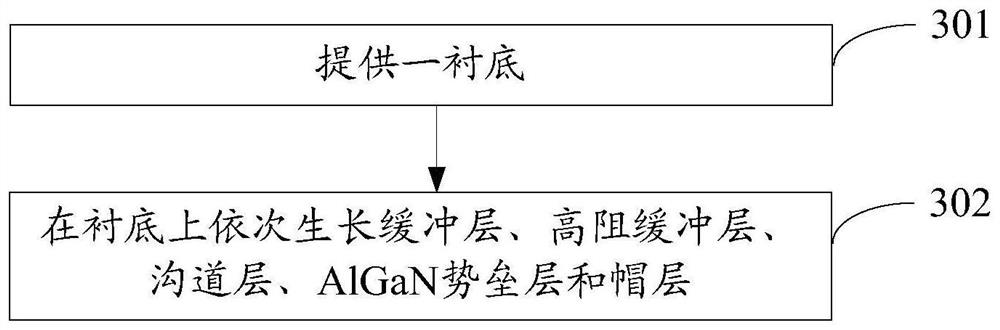

GaN-based high-electron-mobility transistor epitaxial wafer and preparation method thereof

ActiveCN112701160AIncrease the doping concentrationEasy to dopeSemiconductor/solid-state device manufacturingSemiconductor devicesGallium nitrideHigh-electron-mobility transistor

The invention provides a GaN-based high-electron-mobility transistor epitaxial wafer and a preparation method thereof, and belongs to the technical field of semiconductors. The GaN-based high-electron-mobility transistor epitaxial wafer comprises a substrate, a buffer layer, a high-resistance buffer layer, a channel layer, an AlGaN barrier layer and a cap layer, wherein the buffer layer, the high-resistance buffer layer, the channel layer, the AlGaN barrier layer and the cap layer are stacked on the substrate; the cap layer comprises a first semiconductor layer and a second semiconductor layer which are stacked in sequence; the first semiconductor layer is of a P-type doped InxGa1-xN / MgN superlattice structure, wherein x is larger than 0 and is smaller than 1; the second semiconductor layer is of a P-type doped AlyGa1-yN / InzGa1zN superlattice structure, wherein y is larger than 0 and smaller than 1, and z is larger than 0 and smaller than 1. According to the epitaxial wafer, the doping concentration of Mg in the cap layer can be improved, an enhanced HEMT is formed, and meanwhile, the crystal quality of the enhanced HEMT epitaxial wafer is improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

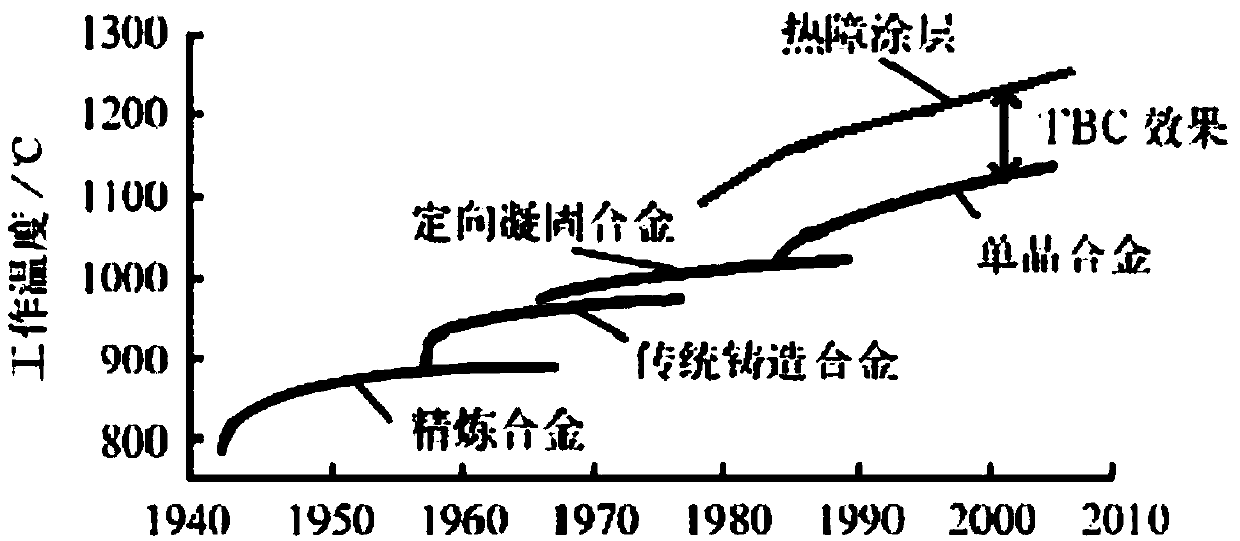

Nickel-based high-temperature alloy powder and preparation method for applying nickel-based high-temperature alloy powder to hollow turbine blade

ActiveCN114214554ADelayed expansionHigh densityTurbinesAdditive manufacturing apparatusSelective laser meltingTurbine blade

The invention provides nickel-based high-temperature alloy powder and a preparation method for applying the nickel-based high-temperature alloy powder to a hollow turbine blade, and solves the technical problem of cracking in the process of preparing the hollow turbine blade through selective laser melting. The Ni-Cr-Co-Ti-W alloy material comprises the following components in percentage by weight: 25% to 30% of Cr, 17.5% to 19% of Co, 2.5% to 3.0% of Al, 2.3% to 2.5% of Ta, 2.6% to 2.8% of Ti, 1.7% to 2.1% of W, 1.5% to 2.5% of Re, 0.1% to 0.15% of C, 0.8% to 1% of Cb, 0.2% to 0.3% of Zr, 0.005% to 0.01% of B, 0.5% to 0.7% of V and the balance of Ni. The method can be widely applied to the technical field of additive manufacturing.

Owner:HARBIN INST OF TECH AT WEIHAI

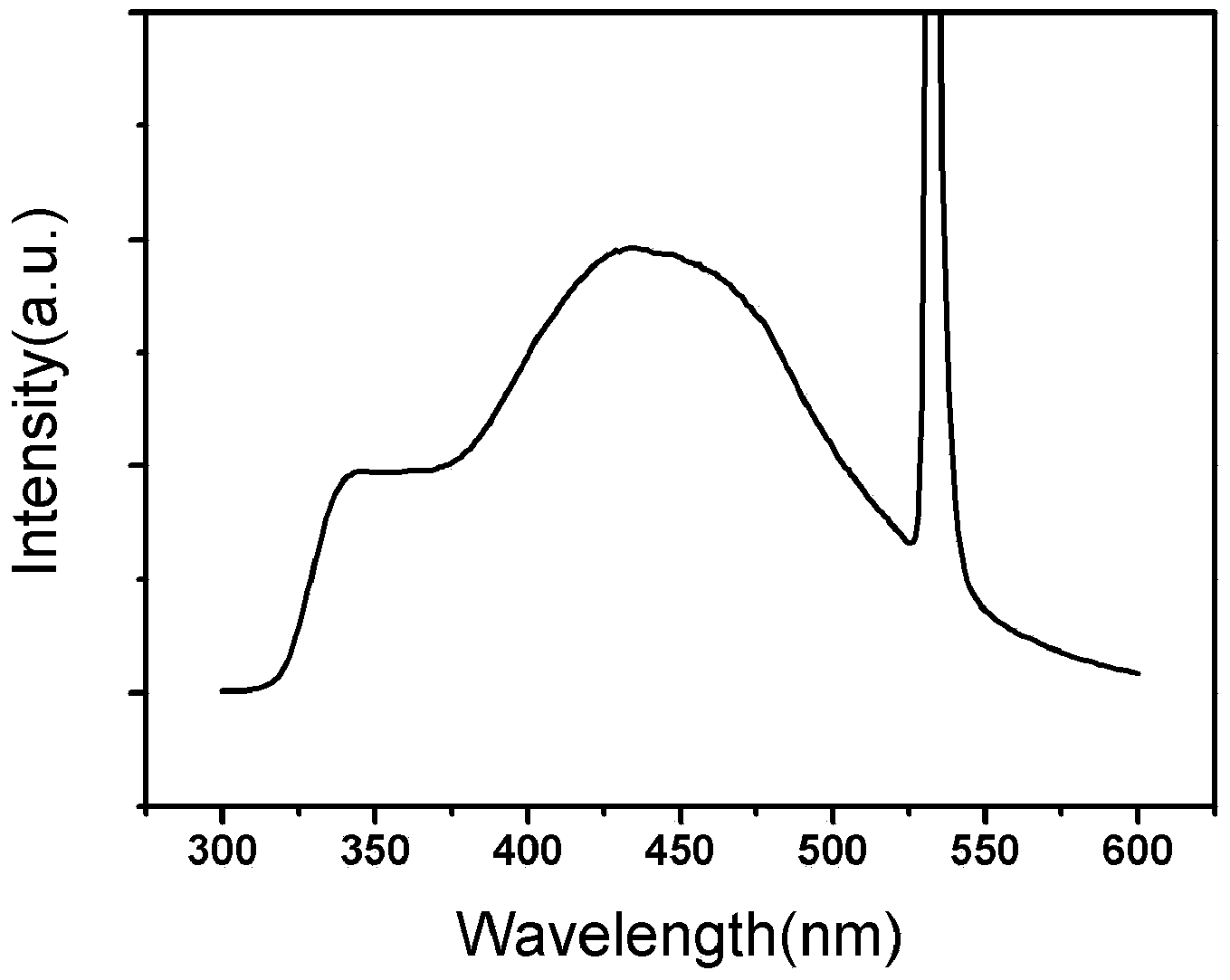

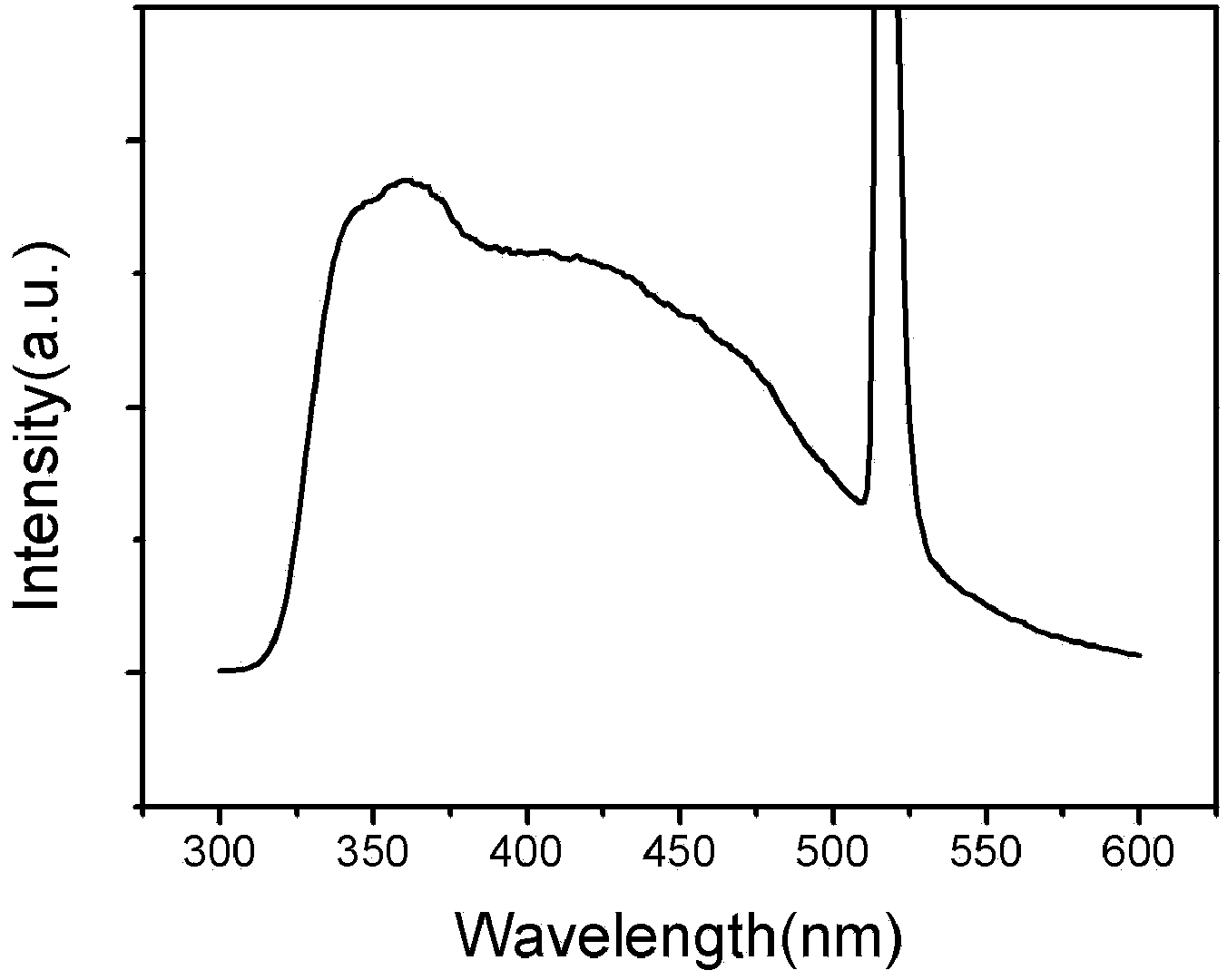

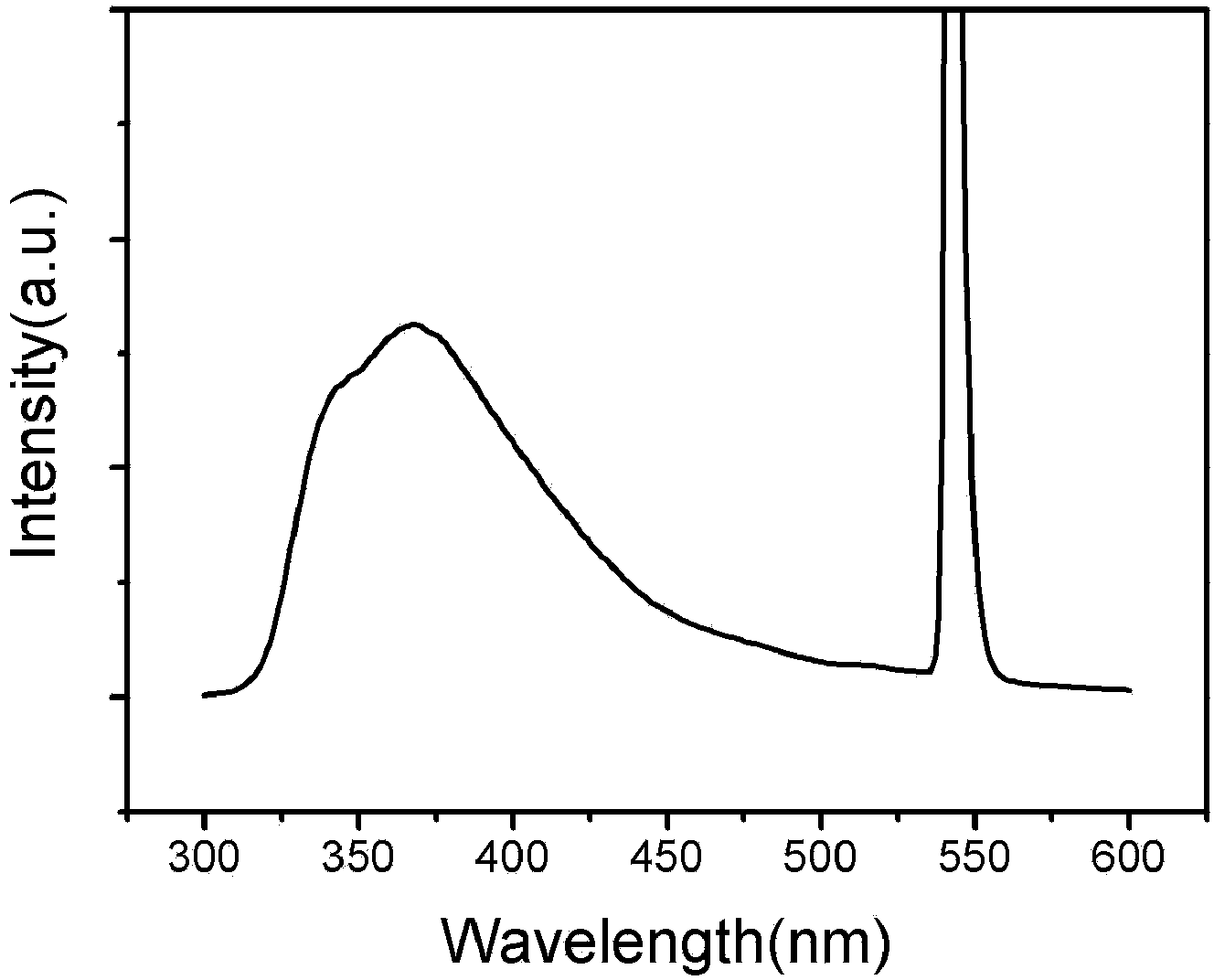

Blue light-ultraviolet continuously-adjustable aluminate fluorescent powder and preparation method thereof

InactiveCN103468257AImprove stabilityImprove luminescence stabilityLuminescent compositionsUltraviolet lightsElectronegativity

The invention provides a blue light-ultraviolet continuously-adjustable aluminate fluorescent powder and a preparation method thereof. A Si-N bond is substituted for a Al-O bond; after the substitution, the internal structure of the fluorescent powder is improved; and thus, the luminescent spectrum of the fluorescent powder is continuously adjustable from blue light to ultraviolet light according to different substitution proportions. The fluorescent powder is more stable due to the doping of the Si-N key. The Si-N bond and Al-O bond have similar bond lengths, Si and Al, and O and N have similar bonding characteristics according to the diagonal line principle, so the Al-O bond in the aluminate-base fluorescent powder can be easily partially substituted by the Si-N bond; according to the charge compensation effect, after (SiN)+ is substituted for (AlO)+, the charge balance can be maintained; the bond length of the Si-N bond is slightly smaller than that of the Al-O bond, so that the matrix lattice constant is reduced, the cell volume is correspondingly reduced, and the atomic arrangement in the matrix is closer; and N with relatively smaller electronegativity can stabilize the Ce<2+>, so the material stability and light-emitting stability of the fluorescent powder are enhanced.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Soda recovery furnace brasque material based on aluminum-rich magnesium aluminate spinel and preparation method thereof

The invention relates to a soda recovery furnace brasque material based on aluminum-rich magnesium aluminate spinel and a preparation method thereof. The preparation method comprises the following steps of: firstly, mixing 50-80wt% of aluminum-rich magnesium aluminate spinel aggregate with 20-50wt% of aluminum-rich magnesium aluminate spinel fine powder to obtain a mixture, adding a binding agent accounting for 4-15wt% of the mixture, stirring, constructing, curing and roasting the mixture to prepare a soda recovery furnace brasque material based on aluminum-rich magnesium aluminate spinel. The main physical properties of the chrome-free and alkali-resistant refractory material based on aluminum-rich magnesium aluminate spinel prepared by the preparation method provided by the invention are as follows: the volume density is 2.60-2.85 g / cm3, the compression strength is 30-45 MPa, and the linear changing rate is 0.19-0.47%. The preparation method provided by the invention has the advantages of simple technique and low energy consumption, and the prepared soda recovery furnace brasque material based on aluminum-rich magnesium aluminate spinel is free of chromium and is excellent in alkali corrosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

Rare earth polishing powder and preparation method thereof

ActiveCN112080207AImprove wear resistanceEnhanced grinding forcePolishing compositions with abrasivesRare-earth elementOxygen vacancy

The invention discloses a preparation method of rare earth polishing powder. The method comprises the following steps of: preparing rare earth fluorocarbonate of rare earth elements lanthanum, cerium,samarium and yttrium, with the addition amount of fluorine being 5%-10% of REO; and roasting and grading the rare earth fluorocarbonate to obtain the rare earth polishing powder. The invention further discloses rare earth polishing powder, which comprises cerium oxide and yttrium oxide, the total amount of rare earth oxide of cerium oxide accounts for 45w%-85w% of CeO2 / TREO, the total amount of rare earth oxide of yttrium oxide accounts for 1w%-10w% of Y2O3 / TREO, and the molar ratio of REO to Y2O3 is 1:0.015-0.15. By precisely calculating the addition amount of Y2O3, the lattice constant of CeO2 is reduced, oxygen vacancies are formed, and the wear resistance, grinding force and reaction activity of the polishing powder are enhanced.

Owner:BAOTOU TIANJIAO SEIMI POLISHING POWDER CO LTD

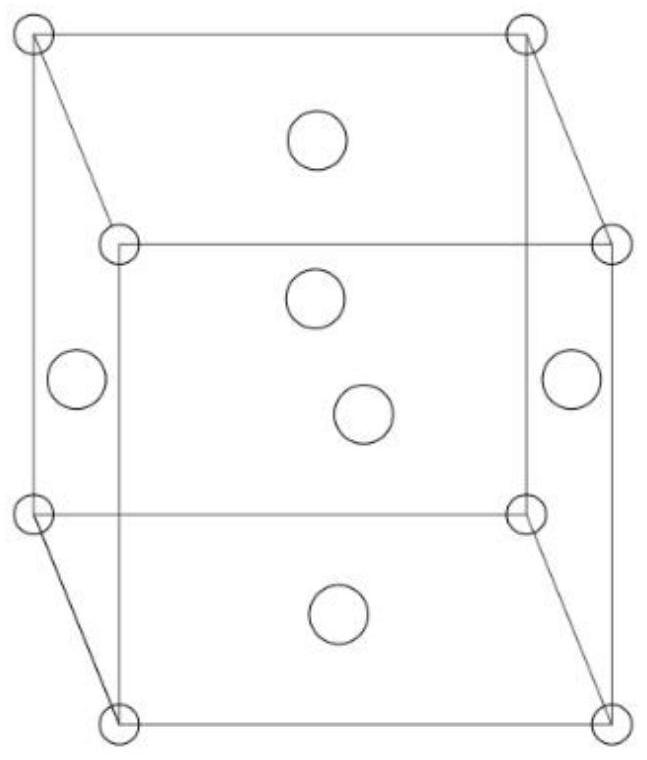

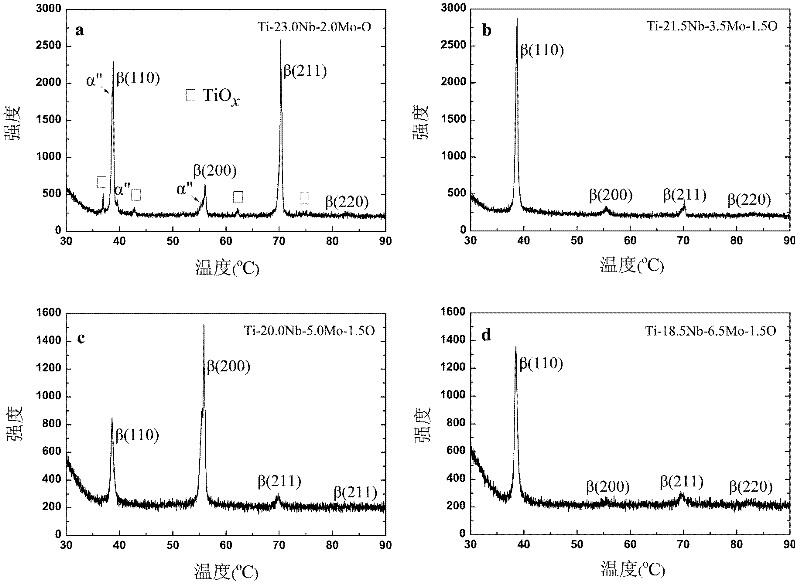

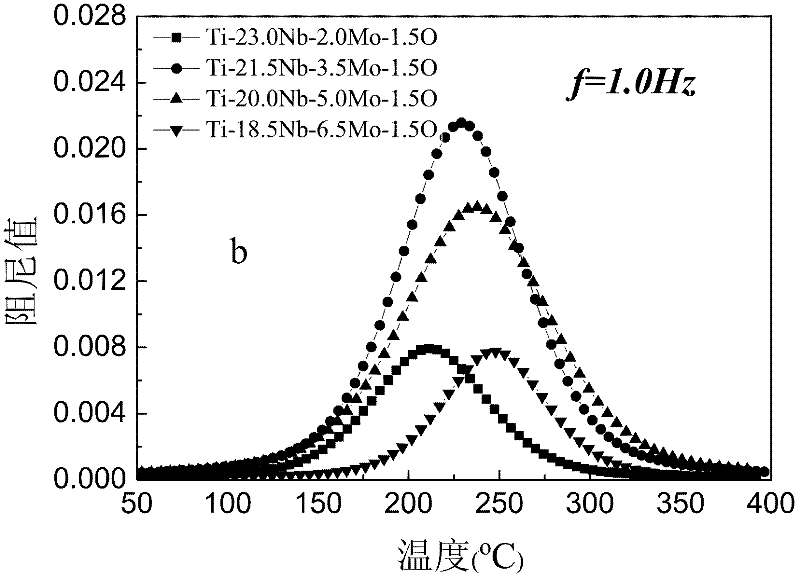

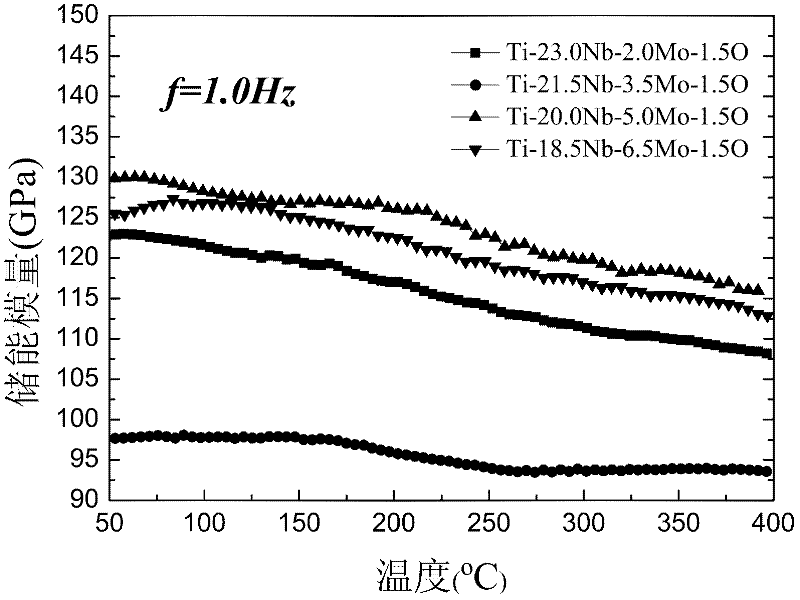

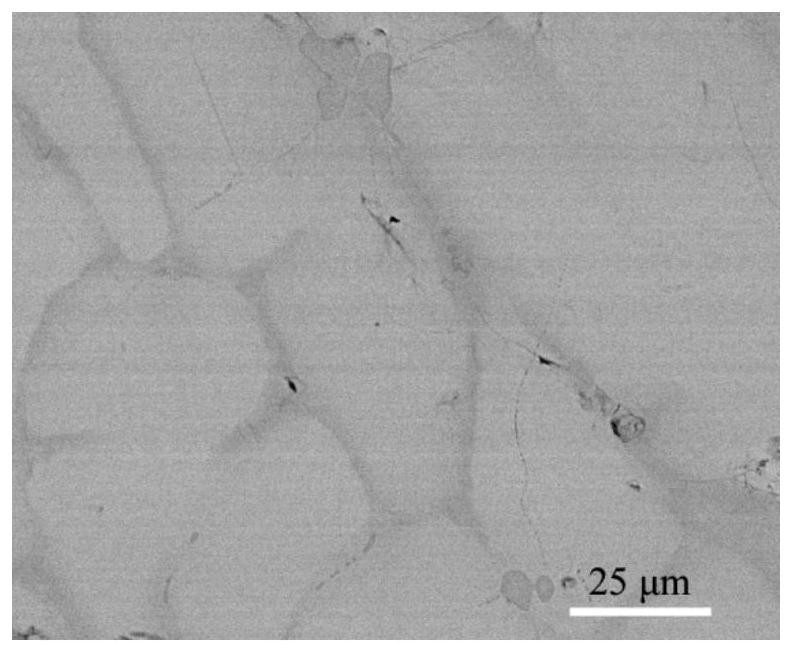

Ti-Nb-Mo-O series high-damp alloy and preparation method thereof

The invention discloses a Ti-Nb-Mo-O series high-damp alloy. The alloy comprises the following chemical components in percentage by atom: 73.5% of Ti, 15.0%-23.0% of Nb, 2.0%-10.0% of Mo and 1.5% of O. In the high-damp alloy disclosed by the invention, two elements with stable beta phases namely Nb and Mo, and O atoms are added, thus the Ti-Nb-Mo-O series alloy belongs to a beta-phase titanium alloy. In the preparation method of the Ti-Nb-Mo-O series high-damp alloy, smelting is repeatedly carried out at least five times by adopting a vacuum arc process, and heat treatment is carried out after preparing an alloy ingot; the O atoms are solved in the beta phase in a solid mode; the stability of a beta-phase substrate (body-centered cubic structure) in the alloy is enhanced through adding Nb and Mo elements; and the alloy has high damp value, good mechanical property and the like. The high-damp alloy of the invention can be used at the temperature ranging from 200 DEG C-300 DEG C and has the characteristics of high damp value, wider effective damp temperature interval, good mechanical property and the like.

Owner:TIANJIN UNIV

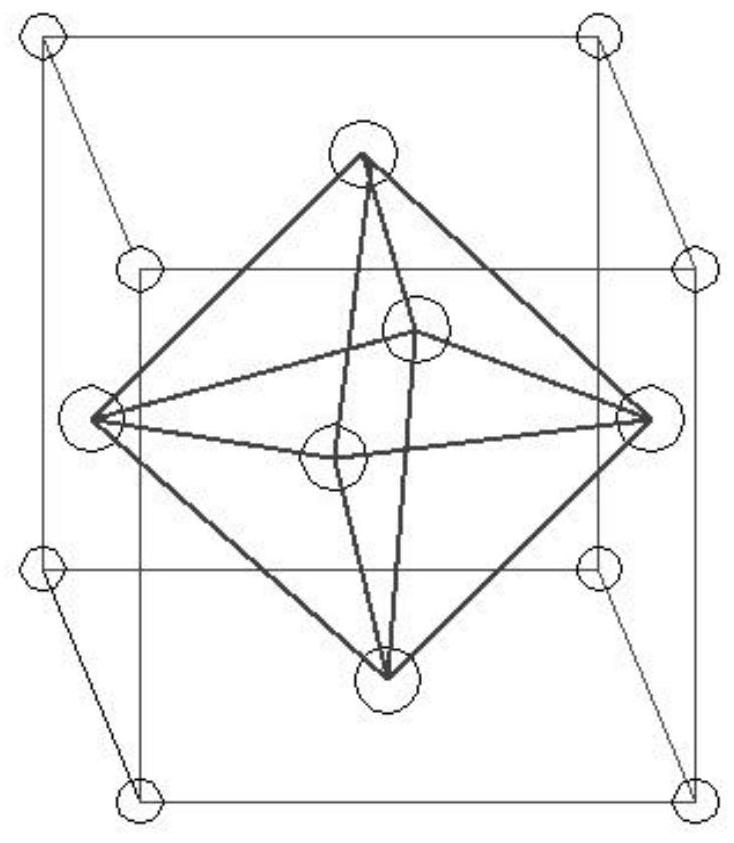

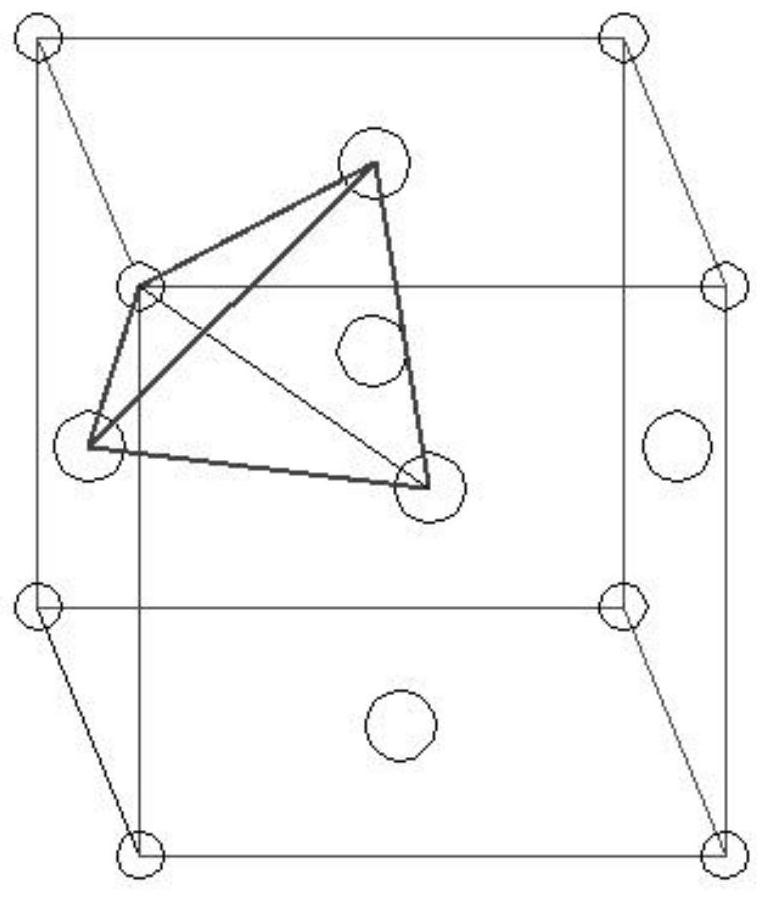

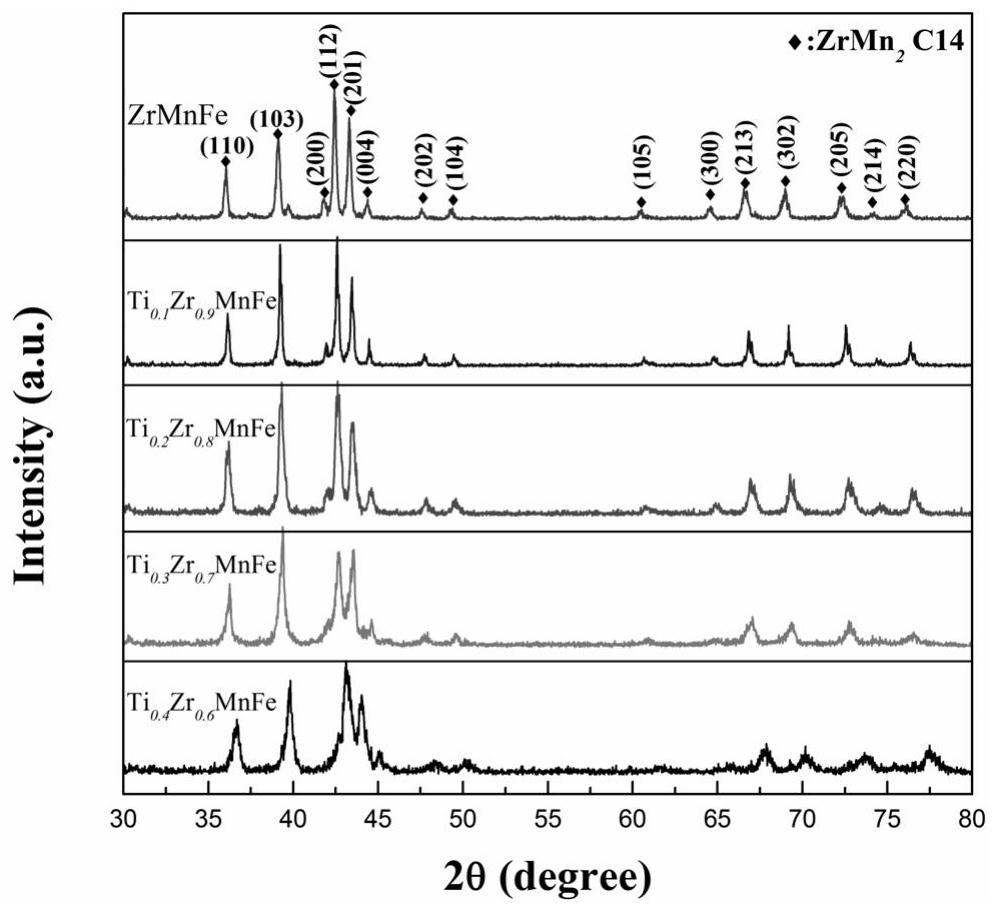

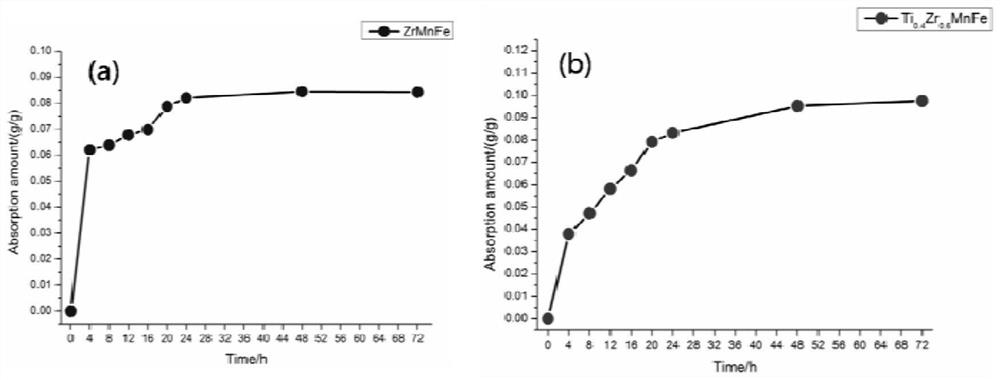

TiZrMnFe quaternary getter alloy material and preparation method and application thereof

InactiveCN112030054AImprove adsorption capacityThe lattice constant decreasesGas treatmentOther chemical processesTitanium zirconiumAdhesive

The invention discloses a TiZrMnFe quaternary getter alloy material and a preparation method and application thereof. The chemical formula of the TiZrMnFe quaternary getter alloy material is TixZr1-xMnFe (x is equal to 0-0.4), and the TiZrMnFe quaternary getter alloy material is specifically composed of, by mass, 2.3 wt%-10.4 wt% of titanium, 29.6 wt% to 41.6 wt% of zirconium; 27.8 wt% to 29.8 wt%of manganese; and 28.0 wt% to 30.3 wt% of iron. The crystal form of the TiZrMnFe quaternary getter alloy material is a C14 type laves crystal structure, and the grain size of the TiZrMnFe quaternarygetter alloy material is 20 microns to 50 microns. The preparation method comprises the steps that Ti, Zr, Mn and Fe pure metal with a certain stoichiometric ratio is weighed, proportioned and smeltedto obtain an alloy ingot, heat treatment is conducted, and the alloy ingot obtained after heat treatment is subjected to crushing, ball milling and sieving to be prepared into TiZrMnFe air suction alloy powder with different particle sizes. The alloy powder is pressed into getter products in various shapes through a cold press, or alloy powder adsorption slurry is brushed on the surface of a device through an adhesive. The preparation process is simple and feasible, the nitrogen adsorption capacity of the getter per unit mass is high and is superior to that of a ternary ZrMnFe alloy, and thepreparation cost is low.

Owner:CENT SOUTH UNIV

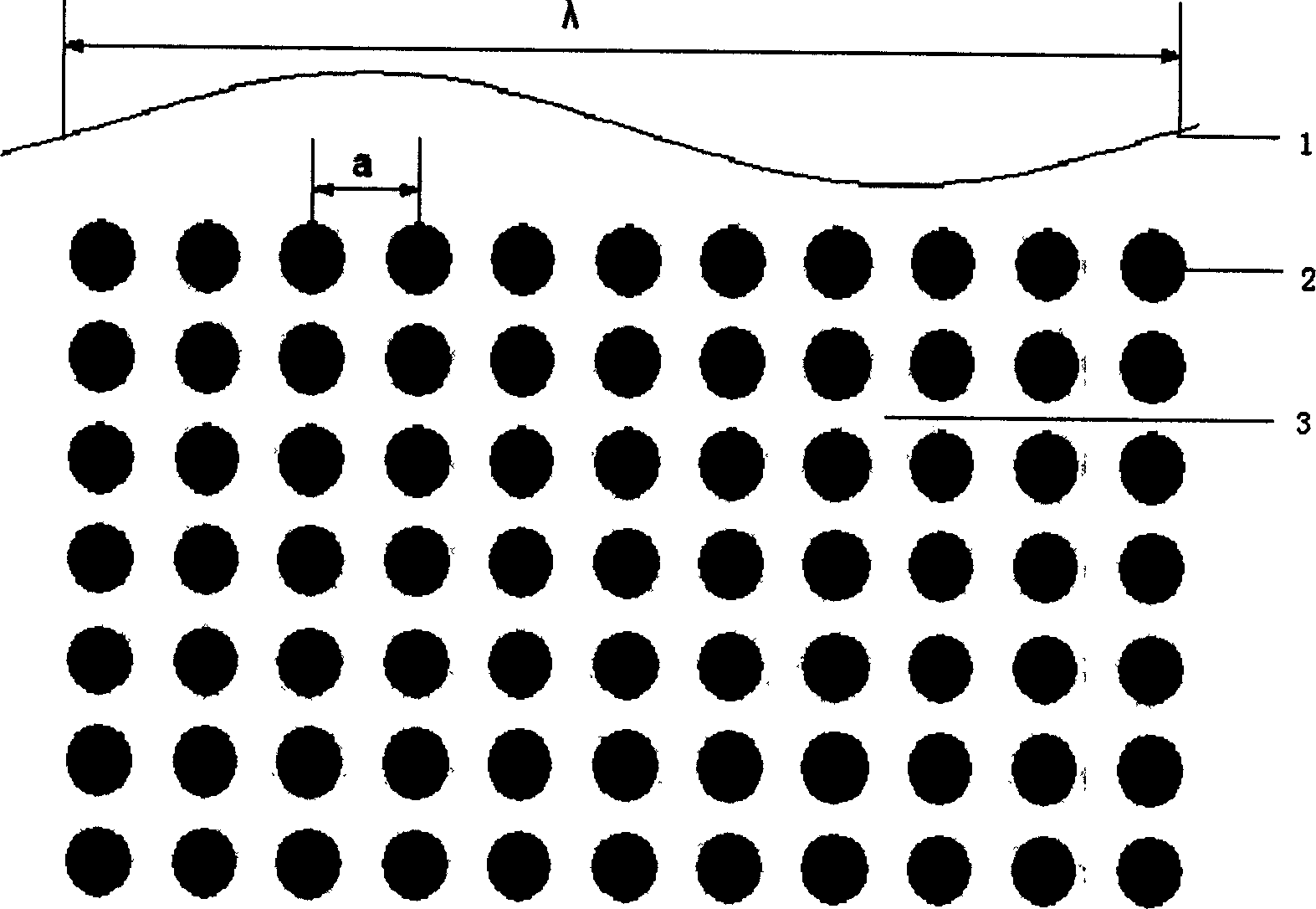

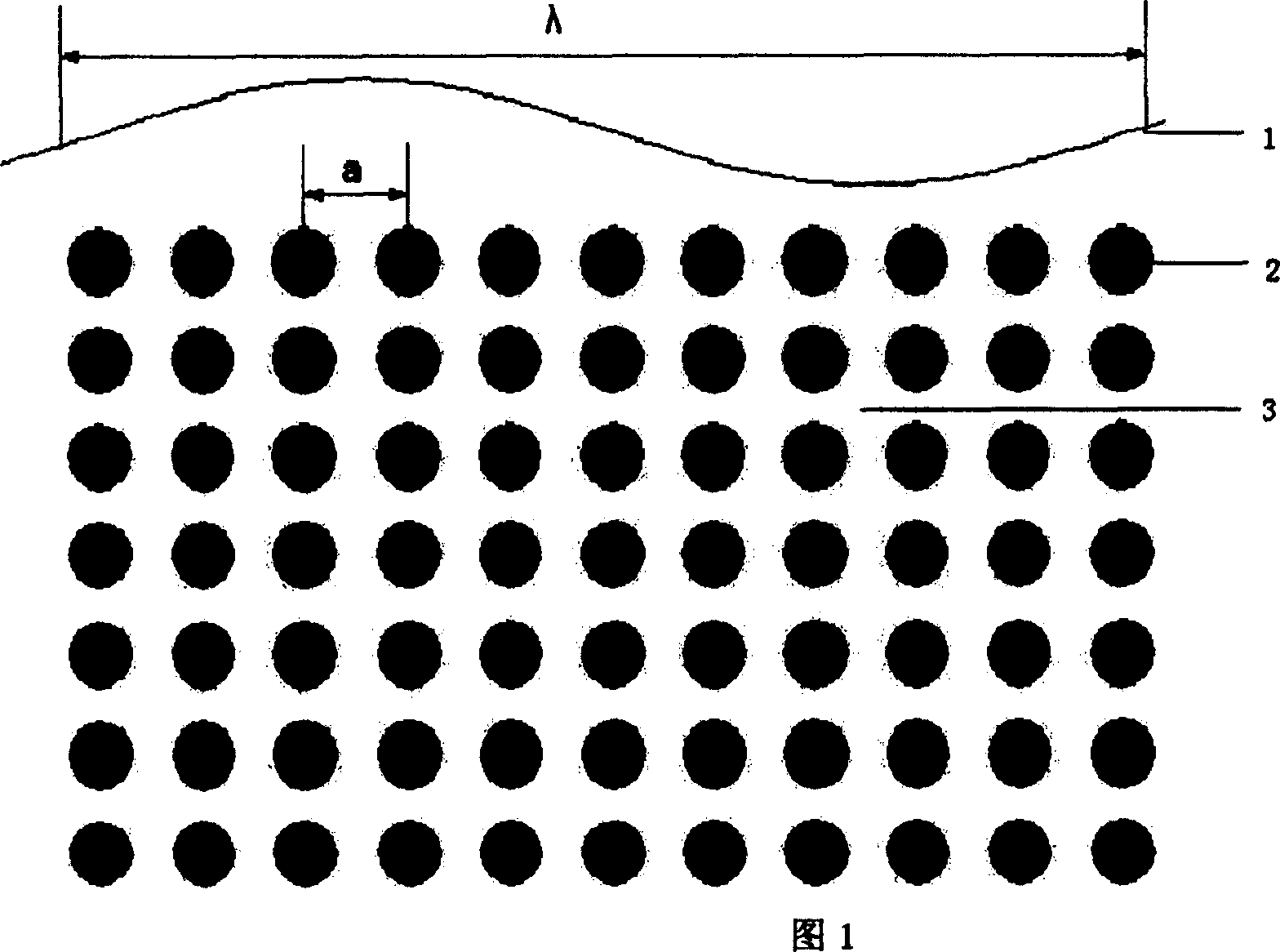

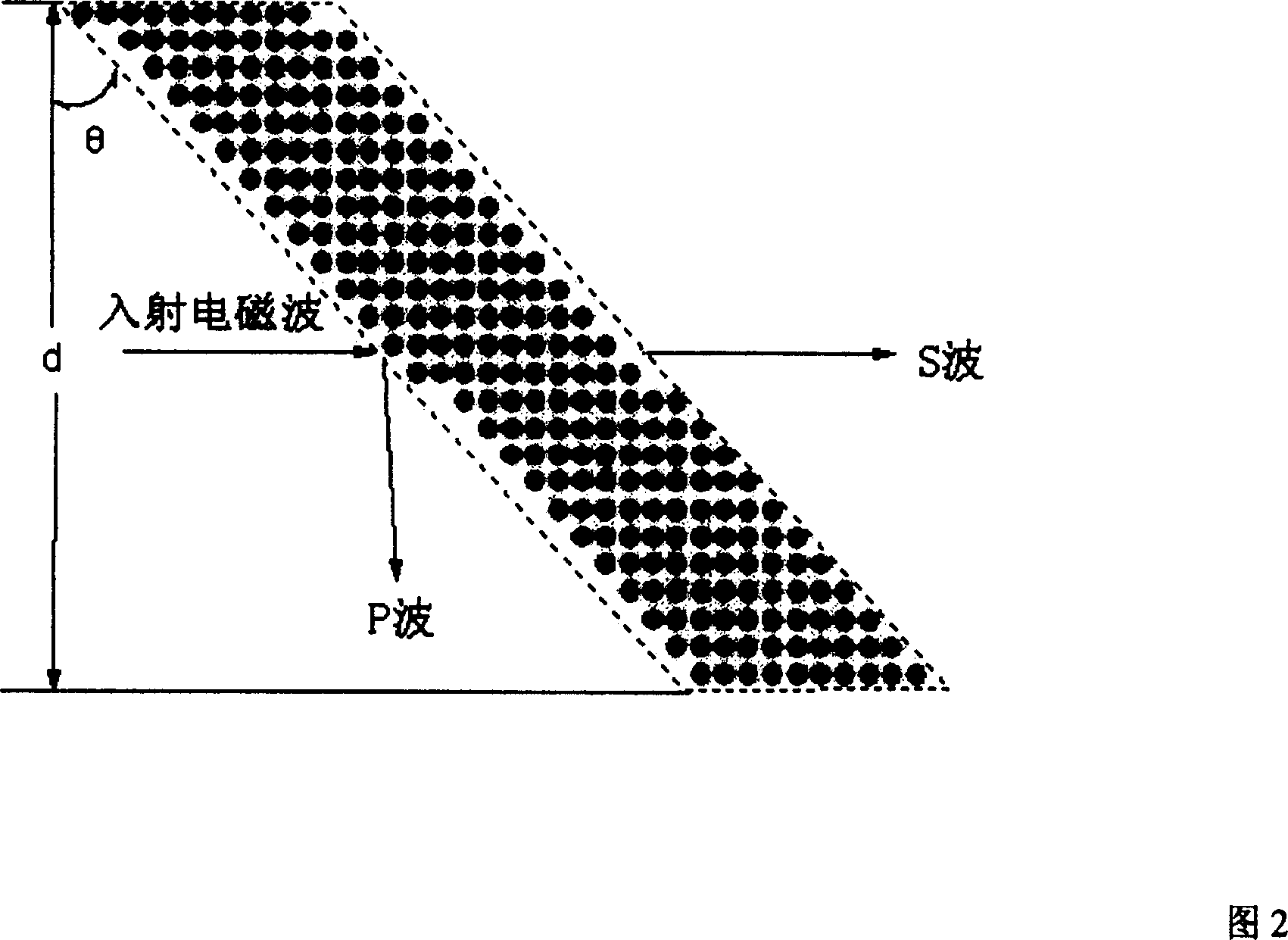

Two-dimensional photor crystal polarization beam dividing device

InactiveCN1641382AHigh degree of polarizationThe lattice constant decreasesPolarising elementsDielectricRefractive index

The planar photon crystal bundle-dispersing polarimeter refers to the field of electromagnetic wave bundle-dispersing polarimeter. Its character is that insert the dielectric stick to the background media whose refractive index is much lower than that of the dielectric stick to form a planar seasonal structure. Along the incident direction of the electromagnetic wave, it's orderly composed of three parts that are the left transmission-enhancing film, the main part and the right transmission-enhancing film. The radius of the dielectric stick in the main part is higher than that of the other two parts. The incident side of the main part is pressed close to the outdiffusing side of the left transmission-enhancing film, and the incident side of the right transmission-enhancing film is pressed close to the side of the outdiffusing side of the main part. This invention has an advantage that the fixity of all the standards of the photon crystal itself won't metamorphose. When the work wavelength is the same, the crystal lattice constant of this invention is much smaller than that of the present planar photon crystal bundle-dispersing polarimeter. Therefore it's portable and cabinet. This invention can also transmit two reciprocally vertical polarizing ponderance at the same time, so it's polarizing degree is high and the transmitted index is big.

Owner:TSINGHUA UNIV

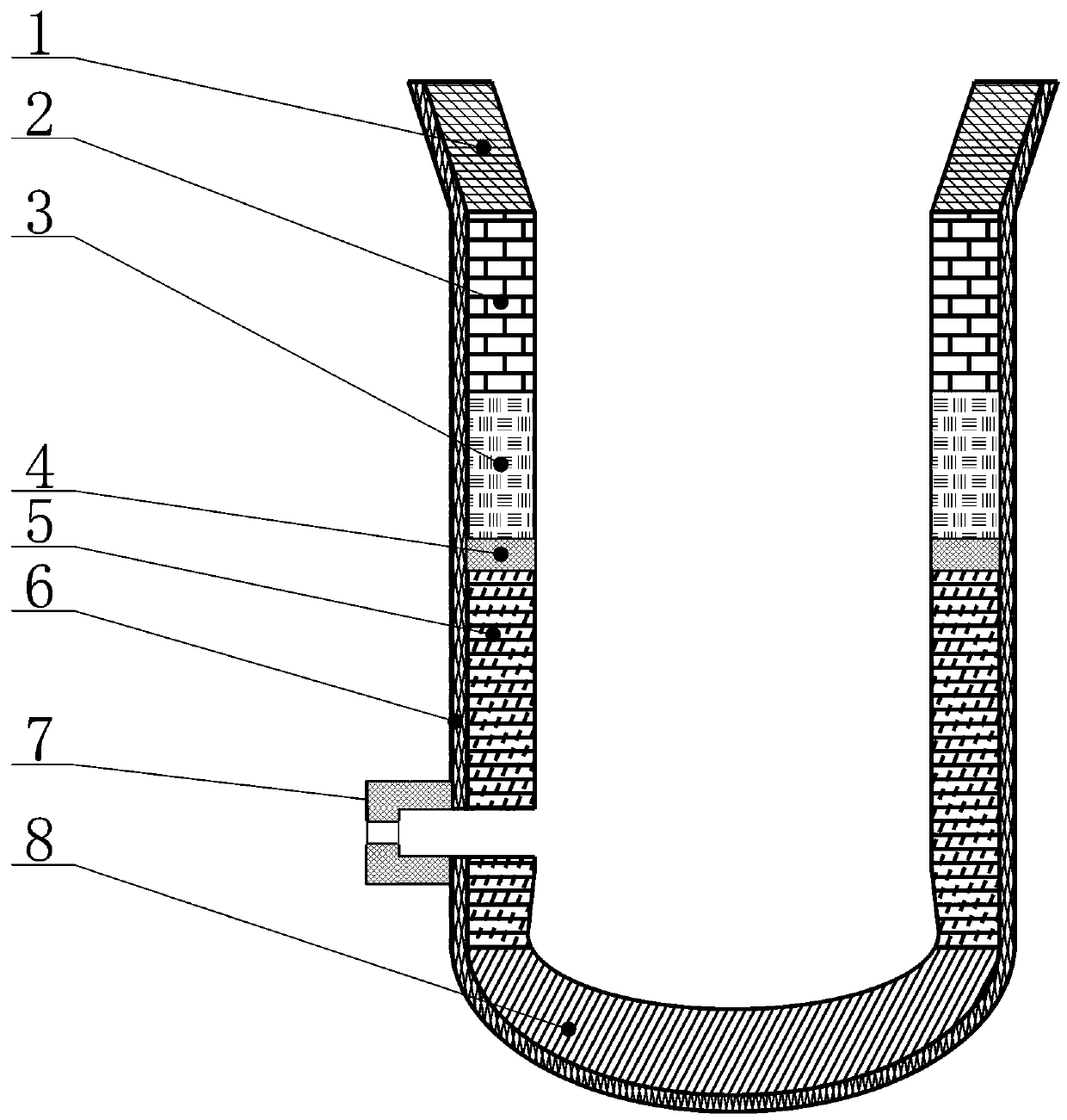

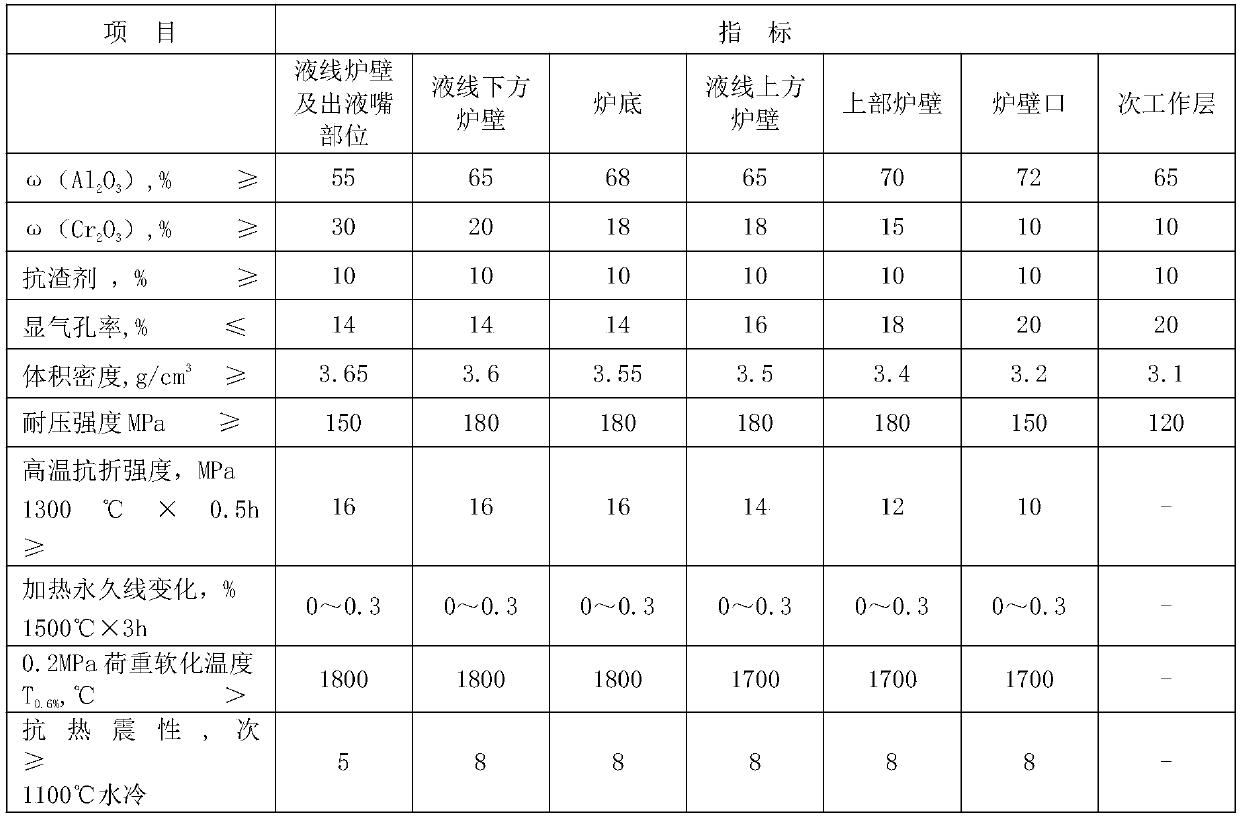

High-strength fusion smelter for colored strengthening smelting

ActiveCN109650856AReduce decomposition reactionsReduce heat responseCharge treatment typeFurnace liningsLiquid lineThermal shock

The invention relates to a high-strength fusion smelter for colored strengthening smelting. The smelter comprises a smelter wall port, an upper smelter wall, a smelter wall above a liquid line, a liquid line smelter wall, a smelter wall below the liquid line, a secondary working layer, a liquid outlet nozzle and a smelter bottom. All the parts of the smelter are made of fire-resistance materials,by analyzing working conditions of different parts of the high-strength fusion smelter for colored strengthening smelting, different kinds of fire-resistance material brasque are used as the corresponding parts, one or more properties of the erosion resistance, thermal shock resistance, washing resistance and permeability resistance of the brasque at the part are improved, the service life of thebrasque is greatly improved, frequent repairing and brasque replacement are avoided, and a large number of human resources and financial resources are saved.

Owner:REFRACTORY MATERIAL OF SINOSTEEL CORP

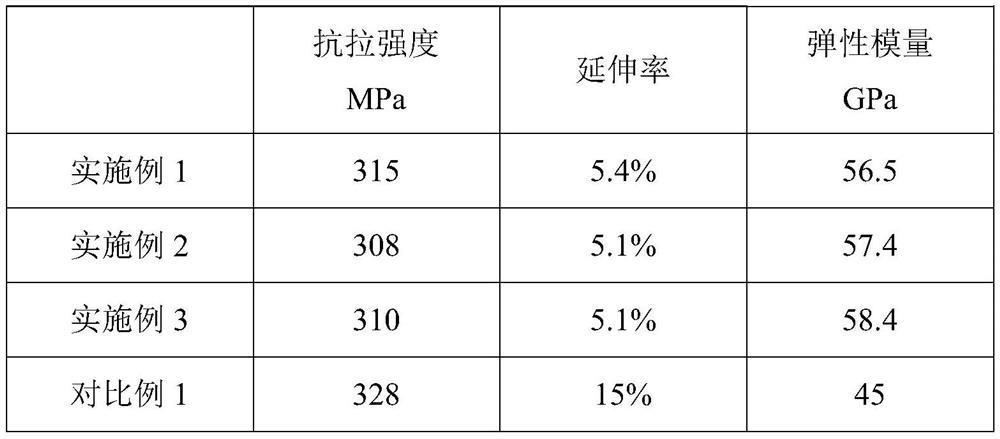

Low-cost high-strength high-modulus cast magnesium alloy and preparation method thereof

PendingCN114318093AHigh modulus of elasticityThe lattice constant decreasesMicron scaleMetallic materials

The invention belongs to the field of metal material magnesium alloys, and discloses a low-cost high-strength high-modulus cast magnesium alloy and a preparation method thereof. According to the total weight of the cast magnesium alloy, the cast magnesium alloy comprises 3.0%-10.0% of Zn, 2%-10.0% of Li, 1%-6.0% of Al, 0.01%-3.0% of Mn, 0.01%-1.0% of Cu and an impurity element Filt. 0.005%, the impurity element of which is Nilt; 0.002%, and the balance of Mg. According to the preparation method, Zn, Li, Al, Cu, Mn and other rare-earth-free elements are adopted, a novel design method of the double-configuration high-modulus-nanophase reinforced high-strength high-modulus magnesium alloy is utilized, the modulus of the alloy is improved through micron-scale primary high-modulus second phase precipitation separated out of the alloy, a nanoscale secondary precipitation strengthening phase is regulated and controlled through a subsequent heat treatment process, the strength and toughness of the alloy are guaranteed, and the high-strength high-modulus magnesium alloy is obtained. Therefore, cooperative control of low cost, high modulus and high strength and toughness is achieved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

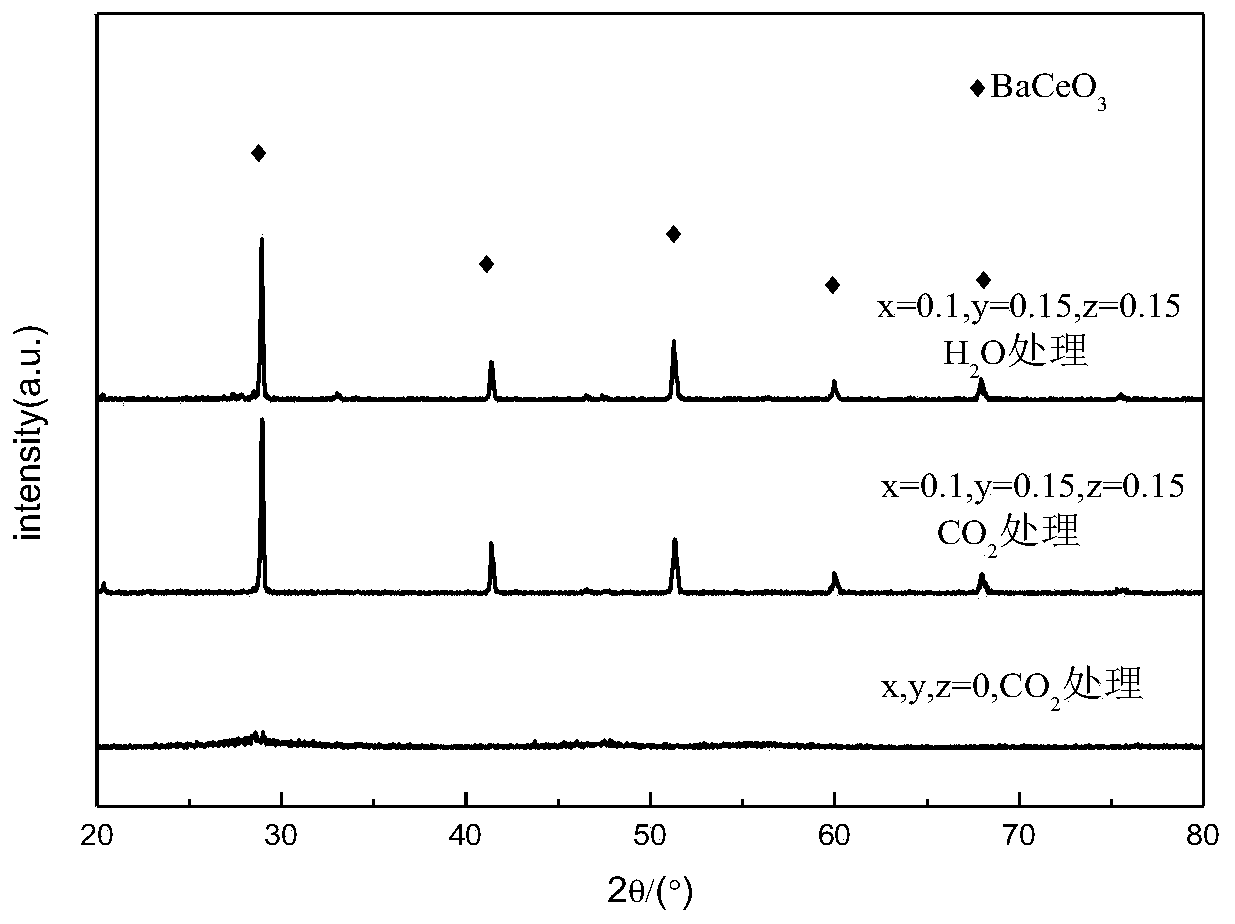

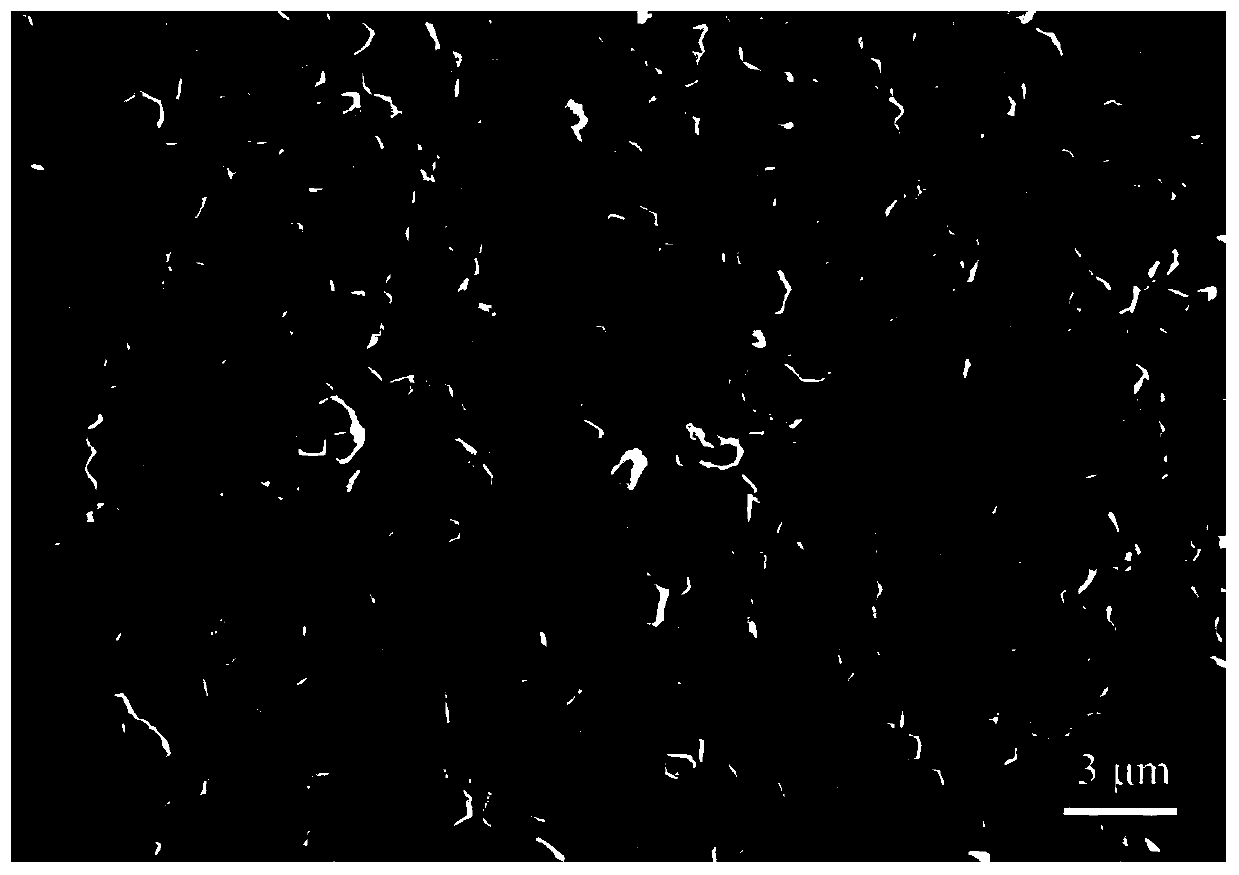

Double-doped BaCeO3-based proton conduction electrolyte material as well as preparation and application thereof

PendingCN110707346AAddressing Chemical Stability IssuesImprove sintering performanceElectrolytesFuel cellsFuel cellsPhysical chemistry

The invention relates to the technical field of fuel cell electrolytes, in particular to a double-doped BaCeO3-based proton conduction electrolyte material as well as preparation and application thereof. The double-doped BaCeO3-based proton conduction electrolyte material is prepared by doping different elements to Ba and Ce sites in a BaCeO3 material and taking the nano antimony tin oxide powderas an additive, wherein the Ba site in the BaCeO3 material is doped with K, the Ce site in the BaCeO3 material is doped with Zr and Sm at the same time, so that the chemical stability problem of the BaCeO3 electrolyte material in an acid gas and an H2O environments can be solved, and the sintering performance of the BaCeO3 electrolyte material is remarkably improved. In addition, the ATO is used as an additive, so that the sintering performance and the proton conduction performance can be further improved.

Owner:GUANGDONG UNIV OF TECH

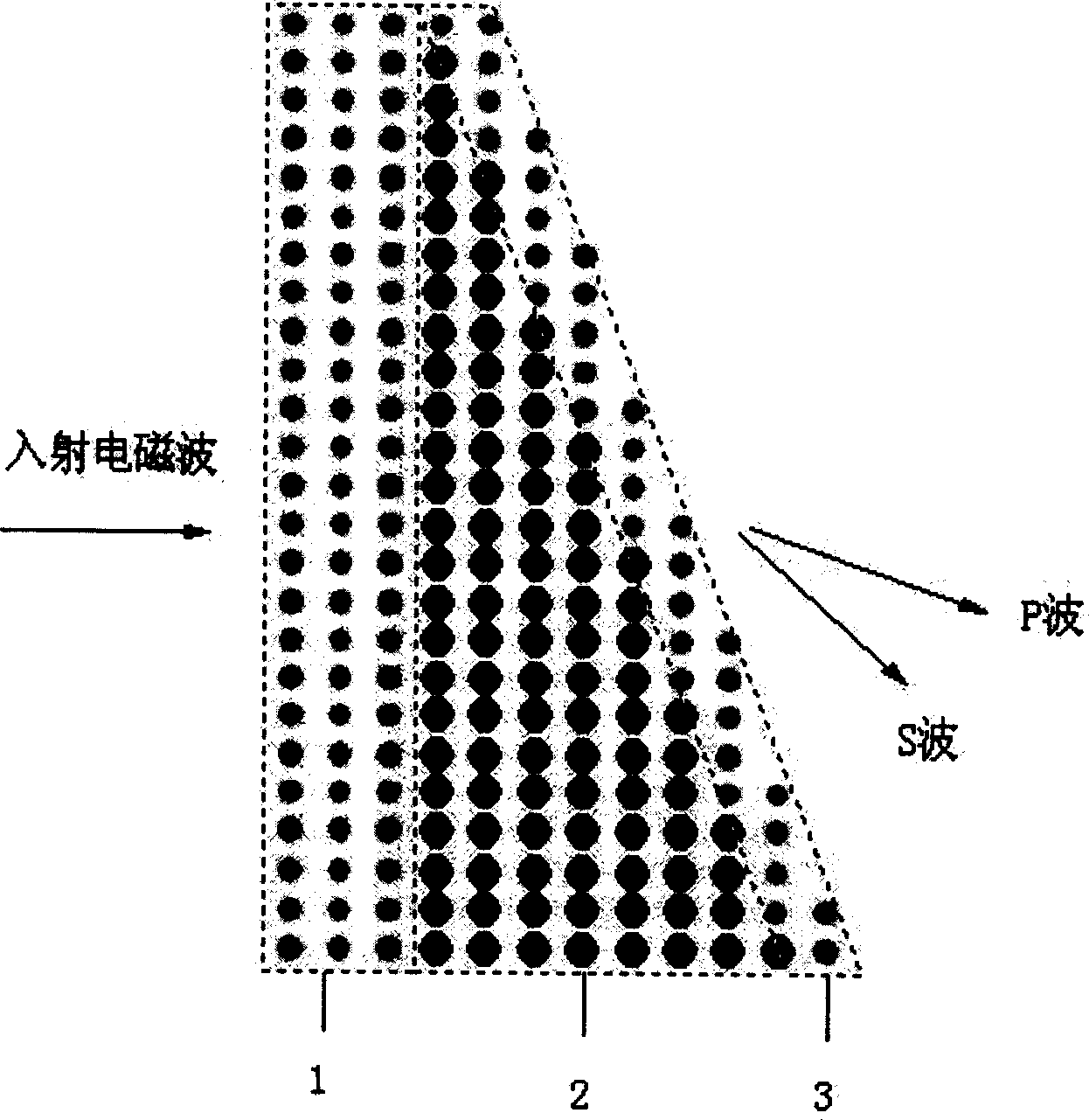

Two-dimensional photon crystal polarization beam dividing device

InactiveCN1304859CHigh degree of polarizationPolarization constantPolarising elementsDielectricPolarimeter

The planar photon crystal bundle-dispersing polarimeter is characterized in that it's a planar seasonal structure. It's structured by inserting the dielectric stick to the background media or form a air stick by any measure in the solid background media whose refractive index is much higher than that of the dielectric stick. From left to right along the incident direction of the electromagnetic wave, the seasonal structure is a quadrangle. The left parallel side that is also the incident side covers all the incident wave beams, and has a angle with the incident electromagnetic wave; the right parallel side covers all the outdiffusing wave beams. The rest two sides are both out of the transmission bound of the wave beam. This invention has an advantage that the fixity of all the standards of the photon crystal itself won't metamorphose. When the work wavelength is the same, the crystal lattice constant of this invention is much smaller than that of the present planar photon crystal bundle-dispersing polarimeter. Therefore it's portable and cabinet.

Owner:TSINGHUA UNIV

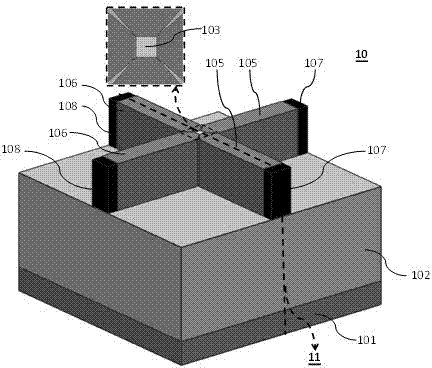

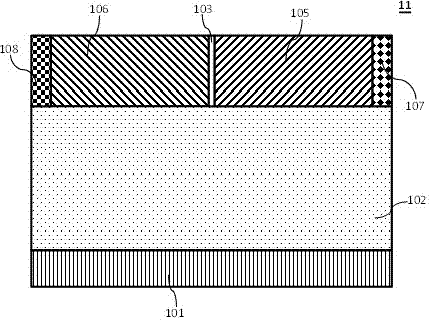

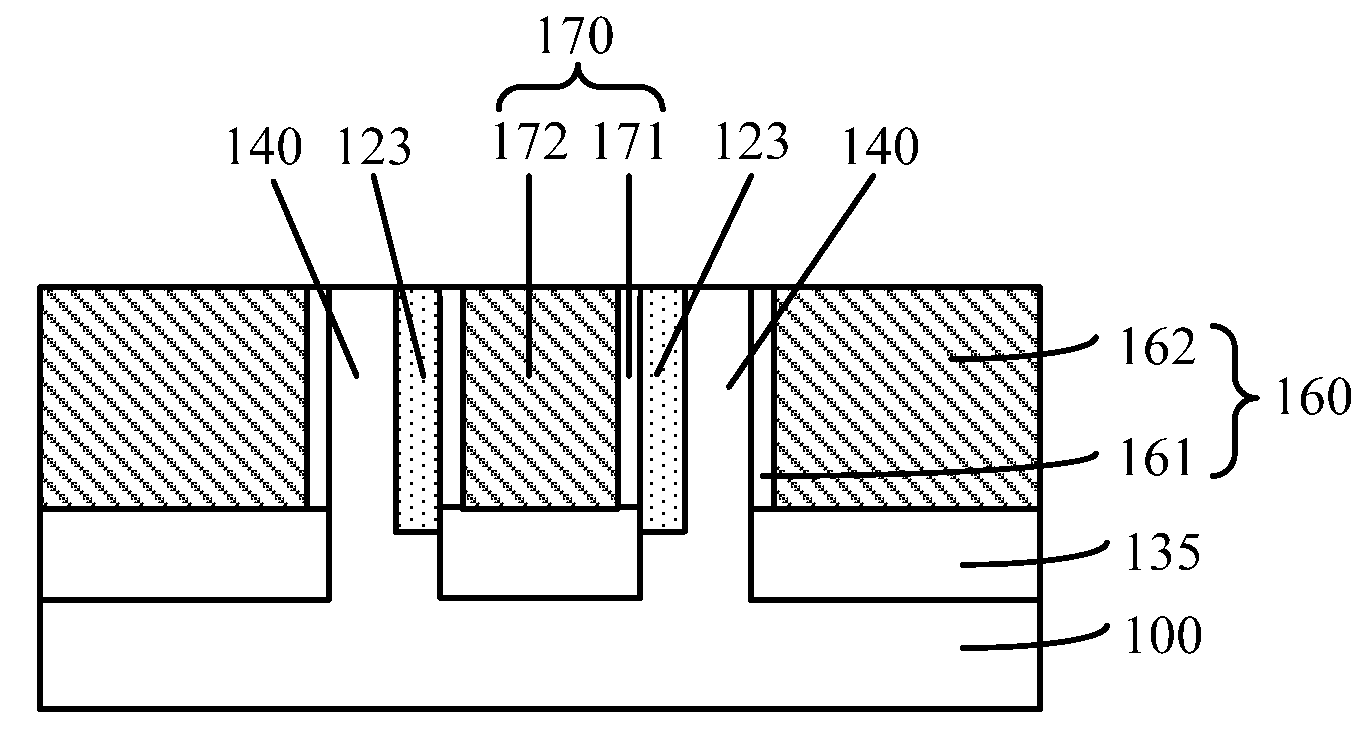

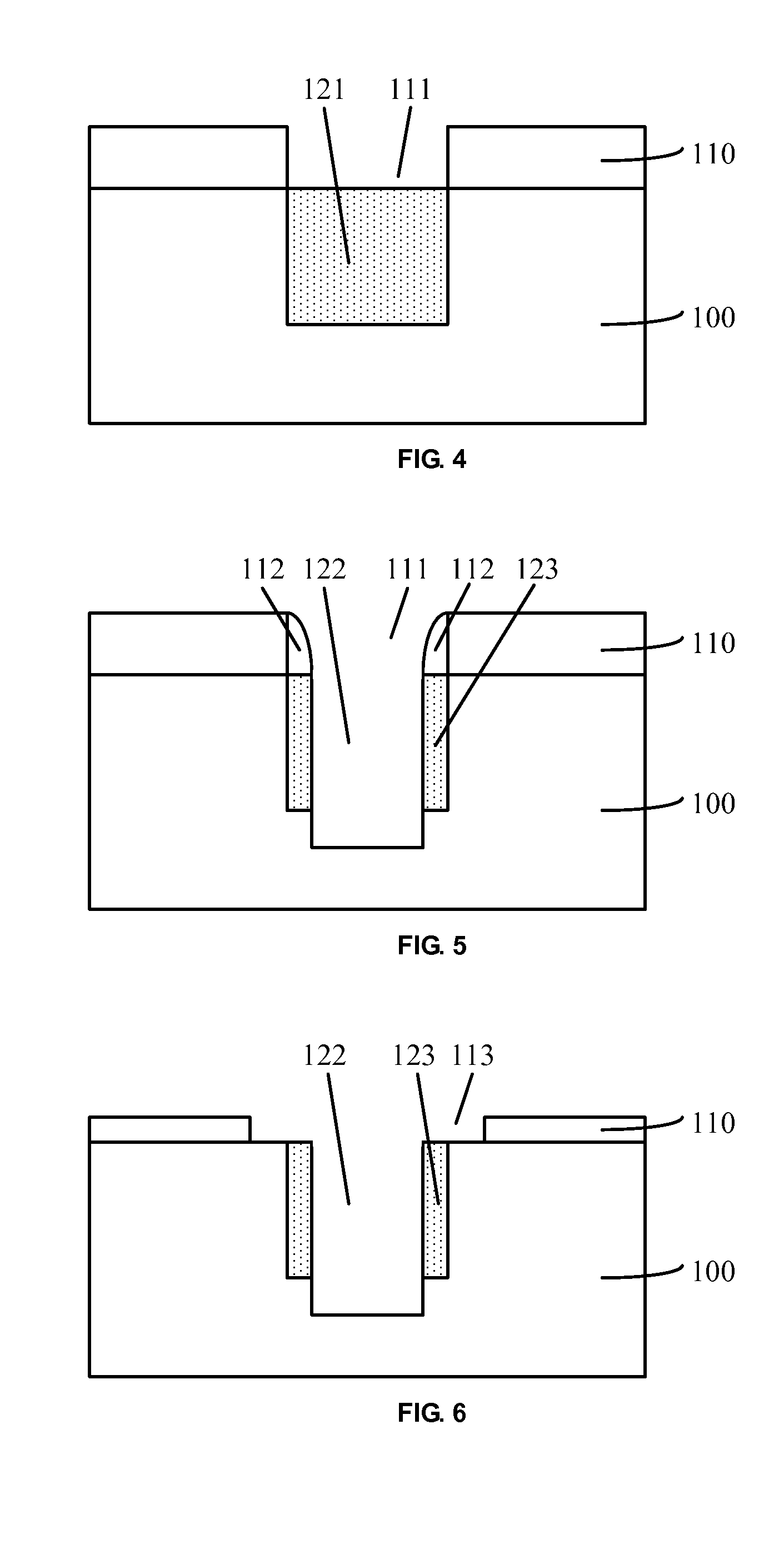

Semiconductor device and fabrication method

ActiveUS9123812B2High carrier mobilityThe lattice constant decreasesSemiconductor devicesSemiconductor packageSemiconductor device

Semiconductor devices and fabrication methods are provided. In an exemplary method, a semiconductor layer including a first opening can be provided. The first opening can be filled with a stress material. The stress material can then be etched to form a second opening having a width less than a width of the first opening to leave a stress material layer in the semiconductor layer and on each sidewall of the second opening. The semiconductor layer can be etched to form a fin structure on a sidewall surface of the stress material layer. A main gate structure can be formed on the sidewall surface of the fin structure. A back gate structure can be formed on the sidewall surface of the stress material layer.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Preparation method of efficient electrode plate

ActiveCN112759037AImprove conductivityImprove anti-passivation performanceWater/sewage treatmentOxygen evolutionBinding force

The invention discloses a preparation method of an efficient electrode plate. The preparation method comprises the following steps: (1) preparing a base material; (2) carrying out surface treatment of the base material; (3) coating a substrate layer; (4) coating a middle layer; (5) coating a surface layer; and (6) sintering. A precursor solution A is used as the substrate layer to seal the bottom of the substrate, so that the binding force between the active components of the substrate layer and the substrate is effectively improved, the conductivity and passivation resistance of the substrate are enhanced, and the service life of the electrode is prolonged in the use process. A precursor solution B is adopted as the middle layer, so that on one hand, cracks of the coating are reduced, diffusion and permeation of oxygen generated in the use process to the substrate are further slowed down, and generation of a high-resistance layer is reduced or hindered; and on the other hand, the oxygen evolution potential of the electrode is improved. A precursor solution C is adopted as the surface layer, so that the poisoning effect of sewage on the active coating can be effectively avoided.

Owner:宜兴艾科森生态环卫设备有限公司

Gallium nitride-based high electron mobility transistor epitaxial wafer and preparation method thereof

ActiveCN112701160BEasy to dopeLower activation energySemiconductor/solid-state device manufacturingSemiconductor devicesGallium nitrideSemiconductor

The present disclosure provides a gallium nitride-based high electron mobility transistor epitaxial wafer and a preparation method thereof, belonging to the technical field of semiconductors. The gallium nitride-based high electron mobility transistor epitaxial wafer includes a substrate and a buffer layer, a high-resistance buffer layer, a channel layer, an AlGaN barrier layer, and a cap layer stacked on the substrate, and the cap layer includes A first semiconductor layer and a second semiconductor layer stacked in sequence, the first semiconductor layer is P-type doped In x Ga 1‑x N / MgN superlattice structure, 0<x<1, the second semiconductor layer is P-type doped Al y Ga 1‑y N / In z Ga 1‑z N superlattice structure, 0<y<1, 0<z<1. The epitaxial wafer can increase the doping concentration of Mg in the cap layer to form an enhancement type HEMT and at the same time improve the crystal quality of the enhancement type HEMT epitaxial wafer.

Owner:HC SEMITEK ZHEJIANG CO LTD

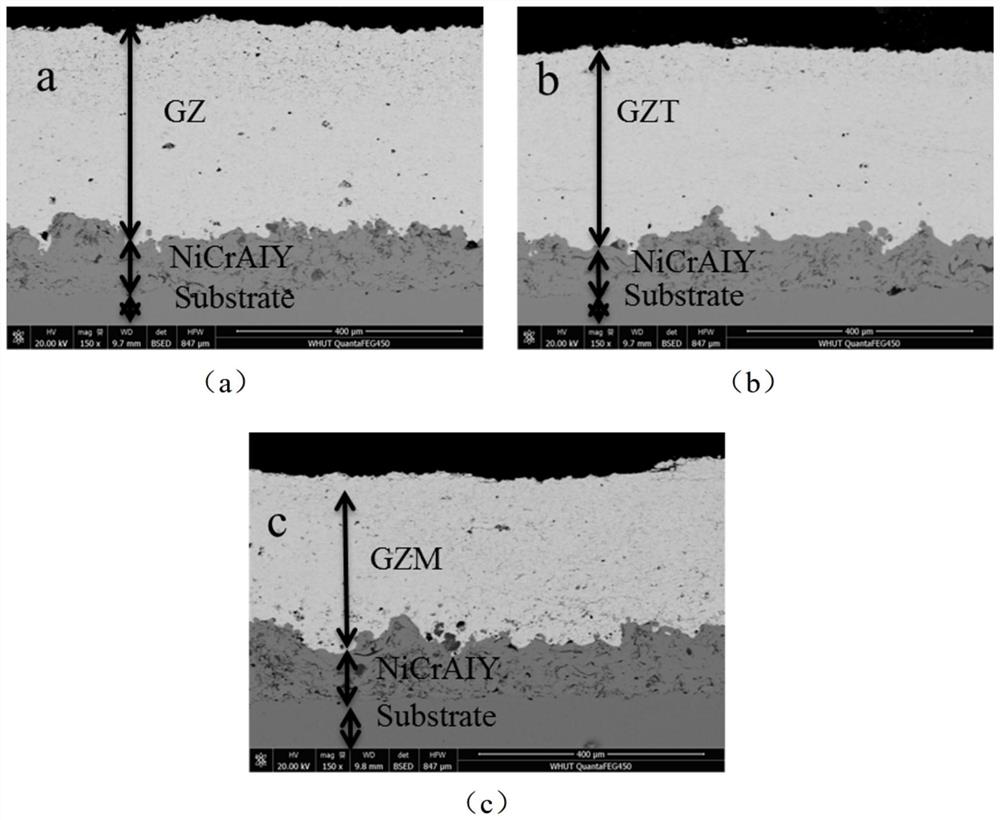

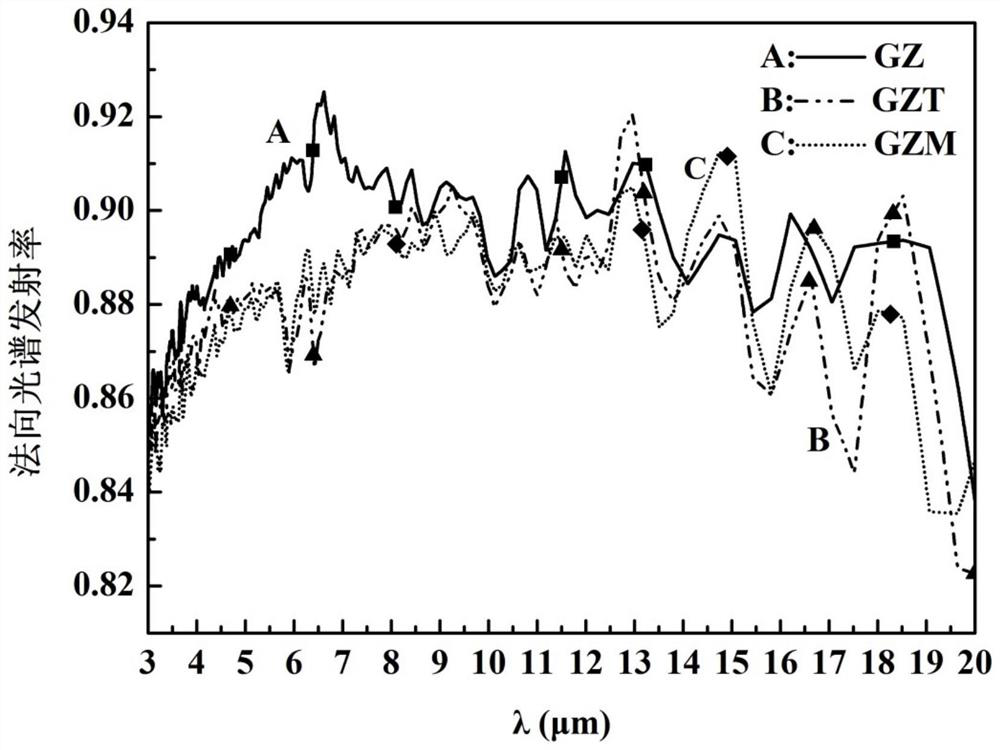

High-temperature high-emissivity heat dissipation coating and its preparation method and application

ActiveCN111118438BReduce the temperatureHigh thermal expansionMolten spray coatingEmissivityPhysical chemistry

The invention provides a high-temperature and high-emissivity heat dissipation coating and its preparation method and application. The preparation method of the heat dissipation coating is: spray ceramic powder on the surface of a substrate with a bonding layer by atmospheric plasma spraying technology to prepare a bonding layer formed on the surface of the substrate. High-temperature and high-emissivity heat dissipation coating containing Gd-Zr, Gd-Zr-Ti or Gd-Zr-Mg system multiple oxides on the ceramic powder, calculated by mass percentage, Gd 2 o 3 The content is 40-60%, ZrO 2 The content is 40-60%, TiO 2 The content is 0-5%, and the MgO content is 0-5%. The invention can solve the problems of low emissivity at high temperature, low service temperature and unstable phase structure of the existing thermal insulation coating, and the prepared thermal insulation coating not only has good thermal insulation performance, but also can dissipate heat well. by Mg 2+ or Ti 4+ Partial replacement of the parent material can also effectively improve the absorption in the near-infrared band.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com