Double-wall cooling structure having longitudinal corrugated impact hole plate for thrust-vectoring nozzle

A vector nozzle and cooling structure technology, applied in the direction of jet propulsion devices, machines/engines, etc., can solve the problems of increasing the impact distance and uneven thermal stress of the corrugated heat shield, so as to increase the flow rate and reduce the flow rate. The effect of resistance and lowering the wall temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

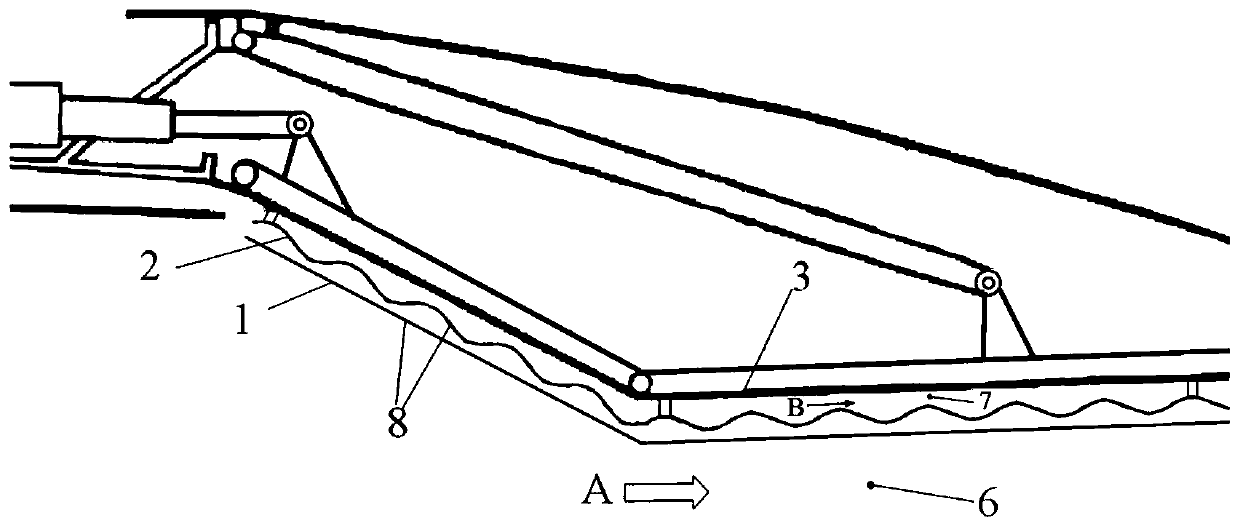

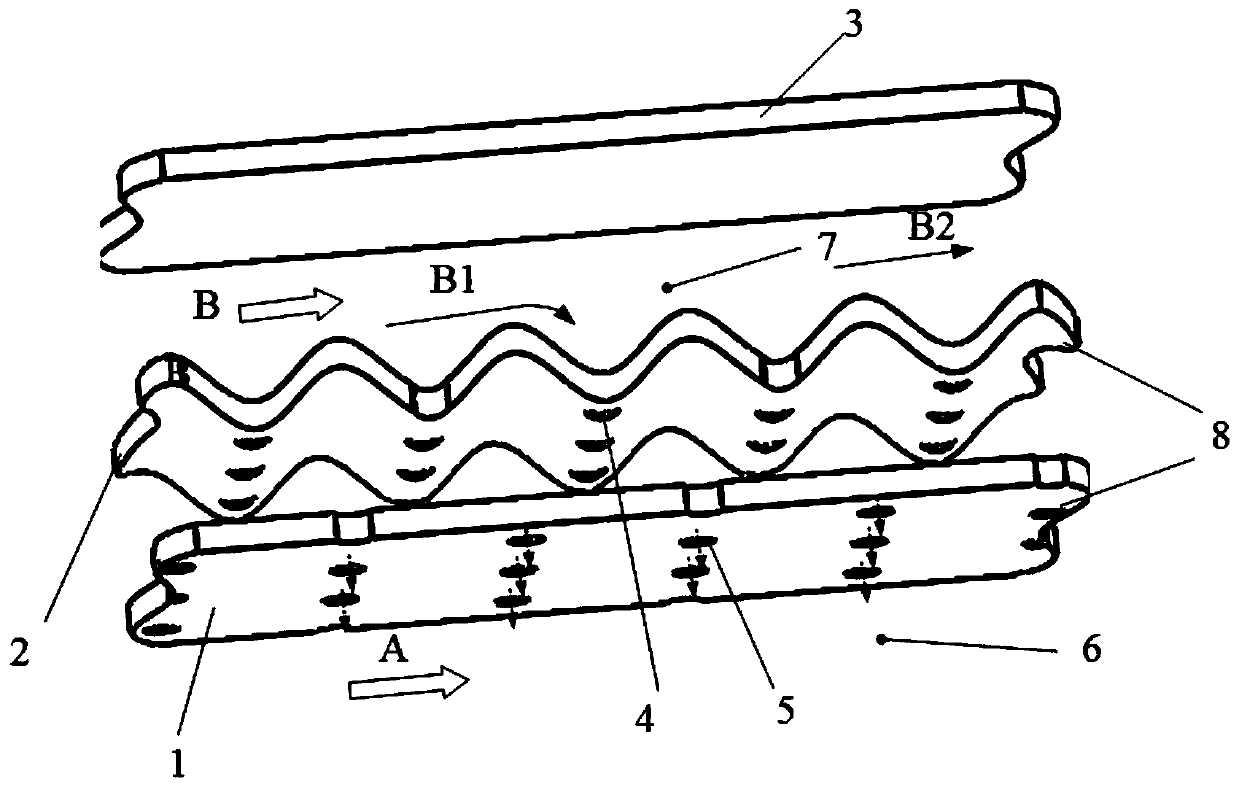

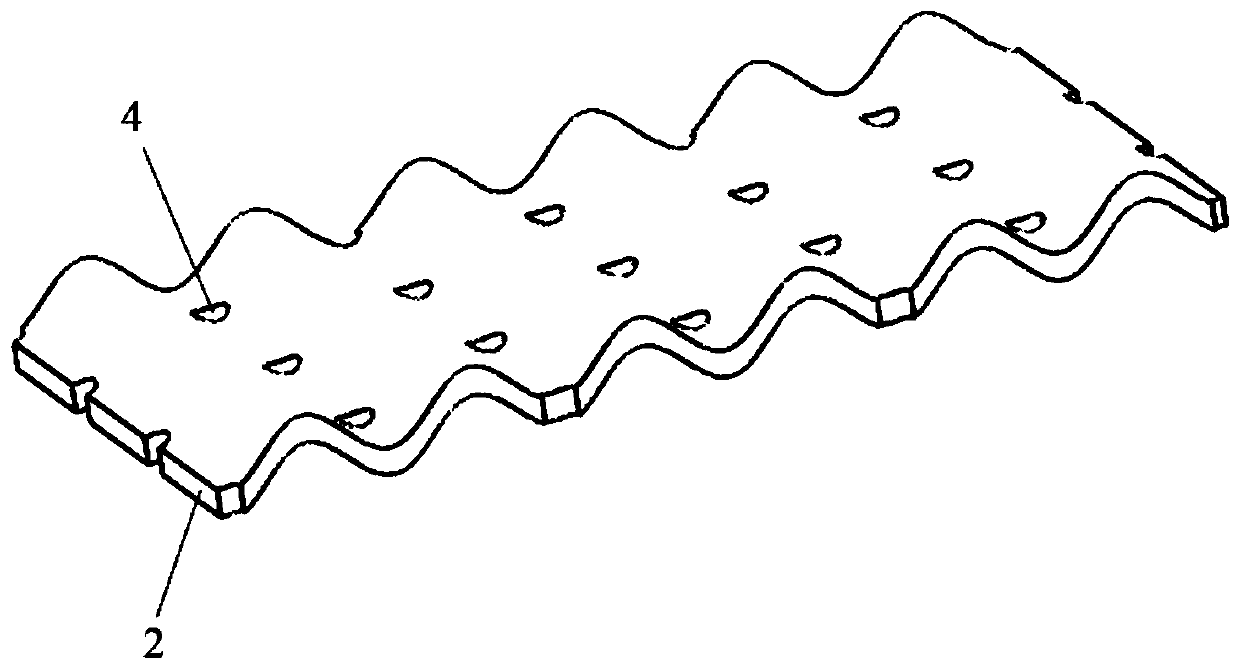

[0019] see figure 1 — Figure 8 , the present invention proposes a novel double-walled cooling structure 8 with longitudinal corrugated impact orifice plate for the nozzle, as attached figure 2 shown. It can solve the contradiction between reducing the impact distance in order to enhance heat transfer, but increasing the impact distance in order to reduce flow resistance, and at the same time solve the problem of uneven thermal stress of the corrugated heat shield. The double-walled cooling structure 8 is jointly composed of a three-dimensional corrugated impact plate 2 and a flat air film orifice plate 1 . The air film orifice plate 1 on the gas side constitutes the inner wall of the vector nozzle cylinder, and the inner side is the main gas duct 6 of the vector nozzle; the corrugated impact orifice plate 2 on the cold air side and the outer wall surface 3 together form the cold air duct 7; the cooling air from the compressor The air flow B flows backward along the axial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com