Locally spraying fixture

A jig and local technology, applied in the direction of spraying device, etc., can solve the problems of wasting paint spraying efficiency, difficult to erase, and reducing the yield rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

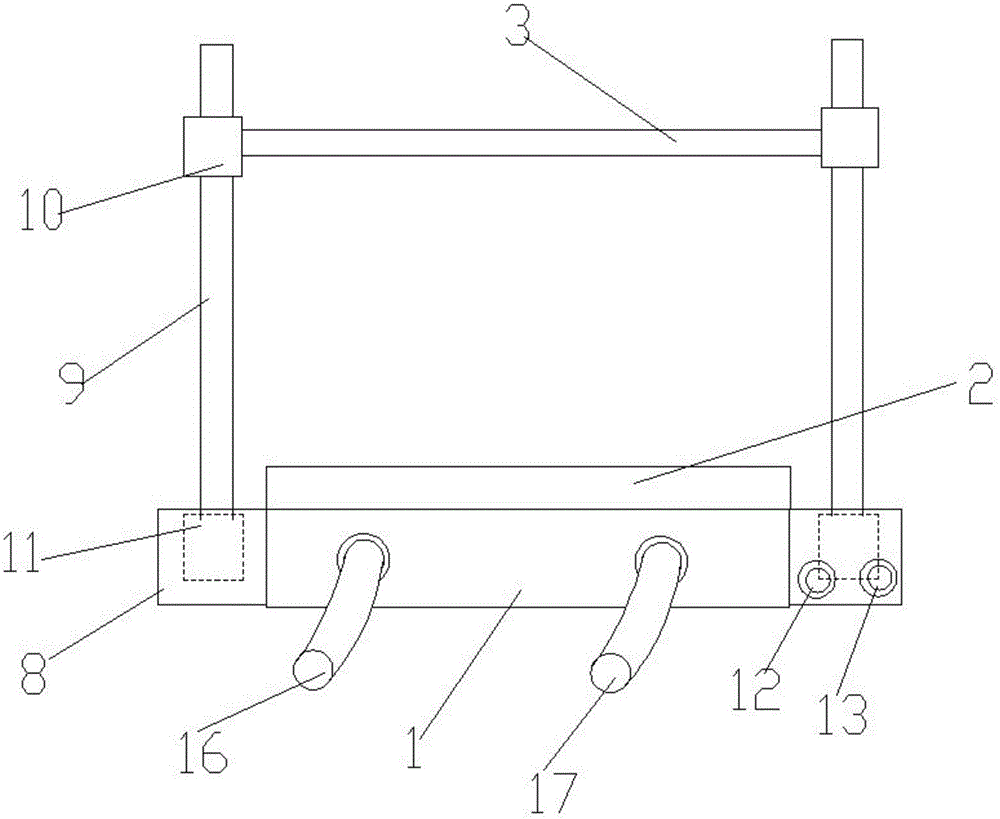

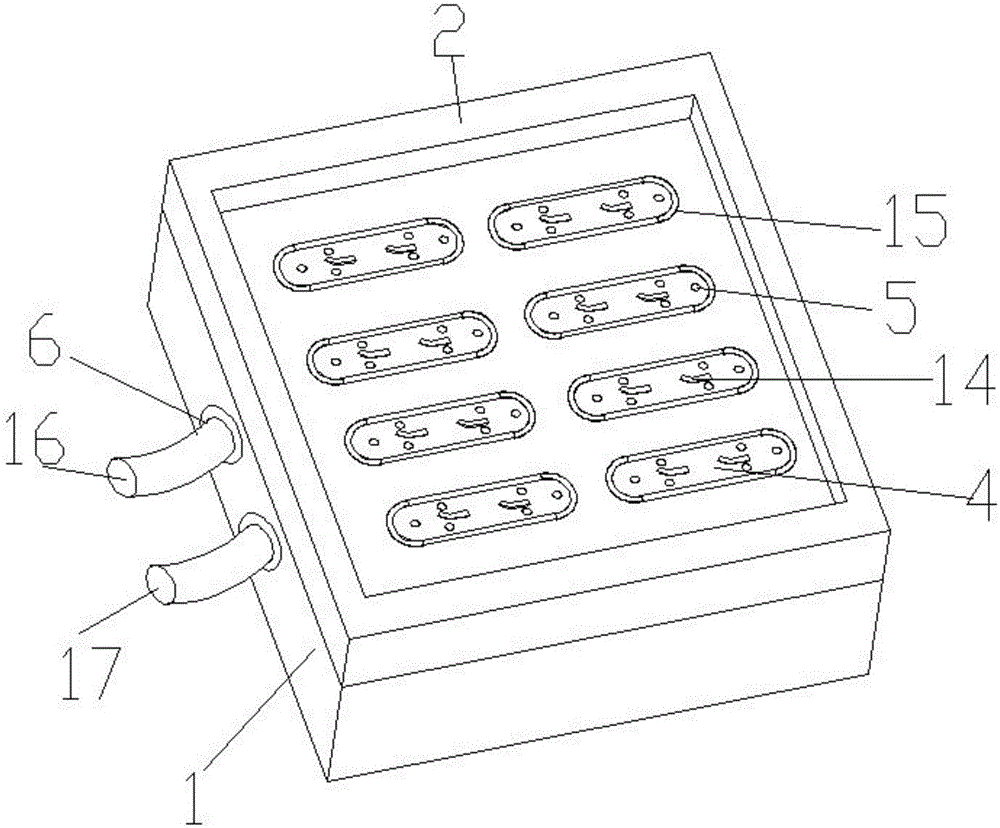

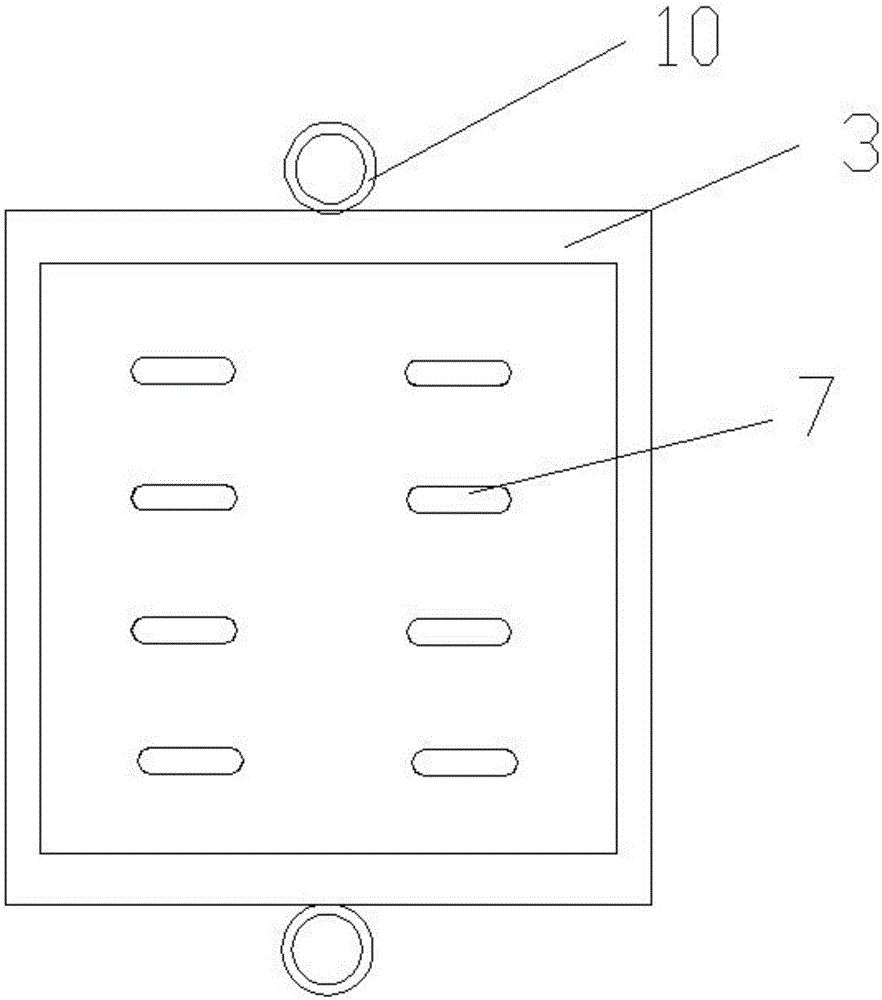

[0019] Embodiment: a local spraying fixture, including a hollow base 1, a positioning plate 2 and a baffle 3, the positioning plate is sealed and fixed on the base, and the positioning plate is evenly spaced A plurality of positioning grooves 4, in which a plurality of through holes 5 are provided, the through holes communicate with the inside of the base, the base is provided with at least one air port 6, and the baffle plate moves up and down to locate On the base and above the positioning plate, a number of cutouts 7 for spraying paint are evenly spaced on the baffle. Place the product that needs to be partially sprayed into the positioning slot of the positioning plate, communicate with the inside of the base through the through hole in the positioning slot, and pump air through the air port, so as to extract the gas between the product that needs to be sprayed and the positioning slot. A vacuum is formed, so that the product to be sprayed is vacuum-adsorbed in the positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com