Patents

Literature

37results about How to "Effective heat protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Double-layer-wall heat insulation screen used for afterburner

InactiveCN103968418AReduce heat load and gas flow lossReduce wall temperatureContinuous combustion chamberCombustion chamberEngineering

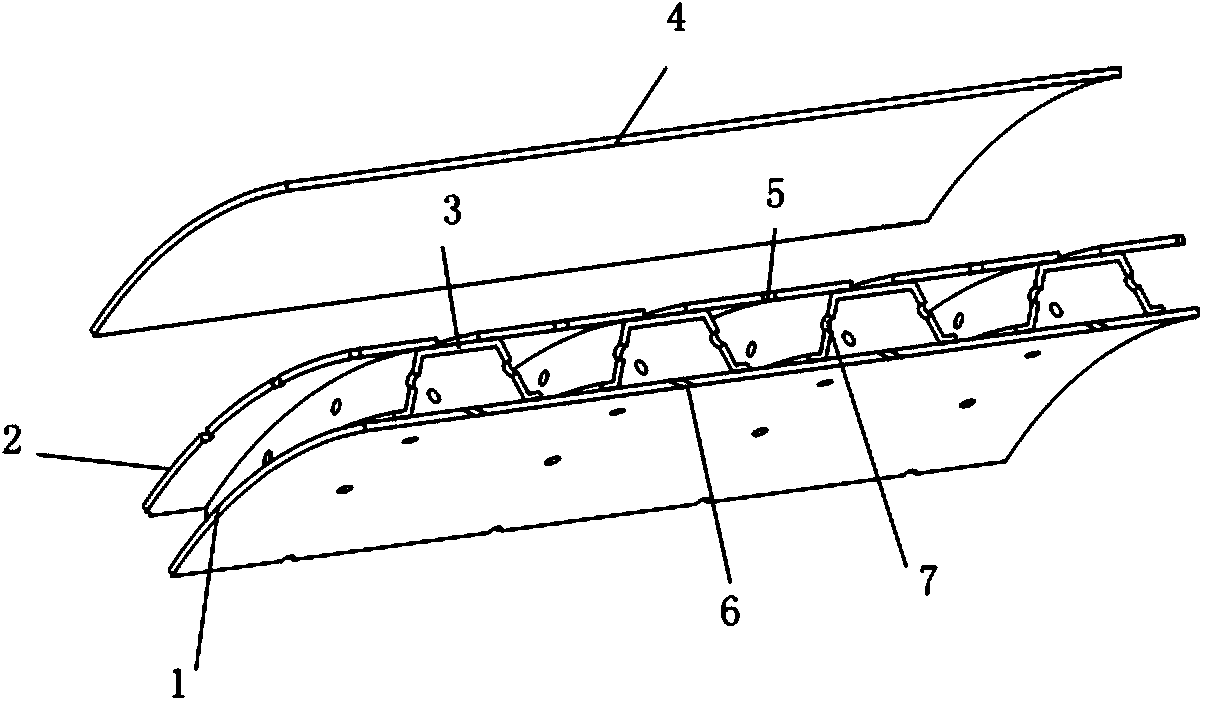

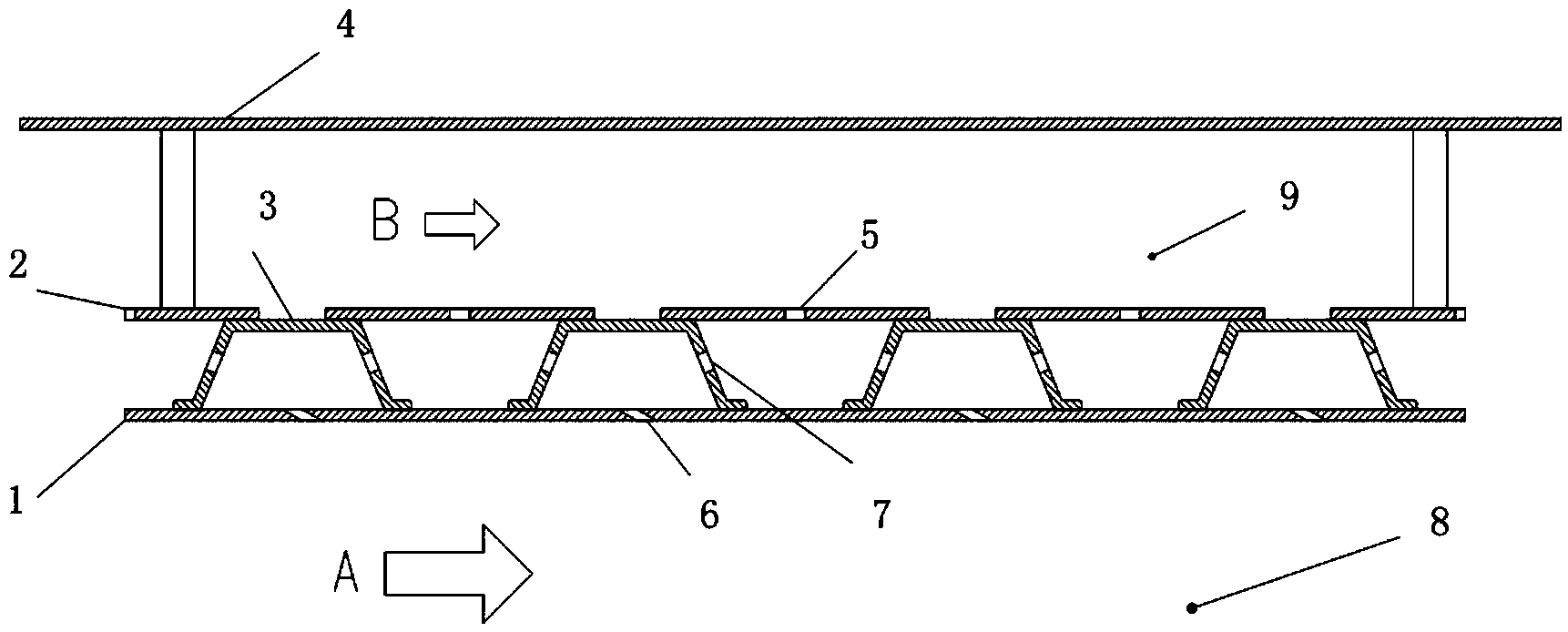

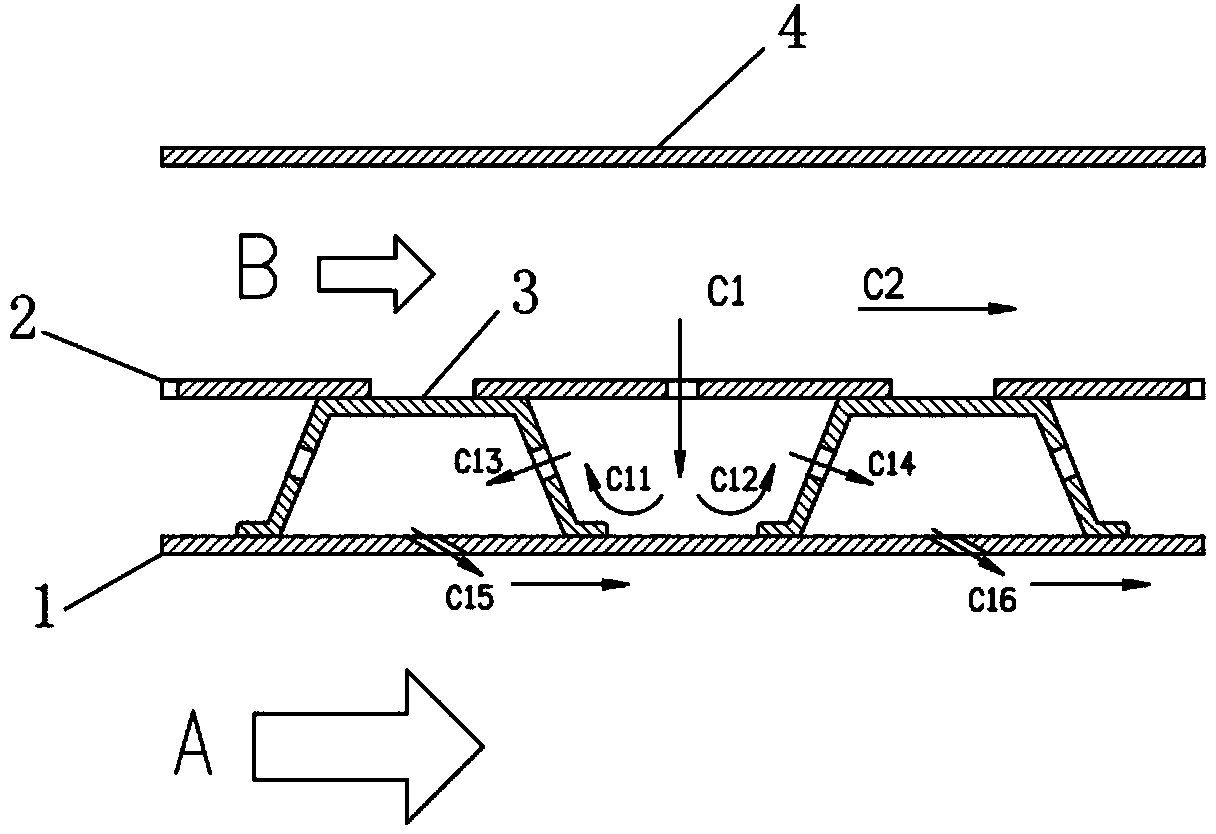

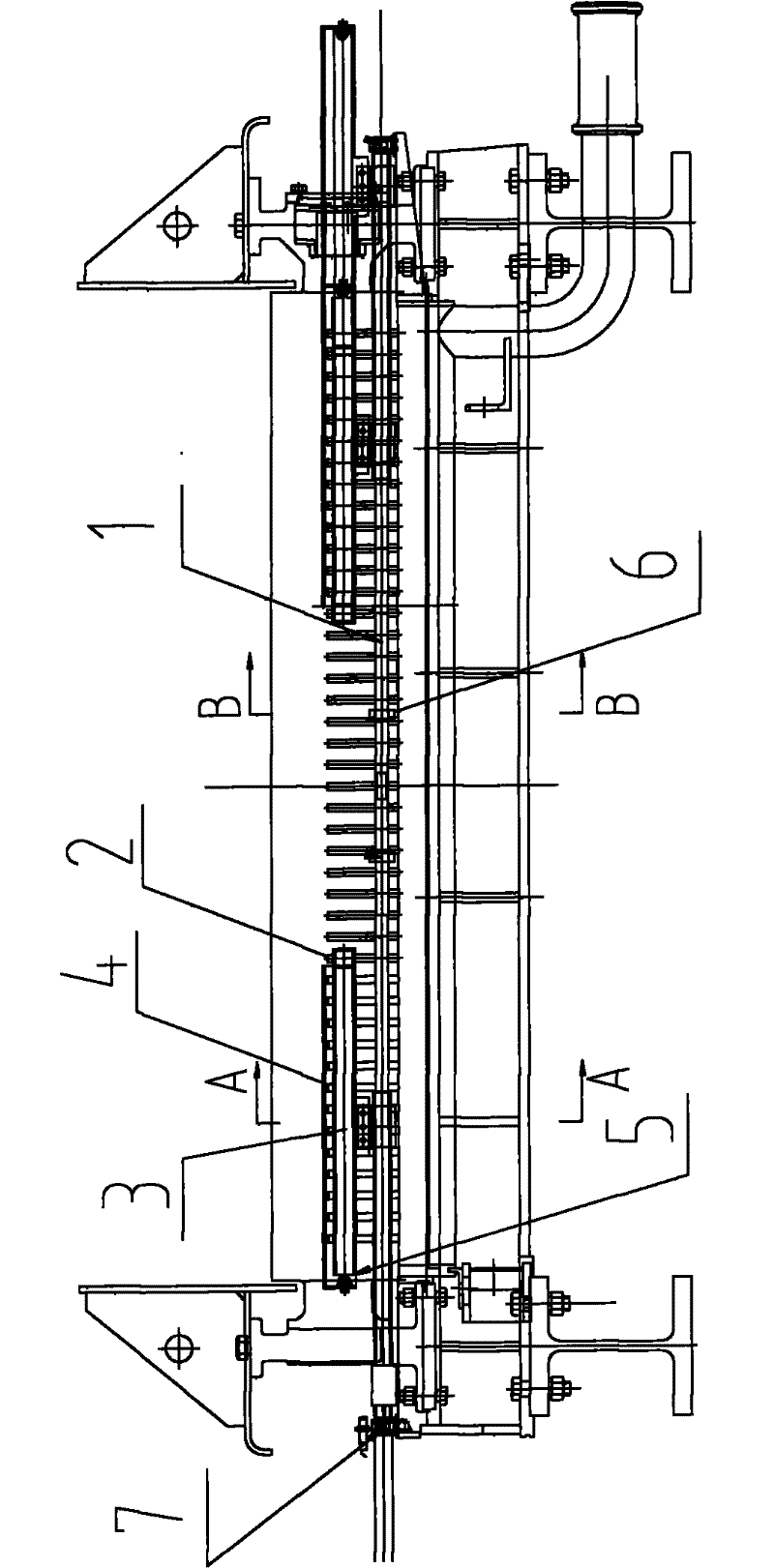

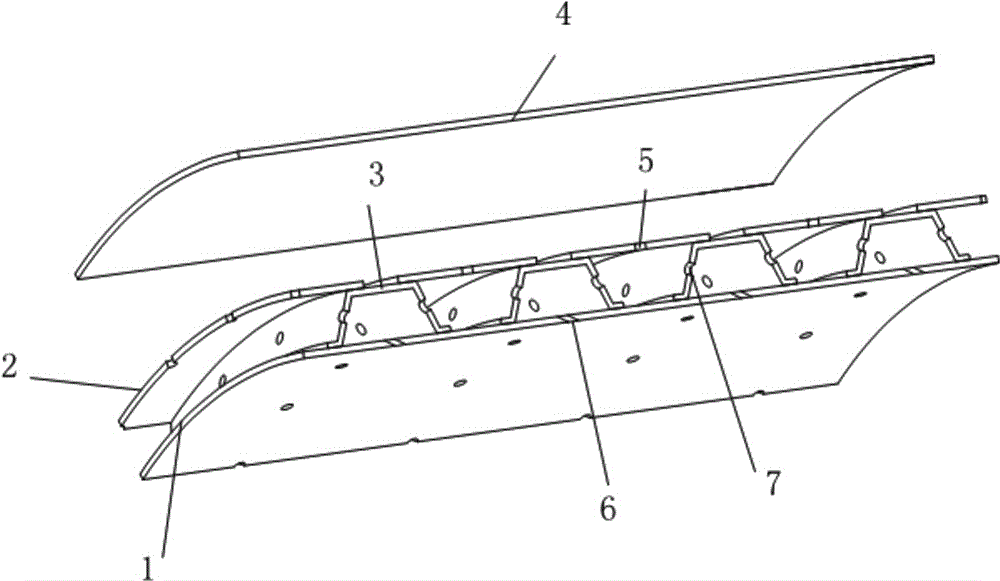

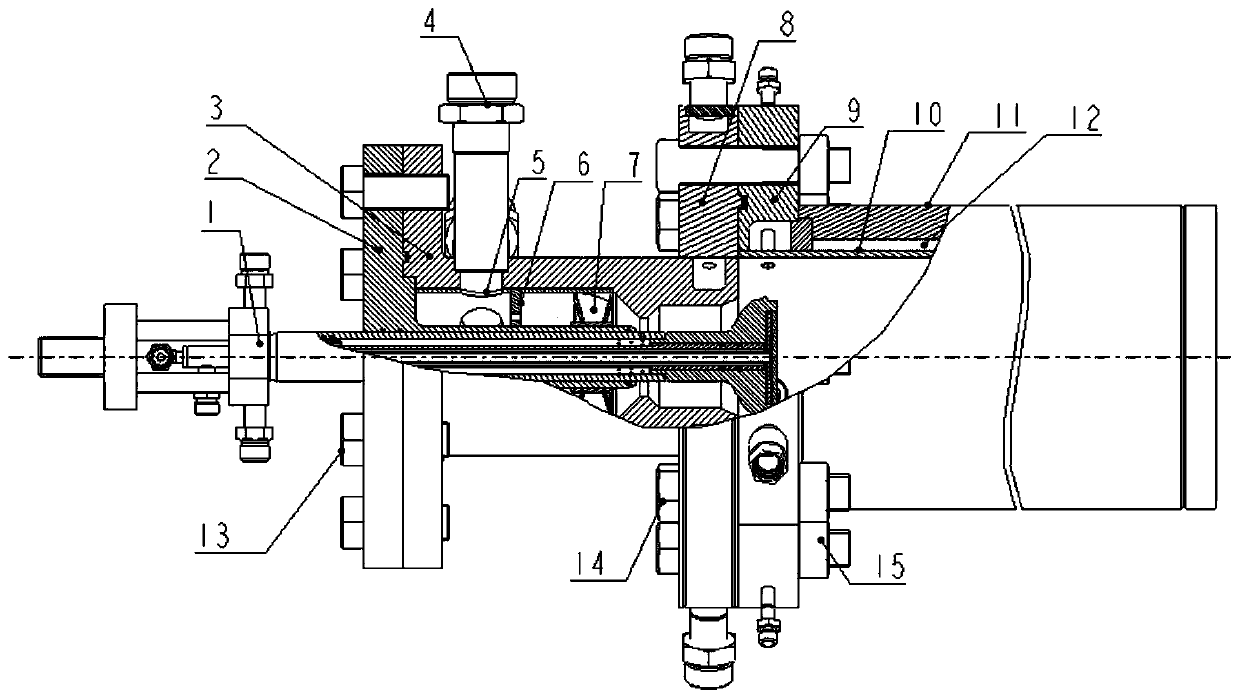

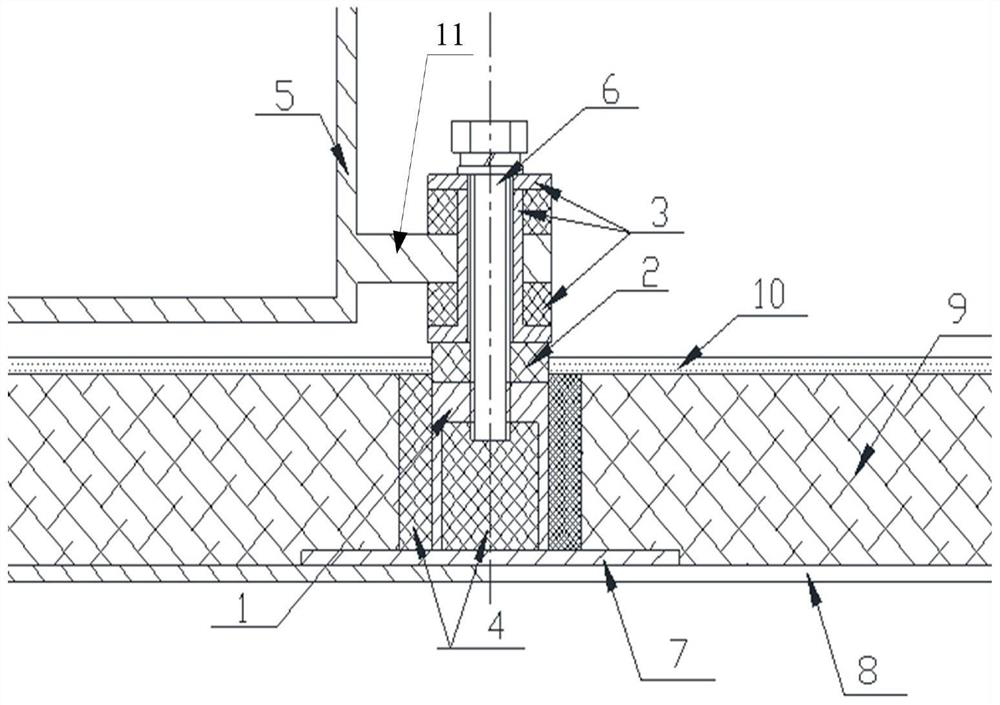

The invention discloses a double-layer-wall heat insulation screen used for an afterburner. Cooling protection is formed for the wall surface of the afterburner by using an inner convection cooling mode and a gas side air film cooling mode. The double-layer-wall heat insulation screen comprises a gas side gas film hole plate, a cool air side impacting plate and a trapezoidal reinforcing frame. The gas side air film hole plate serves as the inner wall of a cylinder body of the afterburner, the inner side of the gas side air film hole plate is provided with a main gas duct of the afterburner, the cool air side impacting plate and an outer wall surface form a cool air duct, and the trapezoidal reinforcing frame is arranged between the impacting plate and the air film hole plate. The double-layer-wall heat insulation screen is formed by the impacting plate, the air film hole plate and the trapezoidal reinforcing frame. Cooling air is made to form an air film on the gas side inner wall of the heat insulation screen, and heat load and gas flow losses are reduced. In addition, composite cooling is formed through inner convection cooling and outer air film cooling of a double-layer wall, incoming heat is brought away through convection heat exchange, and the cool air utilization rate is increased. Reduction is achieved after reflection, the effect of vibration prevention is achieved, the service life of the afterburner is prolonged, and the reliability of the afterburner is enhanced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

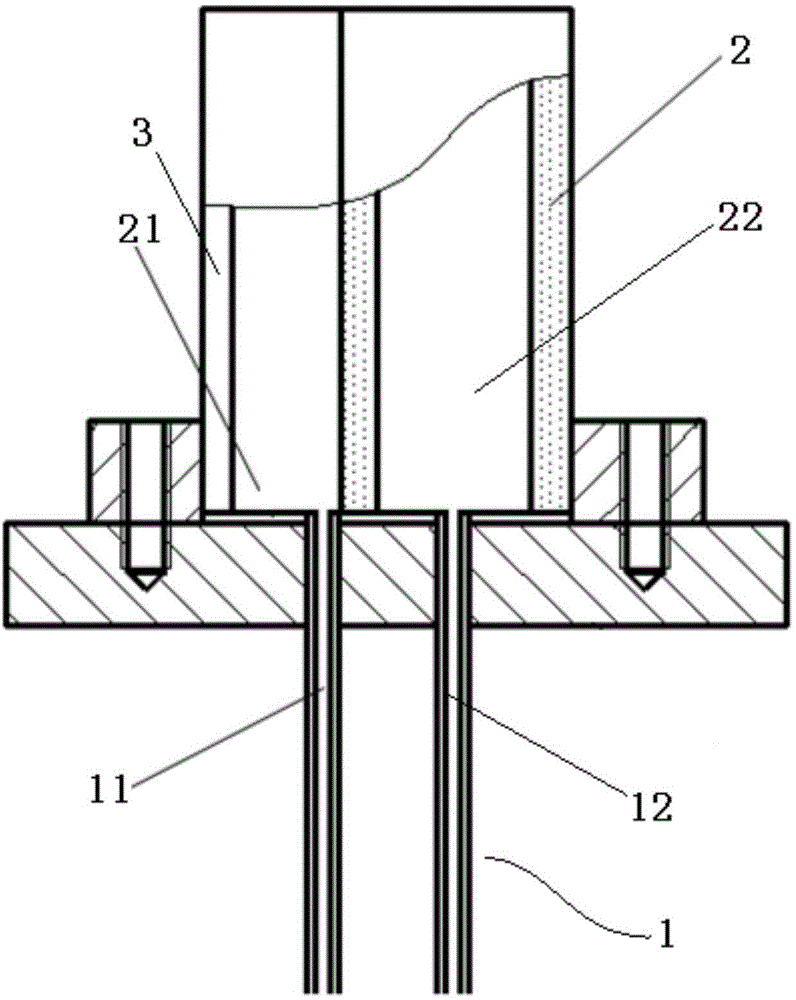

Thermal protection method of porous medium jetting support plate leading edge nose cone

InactiveCN104633709AEffective heat protectionReduce the temperatureContinuous combustion chamberLeading edgeShock wave

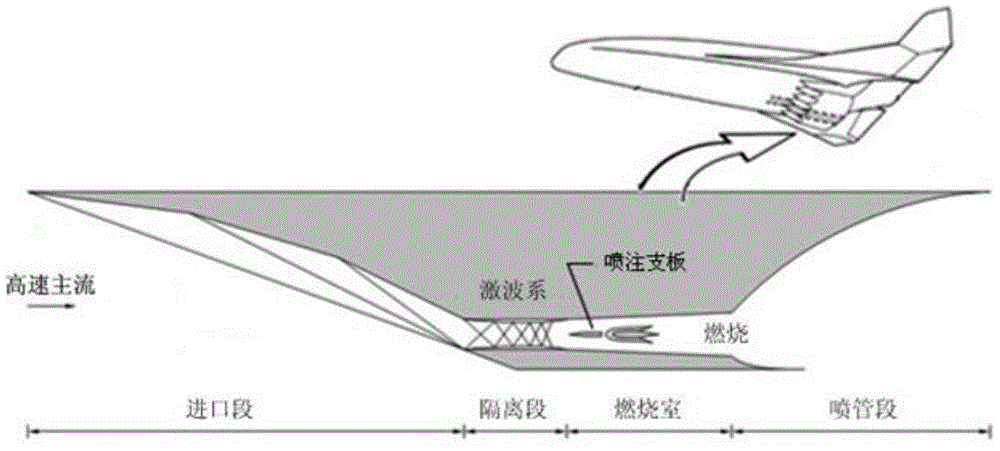

The invention relates to a thermal protection method of a porous medium jetting support plate leading edge nose cone. The thermal protection method comprises the following steps that firstly, a narrow seam is formed in the jetting support plate leading edge nose cone, a front cavity of a jetting support plate is communicated with one fuel pipe, and a back cavity of the jetting support plate is communicated with the other fuel pipe; secondly, most of low-temperature fuel is quickly sprayed out of the narrow seam through the fuel pipe arranged at the front cavity, and the rest part of fuel permeates to the surface of the front cavity in a sweating mode; thirdly, the fuel sprayed to the leading edge is collected through the narrow seam, and produced detached shock waves are pushed away from the leading edge nose cone; fourthly, a thick protection air film is formed at the leading edge nose cone through the fuel sprayed out of the narrow seam and under the action of high-speed main stream, the thick protection air film is fused with a compact air film formed on the surface of the jetting support plate in a sweating and cooling mode, and thermal protection for the jetting support plate is enhanced. According to the thermal protection method, due to the fact that the fuel is sprayed to the high-speed main stream through the narrow seam at the leading edge nose cone, the low-temperature fuel serves as coolant for reducing the temperature of the leading edge nose cone when sprayed out of the narrow seam, meanwhile the sprayed fuel can form the protection air film on the surface of the jetting support plate, and the protection air film can conduct effective thermal protection on the jetting support plate.

Owner:TSINGHUA UNIV

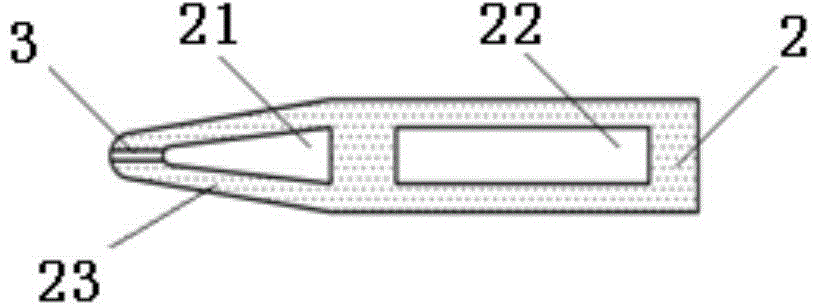

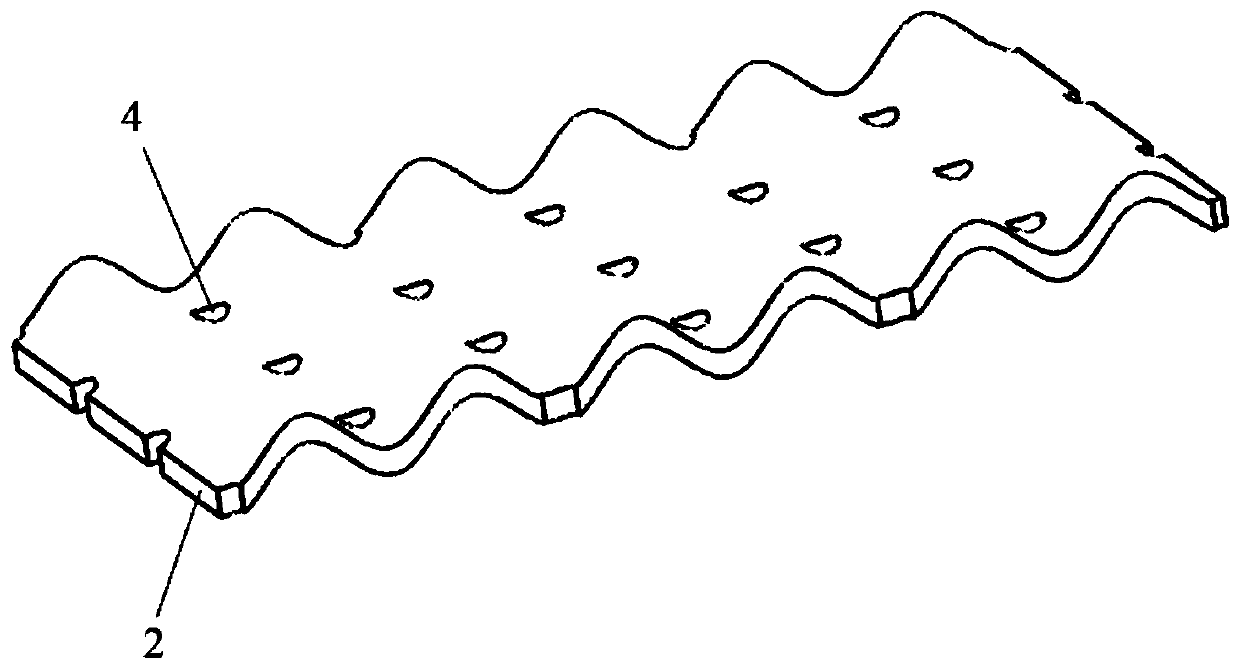

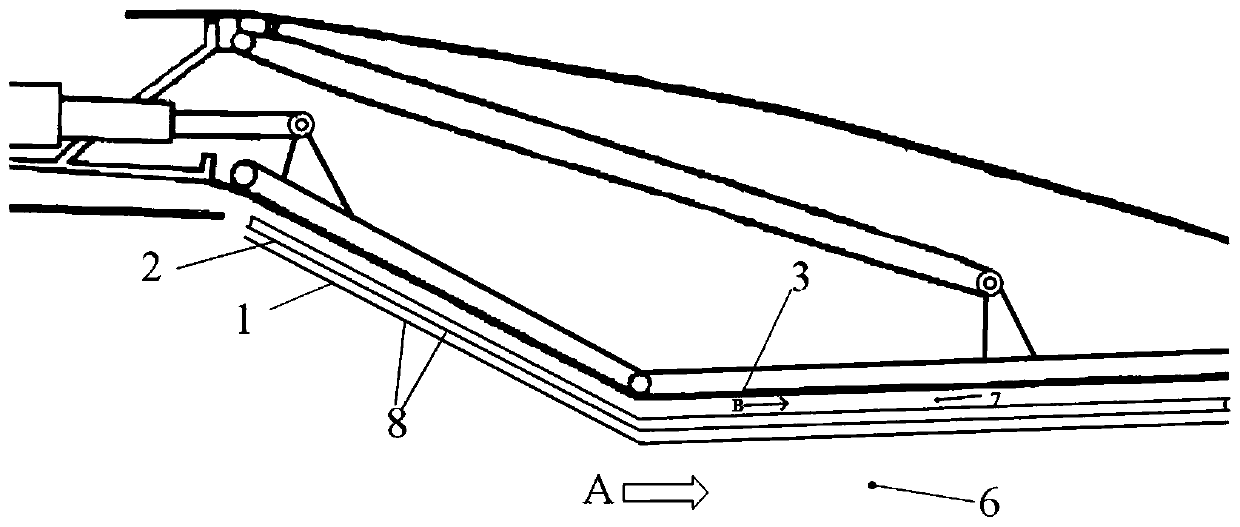

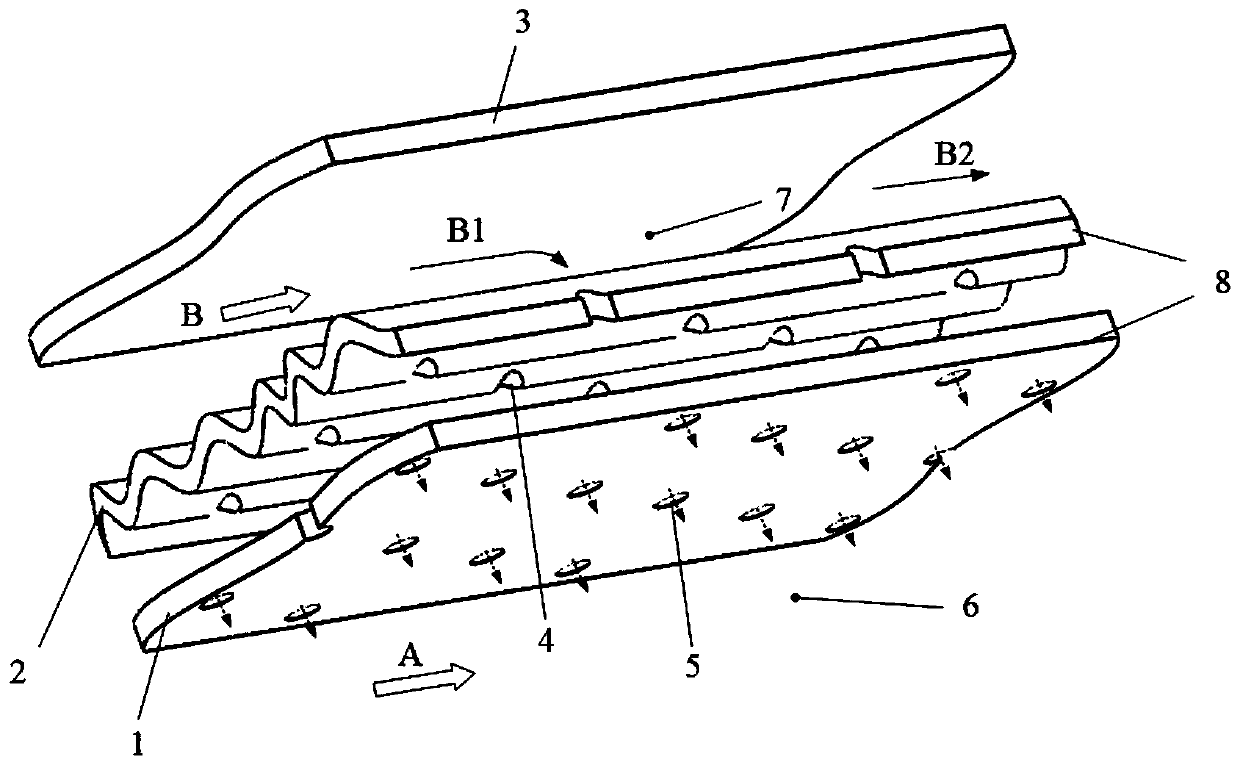

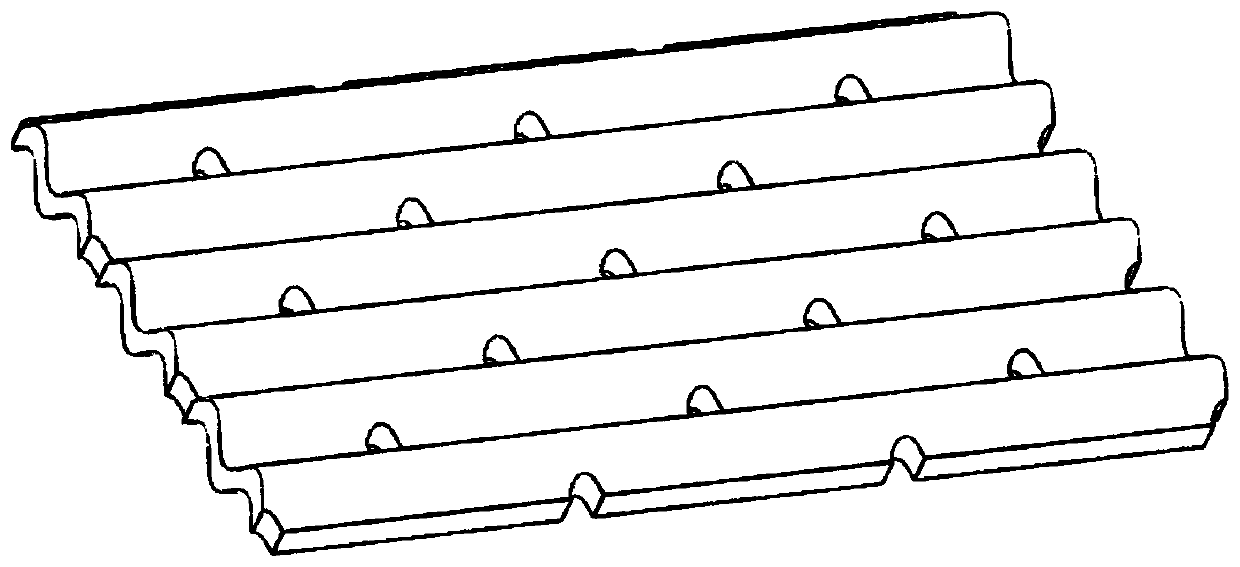

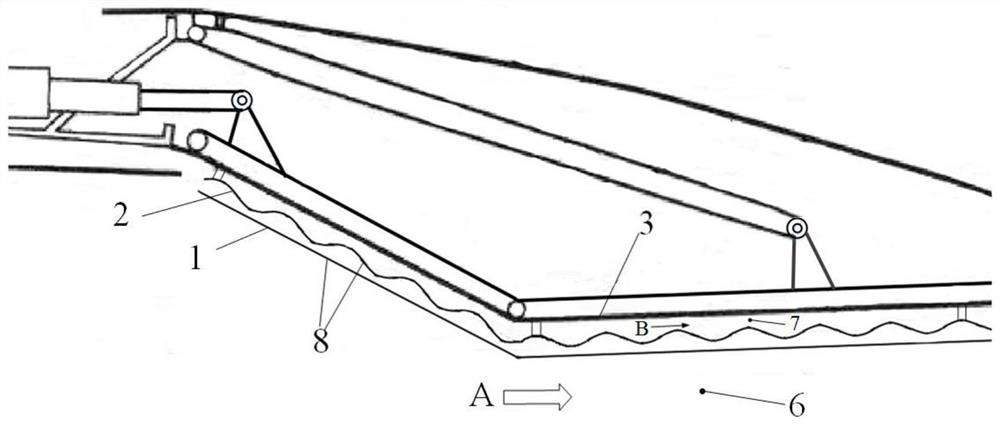

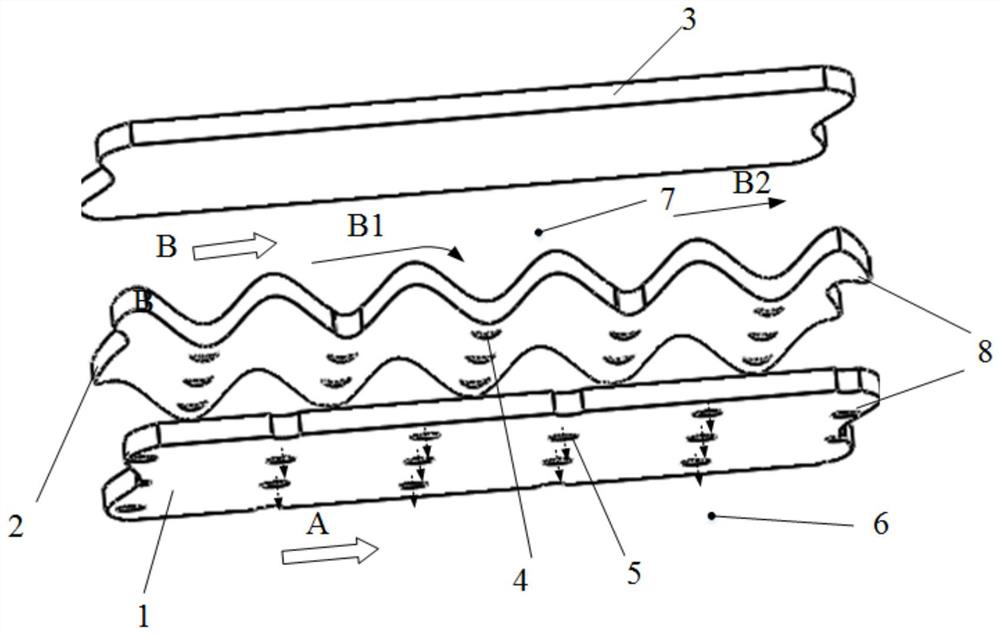

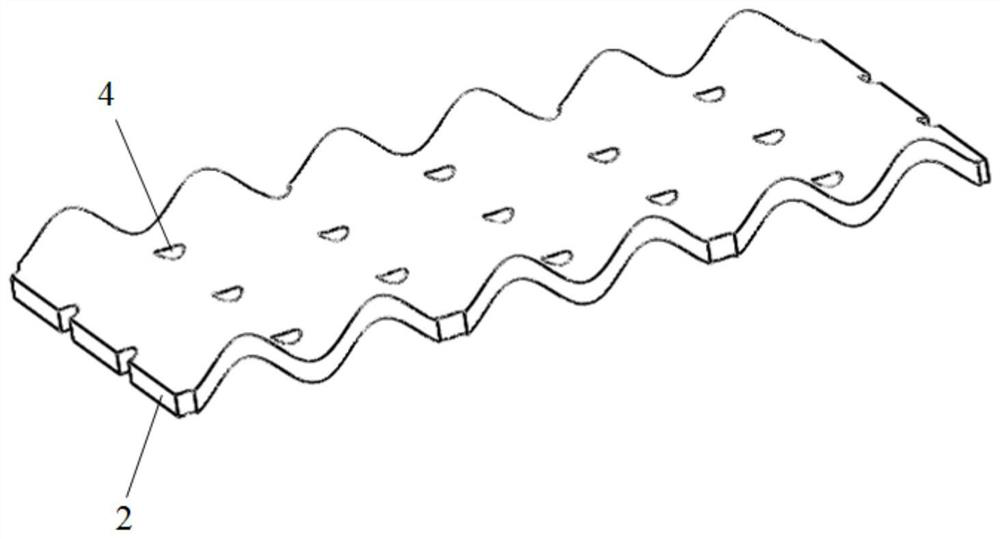

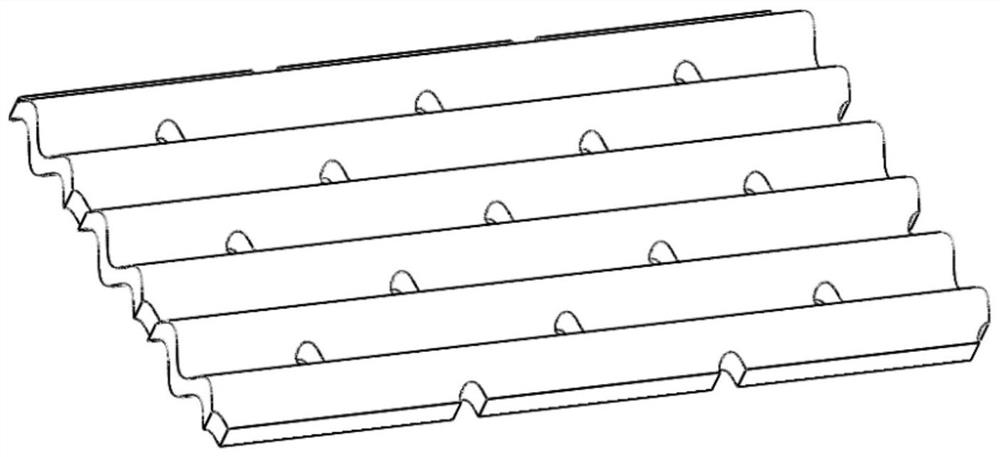

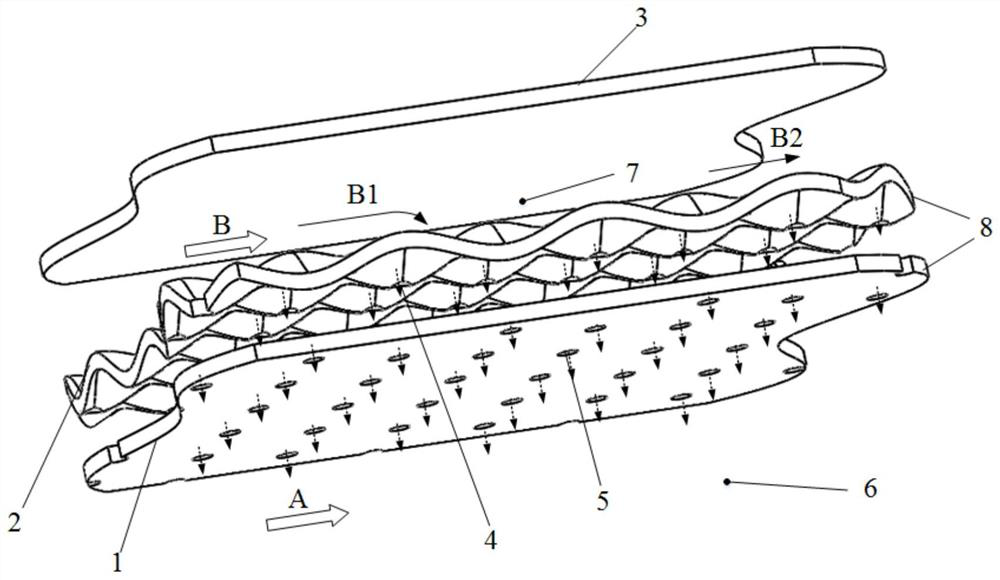

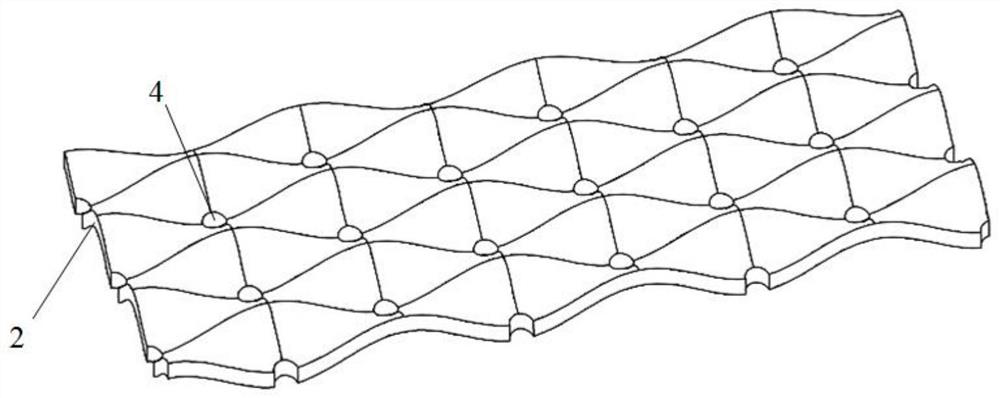

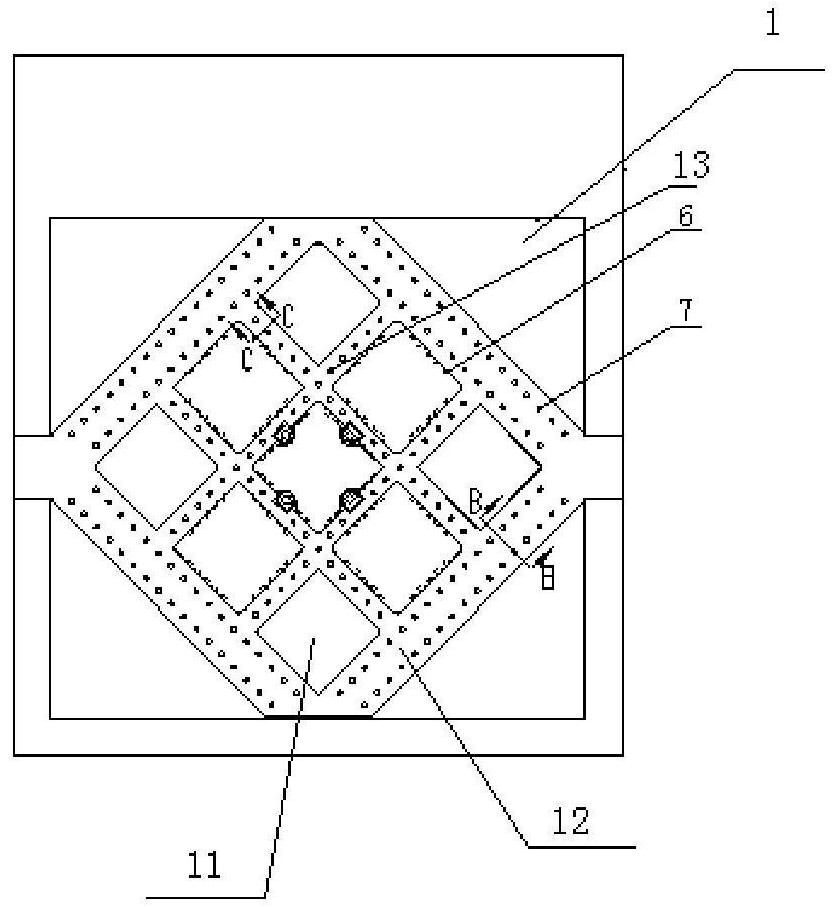

Double-wall cooling structure having longitudinal corrugated impact hole plate for thrust-vectoring nozzle

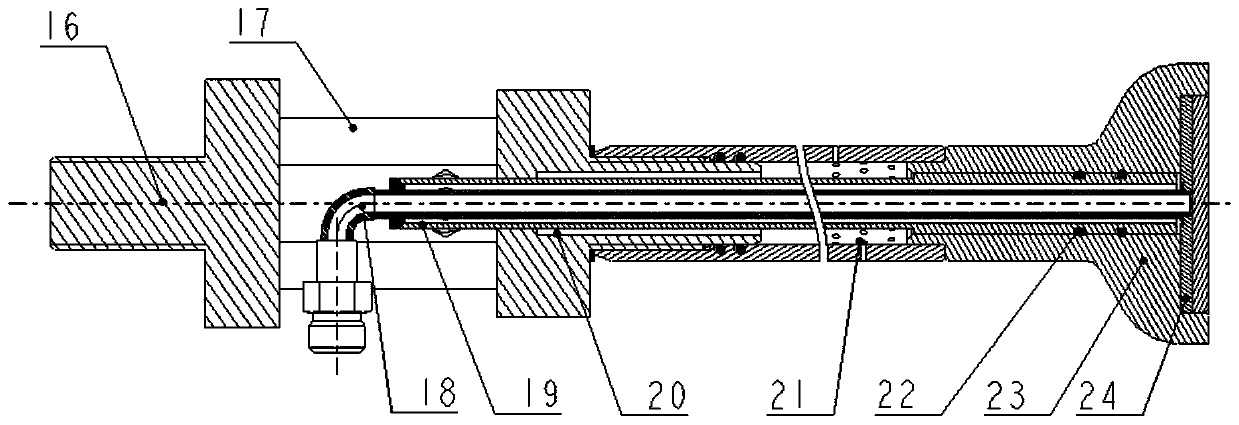

In the invention, a longitudinal corrugated impact pore plate and a flat plate type air film plate are used to constitute a double-wall cooling structure. Impact holes and air film holes are distributed in a staggered manner respectively; impact holes are formed in wave troughs of the corrugated impact hole plate and air film holes in the air film hole plate directly face wave peaks of the corrugated impact hole plate; and each of the corrugated impact pore plate and the air film hole plate is a plurality of unit period structures in the axial direction. A relatively small impact distance is formed between the wave trough and the air film hole plate, so that the heat exchange by impact may be increased; a relatively larger space may be formed between the wave peak and the air film hole plate, full development of cool air flowing is facilitated, outflowing is facilitated, the flow resistance may be reduced, the utilization ratio of cold air is increased and the contradiction between themethod of impact distance reduction for heat exchange enhancement and the method of impact distance increase for flow resistance reduction is solved; and meanwhile, the air film plate is a flat plate, so that air film attachment is facilitated to form effective heat protection, heat stress is reduced and the problem of uneven heat stress of a corrugated heat shield is solved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

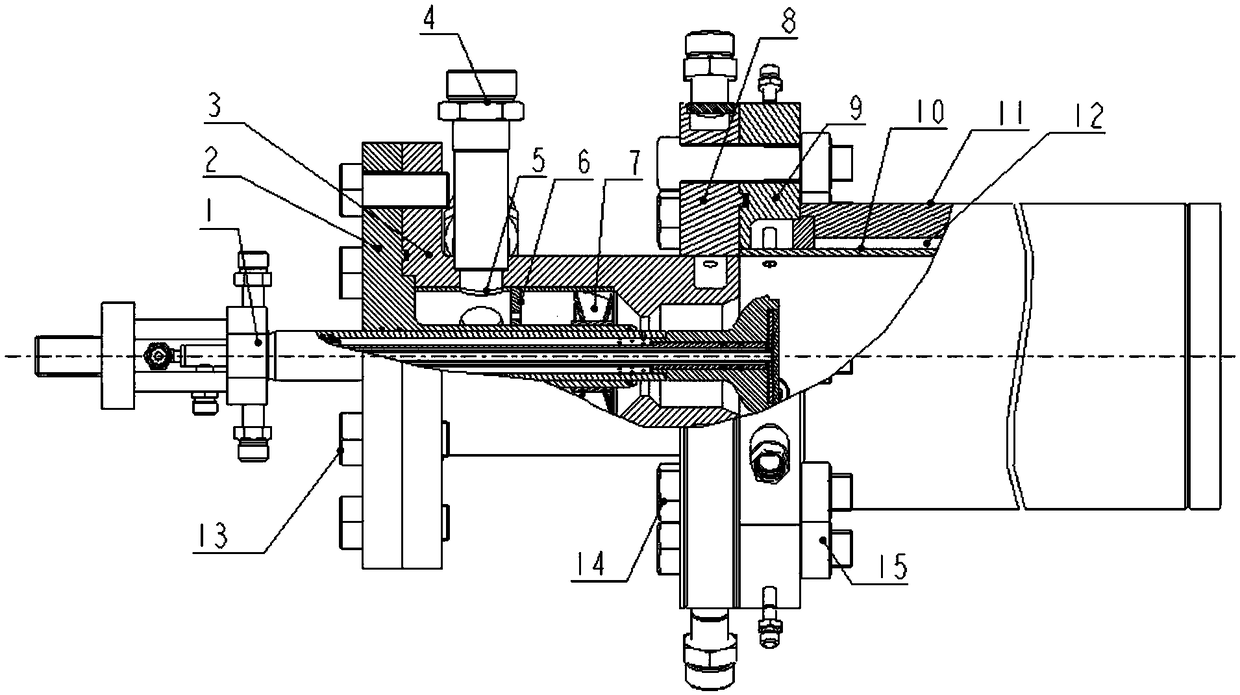

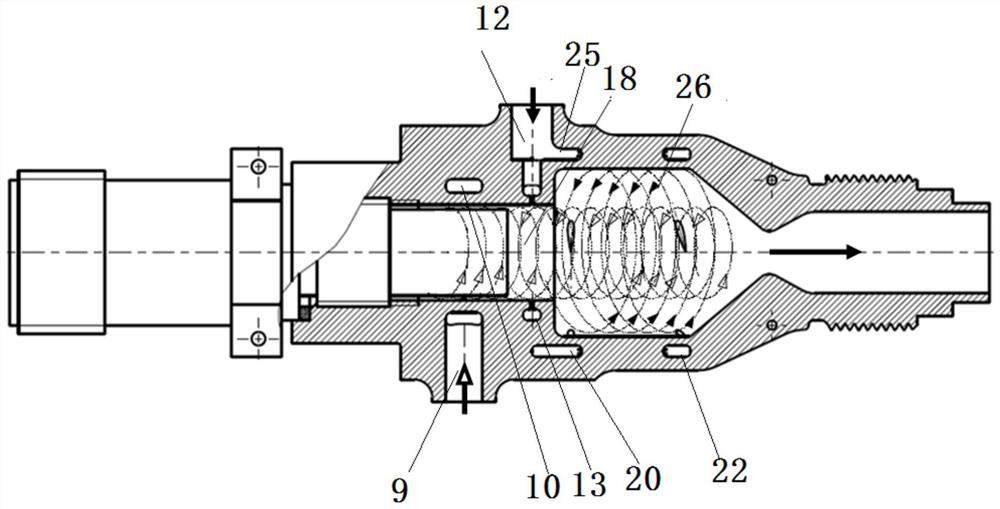

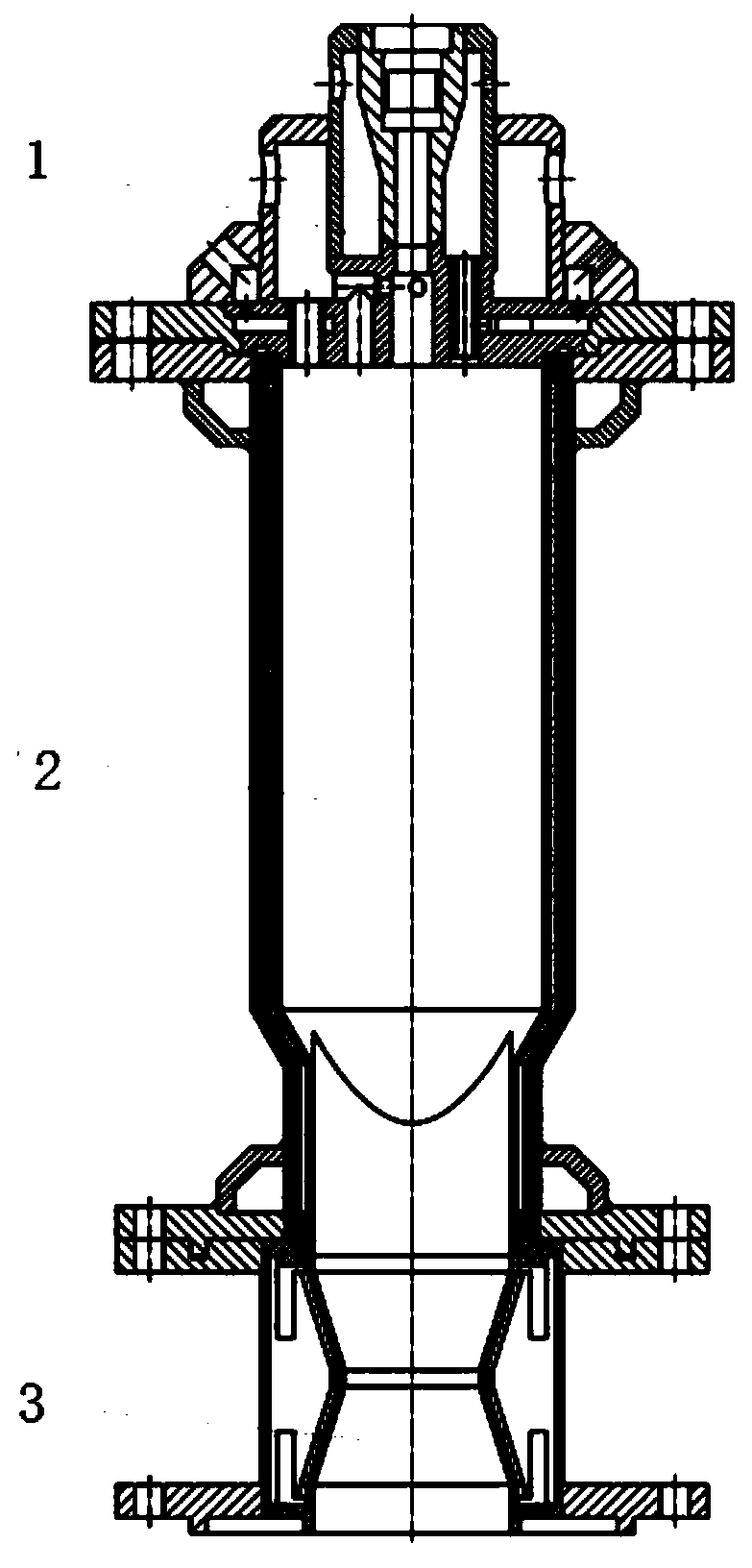

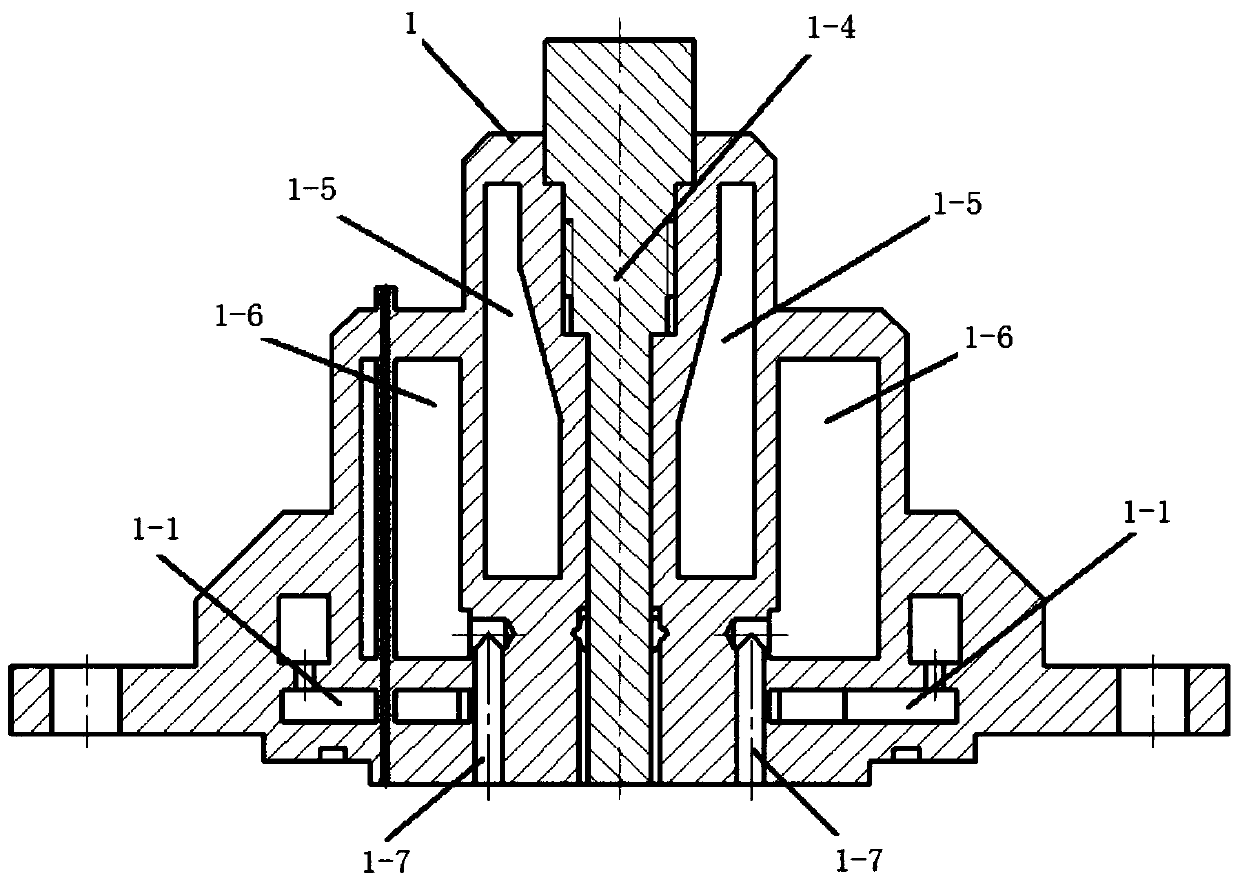

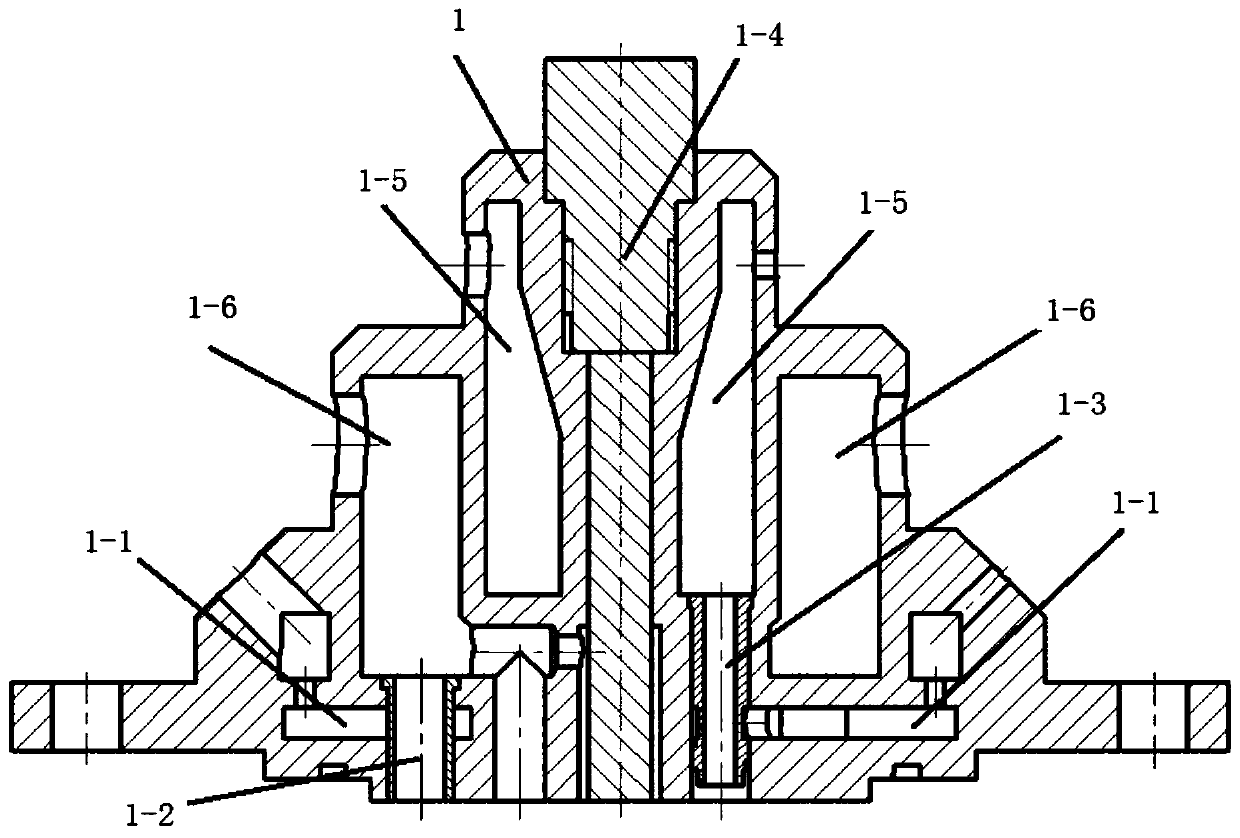

Air/methane combustor for high-temperature pure air heat accumulation type heating device

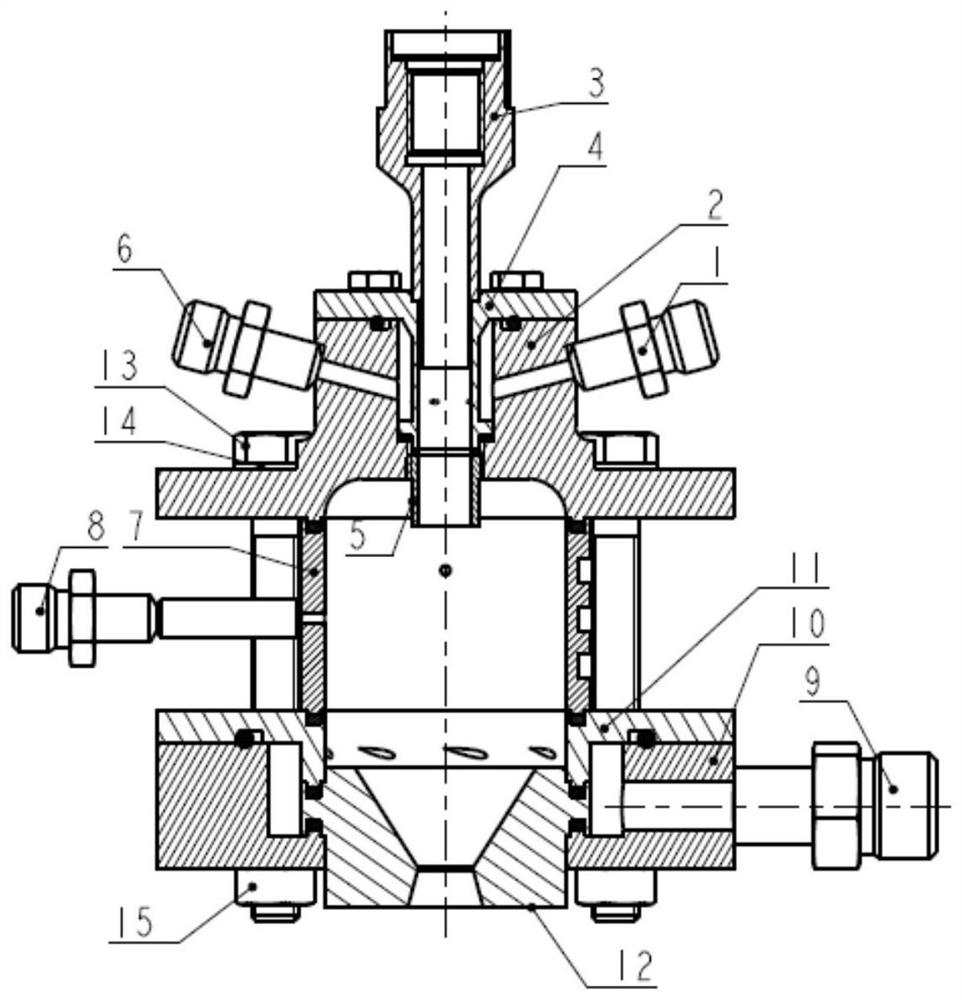

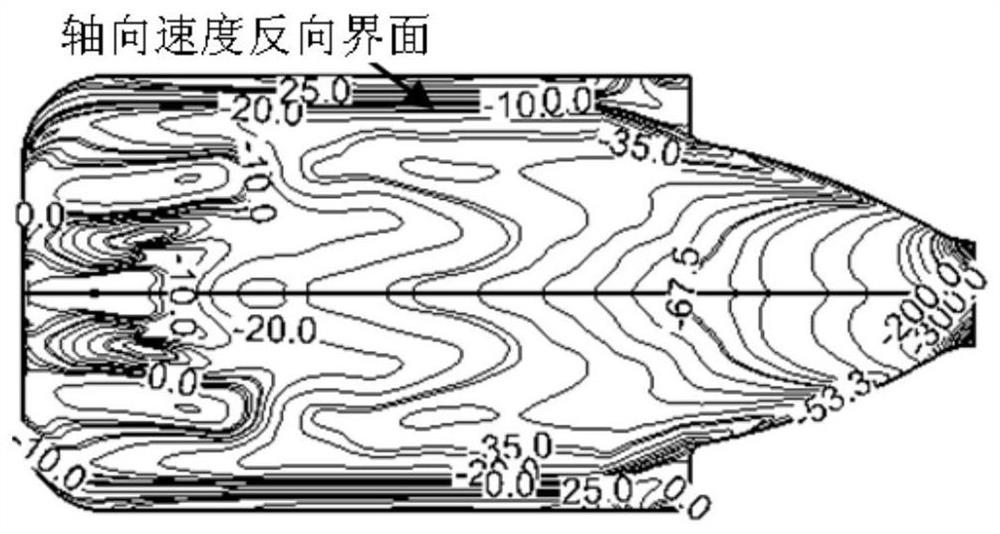

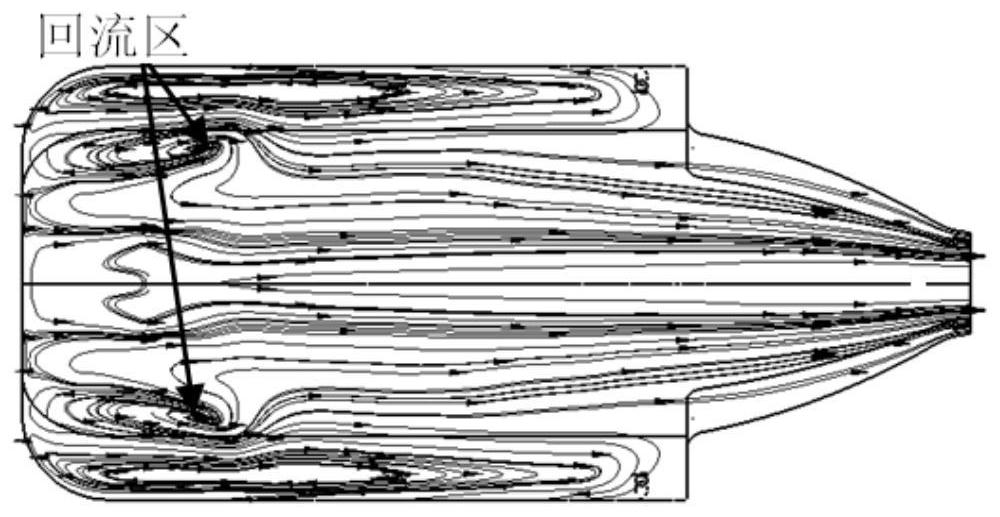

ActiveCN108844063AReliable ignitionReliable combustionIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberMomentum

An air / methane combustor for a high-temperature pure air heat accumulation type heating device is characterized by comprising a head portion and a body portion, wherein the head portion and the body portion are fixedly connected together to form an air / methane combustor integrated structure, a premixing cavity is formed in the head portion, a combustion chamber inner cavity is formed in the body portion, air in the head portion enters the premixing cavity in a rotational flow manner and is mixed with methane, with the flow being adjustable, jetted in the radial direction at the premixing cavity to form premixed gas, a sudden expansion face backflow area is formed at the connection portion between the head portion and the body portion, the air / methane premixed gas is ignited at the sudden expansion face backflow area, and a preheated heat source is provided for the heat accumulation type heating device. According to the air / methane combustor for the high-temperature pure air heat accumulation type heating device, a pintle structure is designed on the head portion, under drive of an actuator, the injection area of a methane spray nozzle is changed, it is guaranteed that gas media arealways mixed at the best momentum ratio, and ignition and efficient combustion of the premixed gas is ensured.

Owner:XIAN AEROSPACE PROPULSION INST

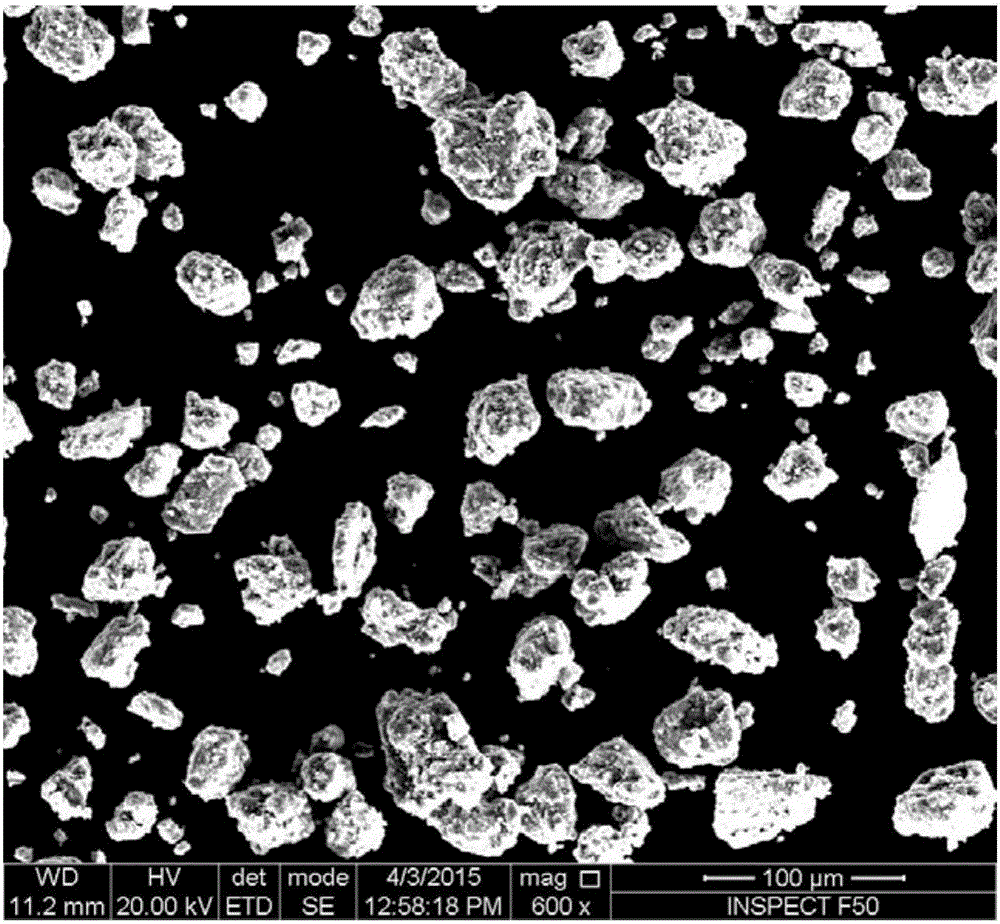

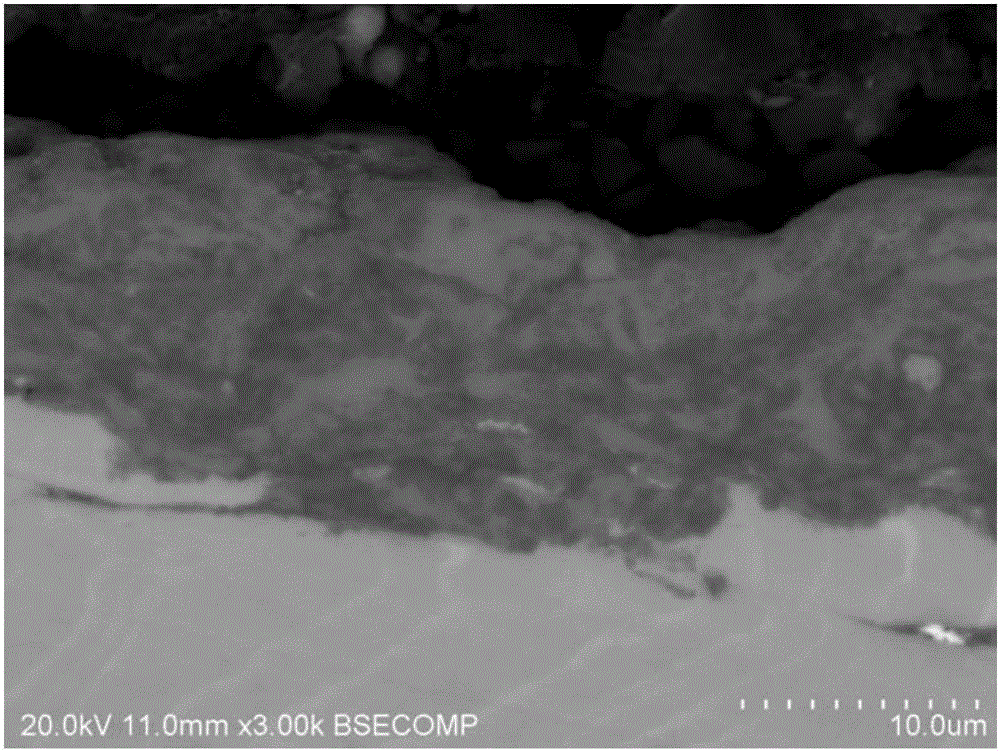

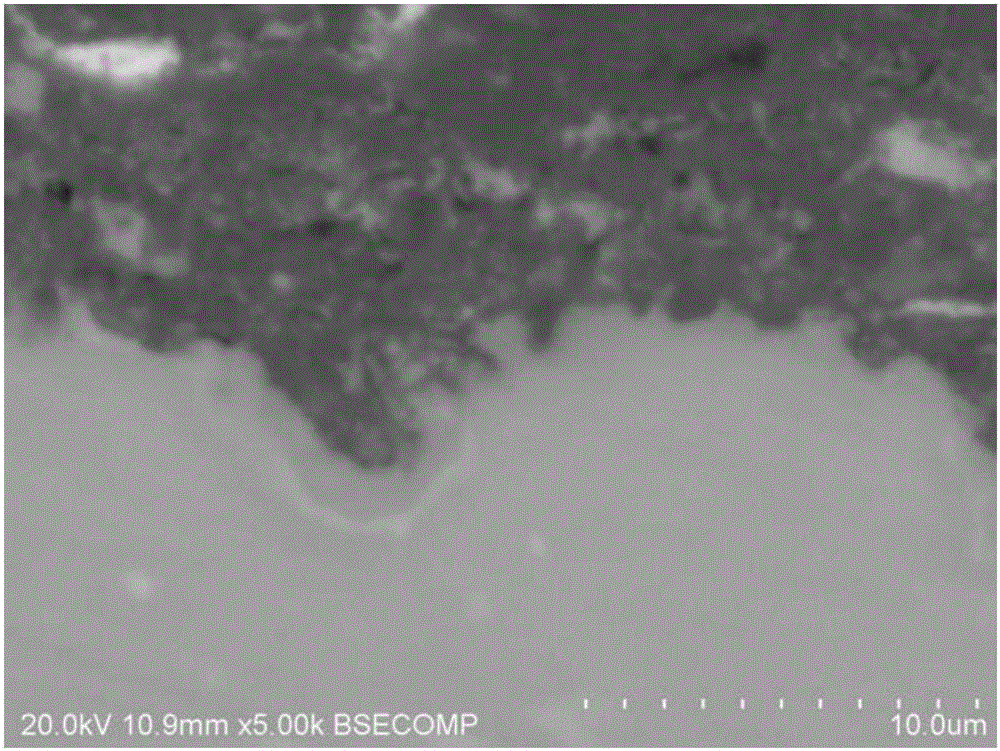

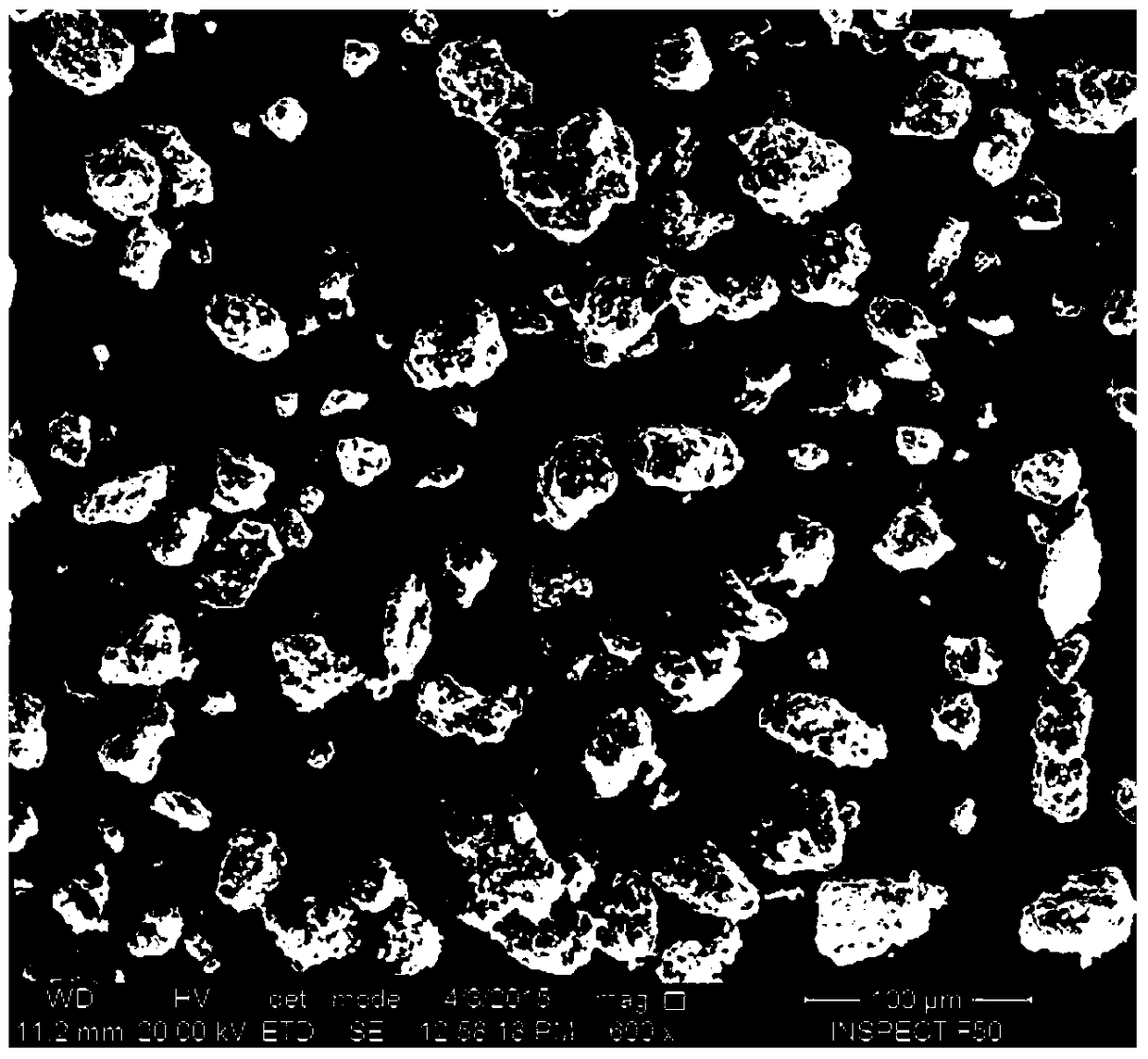

TiAl3/Al2O3 composite powder as well as preparation method and application thereof

ActiveCN106493348AUniform distribution of two phasesIngredients are easy to controlAlloy substrateBinding force

The invention relates to a preparation technology of a titanium alloy high-temperature protective coating and particularly relates to TiAl3 / Al2O3 composite powder as well as a preparation method and application thereof. The preparation method comprises the steps of firstly, carrying out thermal treatment after carrying out high-energy ball milling on pure Al and TiO2 nanopowder according to a certain ratio for a certain time to obtain the TiAl3 / Al2O3 composite powder; and then, spraying the prepared composite powder on a titanium alloy substrate at the temperature of 100-700 DEG C and the pressure of 0.3-5.0MPa by using a cold gas dynamic spraying method to form a TiAl3 / Al2O3 composite coating. The coating comprises the components of TiAl3 and Al2O3, wherein Al2O3 is uniformly distributed in the coating, and the coating is more than 10mu m thick. The preparation method disclosed by the invention is simple in operation, the components are easily controlled, the obtained coating is low in porosity, good in compatibility with matrix and binding force and relatively good in high-temperature oxidation resistance, the mutual diffusion between the coating and the matrix can be greatly reduced, and the problem of high-temperature oxidation of titanium alloy can be favorably solved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

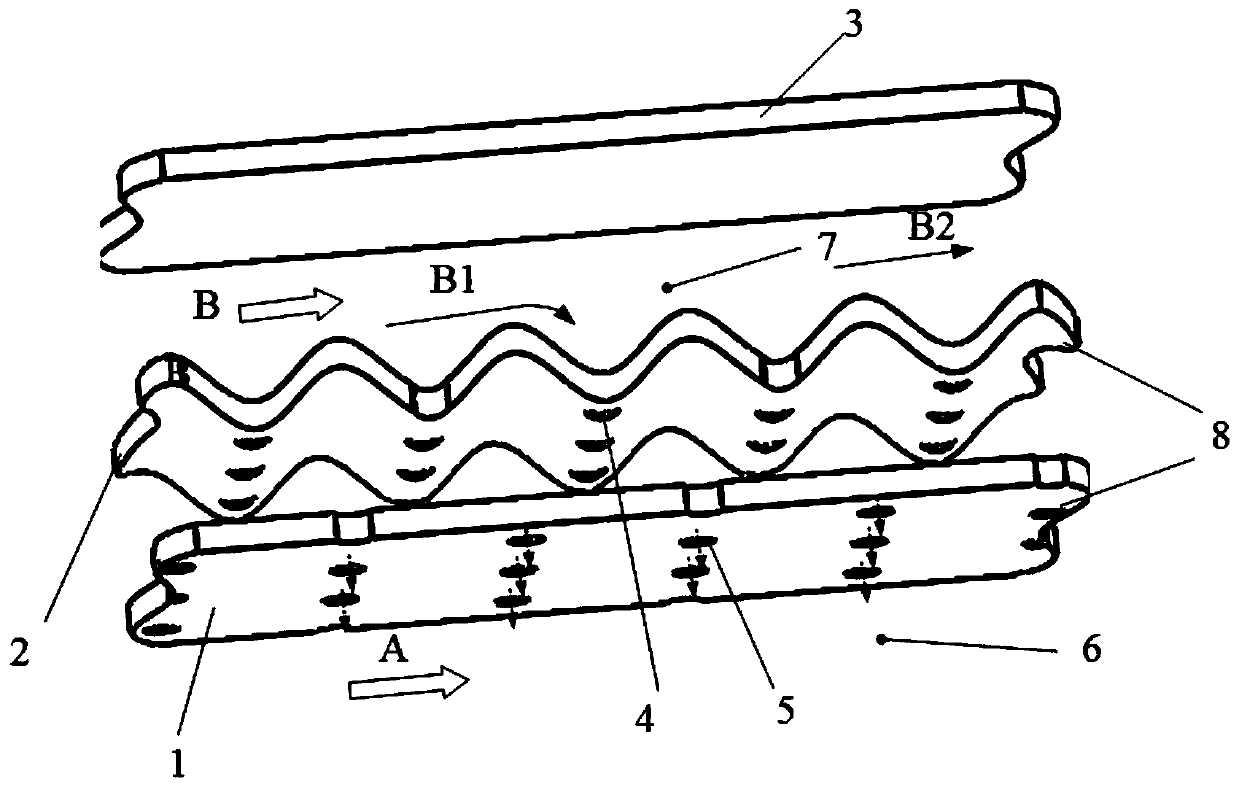

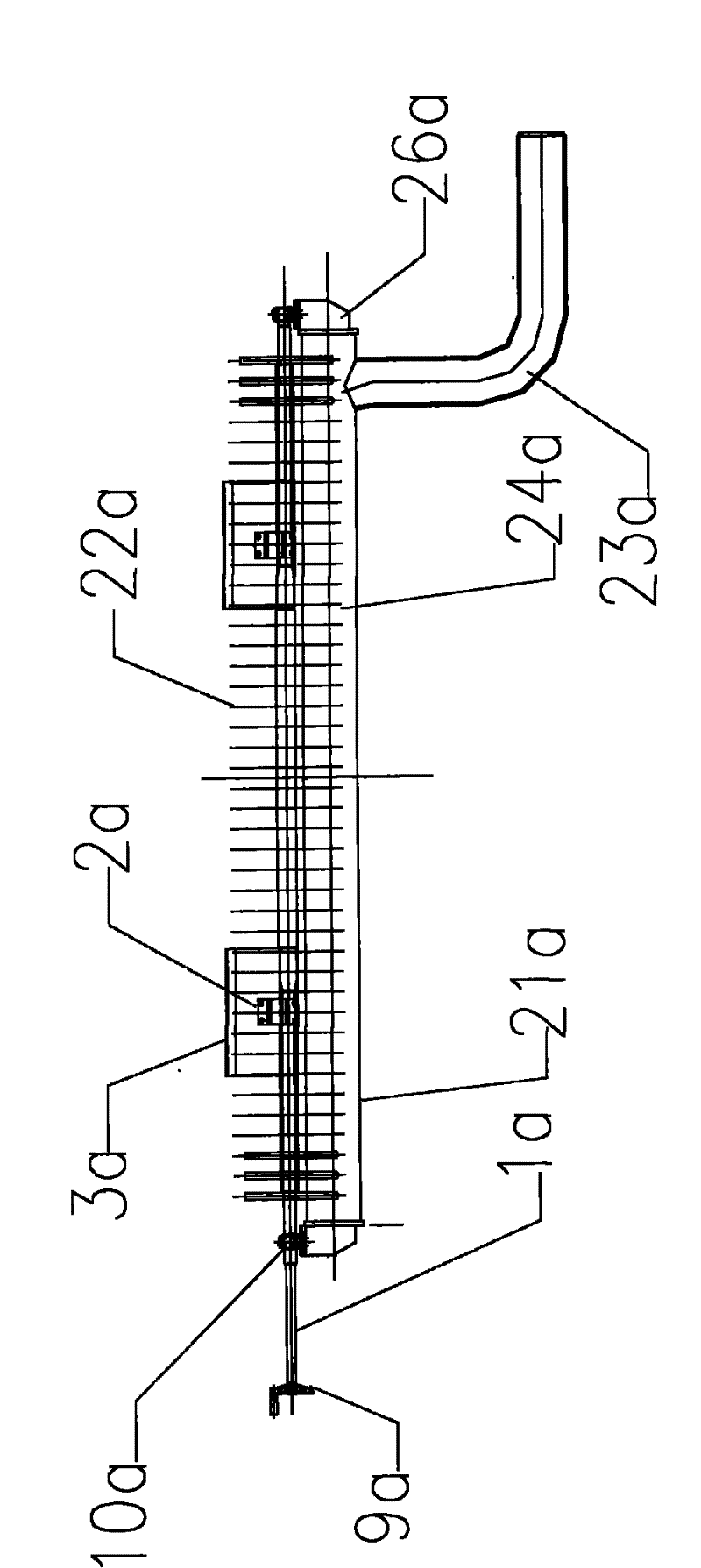

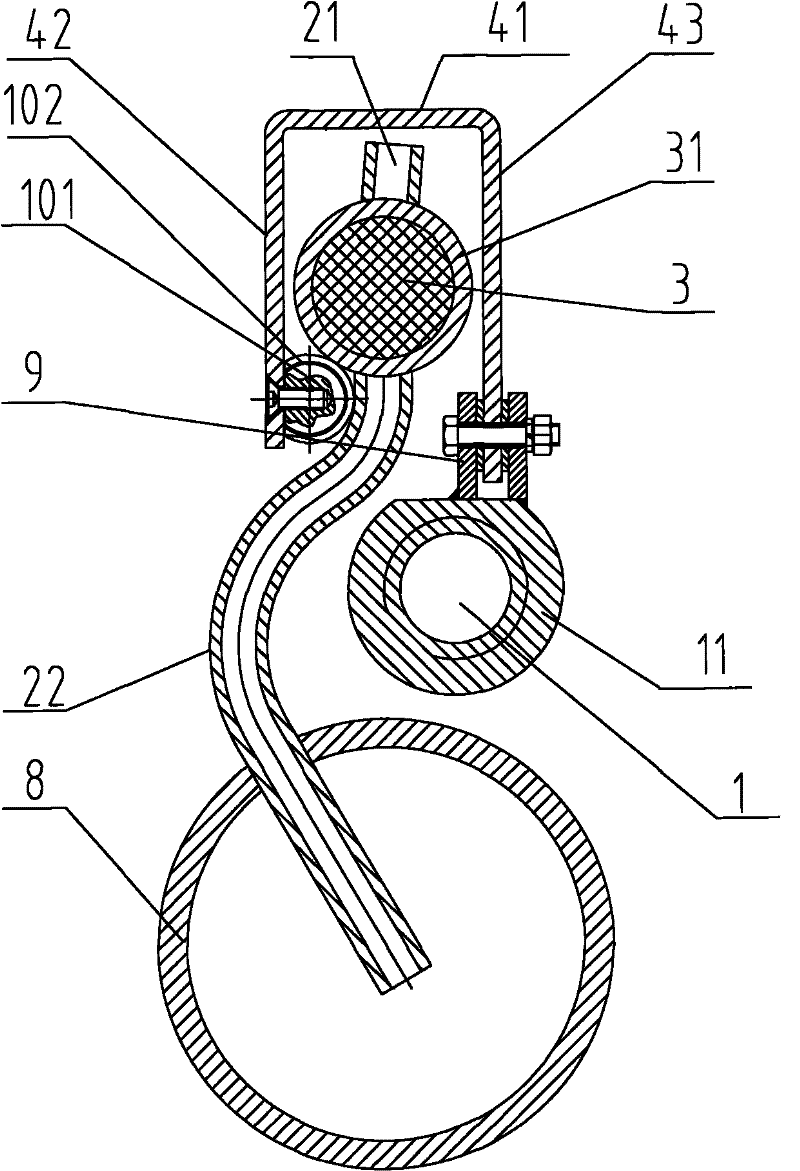

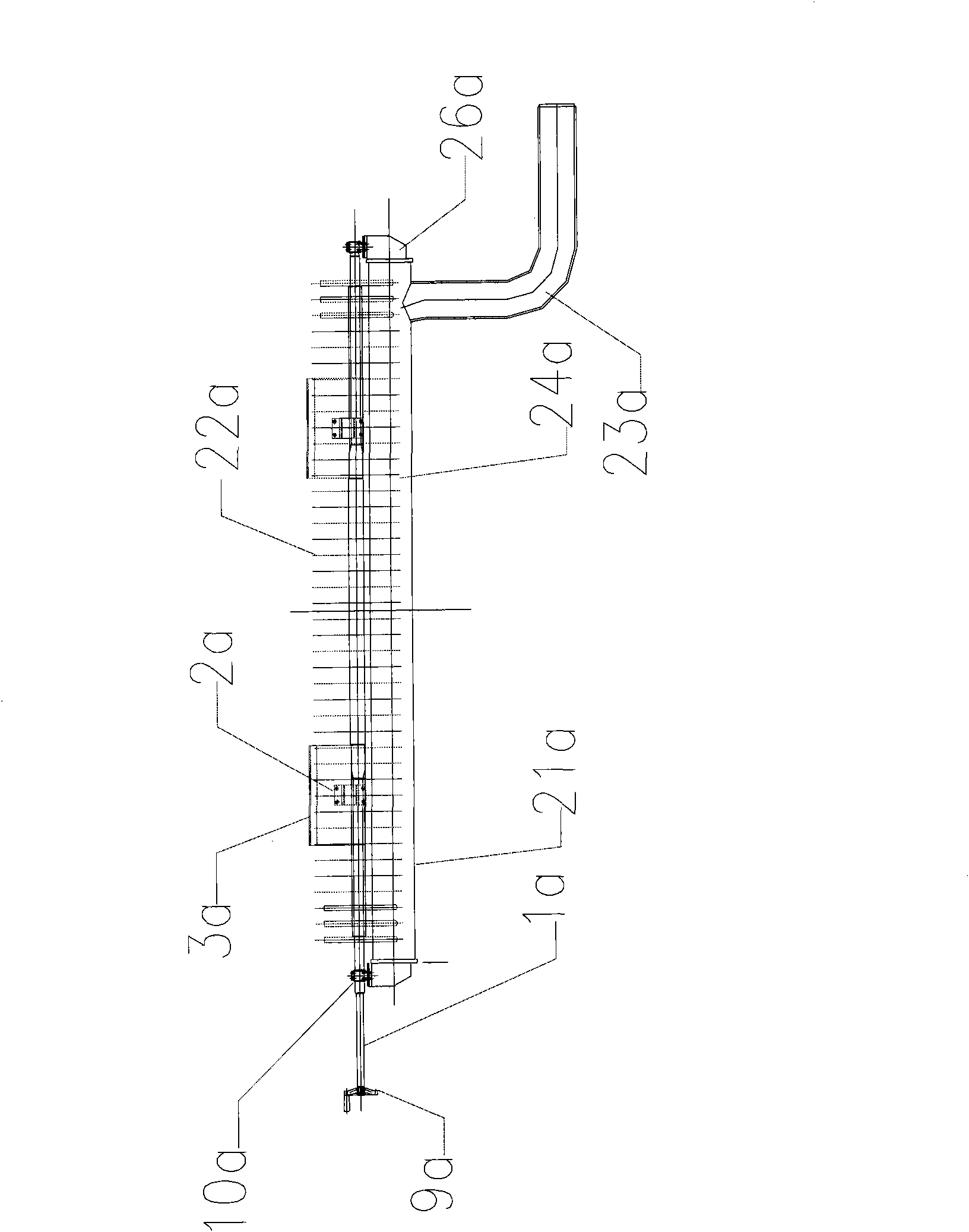

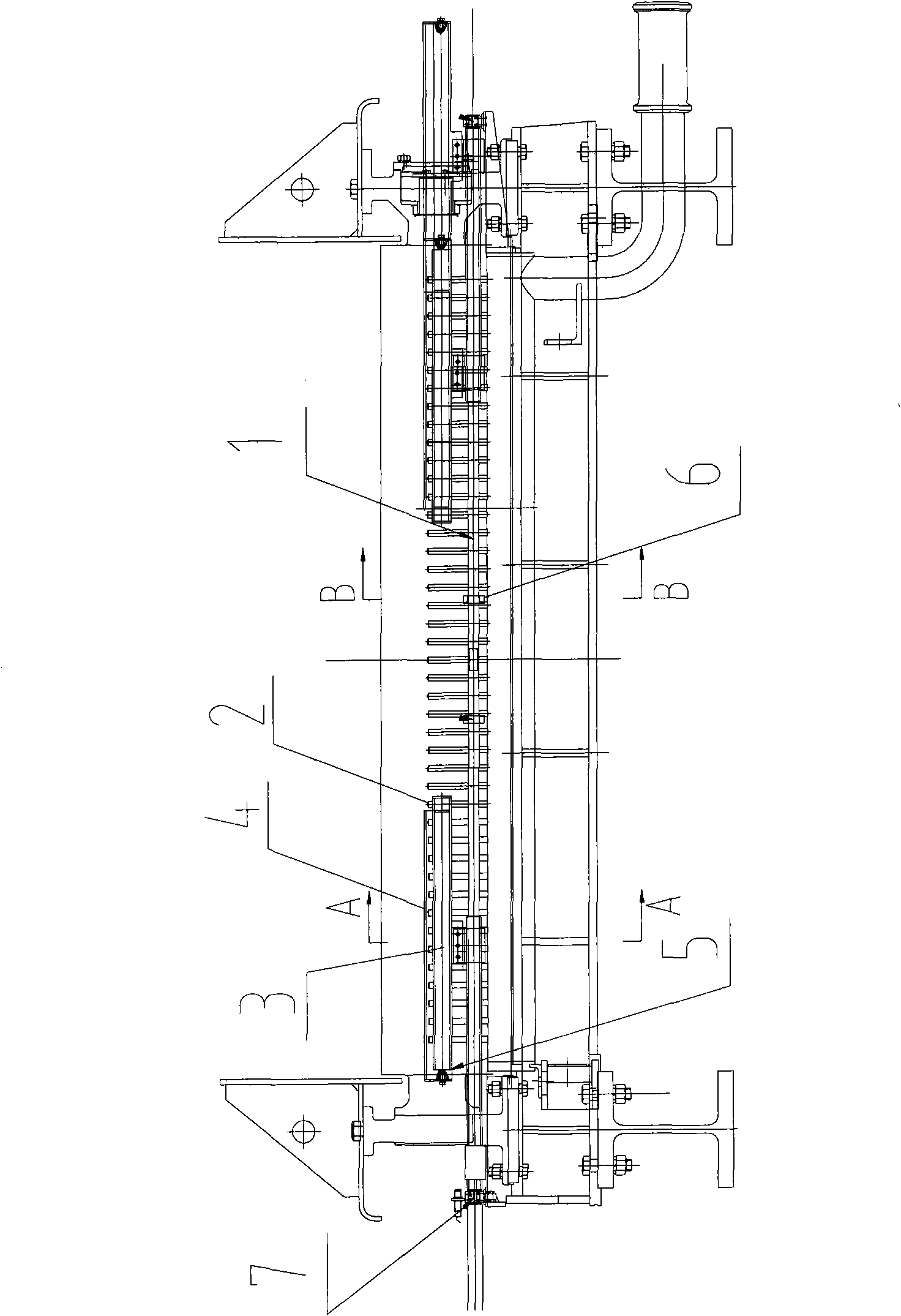

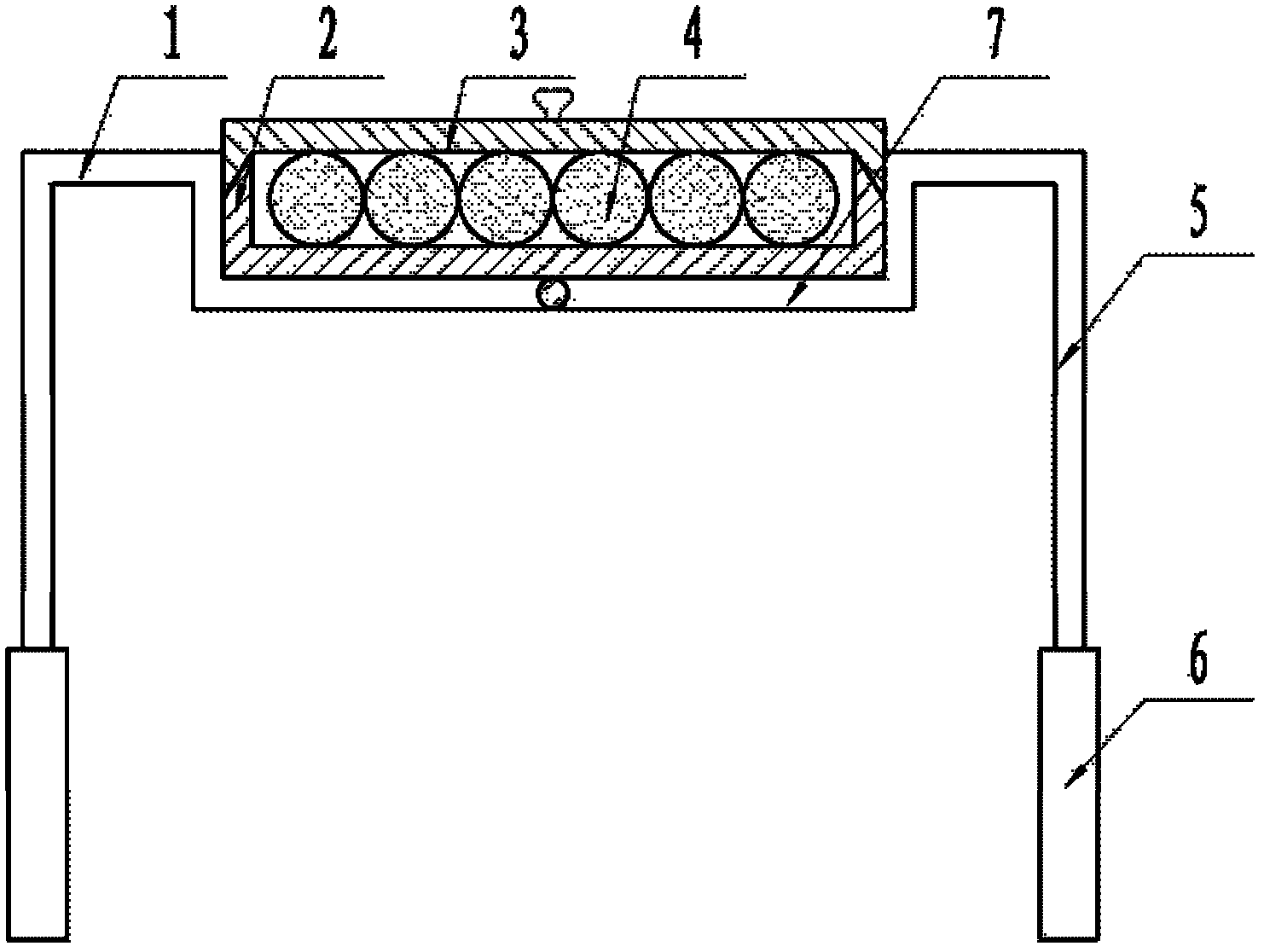

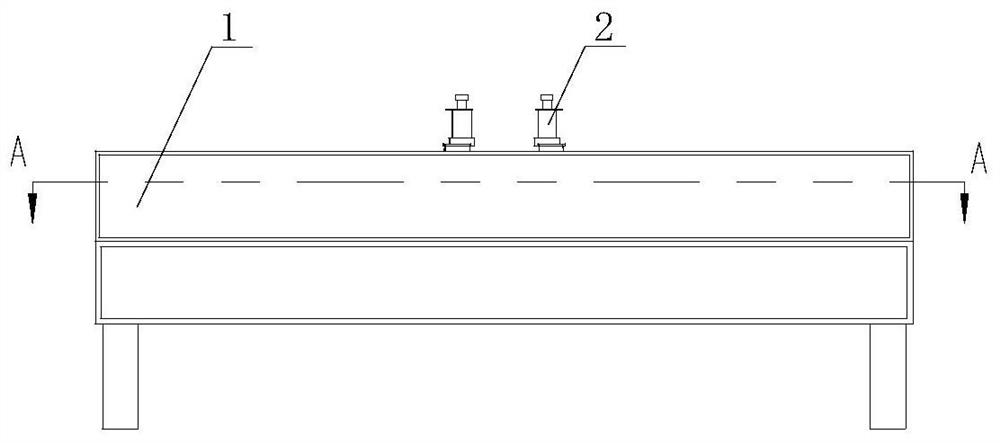

Lower spraying laminar flow cooling device

ActiveCN102189131AReduce consumptionAvoid water wasteWork treatment devicesMetal rolling arrangementsSpray nozzleGoose

The invention discloses a lower spraying laminar flow cooling device. The device comprises a plurality of groups of lower spraying devices, wherein each group of lower spraying device comprises a collecting pipe, two plunger pipes, two plungers and two U-shaped covers; the collecting pipe is fixedly arranged along a direction vertical to the operation direction of strip steel; a plurality of goose neck spray pipes are uniformly distributed on the collecting pipe along the axial direction; the two plunger pipes are fixedly arranged above the two ends of the collecting pipe respectively, pass through the plurality of goose neck spray pipes which are uniformly distributed at the two ends of the collecting pipe respectively, divide the goose neck spray pipes into upper nozzles and lower spraypipes, and are communicated with the upper nozzles and the lower spray pipes of the goose neck spray pipes through a plurality of through holes; the two plungers are arranged in the two plunger pipesrespectively; the two U-shaped covers are covered outside the two plungers in a mode that openings are downward; and the plungers are connected with driving devices through the U-shaped covers, so that movement in the axial direction is realized, the through holes are blocked, and cooling water quantity is adjusted.

Owner:BAOSHAN IRON & STEEL CO LTD

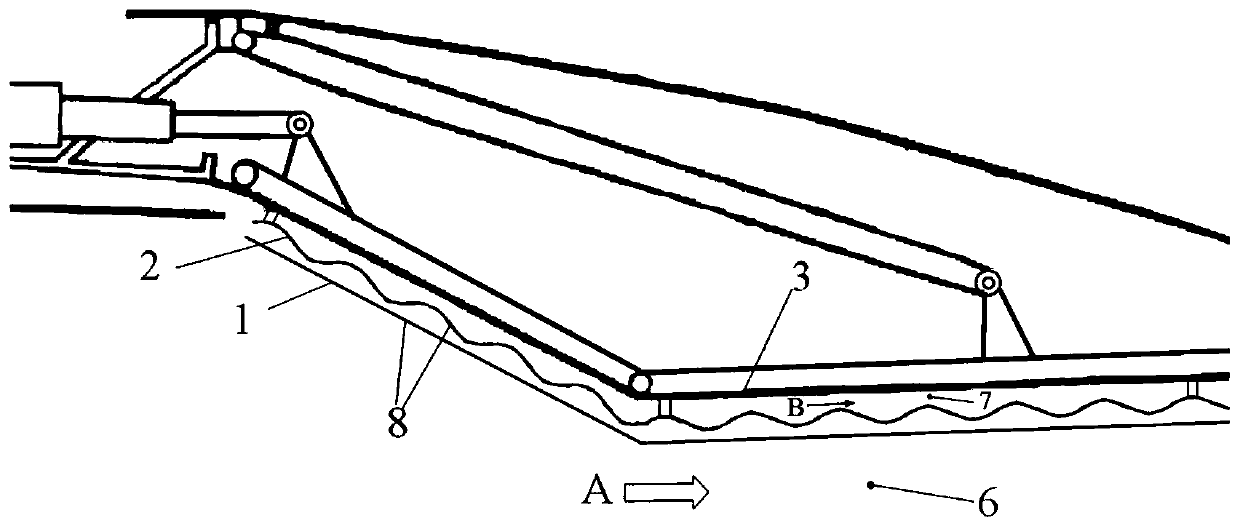

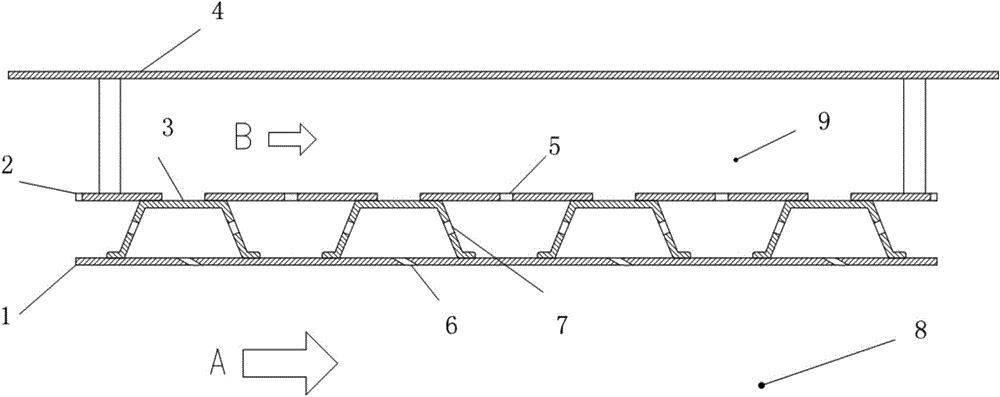

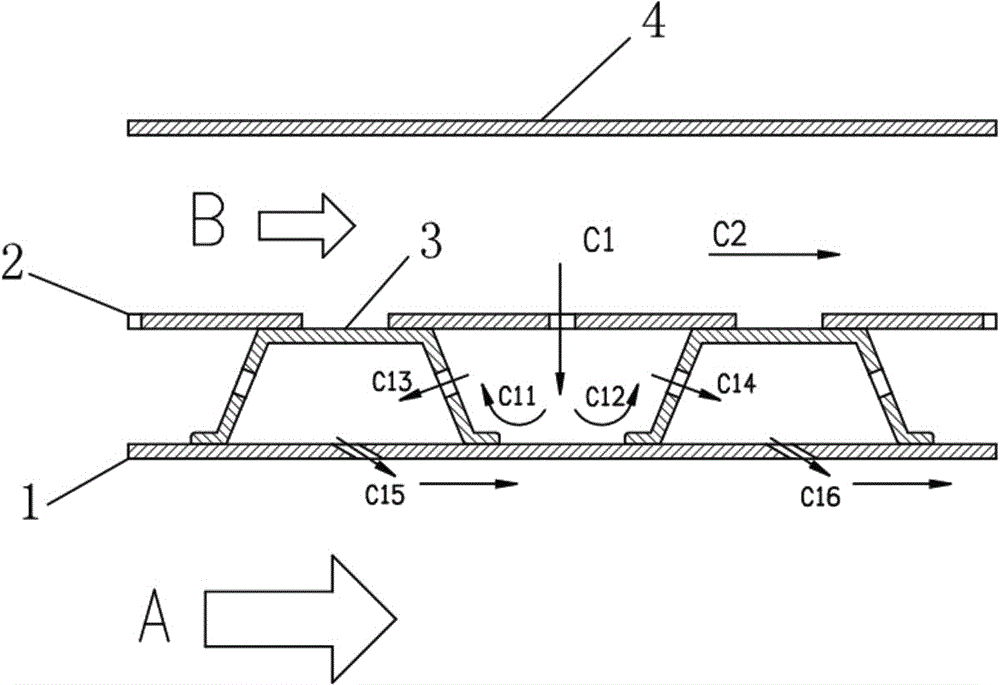

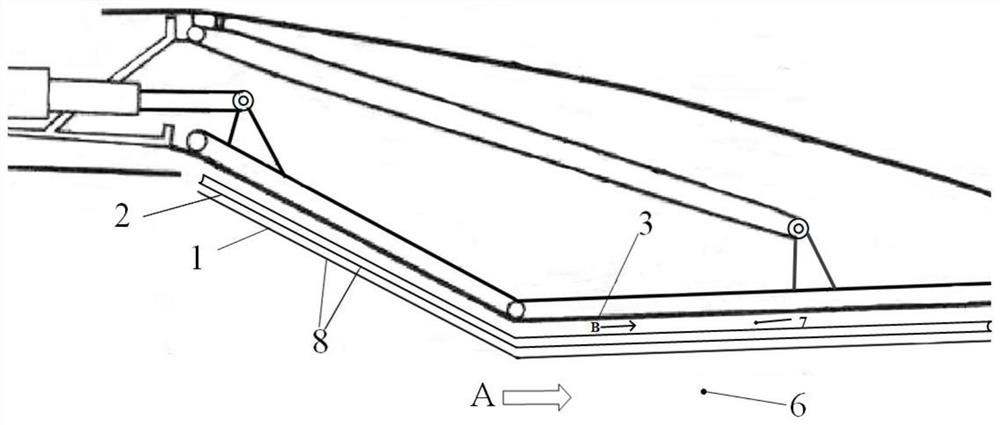

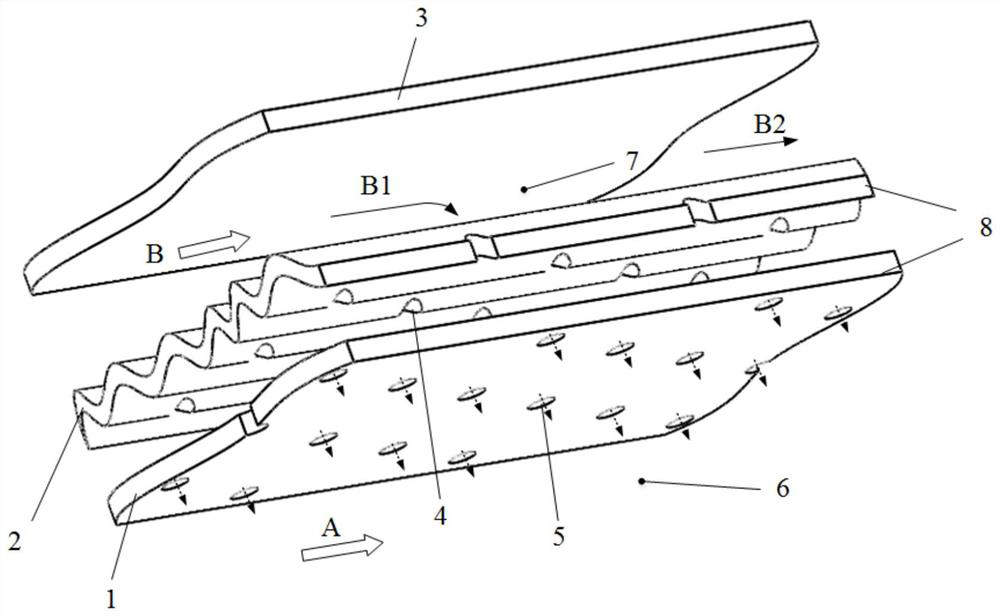

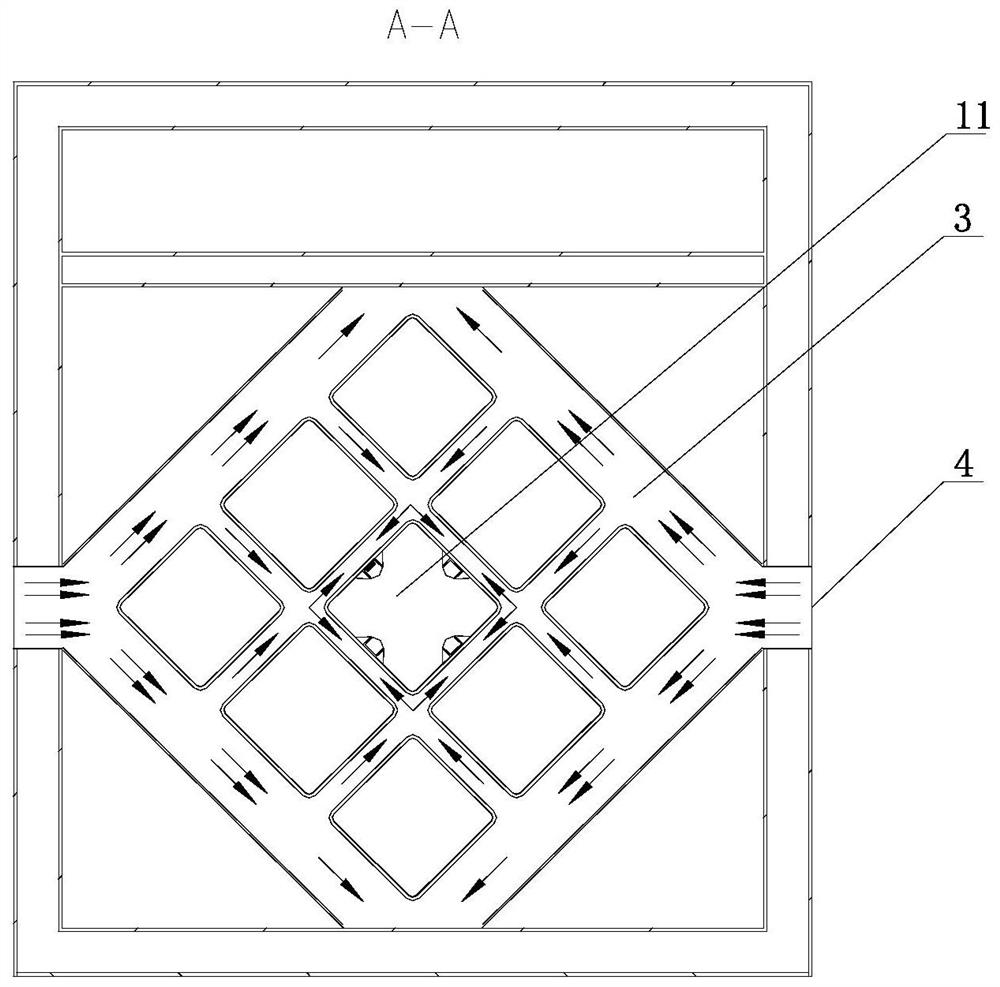

Double-layer wall cooling structure with transverse corrugated impact pore plate for vectoring exhaust nozzle

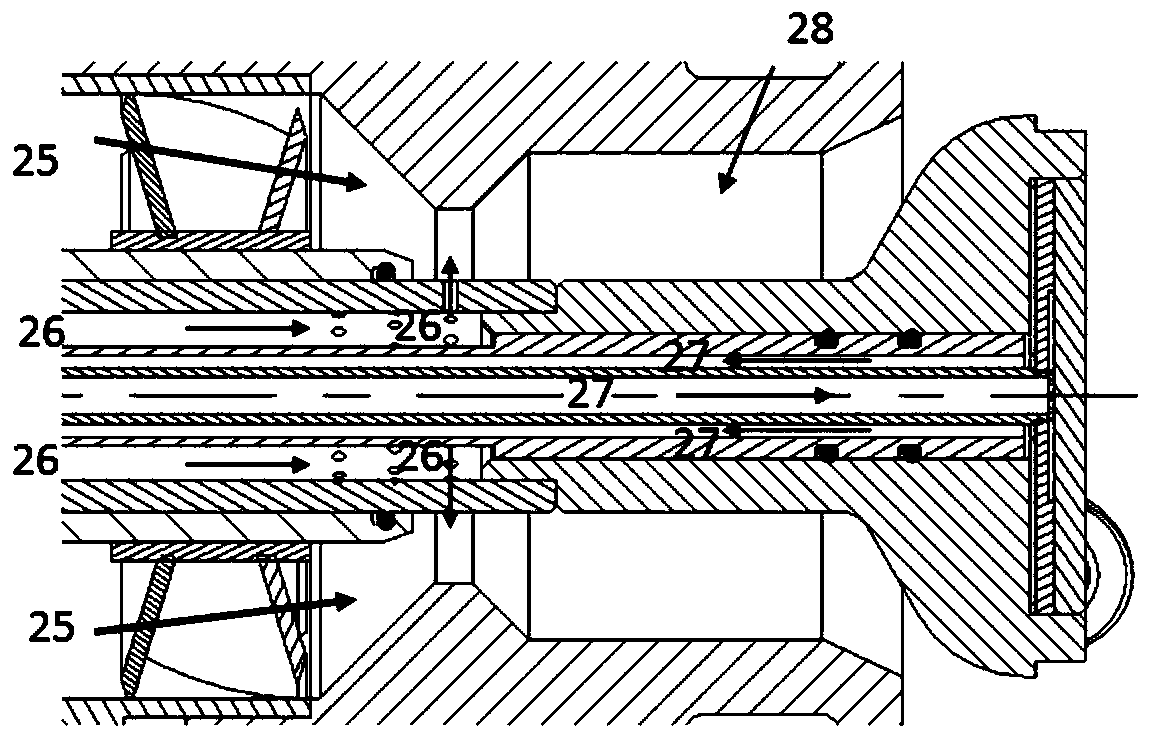

InactiveCN109882314AHigh impact heat transfer strengthSmall flow resistanceJet propulsion plantsEngineeringFlat panel

The invention discloses a double-layer wall cooling structure composed of a transverse corrugated impact plate and a flat plate type gas film plate. According to the double-layer wall cooling structure, impact holes and gas film holes are distributed in a crossed mode, the impact holes are formed in wave troughs of the corrugated impact pore plate, the gas film holes in the gas film pore plate arearranged at wave peaks just opposite to the corrugated impact pore plate, and the corrugated impact pore plate and the gas film pore plate are in a plurality of unit cycle structures in the axial direction. Small impact distances are formed between the wave troughs and the gas film pore plate so that impact heat exchange can be enhanced, larger spaces can be formed between the wave peaks and thegas film pore plate, so that the cold gas flow can be fully developed, flowing out of the cold gas can be facilitated, the flow resistance can be reduced, the cold gas utilization rate can be improved, and the contradiction that the impact distances are reduced so as to enhance the heat exchange, but the impact distances need to be increased so as to reduce the flow resistance is solved. Meanwhile, the gas film plate is a flat plate, so that the adhesion of a gas film is facilitated, then effective heat protection is formed, the thermal stress is reduced, and the problem of non-uniform thermalstress of a corrugated heat insulation screen is solved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A double wall heat shield for an afterburner

InactiveCN103968418BExtend your lifeImprove reliabilityContinuous combustion chamberCombustion chamberDouble wall

The invention discloses a double-layer-wall heat insulation screen used for an afterburner. Cooling protection is formed for the wall surface of the afterburner by using an inner convection cooling mode and a gas side air film cooling mode. The double-layer-wall heat insulation screen comprises a gas side gas film hole plate, a cool air side impacting plate and a trapezoidal reinforcing frame. The gas side air film hole plate serves as the inner wall of a cylinder body of the afterburner, the inner side of the gas side air film hole plate is provided with a main gas duct of the afterburner, the cool air side impacting plate and an outer wall surface form a cool air duct, and the trapezoidal reinforcing frame is arranged between the impacting plate and the air film hole plate. The double-layer-wall heat insulation screen is formed by the impacting plate, the air film hole plate and the trapezoidal reinforcing frame. Cooling air is made to form an air film on the gas side inner wall of the heat insulation screen, and heat load and gas flow losses are reduced. In addition, composite cooling is formed through inner convection cooling and outer air film cooling of a double-layer wall, incoming heat is brought away through convection heat exchange, and the cool air utilization rate is increased. Reduction is achieved after reflection, the effect of vibration prevention is achieved, the service life of the afterburner is prolonged, and the reliability of the afterburner is enhanced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

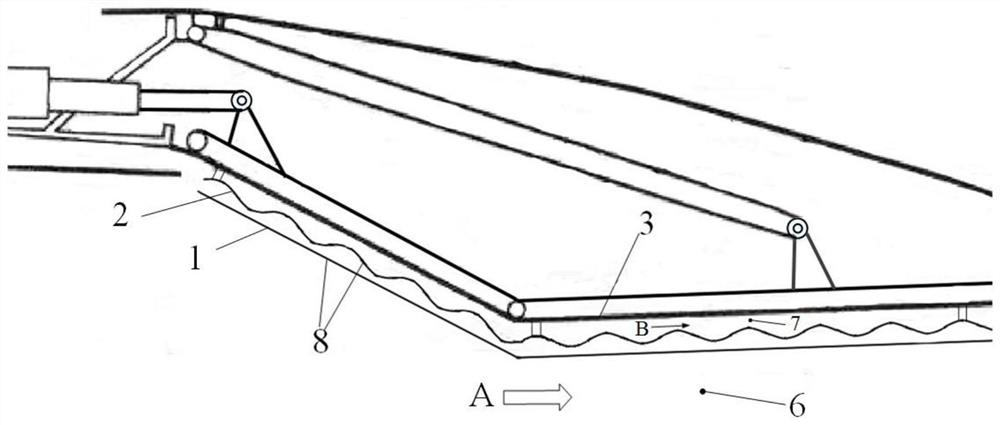

Internal and external cooling combined launch platform

ActiveCN108917471AEffective protectionAchieve internal and external coolingRocket launchersWater flowSurface water

An internal and external cooling combined launch platform is provided. A launch platform body is provided with a supporting frame and a guiding hole for guiding gas in gas flow, and the supporting frame is processed into a through hollow structure to form a built-in flow channel serving as a cooling water flow channel and a water supply channel. The upper surface of the supporting frame and the side wall of the supporting frame facing the guiding hole are provided with a water spraying hole array communicated with the built-in flow channel. The launch platform not only improves the thermal protection capability of the launch platform body structure but also reduces the installation complexity between systems. At the same time, the internal and external cooling of the launch platform is fully achieved by combining the external surface water spraying cooling mode.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

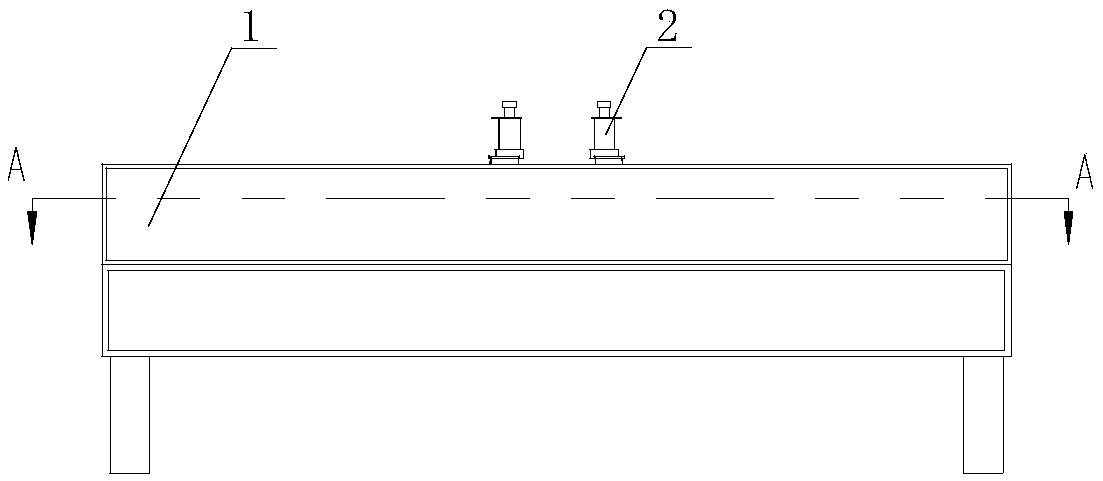

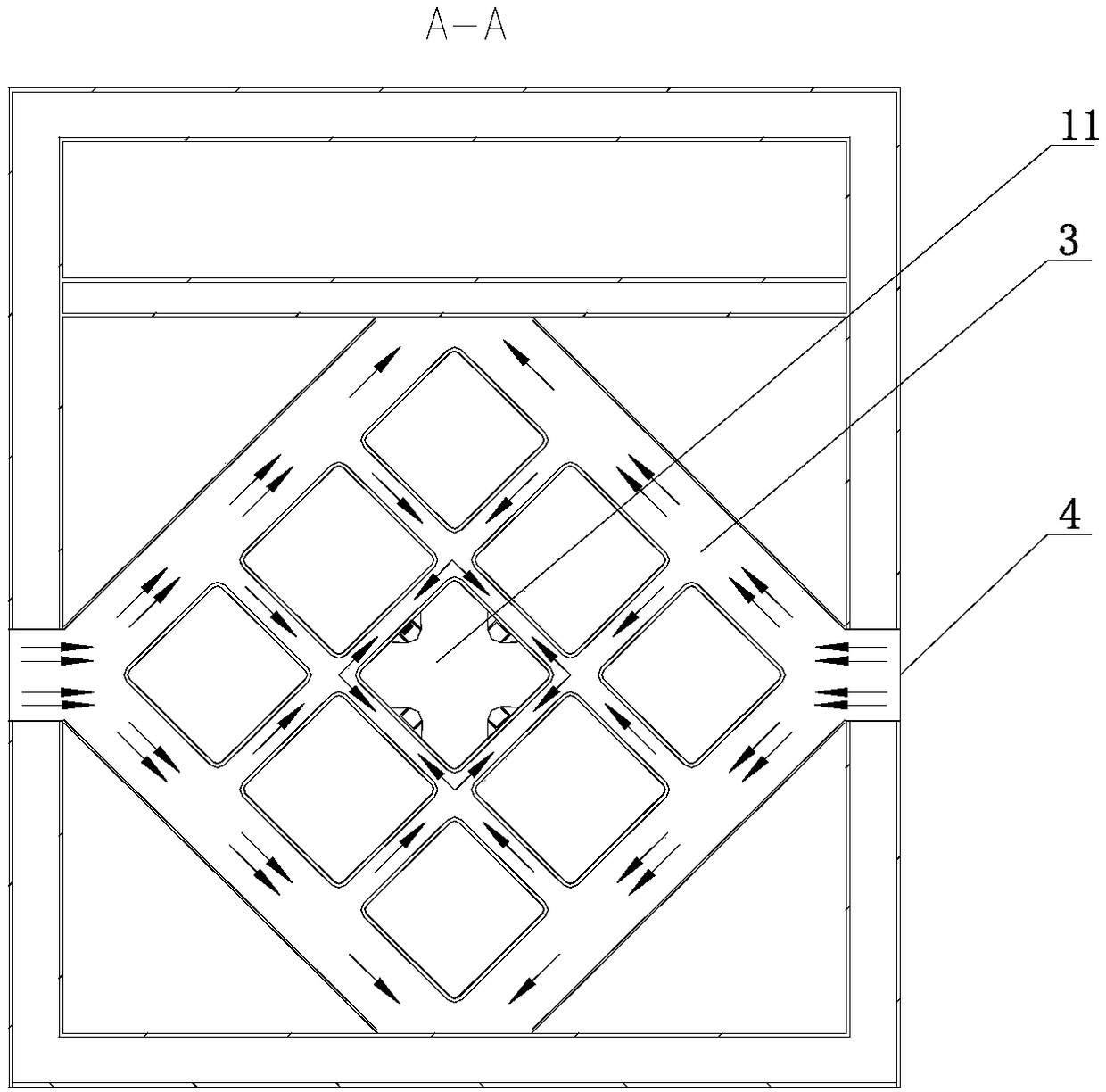

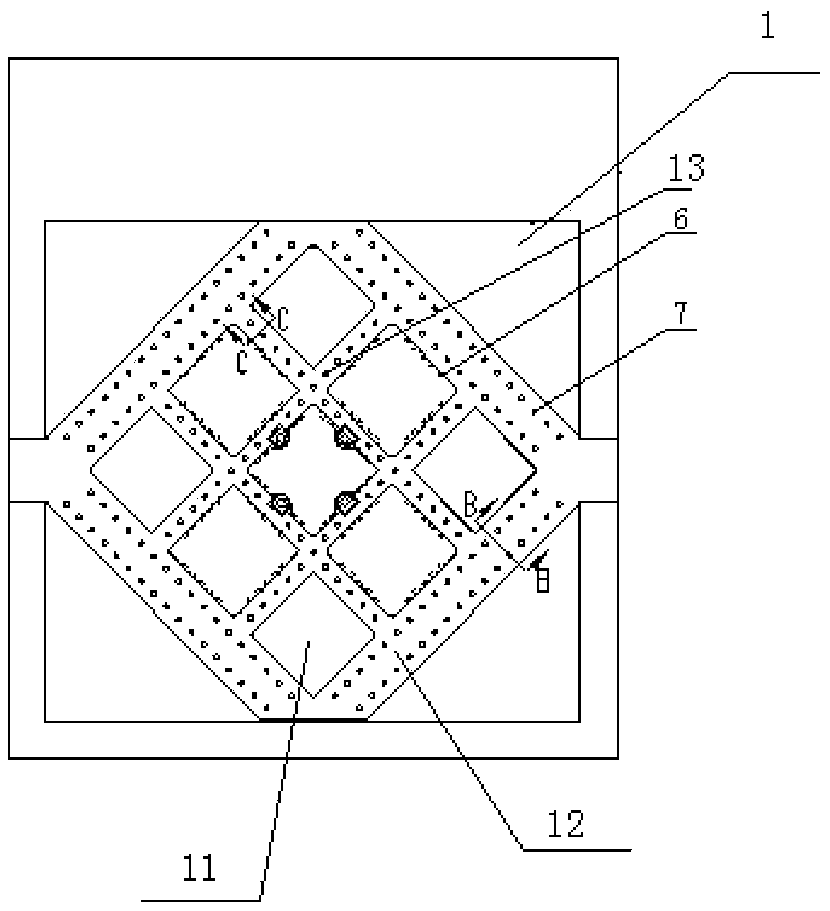

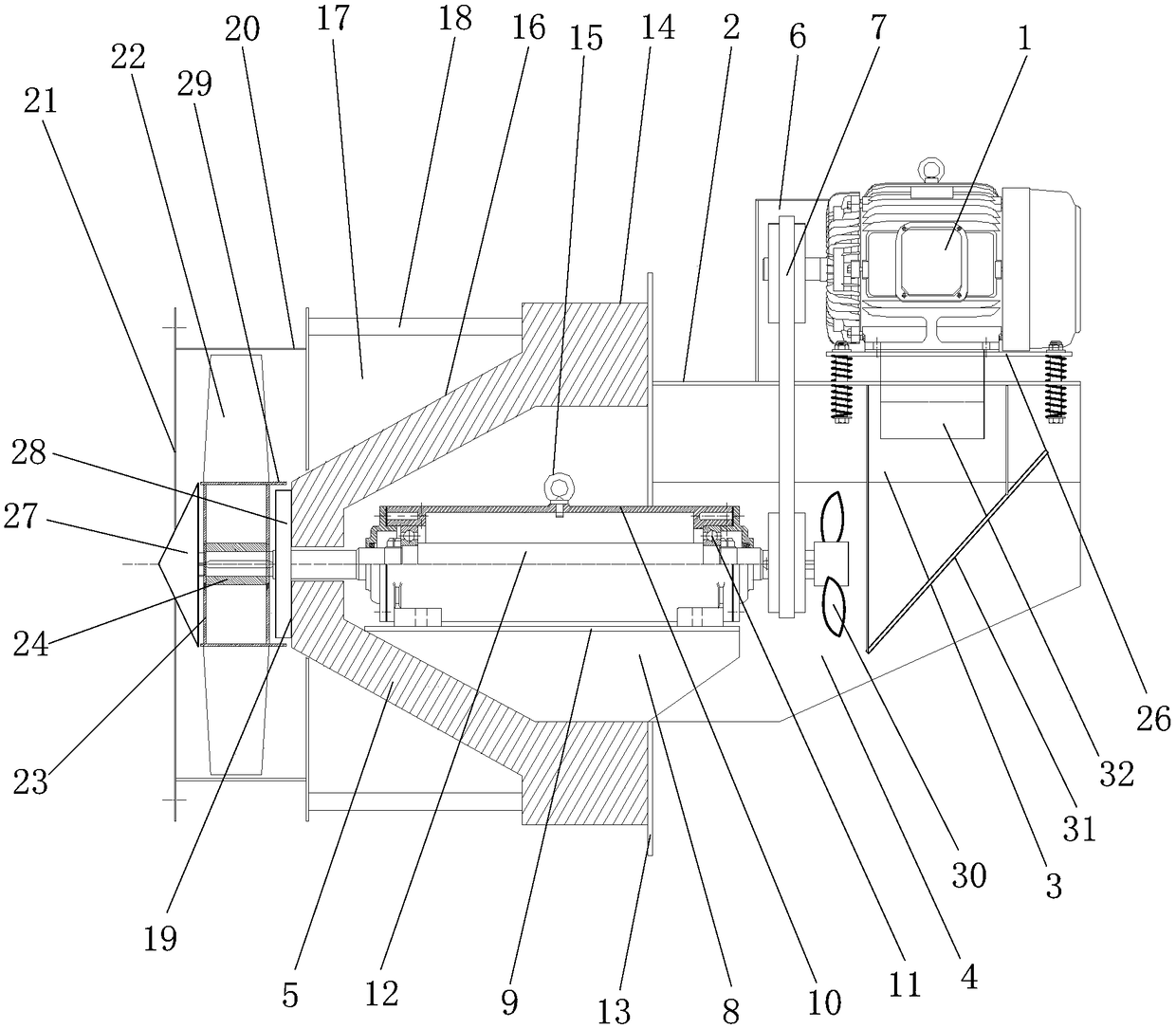

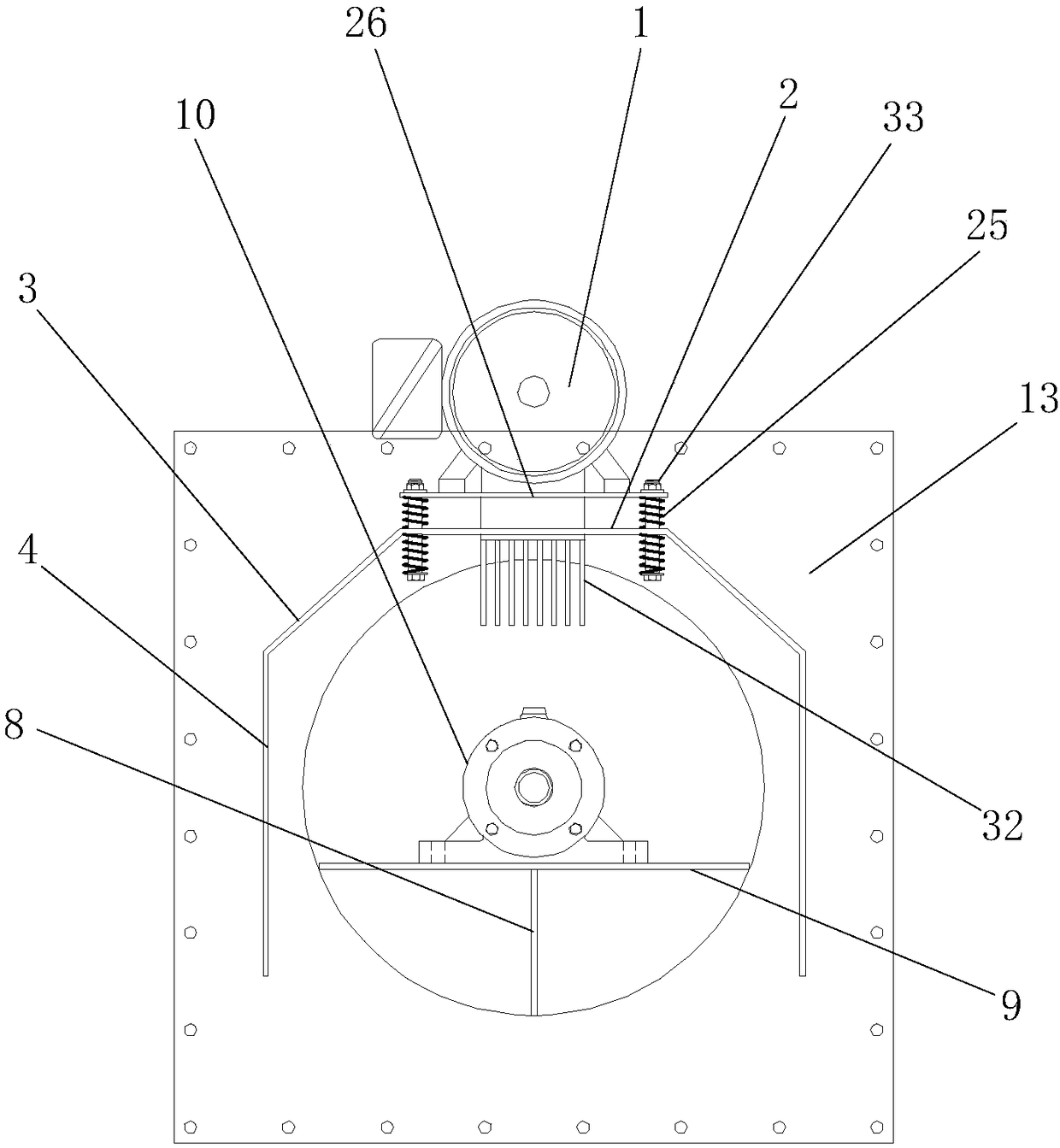

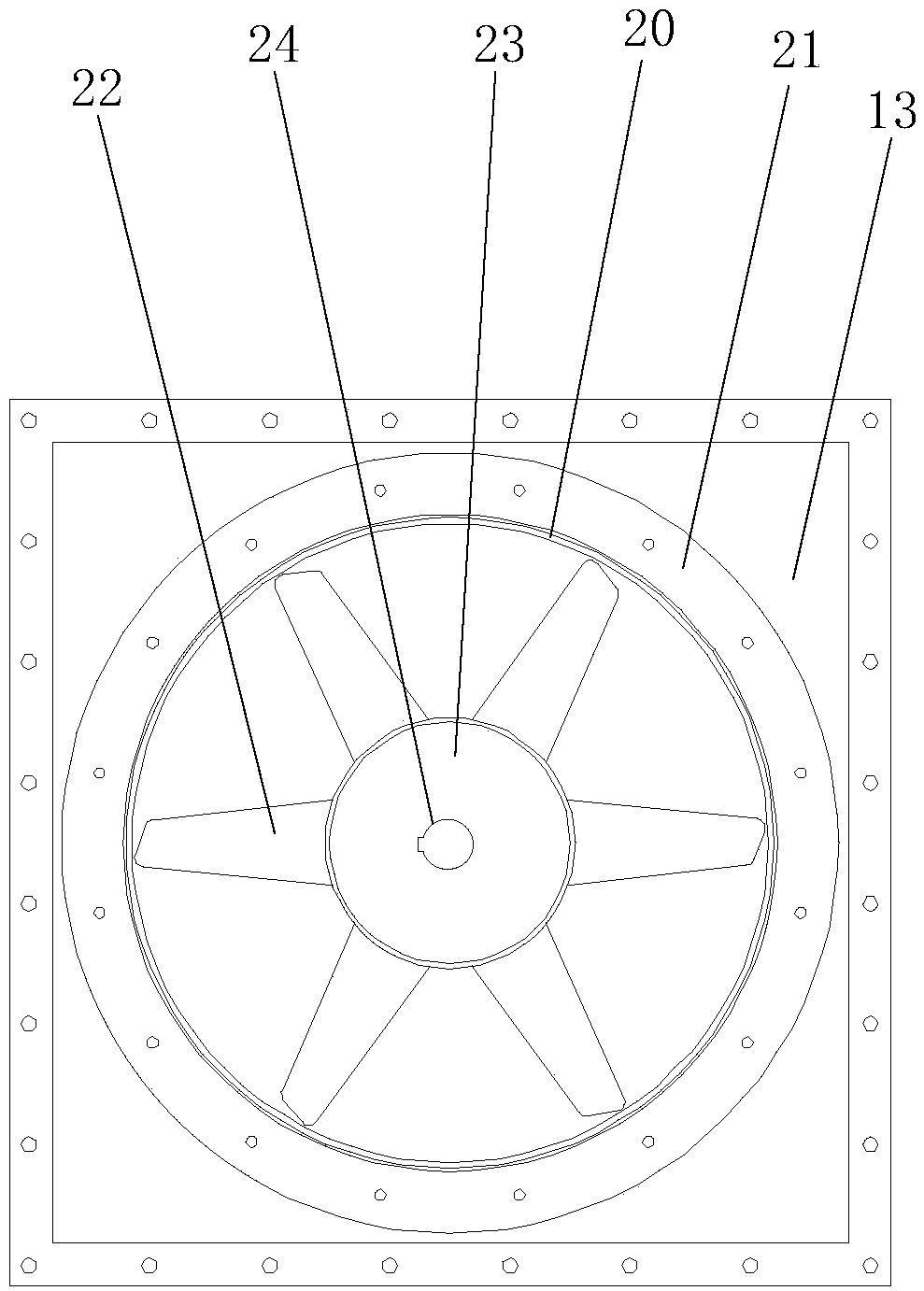

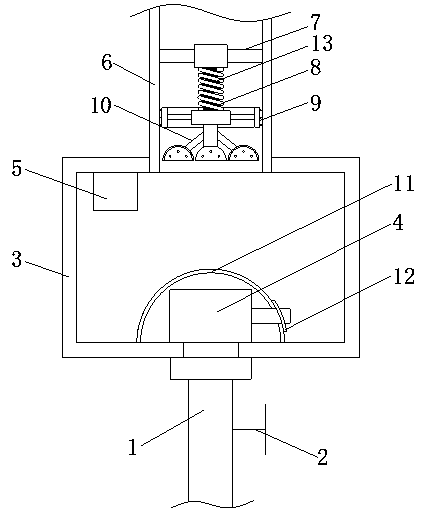

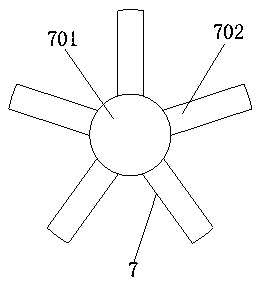

Stable type aging furnace high-temperature-resistant axial flow fan

PendingCN109340153AEffective heat protectionAvoid damagePump componentsPump installationsRotational stabilityImpeller

The invention discloses a stable type aging furnace high-temperature-resistant axial flow fan which comprises a rectangular installation plate, a drive motor, a cooler, an impeller mechanism, a transmission shaft, an impeller shell, a cylindrical air flue, a toroidal base and a conical inner cover. According to the stable type aging furnace high-temperature-resistant axial flow fan, the conical inner cover can be matched with the cylindrical air flue so as to guide hot air, so that the air can be quickly discharged from an air outlet; the conical inner cover can be used for effectively heat-insulating and protecting the cooler; the cooler can be used for heat-insulating the transmission shaft, so that two bearings can be cooled and are prevented from being damaged by high temperature, andthe service life of each bearing is prolonged; and by utilizing a conical flow guiding cover, the front air resistance of the impeller mechanism can be reduced, the inlet air is prevented from causingthe shaking influence on the rotary stability of the impeller structure, so that the impeller mechanism is ensured to rotate stably.

Owner:江苏贝莱德风机制造有限公司

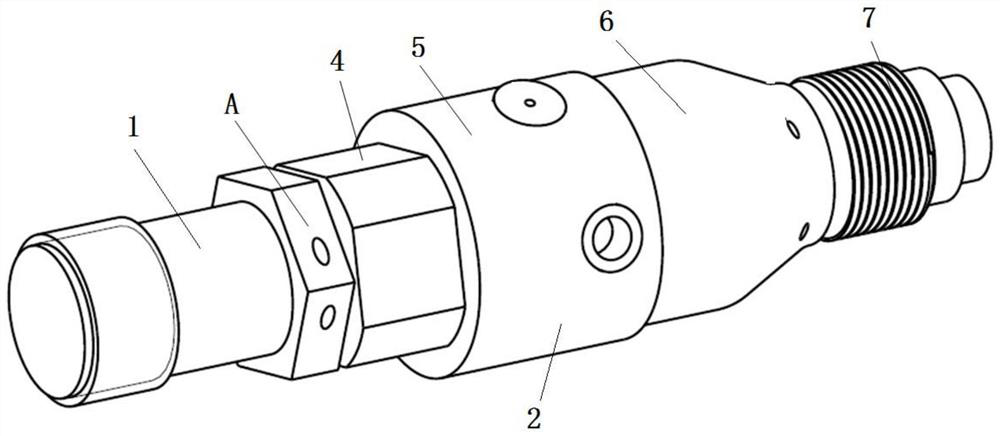

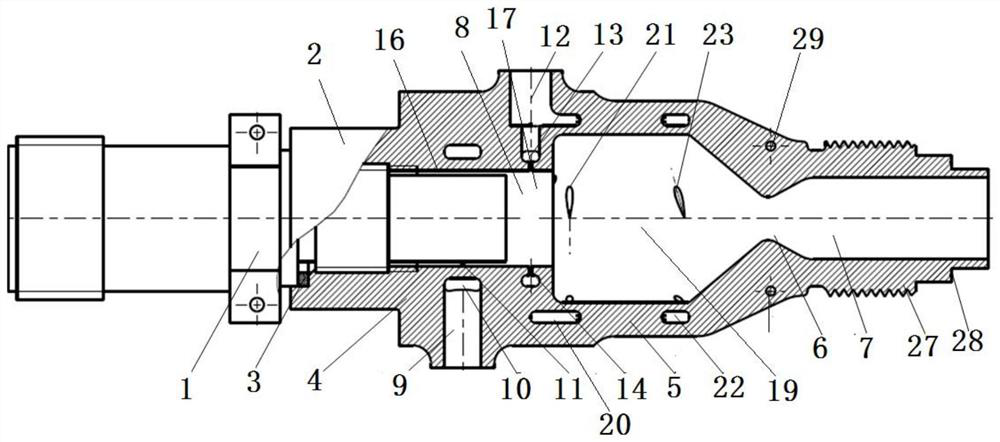

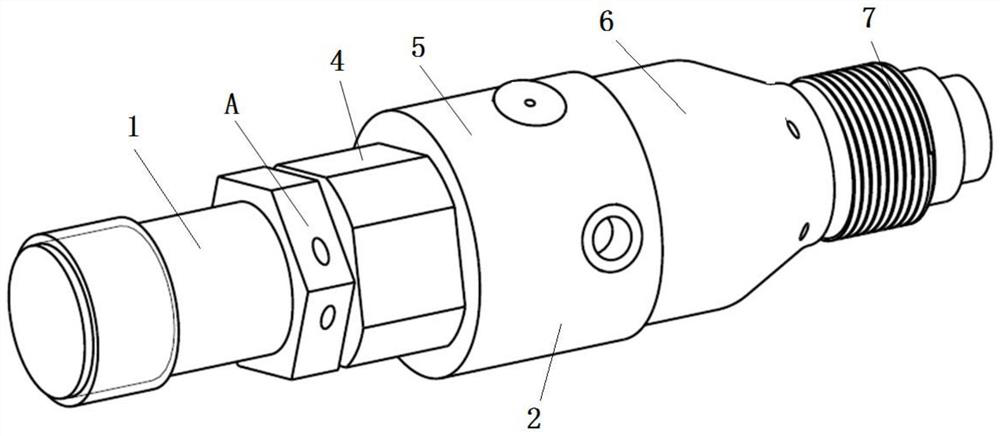

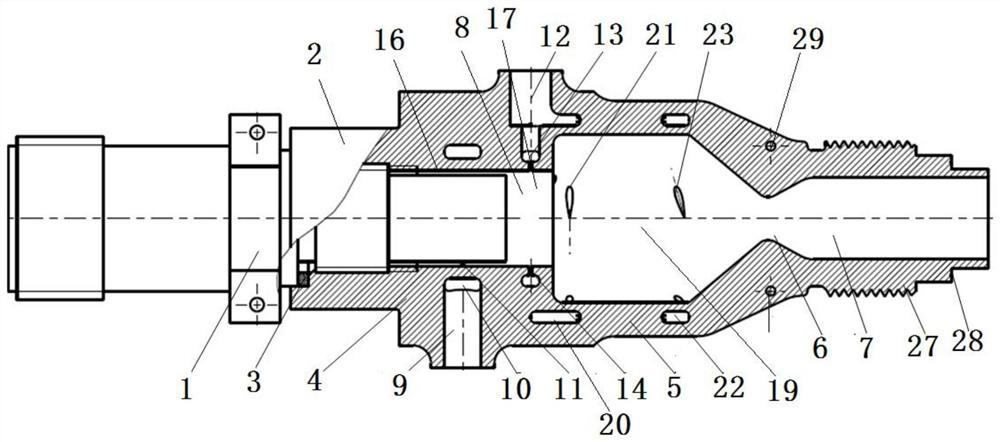

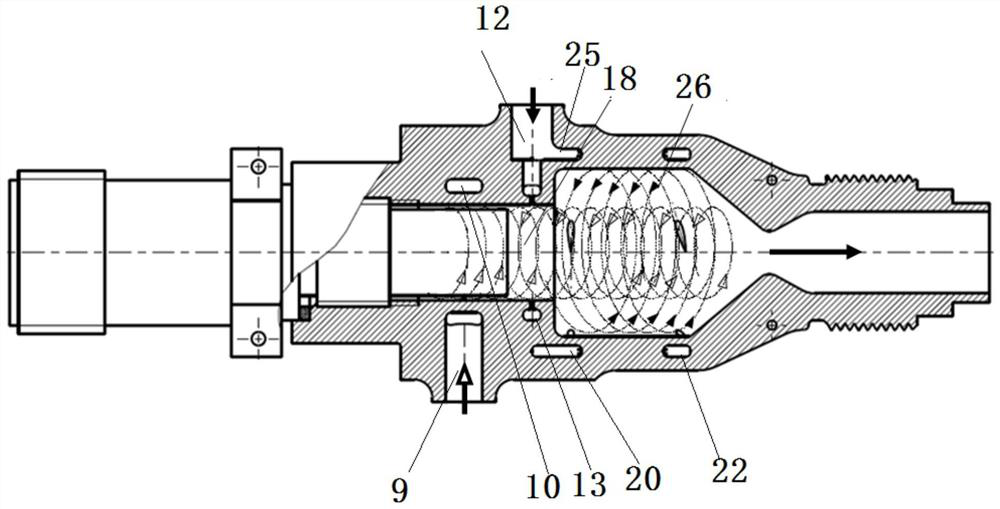

Rotational flow torch igniter based on 3D printing forming

ActiveCN112240570AImprove reliabilitySmooth ignition processContinuous combustion chamberCombustion chamberThrust chamber

The invention discloses a rotational flow torch igniter based on 3D printing forming. The rotational flow torch igniter comprises an electric spark plug rod, a torch ignition tube and a red copper sealing gasket, wherein the torch ignition tube comprises a head tube section, a body tube section, a throat nozzle section and a tail tube section which are integrally arranged in a 3D printing mode; amain working principle of the rotational flow torch igniter is as follows: ignition combustion is carried out in an ignition chamber in the head tube section, secondary combustion is carried out in asecondary combustion chamber of the body tube section, and tertiary blending combustion is carried out in the throat spray tube section, so that the ignition starting process is stable, the combustionprocess is sufficient, and the combustion working reliability of the igniter is greatly improved; and oxidizing agent rotational flow can be arranged on the head tube section to protect the electricspark plug rod, a rotational flow field is arranged in the secondary combustion chamber to form gas film protection on the body tube section, connecting and fastening parts with a thrust chamber are reasonably designed, the appearance structure of the torch igniter is simplified, the miniaturization design of the torch igniter is achieved, the process complexity and cost are reduced, and the manufacturing period is shortened.

Owner:XIAN AEROSPACE PROPULSION INST

Lower spraying laminar flow cooling device

ActiveCN102189131BReduce consumptionAvoid wastingWork treatment devicesMetal rolling arrangementsLaminar coolingSpray nozzle

The invention discloses a lower spraying laminar flow cooling device. The device comprises a plurality of groups of lower spraying devices, wherein each group of lower spraying device comprises a collecting pipe, two plunger pipes, two plungers and two U-shaped covers; the collecting pipe is fixedly arranged along a direction vertical to the operation direction of strip steel; a plurality of goose neck spray pipes are uniformly distributed on the collecting pipe along the axial direction; the two plunger pipes are fixedly arranged above the two ends of the collecting pipe respectively, pass through the plurality of goose neck spray pipes which are uniformly distributed at the two ends of the collecting pipe respectively, divide the goose neck spray pipes into upper nozzles and lower spraypipes, and are communicated with the upper nozzles and the lower spray pipes of the goose neck spray pipes through a plurality of through holes; the two plungers are arranged in the two plunger pipesrespectively; the two U-shaped covers are covered outside the two plungers in a mode that openings are downward; and the plungers are connected with driving devices through the U-shaped covers, so that movement in the axial direction is realized, the through holes are blocked, and cooling water quantity is adjusted.

Owner:BAOSHAN IRON & STEEL CO LTD

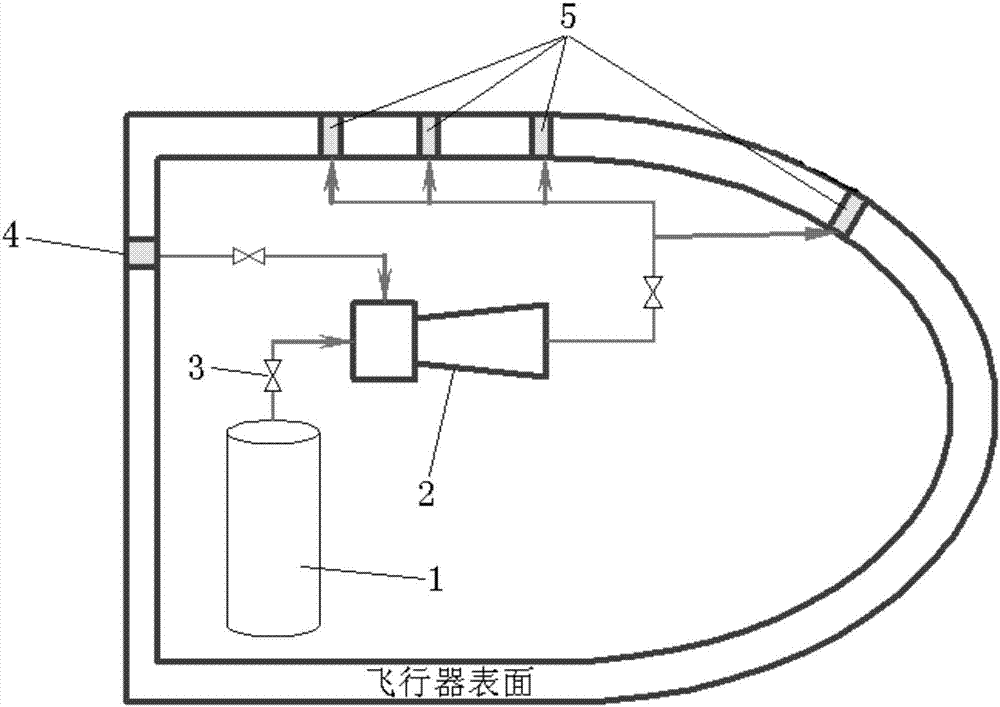

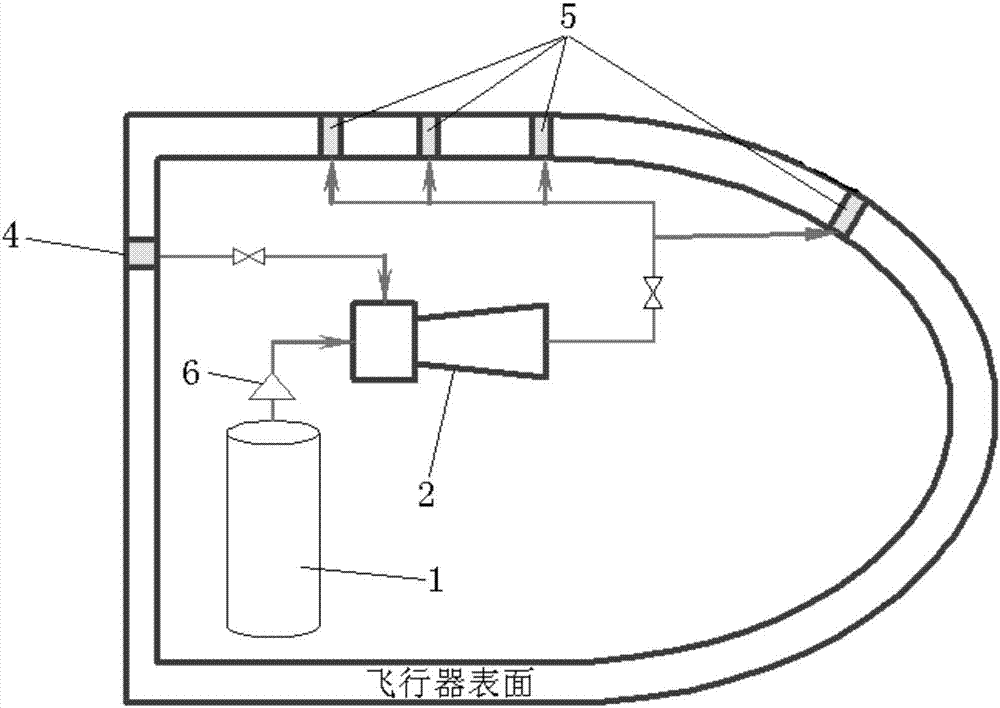

Film cooling system with ejector and method

ActiveCN106882400AQuality improvementImprove cooling effectCosmonautic thermal protectionAircraft indicatorsWorking fluidHigh pressure

The invention relates to a film cooling system with an ejector and a method. The film cooling system comprises a coolant storage container arranged inside an aircraft, a suction hole and a plurality of film cooling micropores which are formed in the surface of the aircraft and the ejector connected with the coolant storage container, the suction hole and the film cooling micropores. According to the method, a high-pressure coolant is adopted as working fluid of the ejector, low-pressure fluid outside the aircraft is sucked, fluid after being mixed is used as cooling fluid of film cooling, after the mixed fluid flows out of the outlet of the ejector and arrives at the plurality of film cooling micropores on the surface of the aircraft, a cooling film is formed in the surface of the aircraft, and thermal protection of the high-temperature surface of a hypersonic aircraft is achieved.

Owner:TSINGHUA UNIV

A power generation device with anti-clogging function using geothermal energy to generate electricity

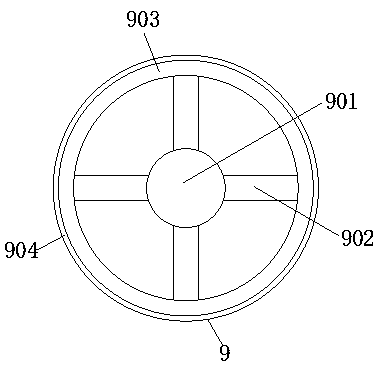

ActiveCN108825456BGreat driving forceTo achieve the purpose of anti-cloggingGeothermal energy generationMachines/enginesThermodynamicsCombustion chamber

The invention discloses a power generation device utilizing geothermal energy to generate power and having an anti-blocking function. The power generation device comprises a collecting pipe, a one-wayvalve is arranged on the right side of the collecting pipe, and a combustion chamber is arranged at the top of the collecting pipe; a water suction pump is arranged at the position, corresponding tothe collecting pipe, of the bottom of the inner wall of the combustion chamber, and a heating device is fixedly installed on the left side of the top of the inner wall of the combustion chamber; the top of the combustion chamber is fixedly connected with a steam pipe communicating with the combustion chamber, a stabilizing frame is arranged inside the steam pipe and comprises a first connecting piece, the surface of the first connecting piece is fixedly connected with first connecting rods, the number of the first connecting rods is five, and the first connecting rods are arranged on the surface of the first connecting piece in a quidistant encircling manner. According to the power generation device, the design is ingenious, the purpose of scraping and removing impurities in the inner wallof the steam pipe is achieved by utilizing upward driving force of water vapor, the manufacturing cost is low, the long-term stable operation of the device can be effectively guaranteed, the maintenance cost is reduced, and the use is facilitated.

Owner:嘉兴市永泰五金塑料有限责任公司

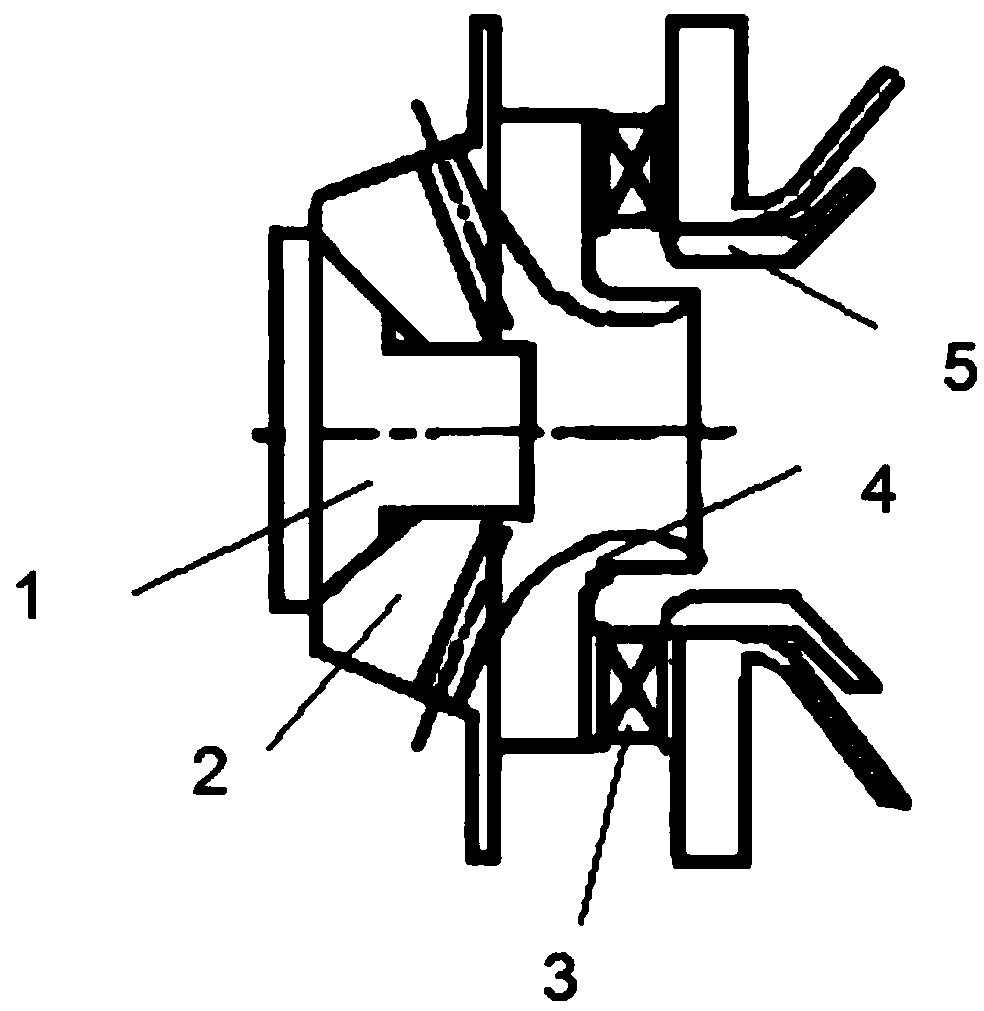

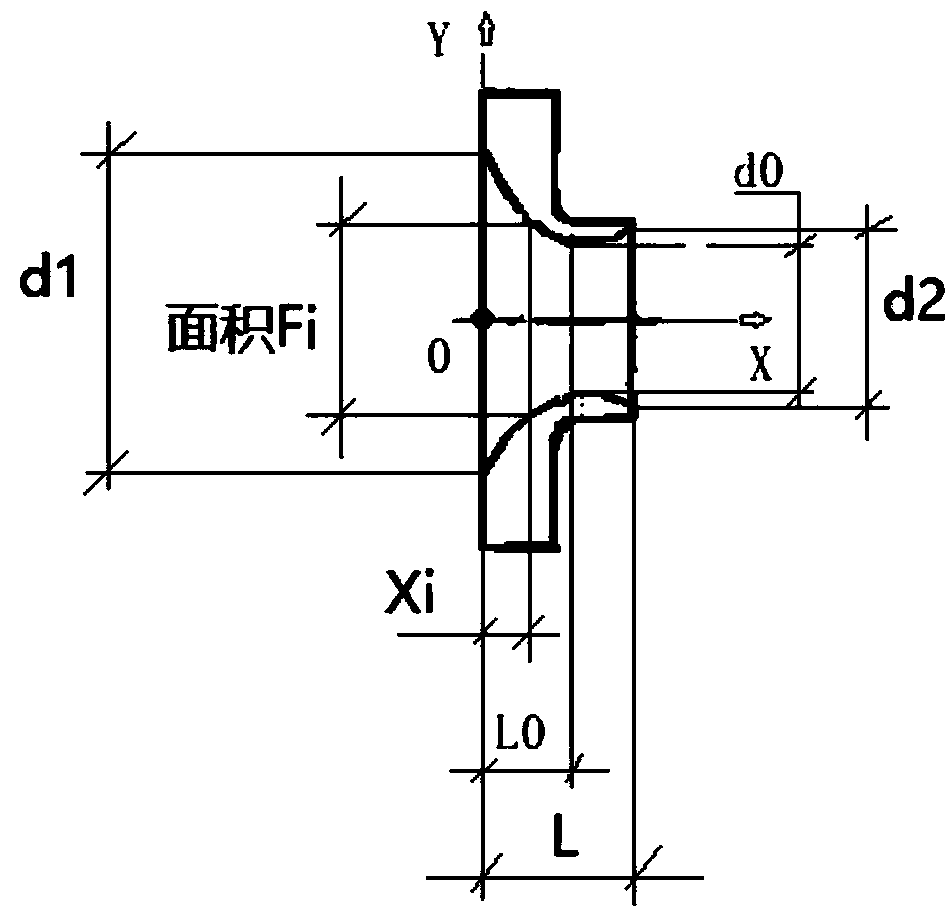

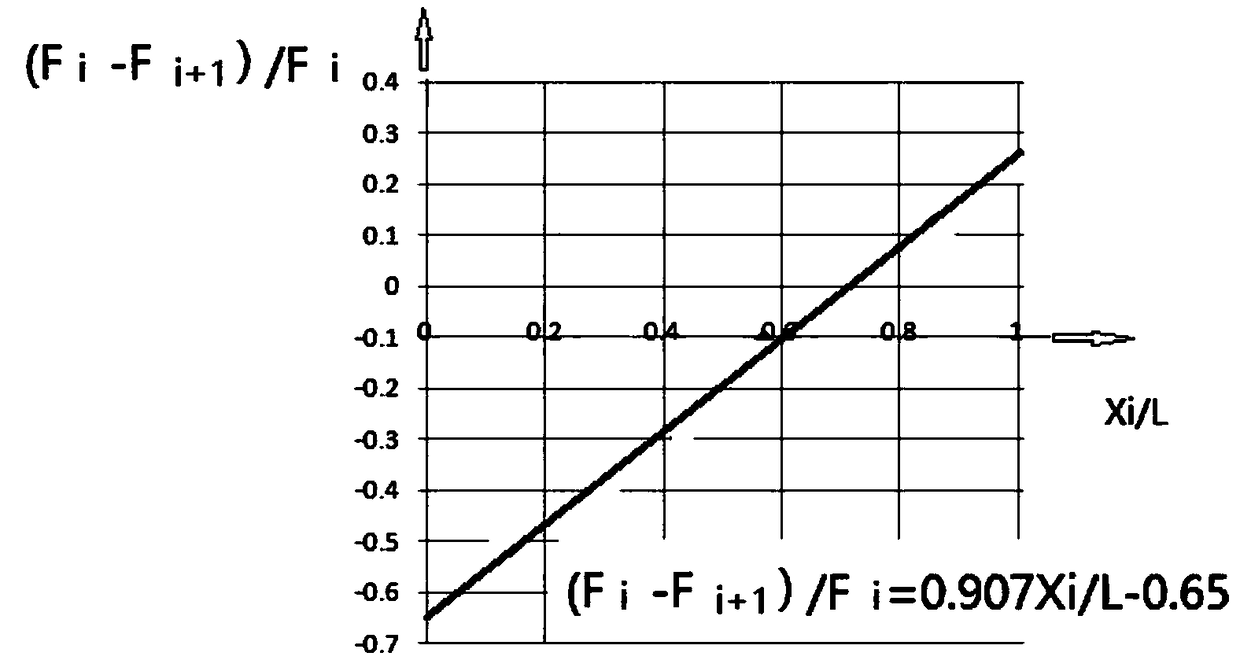

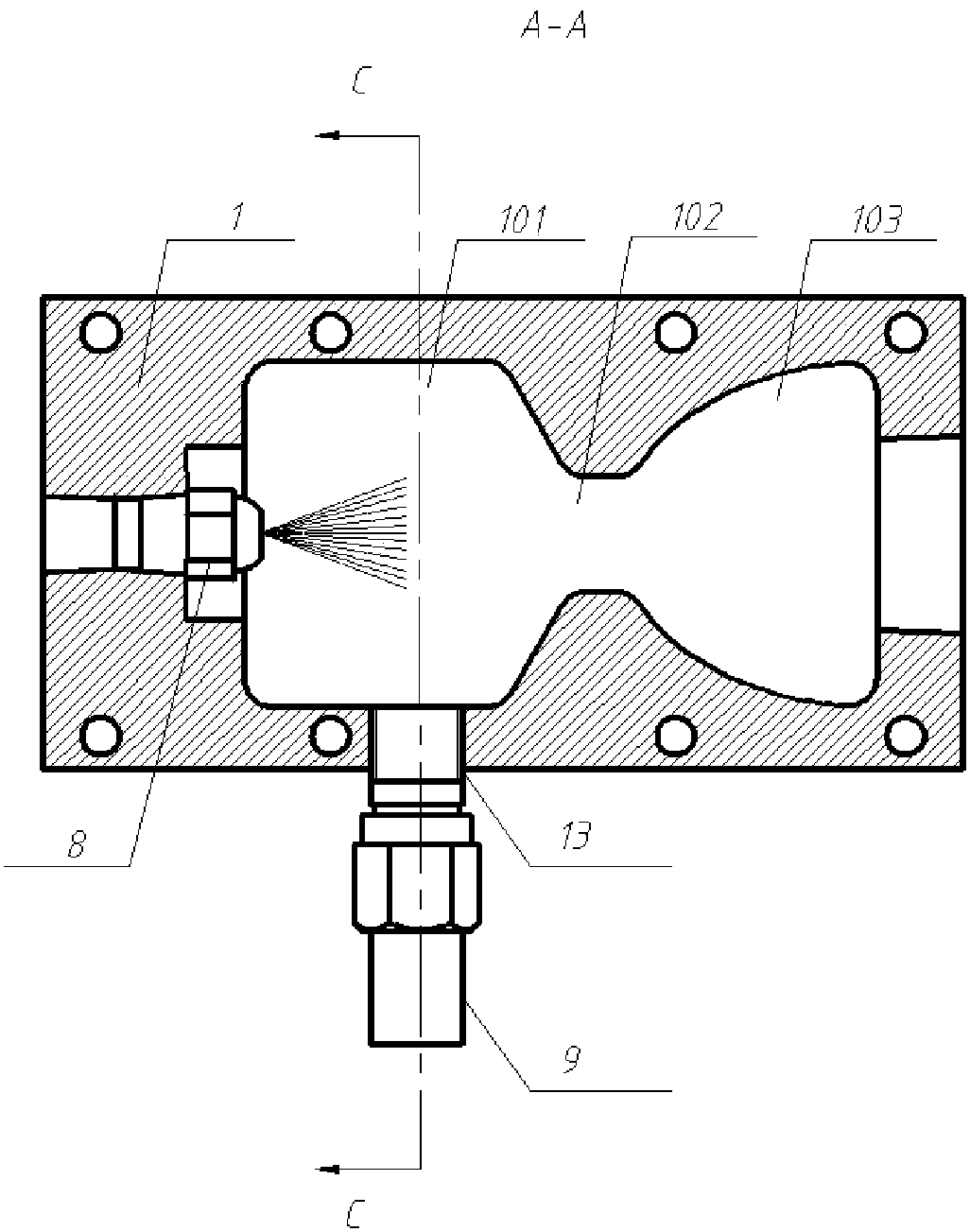

Design method of venturi flow channel of double-swirl atomizing device

ActiveCN109237516AGuarantee the quality of sprayingEfficient mixingContinuous combustion chamberSpray nozzleEngineering

The invention provides a design method of a venturi flow channel of a double-swirl atomizing device, which comprises the following steps of: (1) calculating the air flow passing through the double-swirl atomizing device; (2) calculating the flow WIN of a primary swirler according to that the flow WIN of the primary swirler of the double-swirl atomizing device is equal to the air flow WO passing through the venturi; (3) calculating a throat diameter d0 of the venturi according to the principle that the air flow Mach number of the venturi throat section is 0.1; (4) determining an axial positiondimension L0 of the venturi throat,(5) determining an inlet dimension d1 of the venturi flow channel and an outlet dimension d2 of the venturi flow channel; (6) determining the profile modeling of theventuri flow channel. According to the invention, the design method is an important part in the design of the double-swirl atomizing device, ensures the spray quality of the atomizing device and theeffective thermal protection of a fuel nozzle, and provides a basis for the design work in the future.

Owner:TIANJIN CHENGLI AVIATION TECH CO LTD

Double Wall Cooling Structure with Longitudinal Corrugated Impact Orifice Plates for Vector Nozzles

The present invention uses a longitudinal corrugated impingement plate and a flat air film plate to form a double-wall cooling structure. Both the impact holes and the air film holes are distributed in fork rows; the impact holes are arranged at the troughs of the corrugated impact orifice plate, and the air film holes on the air film orifice plate are arranged at the crests of the corrugated impact orifice plate; the corrugated impact orifice plate Both the air film orifice plate and the air film have a multi-unit periodic structure in the axial direction. A small impact distance is formed between the wave trough and the air film orifice plate, which can enhance the impact heat transfer, and a large space can be formed between the wave crest and the air film orifice plate, which is conducive to the full development of the cold air flow and the outflow, which can reduce the flow It improves the utilization rate of cold air, and solves the contradiction between reducing the impact distance in order to enhance heat transfer, but increasing the impact distance in order to reduce flow resistance. At the same time, the air film panel is a flat plate, which is conducive to the attachment of the air film, forming effective thermal protection, reducing thermal stress, and solving the problem of uneven thermal stress of the corrugated heat shield.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

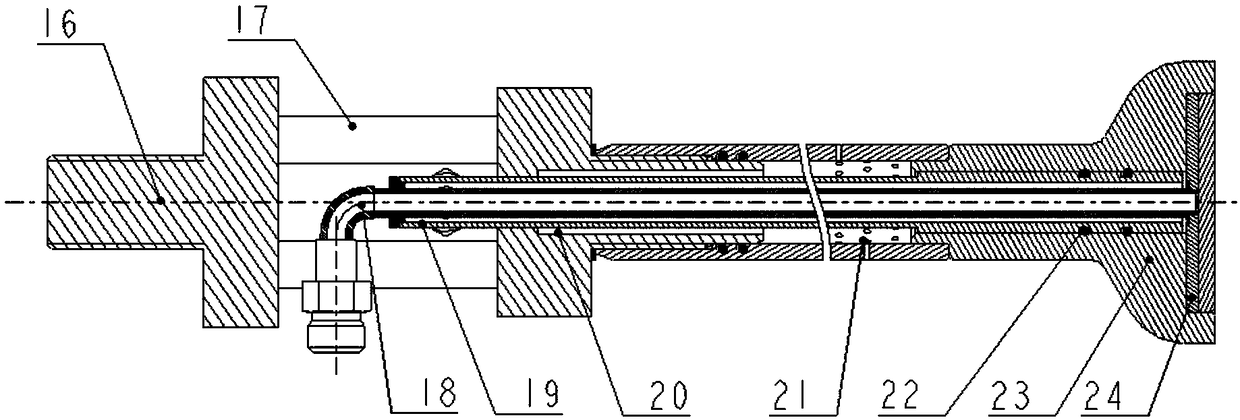

Simulation device for thermal environment of supersonic/subsonic combustion of combined engine

ActiveCN110595792BReliable Thermal ProtectionAchieve heatingGas-turbine engine testingJet-propulsion engine testingCombustion chamberEngineering

The invention discloses a simulation device of composite engine supersonic / subsonic combustion heat environment. The simulation device comprises an injector and a combustion chamber which are connected up and down and communicated; a center cavity with an opened upper side and an opened lower side is formed along with an axle wire of the injector in a penetrating manner, the center cavity is communicated with the combustion chamber, an electric spark igniter is axially arranged in the center cavity; the injector is a three-cavity structure, the three-cavity structure are an oxygen cavity, an air cavity and an alcohol cavity; each cavity is revolved body-shaped, wherein the oxygen cavity surrounds the center cavity, the air cavity surrounds the outside of the oxygen cavity, and the alcoholcavity is located at the lower part of the oxygen cavity; the bottoms of the oxygen cavity, the air cavity and the alcohol cavity are communicated with the combustion chamber to inject the corresponding oxygen, air and alcohol into the combustion chamber. The simulation device can realize the realize reliable injection panel thermal protection, thereby effectively supporting the design of the thermal protection scheme of the engine.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Double wall cooling structure with transverse corrugated impingement orifice for vectoring nozzle

Owner:NORTHWESTERN POLYTECHNICAL UNIV

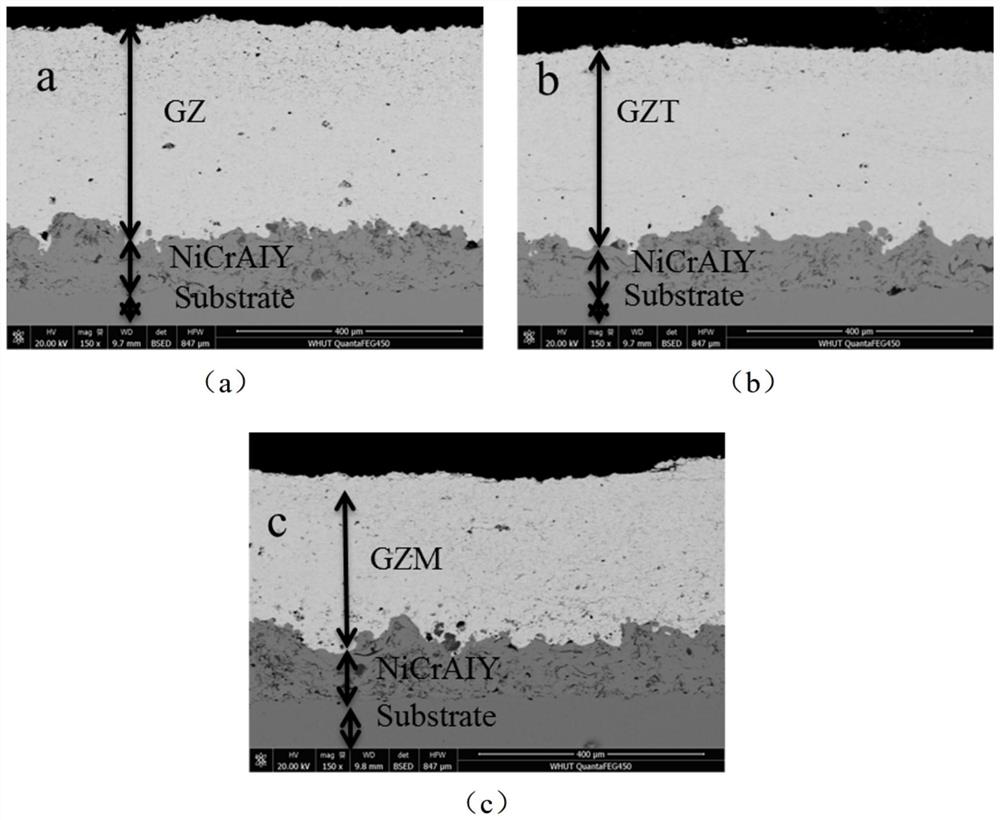

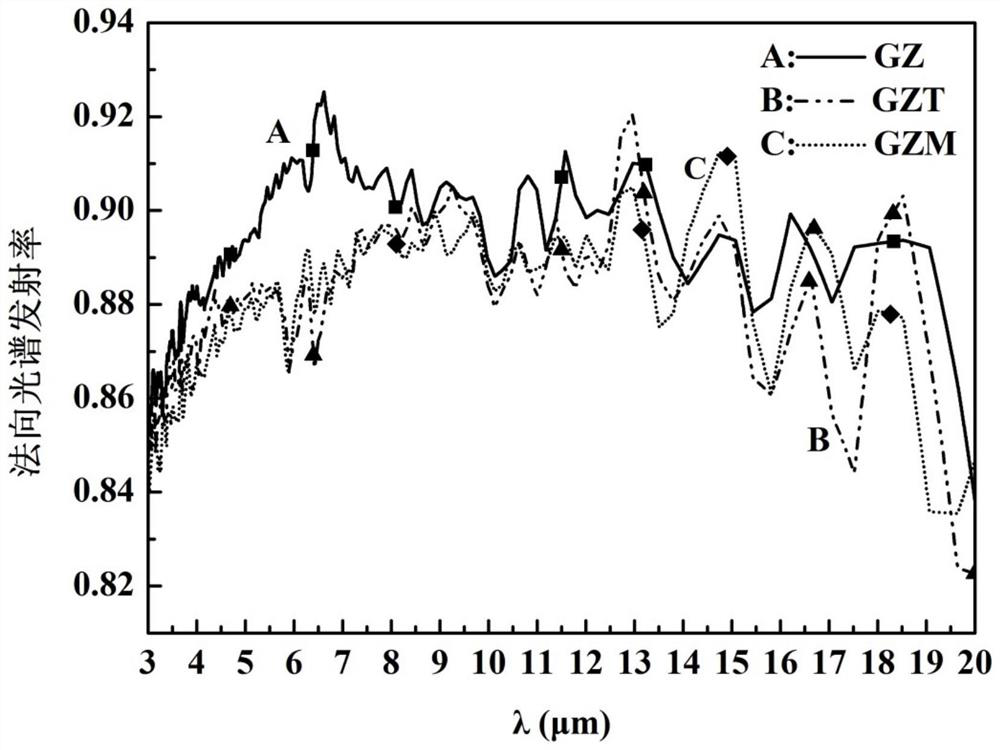

High-temperature high-emissivity heat dissipation coating and its preparation method and application

ActiveCN111118438BReduce the temperatureHigh thermal expansionMolten spray coatingEmissivityPhysical chemistry

The invention provides a high-temperature and high-emissivity heat dissipation coating and its preparation method and application. The preparation method of the heat dissipation coating is: spray ceramic powder on the surface of a substrate with a bonding layer by atmospheric plasma spraying technology to prepare a bonding layer formed on the surface of the substrate. High-temperature and high-emissivity heat dissipation coating containing Gd-Zr, Gd-Zr-Ti or Gd-Zr-Mg system multiple oxides on the ceramic powder, calculated by mass percentage, Gd 2 o 3 The content is 40-60%, ZrO 2 The content is 40-60%, TiO 2 The content is 0-5%, and the MgO content is 0-5%. The invention can solve the problems of low emissivity at high temperature, low service temperature and unstable phase structure of the existing thermal insulation coating, and the prepared thermal insulation coating not only has good thermal insulation performance, but also can dissipate heat well. by Mg 2+ or Ti 4+ Partial replacement of the parent material can also effectively improve the absorption in the near-infrared band.

Owner:WUHAN UNIV OF TECH

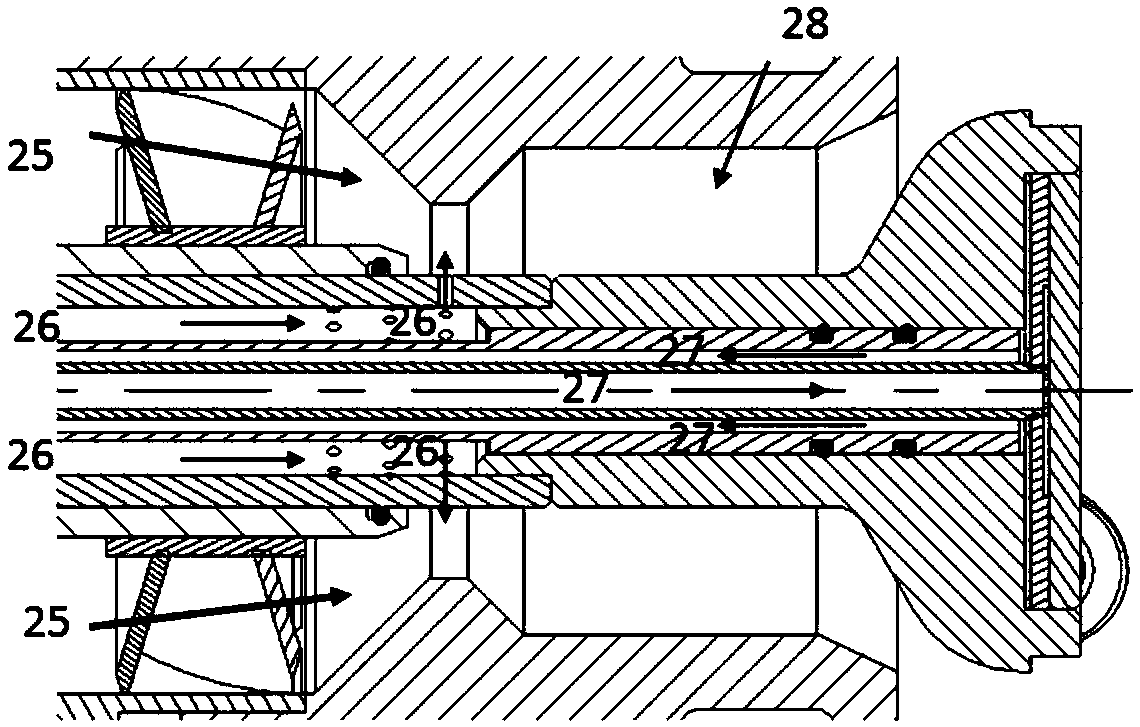

A Double Wall Cooling Structure for Jet Engine Vectoring Nozzle

The invention relates to a double-wall cooling structure for a jet engine vector nozzle, which uses a three-dimensional corrugated impact plate and a flat air film plate to form a double-wall cooling structure. The impact holes and gas film holes are distributed in a "chessboard" pattern, that is, the impact holes are arranged at the troughs of the corrugated impact orifice plate, and the gas film holes on the gas film orifice plate are arranged at the crests of the corrugated impact orifice plate; The corrugated impact orifice plate and the gas film orifice plate have multiple unit periodic structures in the axial direction. A small impact distance is formed between the wave trough and the air film orifice plate, which can enhance the impact heat transfer, and a large space can be formed between the wave crest and the air film orifice plate, which is conducive to the full development of the cold air flow and the outflow, which can reduce the flow Improve the utilization rate of cold air, and solve the contradiction between reducing the impact distance in order to enhance heat transfer, but increasing the impact distance in order to reduce flow resistance. At the same time, the air film plate is a flat plate, which is conducive to the attachment of the air film, forming effective thermal protection and reducing thermal stress.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

A kind of tial3/al2o3 composite powder and its preparation method and application

The invention relates to a preparation technology of a titanium alloy high-temperature protective coating and particularly relates to TiAl3 / Al2O3 composite powder as well as a preparation method and application thereof. The preparation method comprises the steps of firstly, carrying out thermal treatment after carrying out high-energy ball milling on pure Al and TiO2 nanopowder according to a certain ratio for a certain time to obtain the TiAl3 / Al2O3 composite powder; and then, spraying the prepared composite powder on a titanium alloy substrate at the temperature of 100-700 DEG C and the pressure of 0.3-5.0MPa by using a cold gas dynamic spraying method to form a TiAl3 / Al2O3 composite coating. The coating comprises the components of TiAl3 and Al2O3, wherein Al2O3 is uniformly distributed in the coating, and the coating is more than 10mu m thick. The preparation method disclosed by the invention is simple in operation, the components are easily controlled, the obtained coating is low in porosity, good in compatibility with matrix and binding force and relatively good in high-temperature oxidation resistance, the mutual diffusion between the coating and the matrix can be greatly reduced, and the problem of high-temperature oxidation of titanium alloy can be favorably solved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

An air/methane burner for high-temperature pure air regenerative heating equipment

ActiveCN108844063BReliable ignitionAchieve sealingIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberMomentum

An air / methane combustor for a high-temperature pure air heat accumulation type heating device is characterized by comprising a head portion and a body portion, wherein the head portion and the body portion are fixedly connected together to form an air / methane combustor integrated structure, a premixing cavity is formed in the head portion, a combustion chamber inner cavity is formed in the body portion, air in the head portion enters the premixing cavity in a rotational flow manner and is mixed with methane, with the flow being adjustable, jetted in the radial direction at the premixing cavity to form premixed gas, a sudden expansion face backflow area is formed at the connection portion between the head portion and the body portion, the air / methane premixed gas is ignited at the sudden expansion face backflow area, and a preheated heat source is provided for the heat accumulation type heating device. According to the air / methane combustor for the high-temperature pure air heat accumulation type heating device, a pintle structure is designed on the head portion, under drive of an actuator, the injection area of a methane spray nozzle is changed, it is guaranteed that gas media arealways mixed at the best momentum ratio, and ignition and efficient combustion of the premixed gas is ensured.

Owner:XIAN AEROSPACE PROPULSION INST

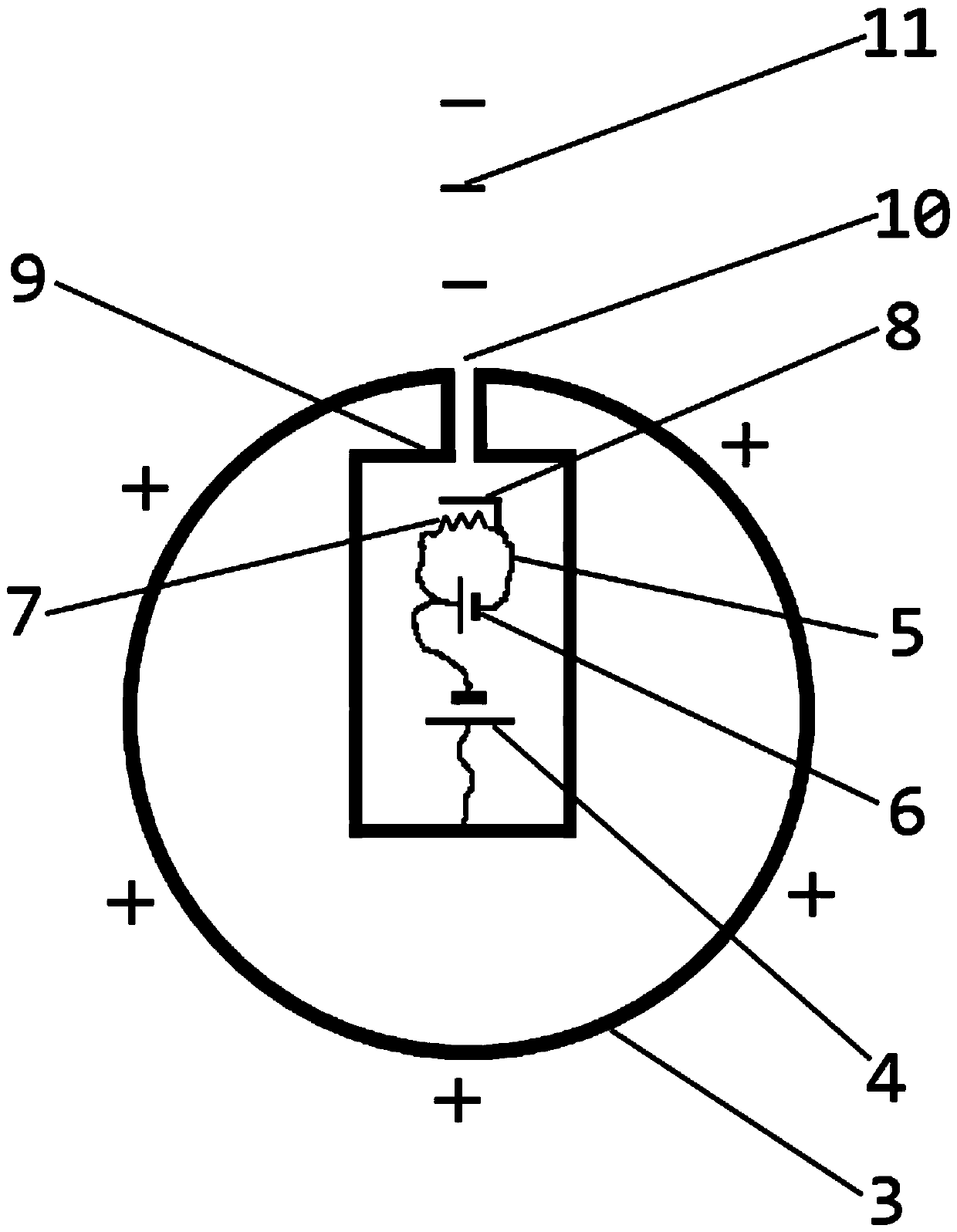

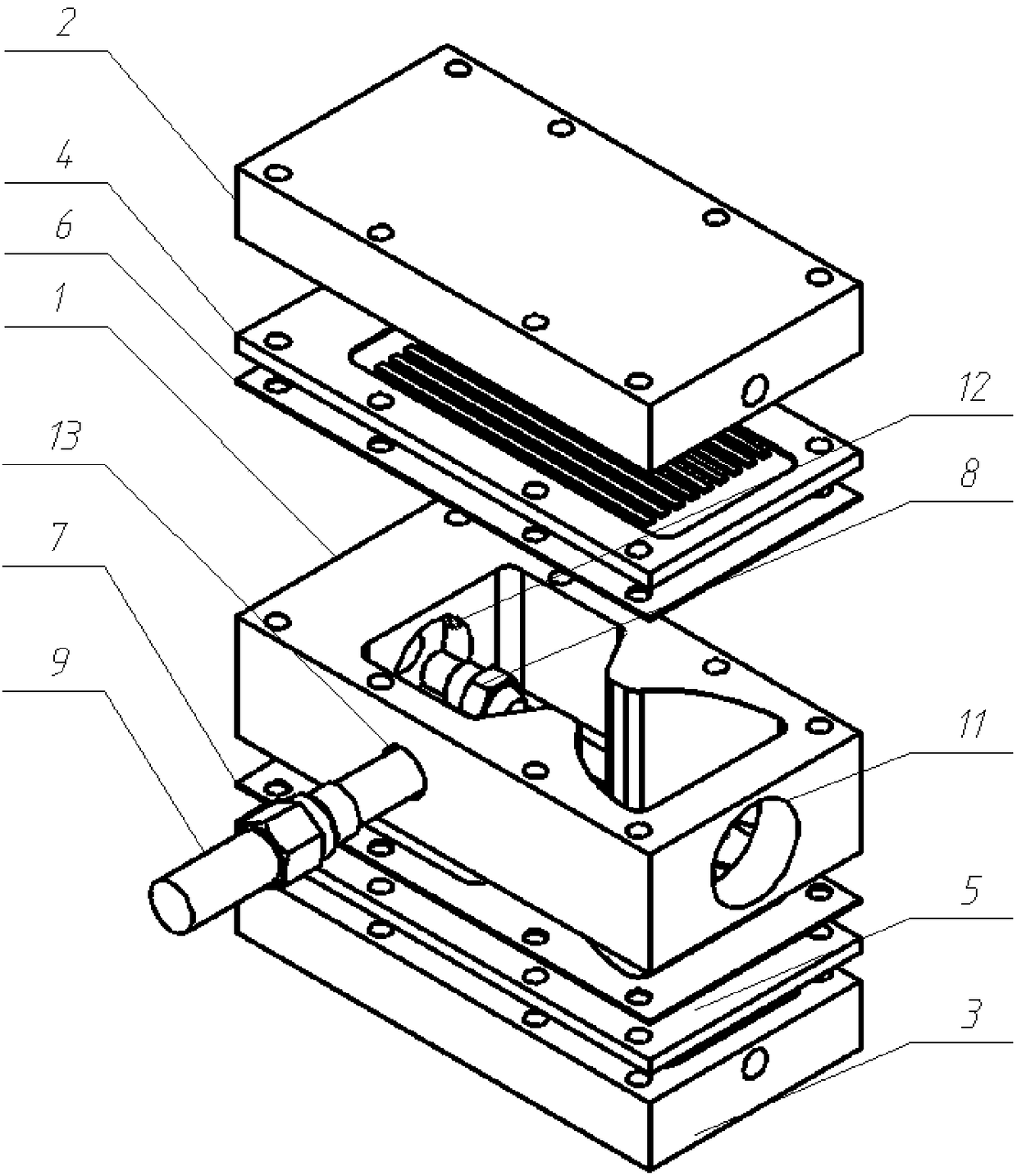

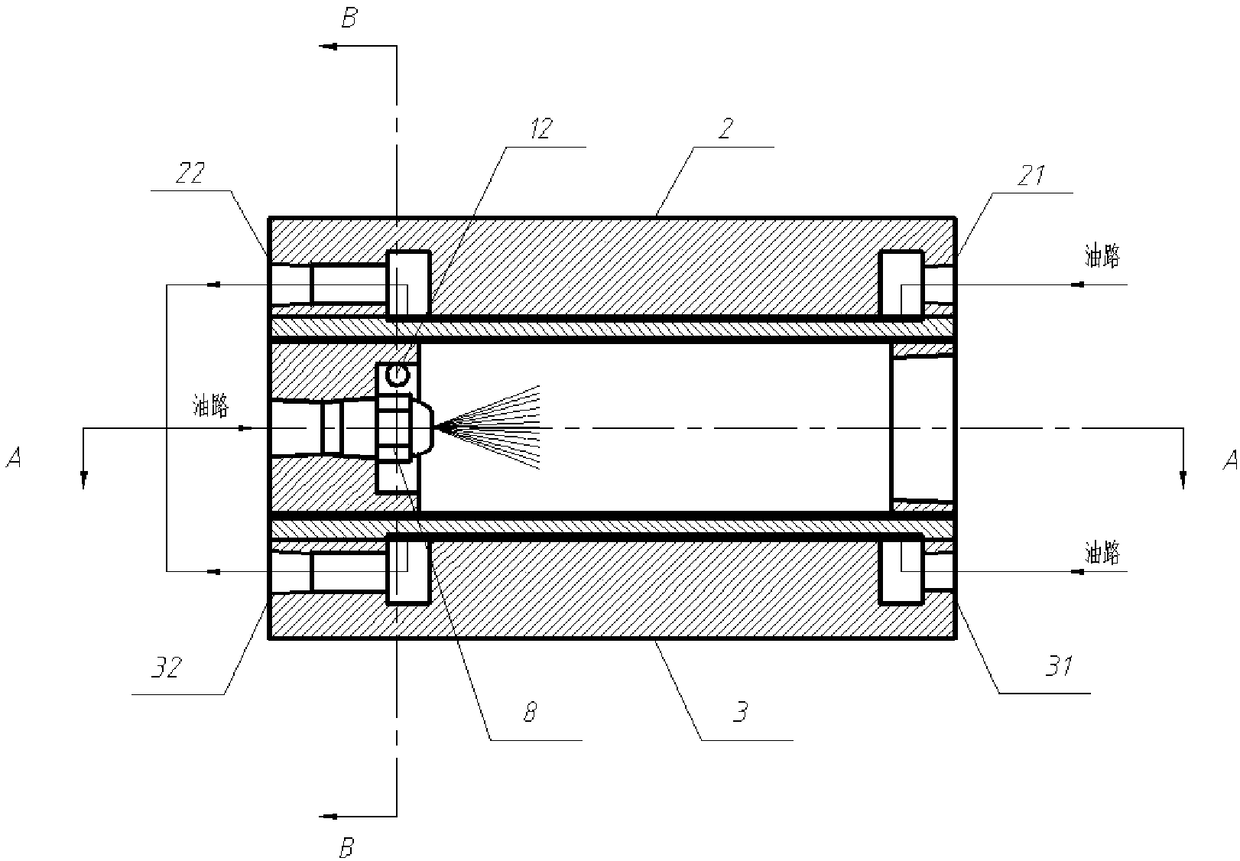

A gas-oxygen/kerosene vortex cooling combustor

ActiveCN108895484BAchieve thermal protectionSimple structureContinuous combustion chamberRocket engine plantsCombustion chamberCombustor

A gas oxygen / kerosene swirl cooled combustion chamber include a head base, body, nozzle, oxygen and kerosene systems, A main body of that head, a body and a nozzle are fixedly connecte from the top tothe bottom to form an integral structure, a combustion chamber cavity is arrange in the body, oxygen is tangentially injected into the combustion chamber cavity by a gas-oxygen system to form a double-swirling airflow structure of an outer swirl current and an inner swirl current, a kerosene system is connecte to the head, and kerosene is injected into the combustion chamber cavity and oxygen inthe inner swirl region to realize mixed combustion. The invention limits the mixing combustion process of the bipropellant to the central region of the combustion chamber, and achieves the purpose ofcooling the wall surface and preventing carbon deposition through the outer oxygen swirling flow. An open centrifugal nozzle and a rotary adjusting sleeve are designed at the head of the combustion chamber. After the fuel is atomized, the internal swirl region and oxygen are mixed to form a stable recirculation zone near the kerosene nozzle outlet, which ensures the reliable ignition and stable combustion of the propellant. The combustor has simple structure, no cooling, good maintenance performance and low cost.

Owner:XIAN AEROSPACE PROPULSION INST

Heat insulating device

The invention relates to a heat insulating device, belonging to the technical field of chemical experiment supplies. The heat insulating device mainly comprises an anti-explosion vessel including a cover, wherein a sand grains heat insulating layer is arranged in the anti-explosion vessel; a support base is arranged below the anti-explosion vessel; the support base comprises a bracket including a support net; plastic sleeves are arranged on the leg parts of the bracket; and a groove corresponding to the outer diameter of the anti-explosion vessel is arranged on the middle of the support net. According to the invention, an asbestos wire gauze is substituted; in a using procedure, the heat insulating device plays a role by dint of change of physical performance of the heat insulating device; in addition, the heat insulating device has safe, non-toxic, environmental-friendly, acid-resist, alkali-resist, moisture-resistant and the like performances and is characterized by low and easily-acquired material, energy saving and long service life.

Owner:徐海芝

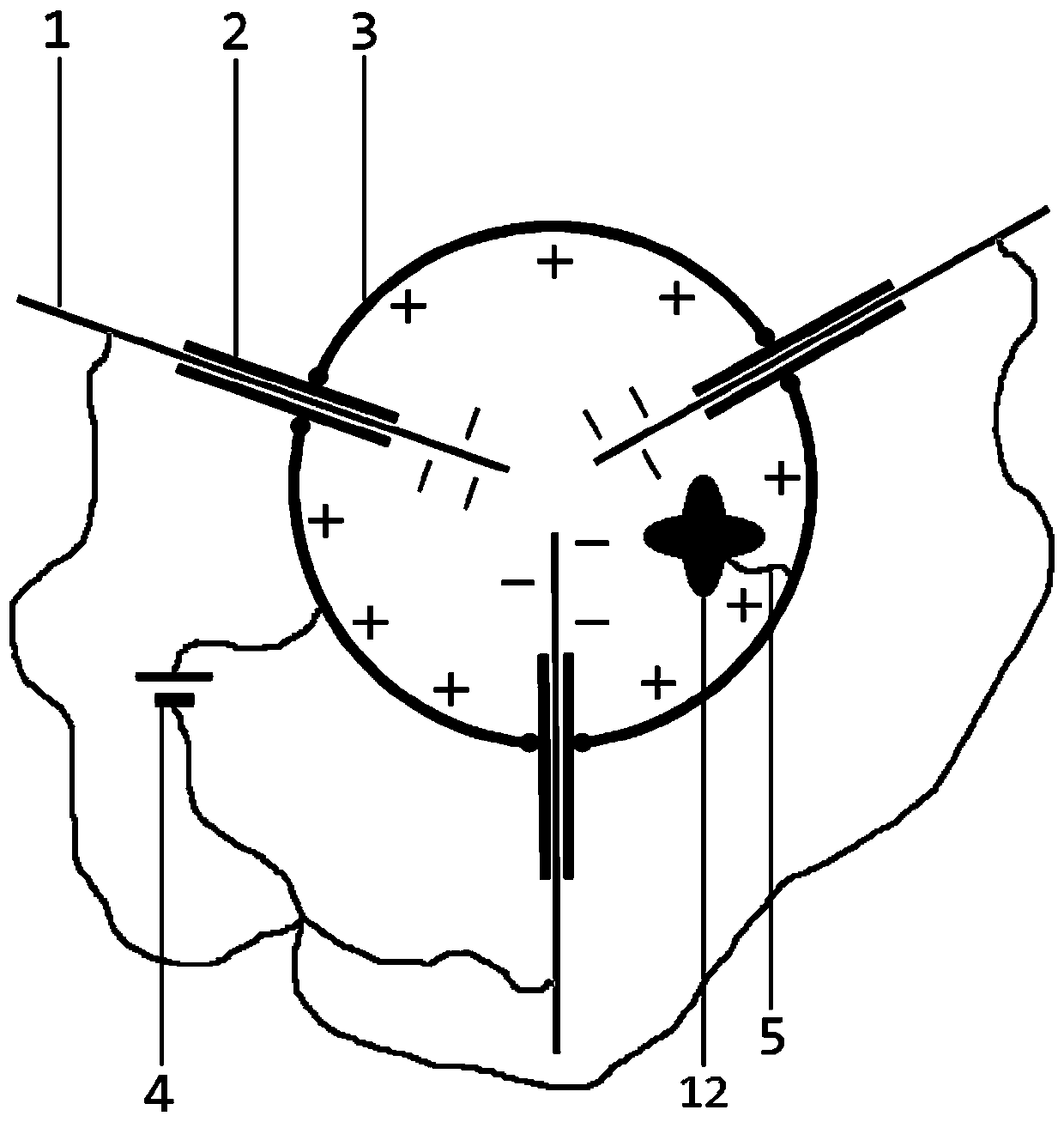

Anode high temperature protection method and protection device

PendingCN109515762AReduce heat generationEffective high temperature protectionCosmonautic thermal protectionGas turbine plantsIonSpacecraft

The invention relates to an anode high temperature protection method and protection device. A positive charge is applied to a shell or a component, meanwhile, a negative charge is applied to a self-renewing or easy-to-replace sacrificial electrode or a substance most in need of heating, or electrons (the negative charge) are emitted to a place far away from a spacecraft by an electron gun, and thespacecraft loses part of the negative charge and gains the positive charge. Positive ions in a high-temperature plasma is repelled by applying the positive charge to the component or shell needing tobe protected, therefore the heating of the positive ions in the high-temperature plasma to the component or the shell is effectively reduced, and the purpose of high temperature protection is achieved. The anode high temperature protection method and protection device are suitable for protection for high temperature generated by friction between the spacecraft shell and atmosphere in the recoveryprocess of the spacecraft, and meanwhile is also suitable for high temperature protection of the inner parts of a rocket engine, a turbine engine and a high-temperature furnace.

Owner:THE FIRST HOSPITAL OF CHINA MEDICIAL UNIV

Thermal bridge suppression structure for equipment installation

ActiveCN113086224AReduce deliveryEffective heat protectionAircraft componentsThermal bridgeThermal protection

The invention provides a thermal bridge suppression structure for equipment installation, wherein equipment is installed in a suspended mode through an adapter lug arranged on an equipment shell, the adapter lug is connected with the top of an installation supporting foot through a connecting screw, the installation supporting foot is installed in an equipment cabin shell thermal protection structure, and the bottom of the installation supporting foot is connected with the equipment cabin shell through an adapter gasket. The installation supporting feet are of a hollow thin-wall structure, and pyrolysis materials are arranged in the inner areas and the outer areas of the installation supporting feet. According to the thermal bridge suppression structure, the hollow structure is adopted for mounting the supporting legs and a suspended mounting mode is adopted, so that heat transferred into a cabin and an equipment shell through a thermal bridge is greatly reduced, and effective thermal protection is realized.

Owner:BEIJING RES INST OF MECHANICAL & ELECTRICAL TECH

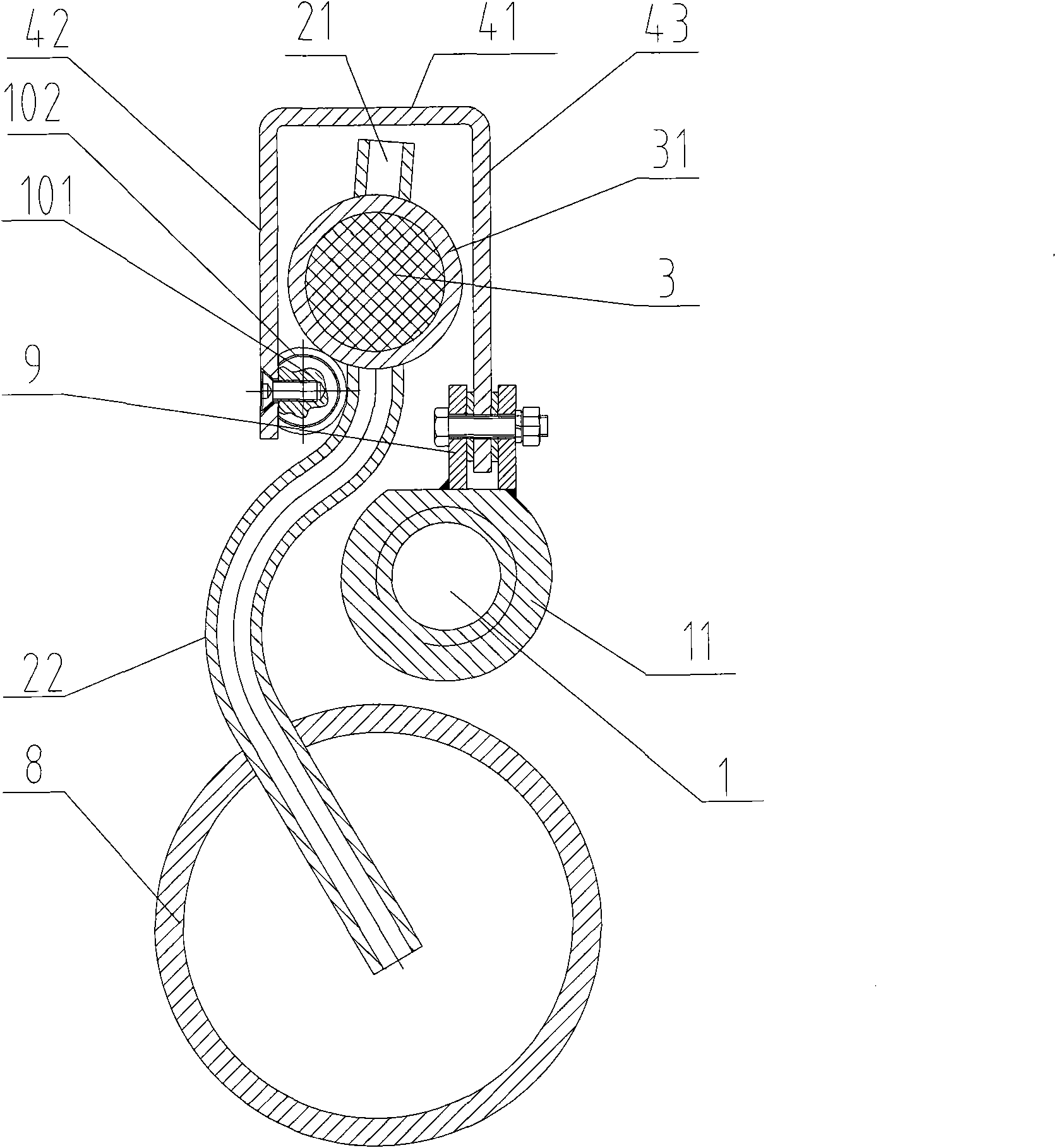

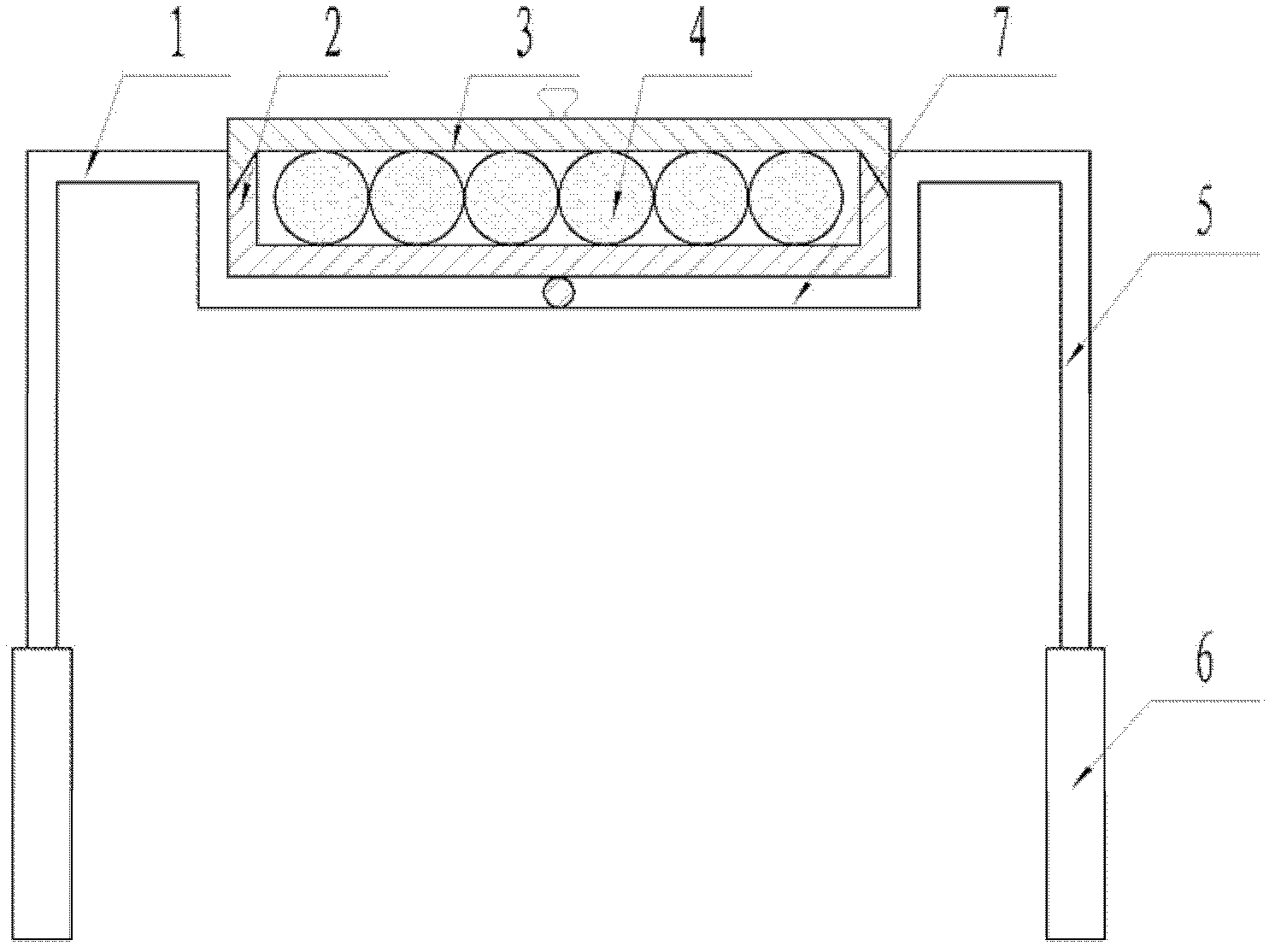

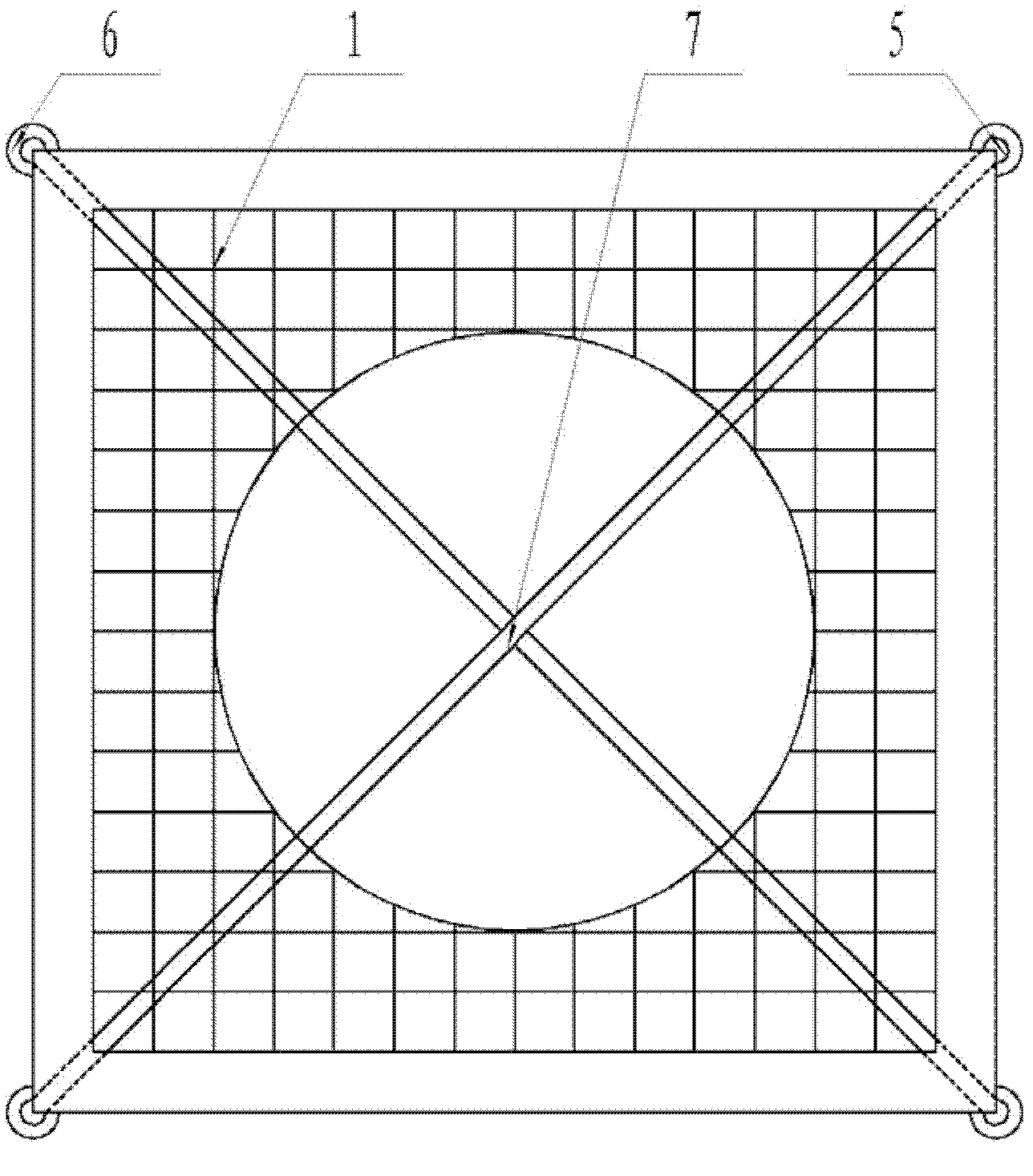

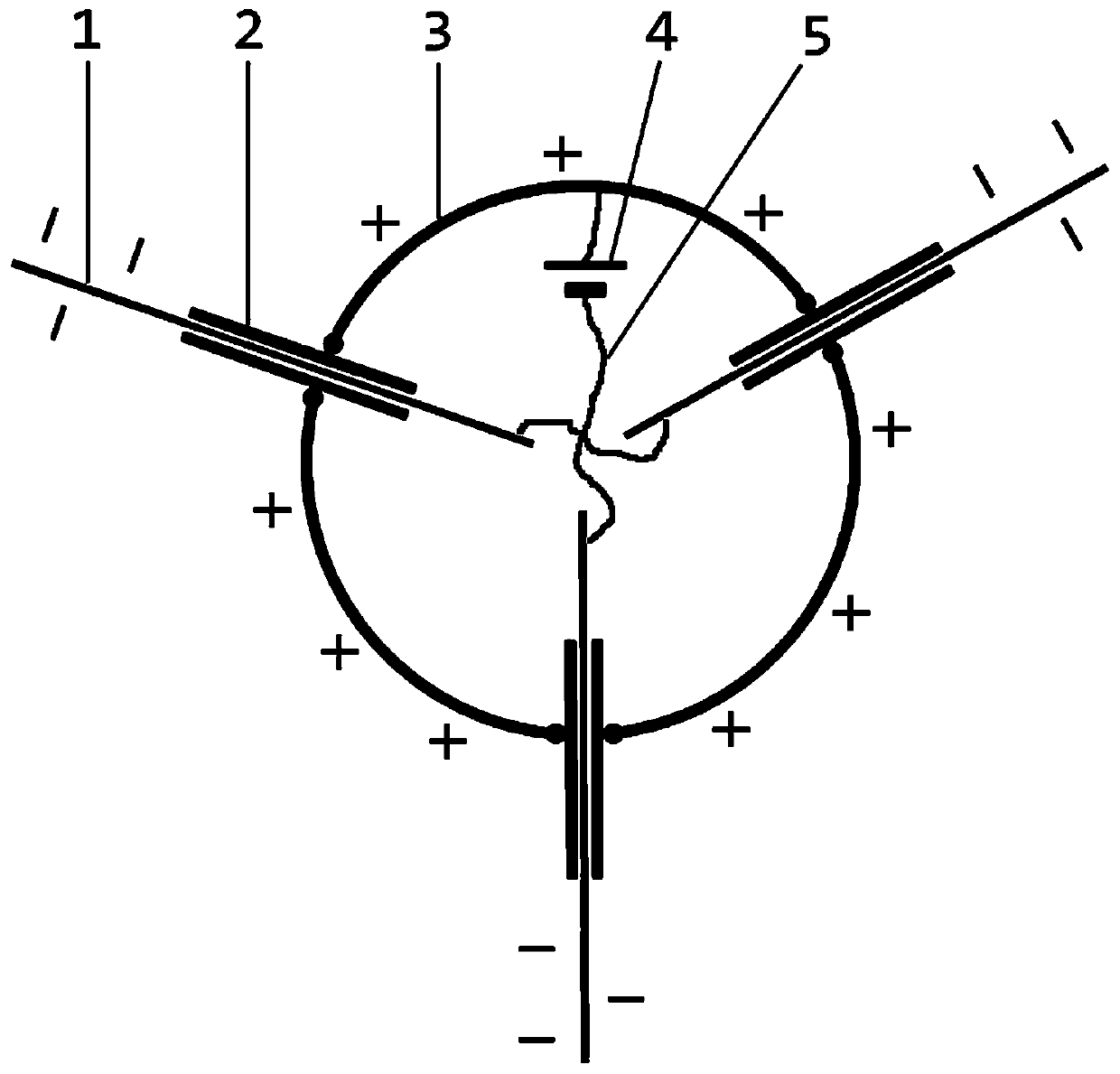

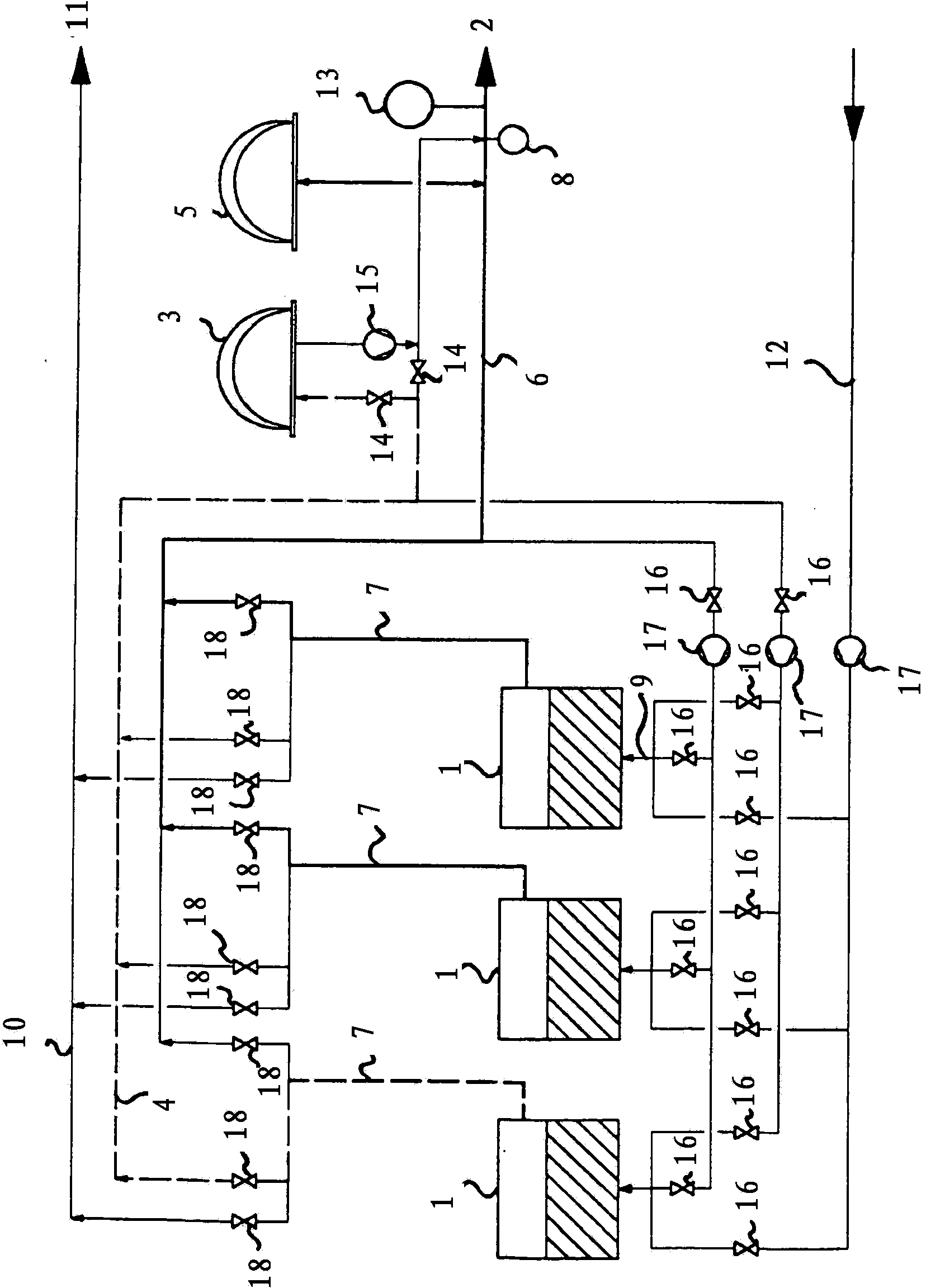

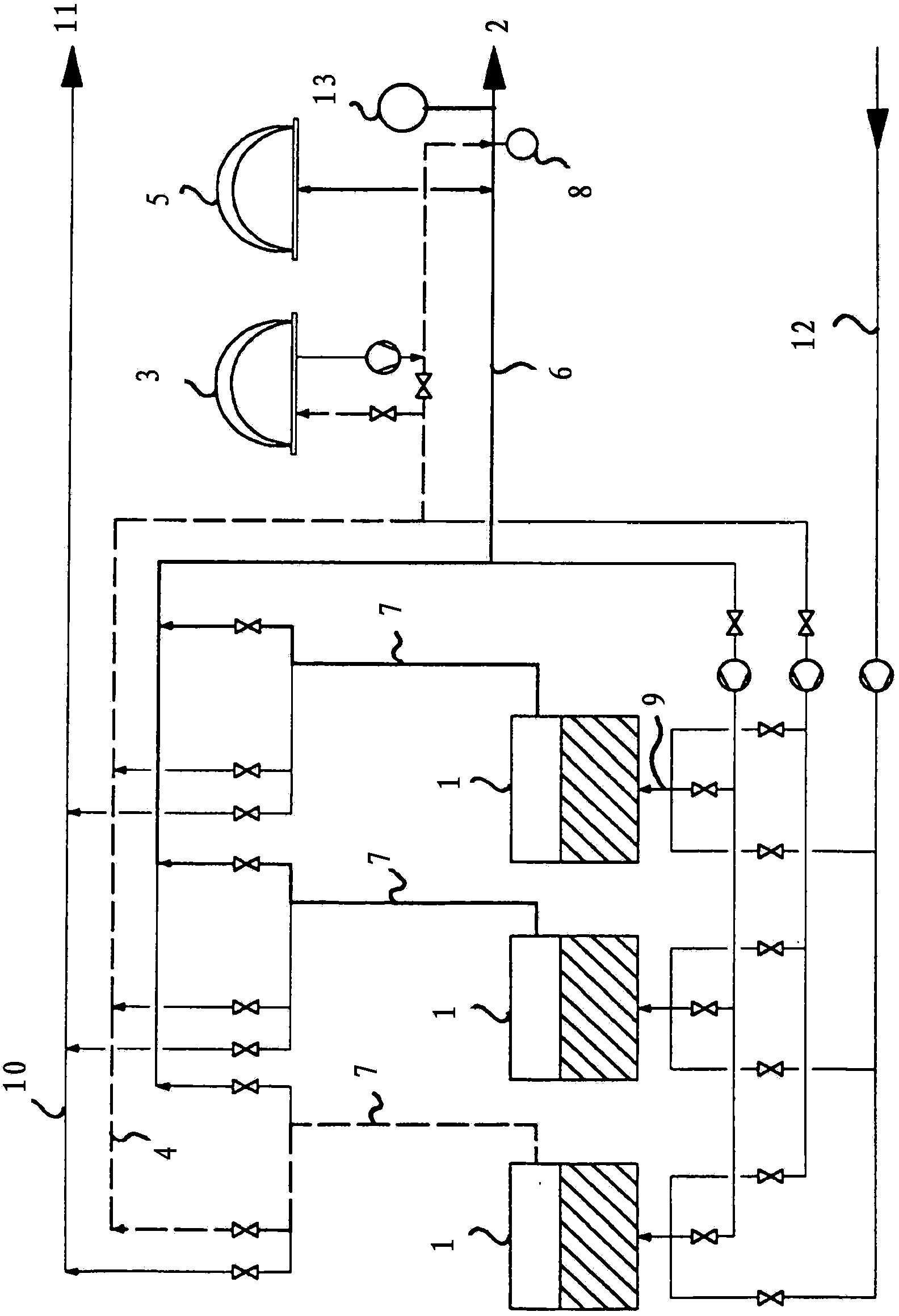

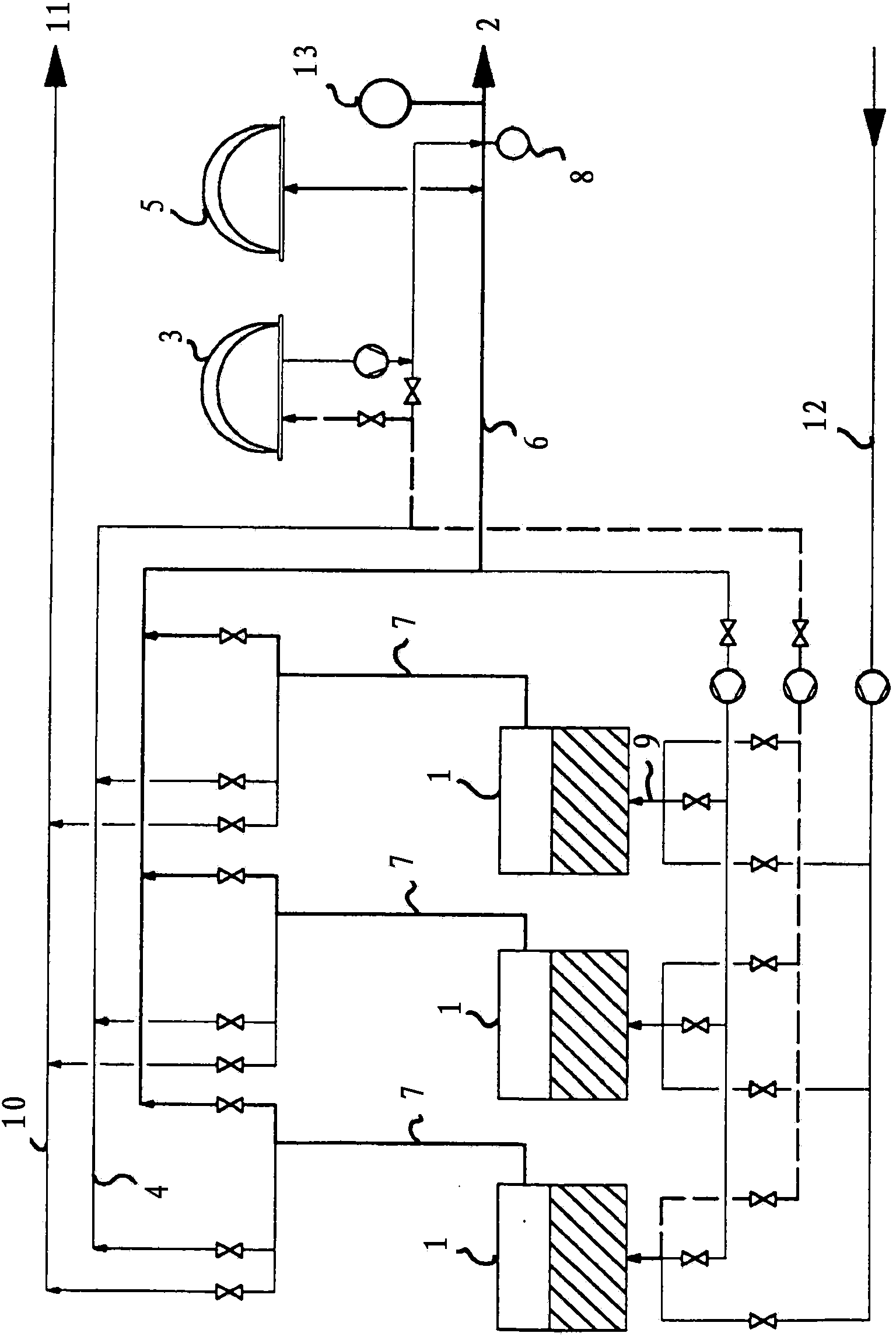

Biogas plant and method for operating a biogas plant

ActiveCN103842494AImprove cooling effectEffective heat protectionBioreactor/fermenter combinationsGas production bioreactorsEngineeringProduct gas

A biogas plant has at least one fermenter (1), preferably a dry fermenter for generating biogas, in addition a biogas utilization appliance (2) and a first gas store (3) for storing biogas. The gas store (3) is connectable to a first biogas conduit (4) that is connectable to a gas outlet (7) of the at least one fermenter (1). The biogas plant has a second gas store (5) for storing biogas. The second gas store (5) is connectable to a second biogas conduit (6) that is connectable to a gas outlet (7) of the at least one fermenter (1). The biogas utilization appliance (2) is connectable to the first biogas store (3) and / or to the first biogas conduit (4) and to the second biogas store (5) and / or to the second biogas conduit (6). The biogas plant has a control appliance (8) for controlling the quantitative ratios of the biogas streams conducted from the biogas conduits (4, 6) and / or the biogas stores (3, 5) to the biogas utilization appliance.

Owner:KOMPOFERM

Launch platform with combined internal and external cooling

ActiveCN108917471BEffective protectionAchieve internal and external coolingRocket launchersWater flowEngineering

A launch platform combining internal and external cooling. The launch platform body is provided with a support frame and diversion holes for gas flow and gas conduction. The support frame is processed into a hollow structure that communicates with each other to form a built-in flow channel. The flow channel serves as a cooling water flow channel and a water supply channel; an array of water spray holes communicating with the built-in flow channel is opened on the upper surface of the support frame and the side wall facing the flow guide hole. The invention not only improves the thermal protection capability of the launch pad body structure, but also reduces the complexity of installation between systems. At the same time, combined with the water spray cooling method on the outer surface, the internal and external cooling of the launch platform is fully realized.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

A swirl torch igniter based on 3D printing

ActiveCN112240570BImprove reliabilitySmooth ignition processContinuous combustion chamberCombustion chamberThrust chamber

The invention discloses a swirl torch igniter based on 3D printing, which includes an electric spark plug rod, a torch ignition tube, and a copper sealing gasket; the torch ignition tube includes a head section and a body section integrally formed by 3D printing , throat nozzle section and tail pipe section; its main working principle is: ignition and combustion in the ignition chamber in the head pipe section, secondary combustion in the secondary combustion chamber of the body pipe section, and three times mixing in the throat nozzle section Combustion, so that the ignition process is stable and the combustion process is sufficient, which greatly improves the reliability of the igniter's combustion work, and can form an oxidant swirl in the head pipe section to protect the electric spark plug rod, and form a swirl flow in the secondary combustion chamber The air film protection is formed on the body pipe section, the connection and fastening parts with the thrust chamber are reasonably designed, the shape and structure of the torch igniter are simplified, the miniaturization design of the torch igniter is realized, the process complexity and cost are reduced, and the production cycle is shortened .

Owner:XIAN AEROSPACE PROPULSION INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com