High-temperature high-emissivity heat dissipation coating and its preparation method and application

A high-emissivity, heat-dissipating coating technology, used in coatings, metal material coating processes, melt spraying, etc., can solve the problems of low emissivity, low service temperature, and unstable phase structure of thermal insulation coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation:

[0026] Gd dried at 1000℃ 2 o 3 , ZrO 2 The raw materials are mixed according to the mass ratio of 60% and 40%, ball milled for 24 hours, dried, solid-phase reaction at 1600°C for 12 hours, mixed with ammonium citrate and gum arabic, ball milled for 72 hours, spray granulated, and vibrating sieved to obtain Ceramic powder with a particle size of about 45-60 μm and good fluidity.

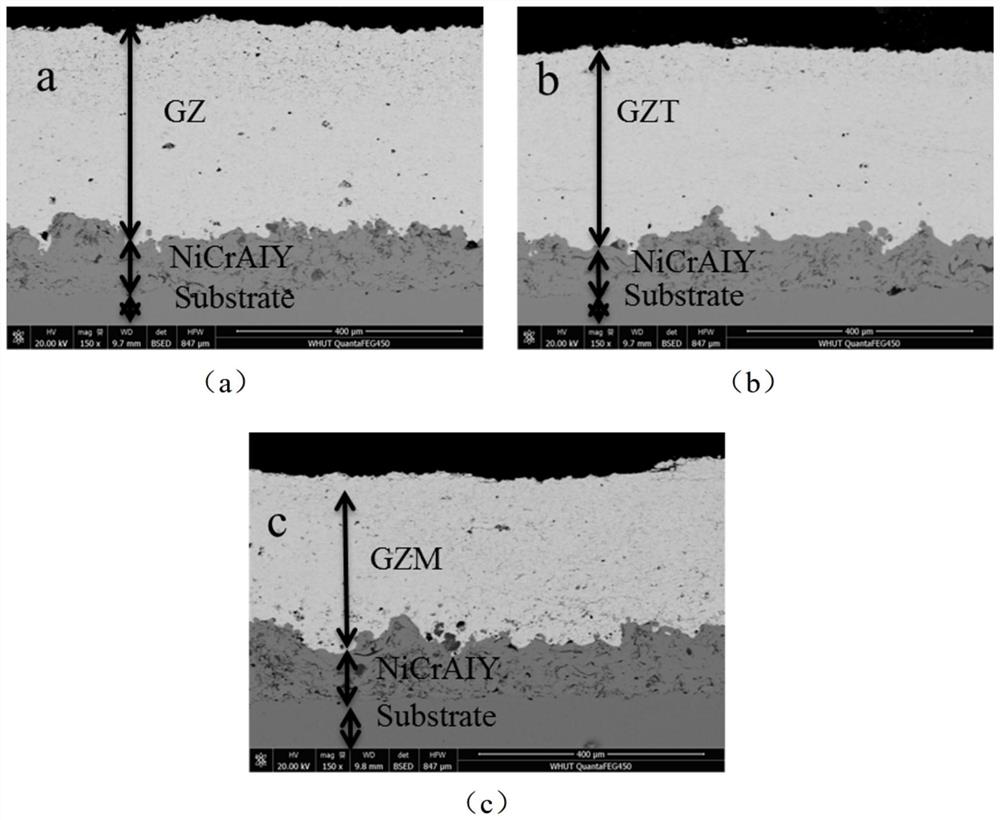

[0027] The ceramic powder is sprayed on the treated superalloy substrate by atmospheric plasma spraying to obtain such as figure 1 (a) The high-temperature high-emissivity heat-dissipating GZ coating shown in (a) has a thickness of 280 μm. The spraying parameters include spraying current 600A, spraying voltage 75V, spraying distance 100mm, ceramic powder feeding rate 15%, plasma gas flow: argon 35L min -1 , Hydrogen 12L·min -1 .

[0028] Performance Characterization:

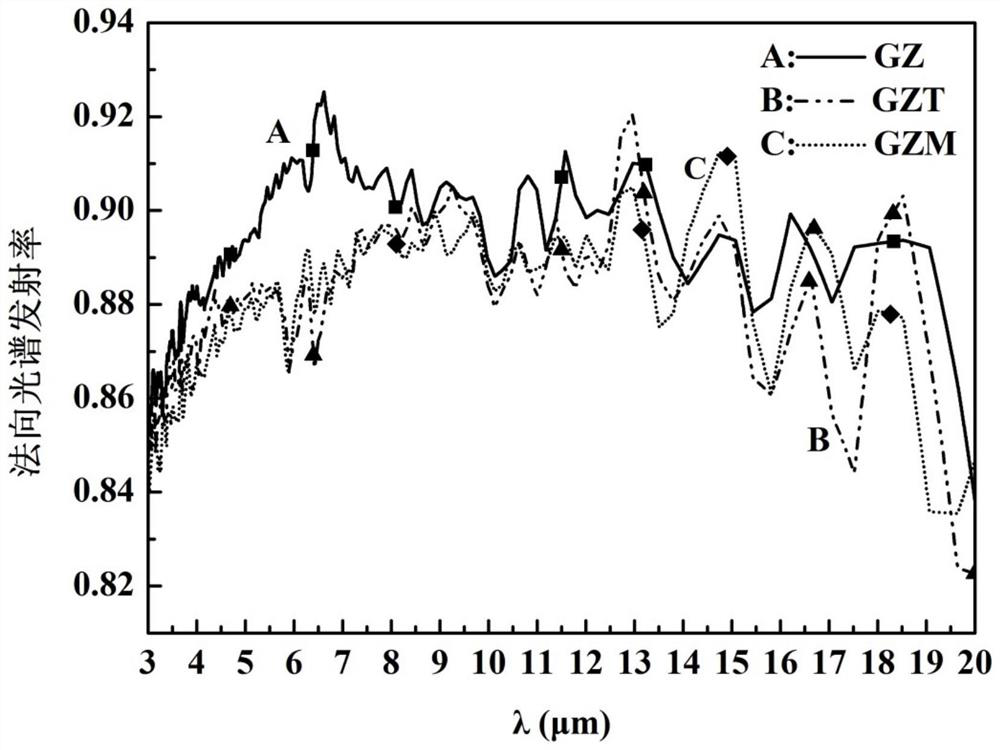

[0029] Such as figure 2 As mentioned above, at 800°C, the average normal spectral emissivity of the GZ...

Embodiment 2

[0031] Preparation:

[0032] Gd dried at 1050°C 2 o 3 , ZrO2 、TiO 2 The raw materials are mixed according to the mass ratio of 59%, 39.5% and 1.5%, ball milled for 24 hours, dried, solid-phase reaction at 1650°C for 12 hours, mixed with ammonium citrate and gum arabic, ball milled for 72 hours, spray granulated, vibrated Sieve to obtain a ceramic powder with a particle size of about 45-60 μm and good fluidity.

[0033] The ceramic powder is sprayed on the treated superalloy substrate by atmospheric plasma spraying to obtain such as figure 1 (b) The high-temperature high-emissivity heat dissipation GZT coating shown in (b) with a thickness of 250 μm. The spraying parameters include spraying current 650A, spraying voltage 70V, spraying distance 105mm, ceramic powder feeding rate 15%, plasma gas flow rate: argon 30L min -1 , Hydrogen 8L·min -1 .

[0034] Performance Characterization:

[0035] Such as figure 2 It is stated that, at 800°C, the average normal spectral emis...

Embodiment 3

[0037] Preparation:

[0038] Gd dried at 1100℃ 2 o 3 , ZrO 2 , MgO raw materials are mixed according to the mass ratio of 55%, 40% and 5%, ball milled for 24 hours, dried, solid-phase reaction at 1650°C for 12 hours, mixed with ammonium citrate and gum arabic, ball milled for 72 hours, spray granulated , vibrating sieving to obtain a ceramic powder with a particle size of about 45-60 μm and good fluidity.

[0039] The ceramic powder is sprayed on the treated superalloy substrate by atmospheric plasma spraying to obtain such as figure 1 (a) High-temperature high-emissivity heat-dissipating GZM coating shown in (a), with a thickness of 300 μm. Among them, the spraying parameters include spraying current 700A, spraying voltage 65V, spraying distance 110mm, ceramic powder feeding rate 15%, plasma gas flow rate: argon 40L min -1 , Hydrogen 5L·min -1 .

[0040] Performance Characterization:

[0041] Such as figure 2 As mentioned above, at 800°C, the average normal spectral...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com