Rare earth polishing powder and preparation method thereof

A technology of rare earth polishing powder and polishing powder, which is applied in the direction of polishing compositions containing abrasives, etc., can solve the problem that polishing powder cannot be used for precision polishing, and achieve the effect of enhancing wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

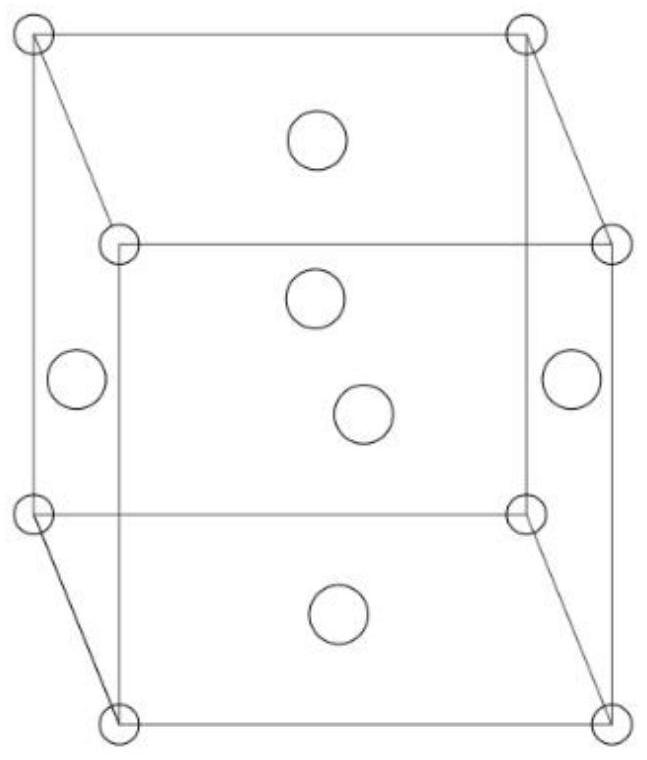

[0074] The preparation method of rare earth polishing powder, concrete steps are as follows:

[0075] Step 1: Prepare rare earth fluorocarbonates of rare earth elements lanthanum, cerium, samarium, and yttrium, and the amount of fluorine added is 5% to 10% of REO;

[0076] Raw materials are single rare earth chlorides, mixed rare earth chlorides, lanthanum-rich rare earth chlorides, rare earth carbonates or rare earth nitrates, of which lanthanum (La 2 o 3 / TREO>75%), samarium (Sm 2 o 3 / TREO>99.9%), cerium (CeO 2 / TREO=99.95%), Yttrium (Y 2 o 3 / TREO=99.999%).

[0077] Preparation method 1 of rare earth fluorocarbonate: Mix the solutions of lanthanum chloride, cerium chloride, samarium chloride, and yttrium chloride according to the set ratio, put the mixed material liquid into the reaction kettle, and adjust the rare earth element oxide (REO) Concentration = 50-100g / L, control the reaction temperature at 40°C-65°C, add metered hydrofluoric acid, phosphoric acid, and a...

Embodiment 1

[0115] With 6000ml lanthanum cerium rare earth chloride feed solution (REO=274g / L, CeO 2 / TREO=74.28%, La 2 o 3 / TREO=25.72%), 714ml samarium chloride feed solution (REO=126g / L, Sm 2 o 3 / TREO=99.2%), 412ml yttrium chloride feed solution (REO=80.2g / L, Y 2 o 3 / TREO=99.99%) were uniformly mixed, placed in a 50L enamel reaction kettle, and 18L deionized water was added. Stir well and heat to 55°C. This mixed liquid is designated as liquid A.

[0116] Take NH 4 HCO 3 Solution (120g / L) 22L is packed in another 50L enamel reaction kettle, add 250g hydrofluoric acid (50%, wt%), 82g phosphoric acid (85%, wt%), this solution is heated to 55 ℃. This mixed liquid is designated as liquid B.

[0117] Add solution B to solution A at a rate of 350ml / min for reaction. After the reaction, it was aged at 40° C. for 8 hours. Aspirate the supernatant, add 20L deionized water, keep stirring at 40°C to wash the precipitate, and repeat the washing once. Suction filter with Buchner funn...

Embodiment 2

[0125] Weigh 2000g lanthanum cerium carbonate (REO=48.78%, CeO 2 / TREO=65%), 445g samarium carbonate (REO=45.12%, Sm 2 o 3 / TREO=99.5%), 100g yttrium carbonate (REO=44.38%,

[0126] Y 2 o 3 / TREO=99.5%), put in a 5000ml beaker, add 1.2L deionized water, heat to 40°C, add 500g hydrofluoric acid (50%, wt%), and place the mixture at 40°C for 16 hours.

[0127] Transfer the above mixed solution into a 50-liter disperser, add 5 L of water, add 5500 g of lanthanum cerium carbonate, and disperse vigorously for 30 minutes. Filter with suction and dry at 150°C. The dried product is placed in a crucible and calcined in a muffle furnace in the calcination mode 1. The fired product is classified to obtain the quaternary rare earth polishing powder of the present invention, which is denoted as P-2, and the measurement results are shown in Table 3.

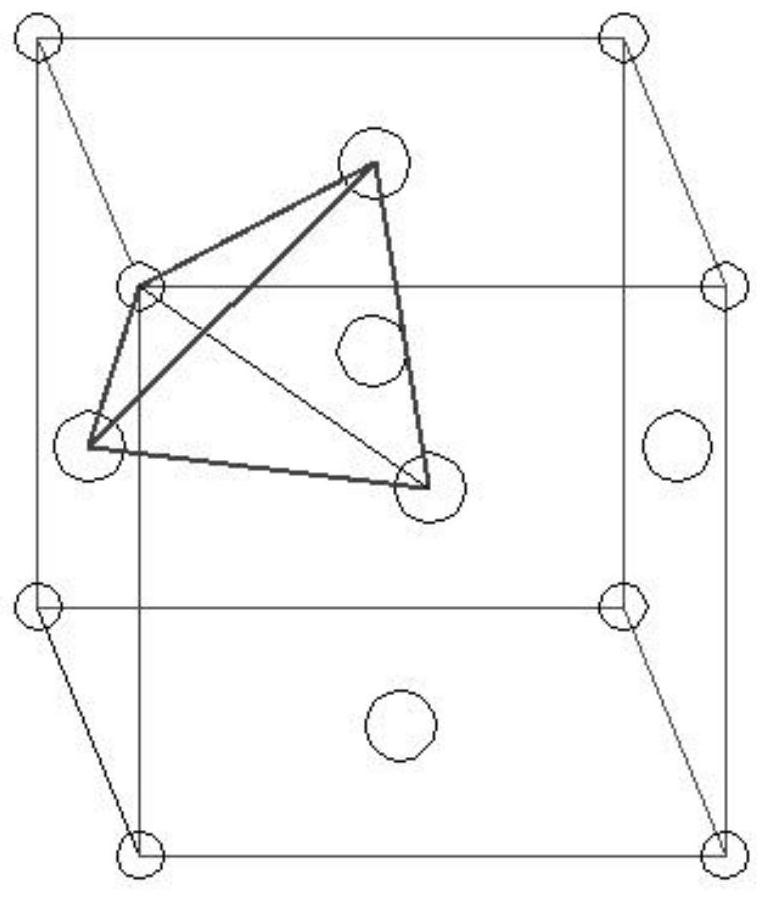

[0128] Such as Figure 8 Shown is the XRD diffraction pattern of the quaternary rare earth polishing powder in Example 2 of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com