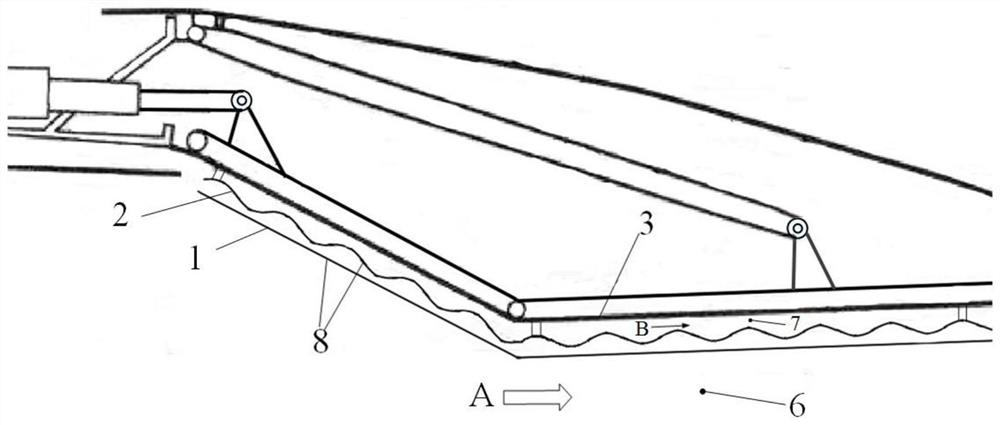

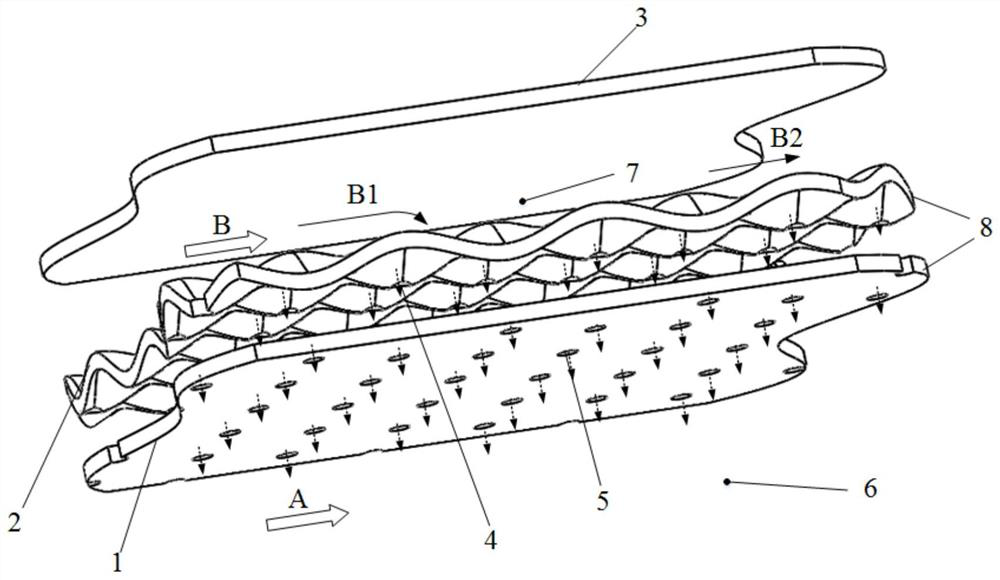

A Double Wall Cooling Structure for Jet Engine Vectoring Nozzle

A technology of jet engine and vector nozzle, applied in the direction of machine/engine, jet propulsion device, etc., can solve the problems of increasing impact distance and uneven thermal stress of corrugated heat shield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

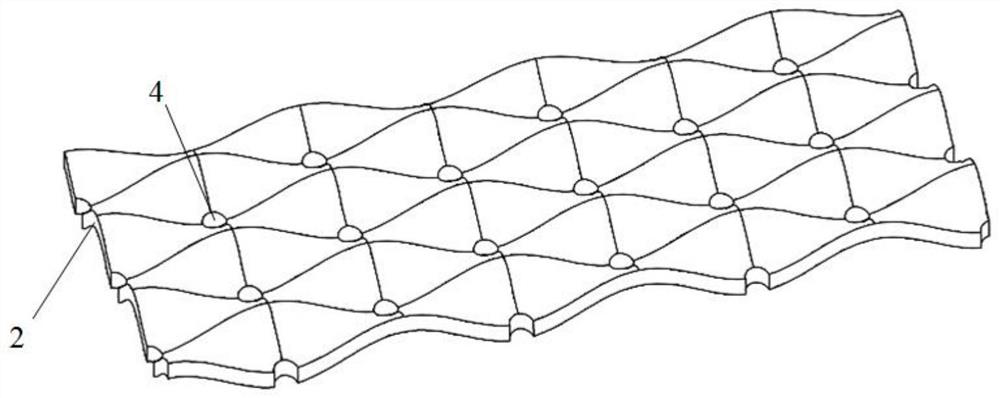

[0049] Embodiment one: impact hole diameter d c is 1mm, and the diameter of the gas film hole is d f is 1mm, and the impact distance h is 3d c , the distance between the impact holes along the gas flow direction P c1 10mm, spanwise spacing of impact holes P c2 is 5mm, and the distance between gas film holes along the gas flow direction is P f1 is 10mm, the spanwise spacing of gas film holes P f2 is 5mm. The impact plate is divided into two types, one is the impact corrugated plate amplitude A c 0.2mm, and the other is the impact plate, that is, the traditional impact plate. Impact plate and air film plate thickness δ c , f Both are 1mm, the angle θ formed by the impact hole and the gas film hole and the gas flow direction c , θ f Both are 90°, and Re is 1700.

Embodiment 2

[0050] Embodiment two: impact hole diameter d c is 1mm, and the diameter of the gas film hole is d f is 1mm, and the impact distance h is 3d c , the distance between the impact holes along the gas flow direction P c1 10mm, spanwise spacing of impact holes P c2 is 5mm, and the distance between gas film holes along the gas flow direction is P f1 is 10mm, the spanwise spacing of gas film holes P f2 is 5mm. The impact plate is divided into two types, one is the impact corrugated plate amplitude A c 0.5mm, and the other is the impact plate, that is, the traditional impact plate. Impact plate and air film plate thickness δ c , f Both are 1mm, the angle θ formed by the impact hole and the gas film hole and the gas flow direction c , θ f Both are 90°, and Re is 1700.

Embodiment 3

[0051] Embodiment three: impact hole diameter d c is 1mm, and the diameter of the gas film hole is d f is 1mm, and the impact distance h is 3d c , the distance between the impact holes along the gas flow direction P c1 10mm, spanwise spacing of impact holes P c2 is 5mm, and the distance between gas film holes along the gas flow direction f1 10mm, air film hole spanwise spacing P f2 is 5mm. The impact plate is divided into two types, one is the impact corrugated plate amplitude A c 0.8mm, the other is the impact plate, that is, the traditional impact plate. Impact plate and air film plate thickness δ c ,δ f Both are 1mm, the angle θ formed by the impact hole and the gas film hole and the gas flow direction c , θ f Both are 90°, and Re is 1700.

[0052] When analyzing the results, the Nusselt number Nu is used to measure the heat transfer effect, and the flow coefficient C is used. d A measure of pressure loss. as attached Figure 9 As shown, the horizontal axis is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com