Robot control method capable of being used for multi-vehicle intelligent spraying

A control method and robot technology, applied in the direction of spraying device, etc., can solve the problems of longer spraying consumption time, increased equipment computing burden, position error, etc., and achieve the effect of reducing redundant moving actions, avoiding computing burden, and improving spraying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to more clearly illustrate the embodiments of the present invention and / or the technical solutions in the prior art, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings. Obviously, the accompanying drawings in the following description are only some embodiments of the present invention, and those skilled in the art can obtain other accompanying drawings based on these drawings and obtain other implementations. In addition, the affiliation related to the orientation only indicates the relative positional relationship between the components, not the absolute positional relationship.

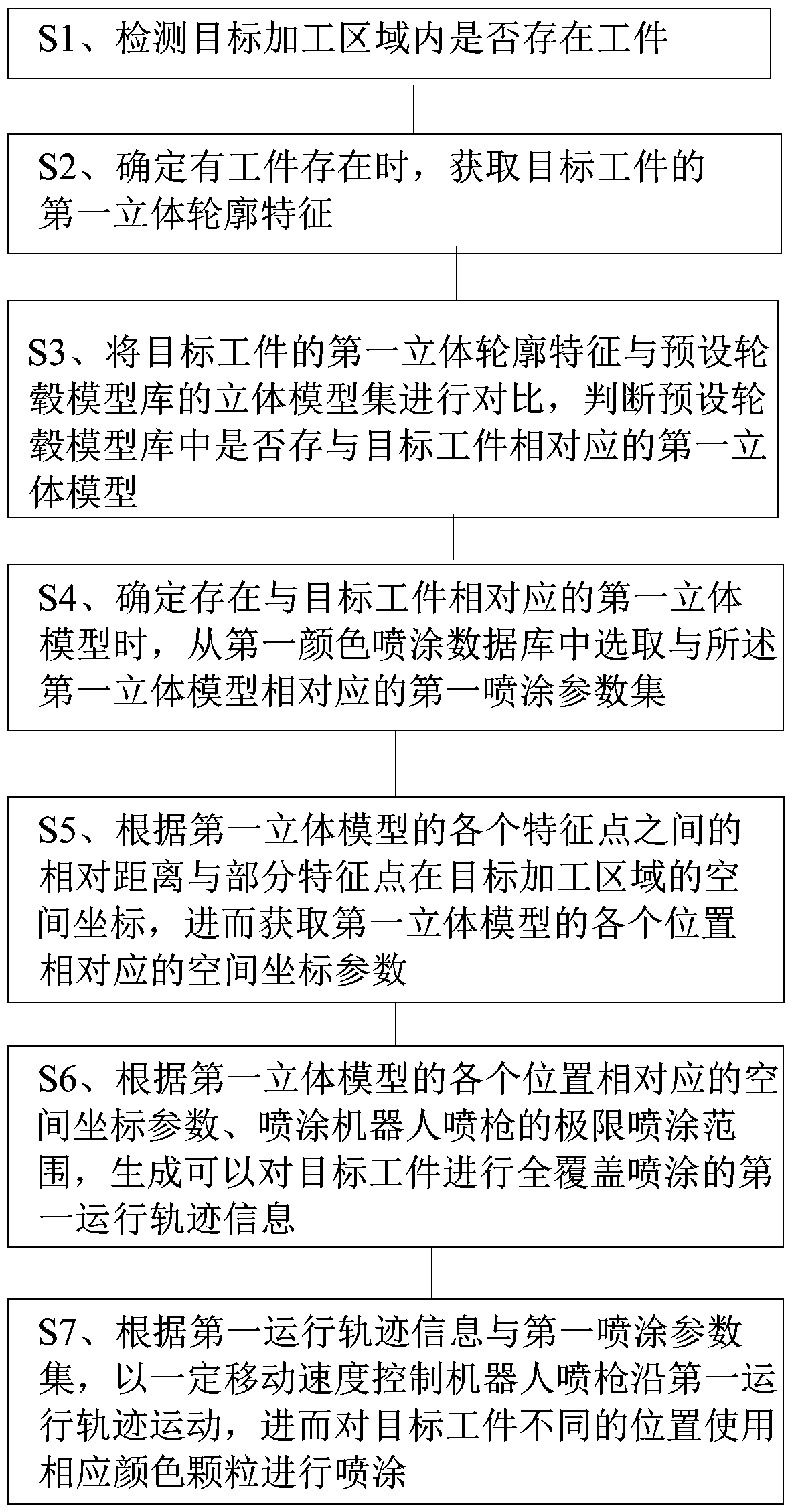

[0022] like figure 1 As shown, the present invention provides a robot control method that can be used for intelligent spraying of multiple vehicle models, for identifying and spraying particles on wheel hubs of different models, including the following steps S1 to S7.

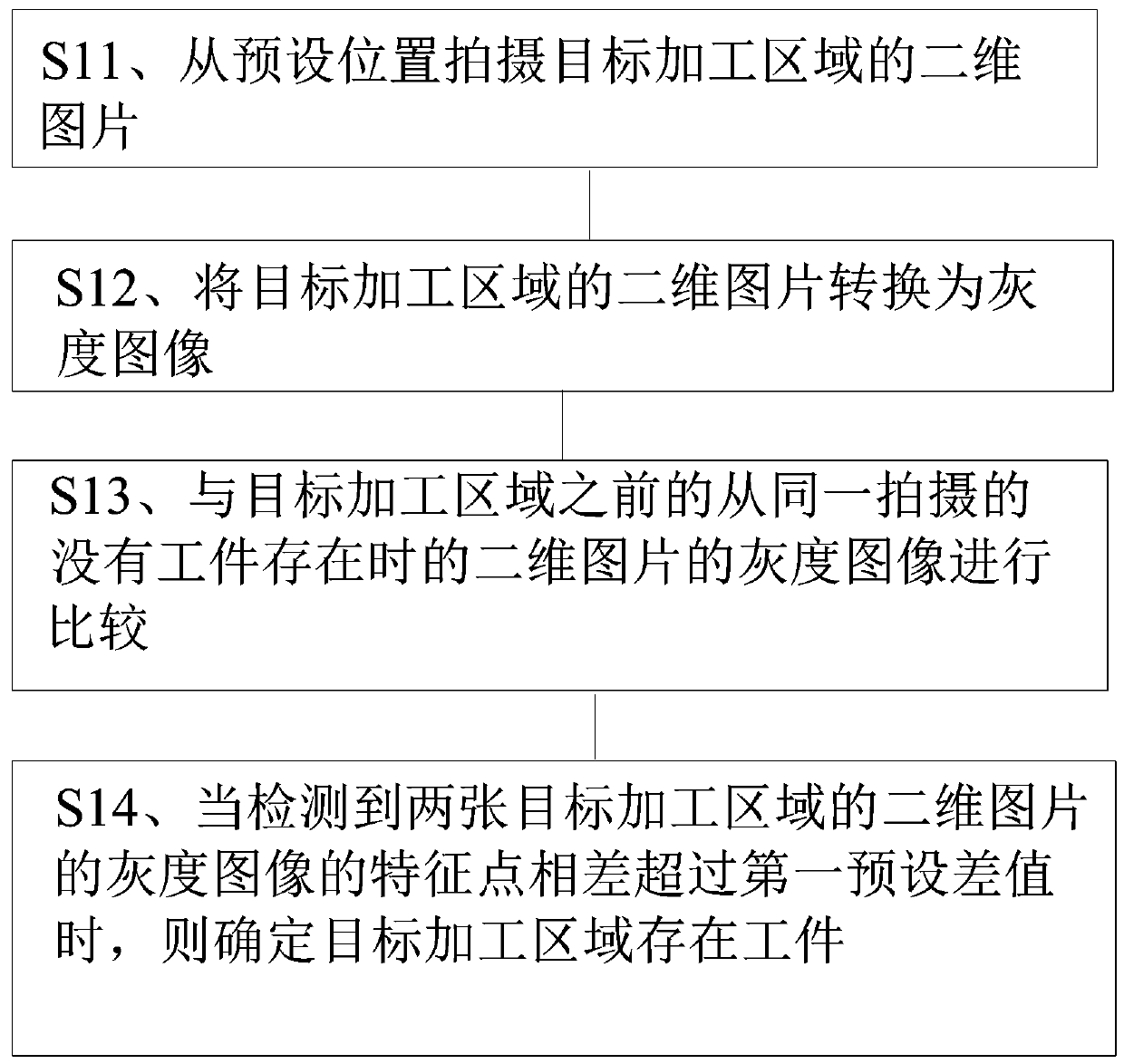

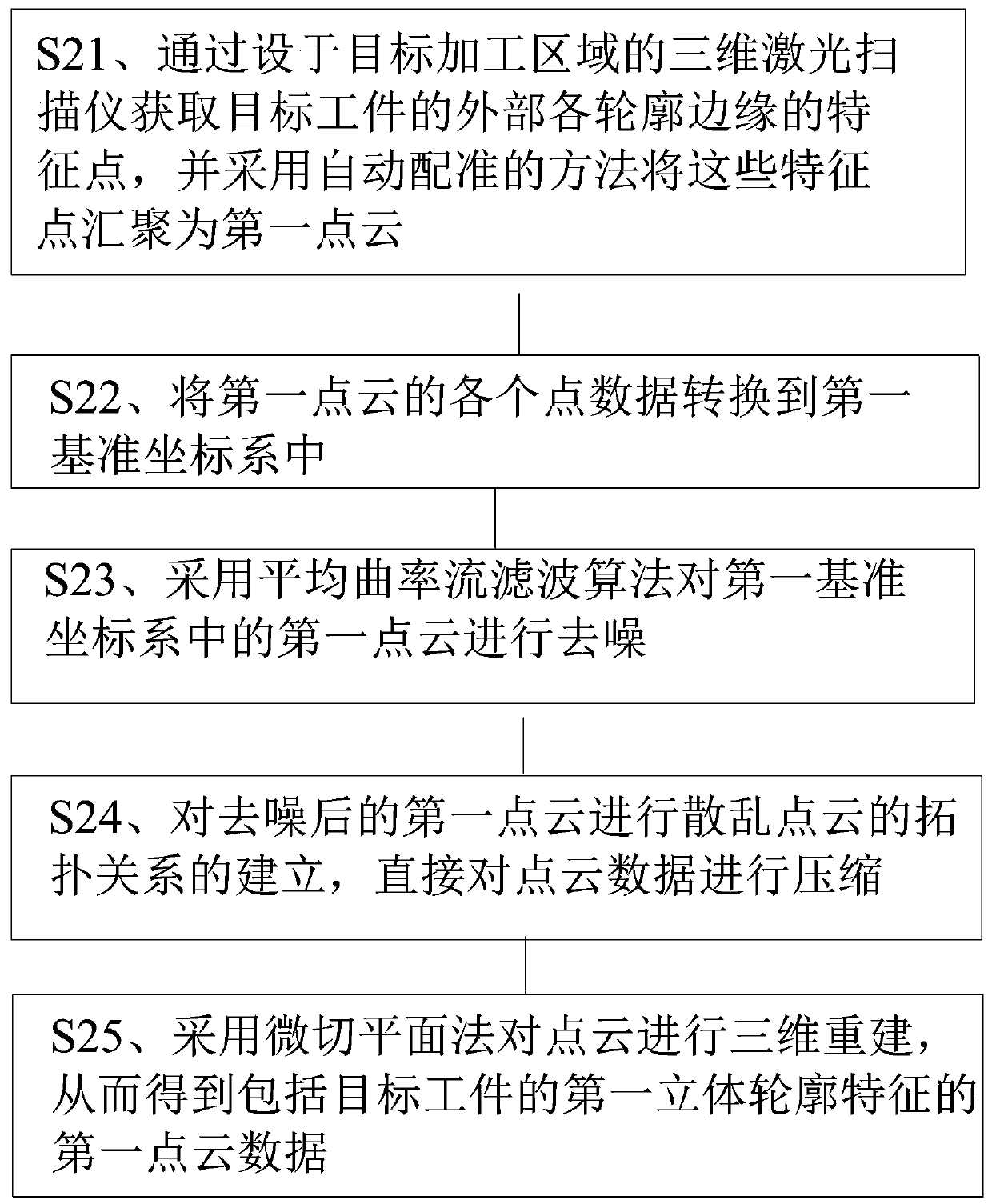

[0023] S1. Detect whether there is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com