Blue light-ultraviolet continuously-adjustable aluminate fluorescent powder and preparation method thereof

A fluorescent powder and aluminate technology, applied in the field of rare earth luminescent materials, can solve the problems of inability to enhance the stability of fluorescent powder, singleness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The chemical formula of the blue-light ultraviolet continuously adjustable aluminate phosphor is: CeAl 11-x Si x o 18-x N x , in this embodiment, take x=0.1. Its preparation method includes the following steps: (1), fully grind and mix cerium oxide, aluminum oxide, silicon nitride and silicon oxide according to the atomic weight ratio of each element in the chemical formula of the above-mentioned phosphor; (2), and then mix the above-mentioned mixed powder , placed in a boron nitride boat and placed in a sintering furnace, vacuumed to 10 -3 Pa, nitrogen gas is introduced to make the nitrogen pressure reach an atmospheric pressure, and the flow rate is 0.3L / min; (3) the temperature is raised from room temperature to 1200°C at a rate of 3°C / min, and the temperature is kept at 8 hours; (4), the sintered product can be ground The blue-light ultraviolet continuously adjustable aluminate phosphor is obtained.

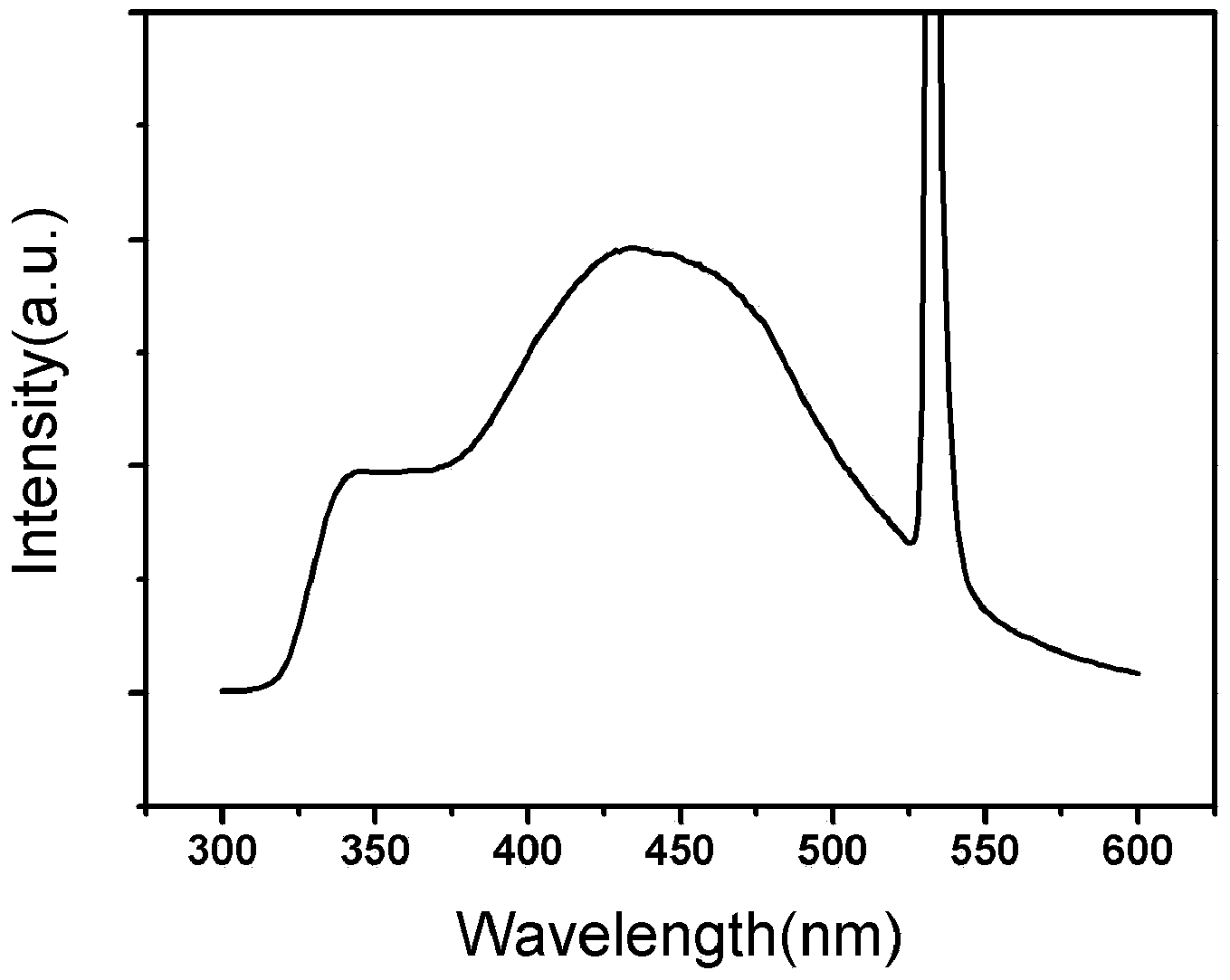

[0019] In this embodiment, the emission spectrum of the blue...

Embodiment 2

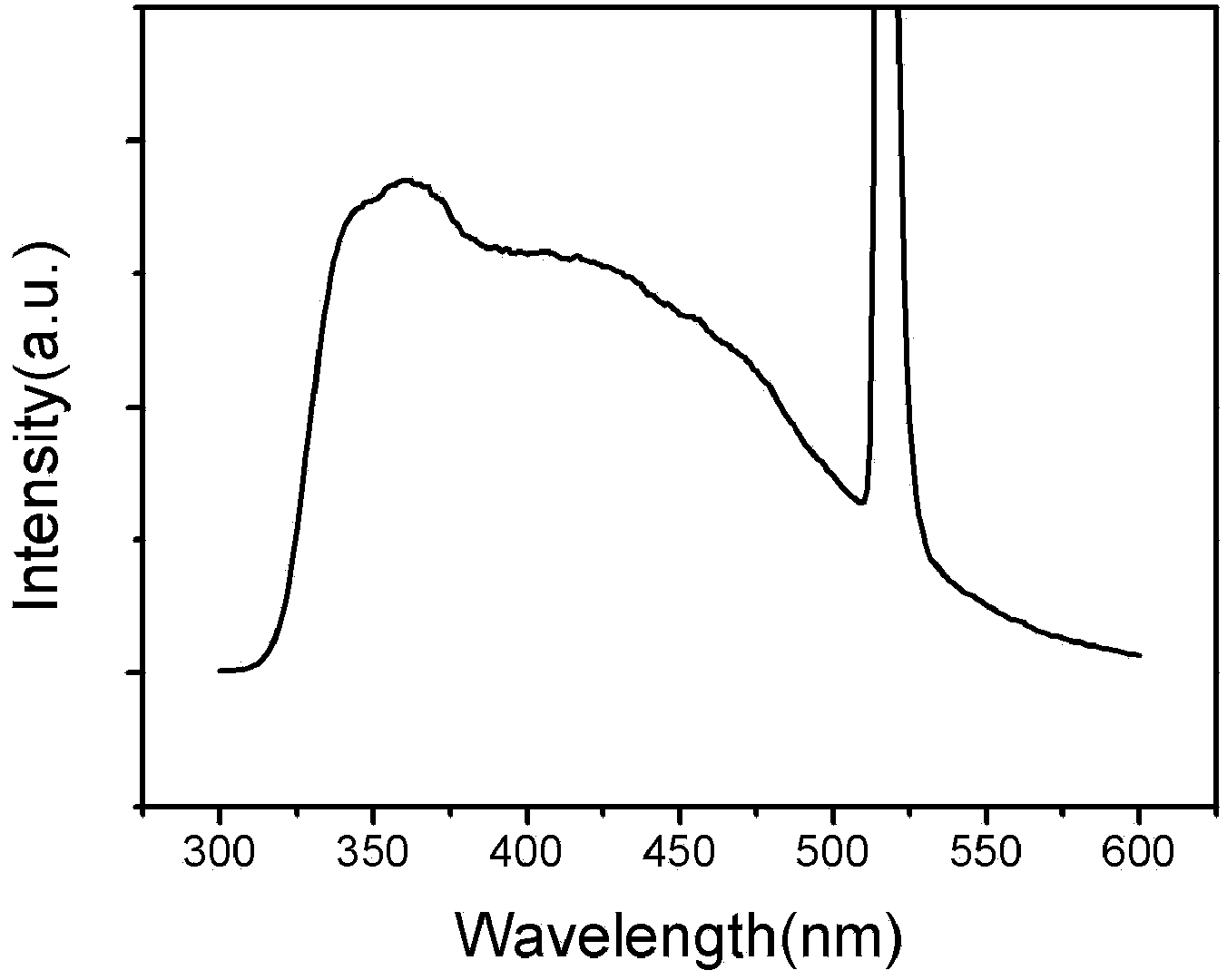

[0021] The chemical formula of the blue-light ultraviolet continuously adjustable aluminate phosphor is: CeAl 11-x Si x o 18-x N x , in this embodiment, take x=1.3. The preparation method includes the following steps: (1) thoroughly grinding and mixing cerium oxide, aluminum oxide, silicon nitride and silane according to the atomic weight ratio of each element in the chemical formula of the phosphor powder; (2) and then mixing the above mixed powder, Put it in a boron nitride boat and place it in a sintering furnace, and vacuumize it to 10 -3 Pa, a mixed gas of nitrogen and hydrogen is introduced, the volume fraction of hydrogen is 10%, the air pressure is brought to an atmospheric pressure, and the flow rate is 0.1L / min; (3), the temperature is raised from room temperature at 20°C / min to 1500°C, and the temperature is kept for 4 Hours; (4) After grinding the sintered product, the aluminate phosphor powder with continuously adjustable blue light and ultraviolet light can b...

Embodiment 3

[0024] The chemical formula of the blue-light ultraviolet continuously adjustable aluminate phosphor is: CeAl 11-x Si x o 18-x N x , in this embodiment, take x=4. The preparation method includes the following steps: (1) fully grinding and mixing cerium nitrate, aluminum nitrate, silicon nitride and silicon oxide according to the atomic weight ratio of each element in the chemical formula of the above-mentioned phosphor; (2) then putting the above-mentioned mixed powder into Put it into the boron nitride boat and place it in the sintering furnace, and vacuumize it to 10 -3 Pa, a mixed gas of nitrogen and hydrogen is introduced, the volume fraction of hydrogen is 20%, the pressure is brought to an atmospheric pressure, and the flow rate is 1L / min; (3) The temperature is raised from room temperature to 1800°C at a rate of 10°C / min, and the temperature is kept for 1 hour; (4) Just grind the sintered product.

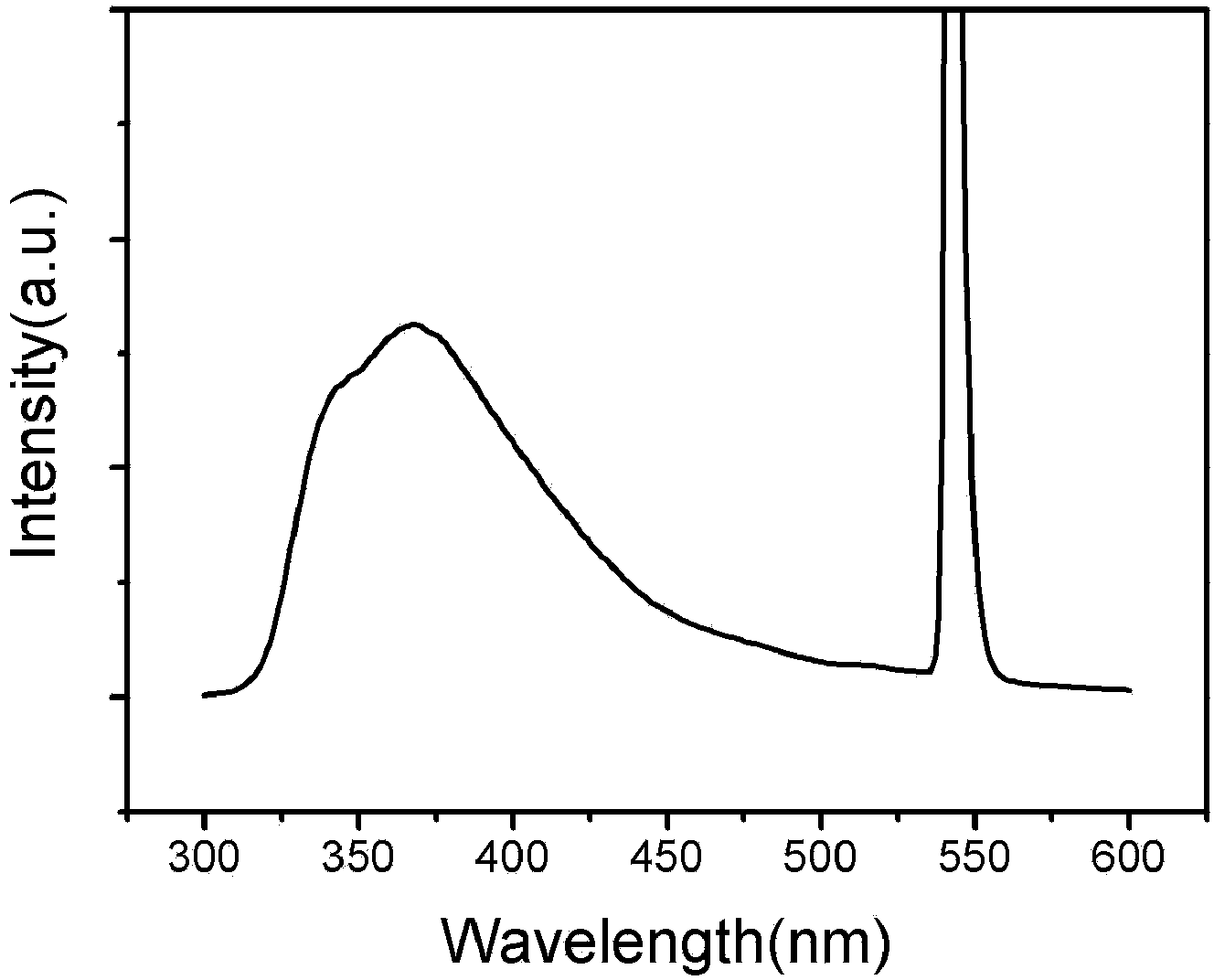

[0025] In this embodiment, the emission spectrum of the blue-light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com