An air/methane burner for high-temperature pure air regenerative heating equipment

A heating equipment and methane combustion technology, applied in the field of air/methane burners, can solve the problems of lack of preheating burners, etc., and achieve the effects of effective thermal protection, wide working range and stable combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

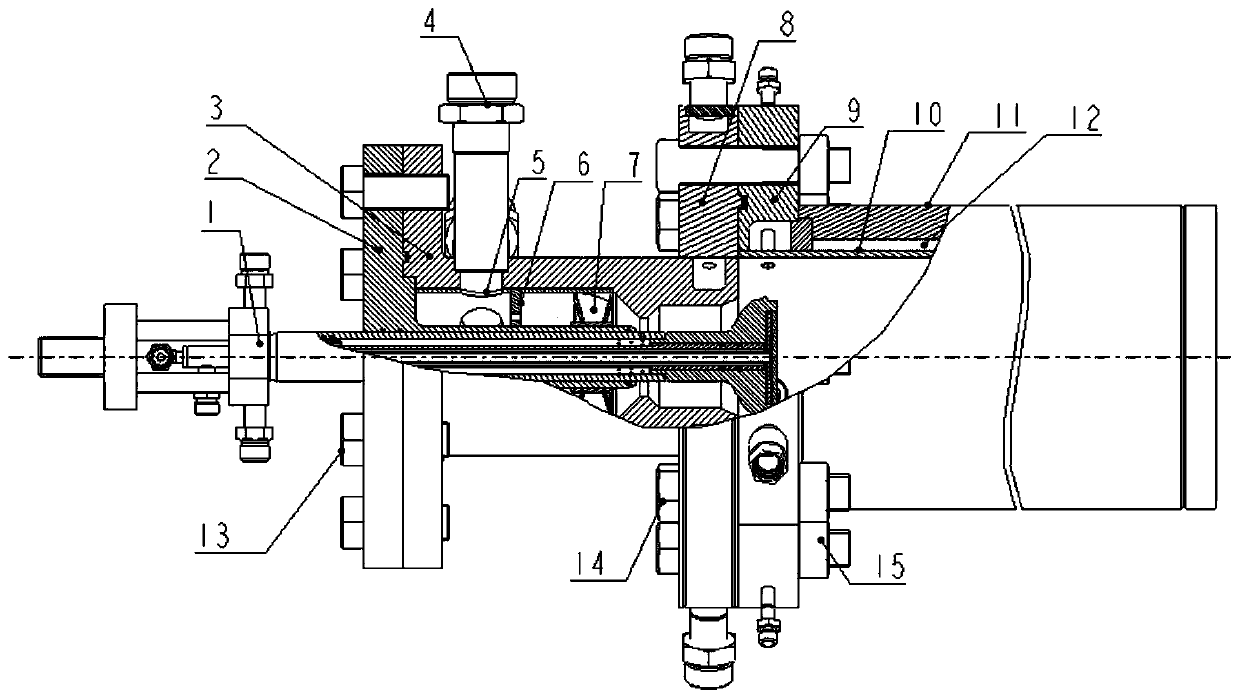

[0045] According to the application requirements of a certain high-temperature pure air regenerative heating equipment, a 50-500kW air / methane preheating burner is designed. The structure is as follows figure 1 shown. The working range of the burner air is 68.0-174.5g / s, and the working range of methane is 1.0-10.0g / s, which can meet the requirements of high-temperature pure air regenerative heating equipment under different power and temperature conditions. Under the matching conditions of different working conditions, The burner can achieve reliable ignition and stable combustion with 10 times the range of operating conditions.

[0046] The air / methane burner of the high-temperature pure air regenerative heating equipment of the present invention has achieved the expected purpose after many tests and assessments. When the working conditions change in a wide range, the ignition is reliable, the combustion is stable, and the shutdown on the reverse side is effective.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com