TiAlN ultra-hard composite coating provided with hardness gradient layer for supporting and preparation method of TiAlN ultra-hard composite coating

A technology of hardness gradient and hard coating, applied in coating, superimposed layer plating, metal material coating process, etc., can solve the problems of insufficient bearing capacity, unreliable bonding force of hard film, poor temperature resistance, etc. , to achieve the effect of improving life expectancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] like Figure 4As shown, a TiAlN composite superhard coating supported by a hardness gradient layer, the superhard coating is a three-layer structure consisting of a base material, an expansion layer and a deposition layer from bottom to top; the base material is 300M high-strength steel; the expansion layer is a plasma nitrocarburizing layer; the deposition layer is a nitrogen-aluminum-titanium coating 1.

[0034] The hardness of the plasma nitrocarburizing layer gradually increases from bottom to top.

[0035] The thickness of the plasma nitrocarburizing layer is 100 μm; the thickness of the titanium nitride aluminum coating is 3 μm.

[0036] A method for preparing a TiAlN composite superhard coating supported by a hardness gradient layer, the steps are as follows:

[0037] 1) The plasma nitrocarburizing layer was prepared on the upper surface of the 300M high-strength steel through the plasma nitrocarburizing technology enhanced by the hollow cathode effect and fiel...

Embodiment 2

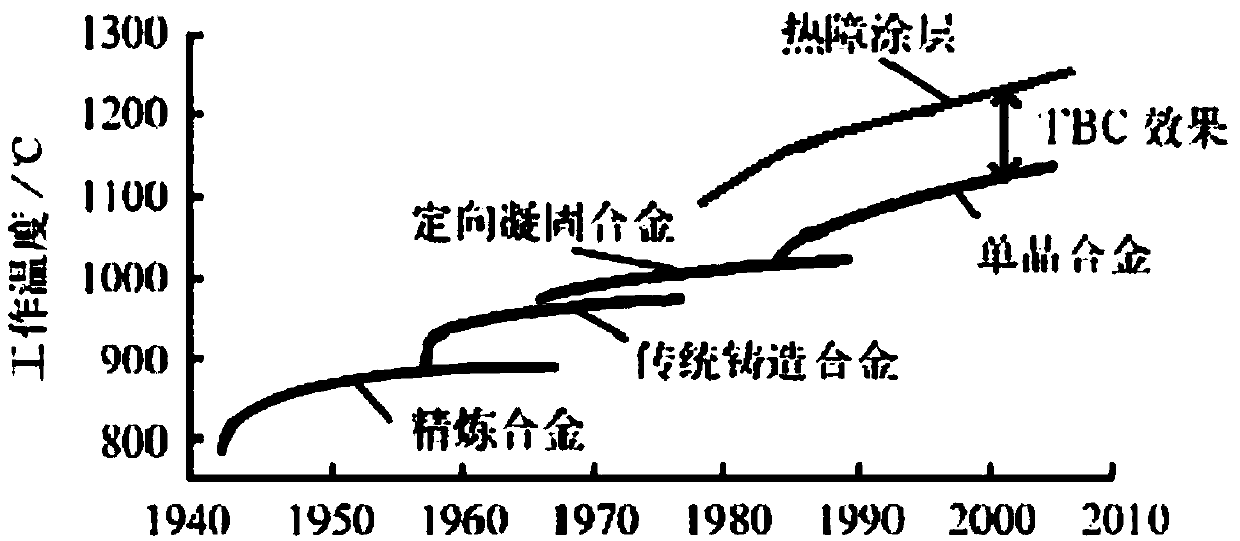

[0045] like Figure 4 As shown, a TiAlN composite superhard coating supported by a hardness gradient layer, the superhard coating is a three-layer structure consisting of a base material, an expansion layer and a deposition layer from bottom to top; the base material is Nickel-based alloy; the expansion layer is a plasma nitrocarburizing layer; the deposition layer is a nitrogen-aluminum-titanium coating.

[0046] The hardness of the plasma nitrocarburizing layer gradually increases from bottom to top.

[0047] The thickness of the plasma nitrocarburizing layer is 200 μm; the thickness of the aluminum nitride titanium coating is 6 μm.

[0048] A method for preparing a TiAlN composite superhard coating supported by a hardness gradient layer, the steps are as follows:

[0049] 1) The plasma nitrocarburizing layer is prepared on the surface of the base material through the plasma nitrocarburizing technology enhanced by the hollow cathode effect and field discharge;

[0050] 2)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com