Design method of venturi flow channel of double-swirl atomizing device

A technology of an atomization device and a design method, which is applied in the field of fuel nozzle design, can solve the problems of poor fuel atomization quality, no modeling method, and lack of thermal protection for fuel nozzles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below with reference to the accompanying drawings and examples.

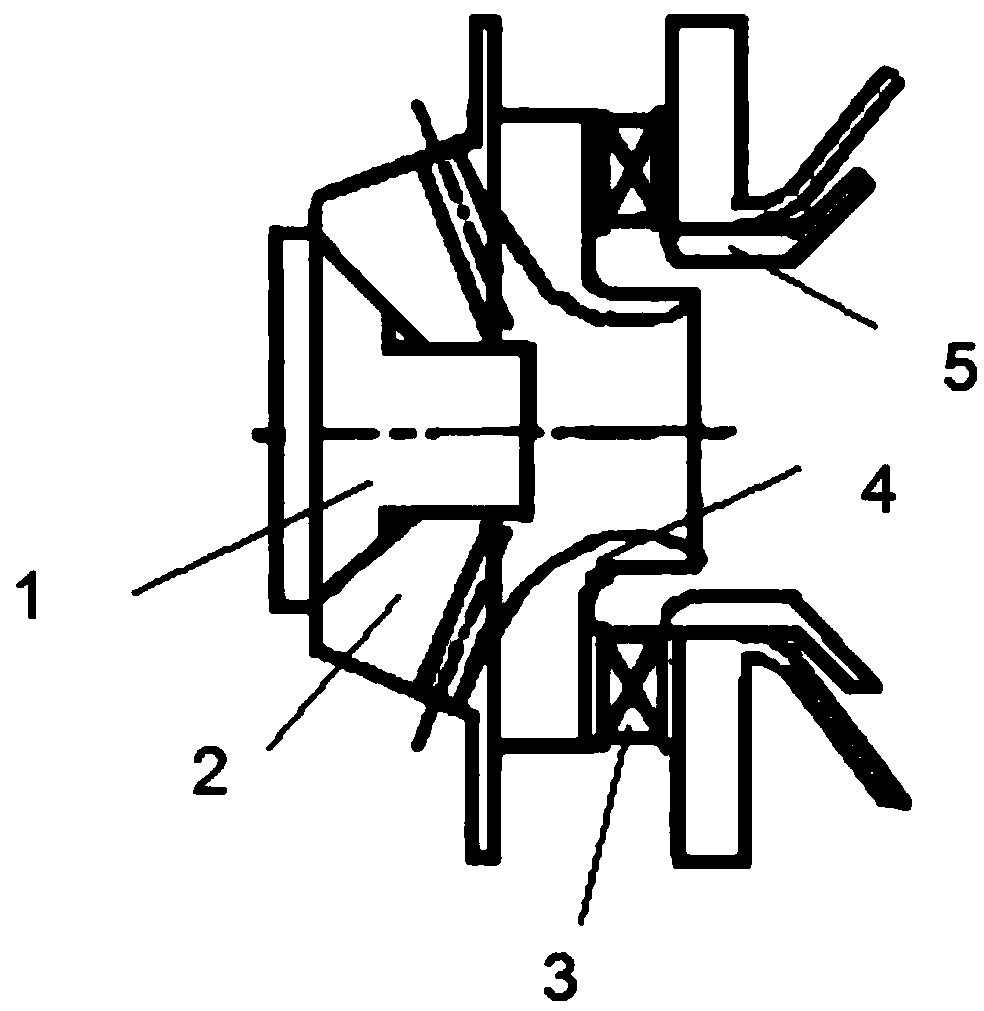

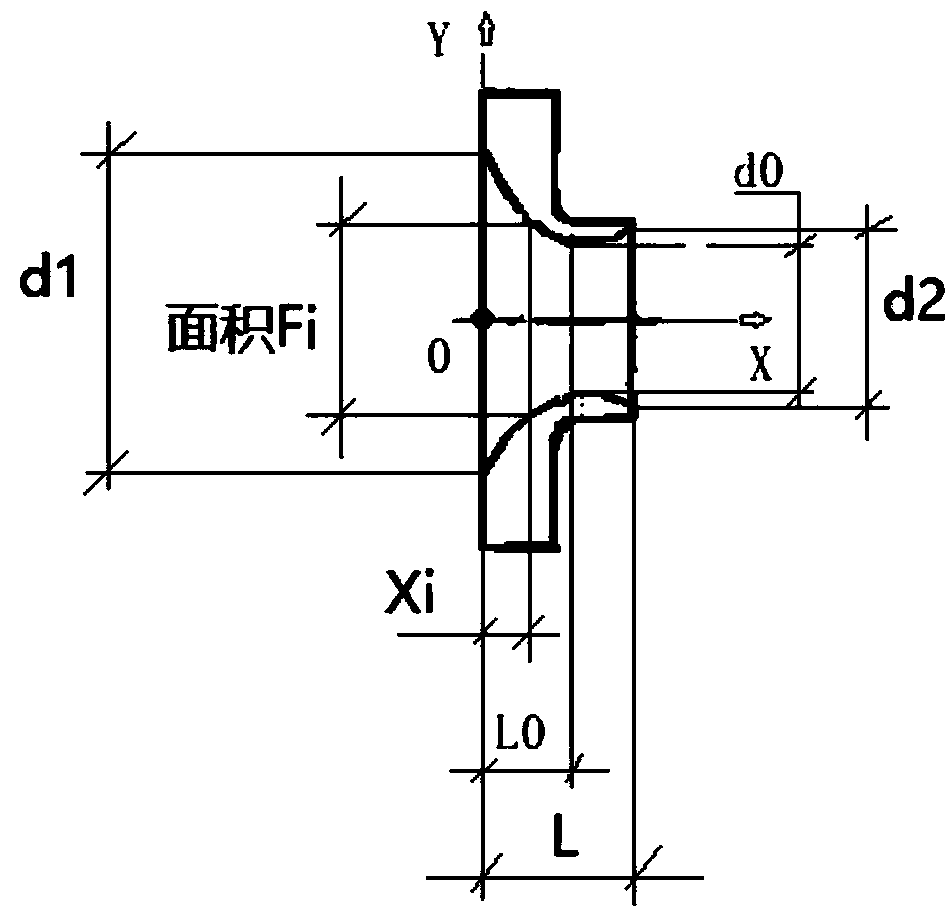

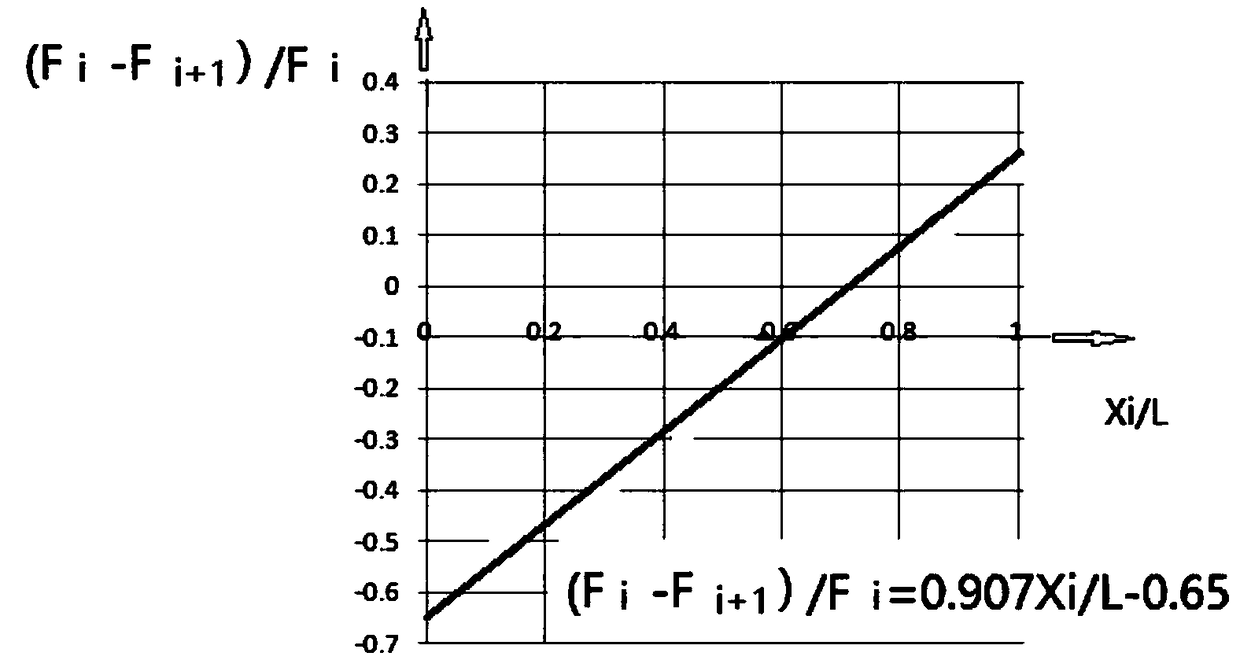

[0046] A method for designing a venturi flow path of a double swirl atomization device, the design of the venturi flow path includes the diameter of the venturi throat cross section, the axial position of the venturi throat cross section and the The design of Venturi tube flow channel profile molding, the design method of described Venturi tube flow channel comprises the following steps:

[0047] (1) Collect the inlet airflow parameters of the combustor in the design state of the combustor, including air pressure, temperature and flow, and the ratio of the primary flow that flows through the air intake device at the head of a single flame tube obtained in the calculation of the flow distribution of the flame tube, according to the following formula Calculate the air flow through the double swirl atomizer,

[0048] W i0 =F 1 *Wa / (Ff0 *i),

[0049] In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com