Heat insulating device

A technology of heat insulation device and heat insulation layer, which is applied in the direction of laboratory equipment, chemical instruments and methods, etc., can solve the problems of physical health threats to experimenters, asbestos fibers are harmful to human body, and asbestos nets are not resistant to high temperature, etc., and achieve low cost , wide application range and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

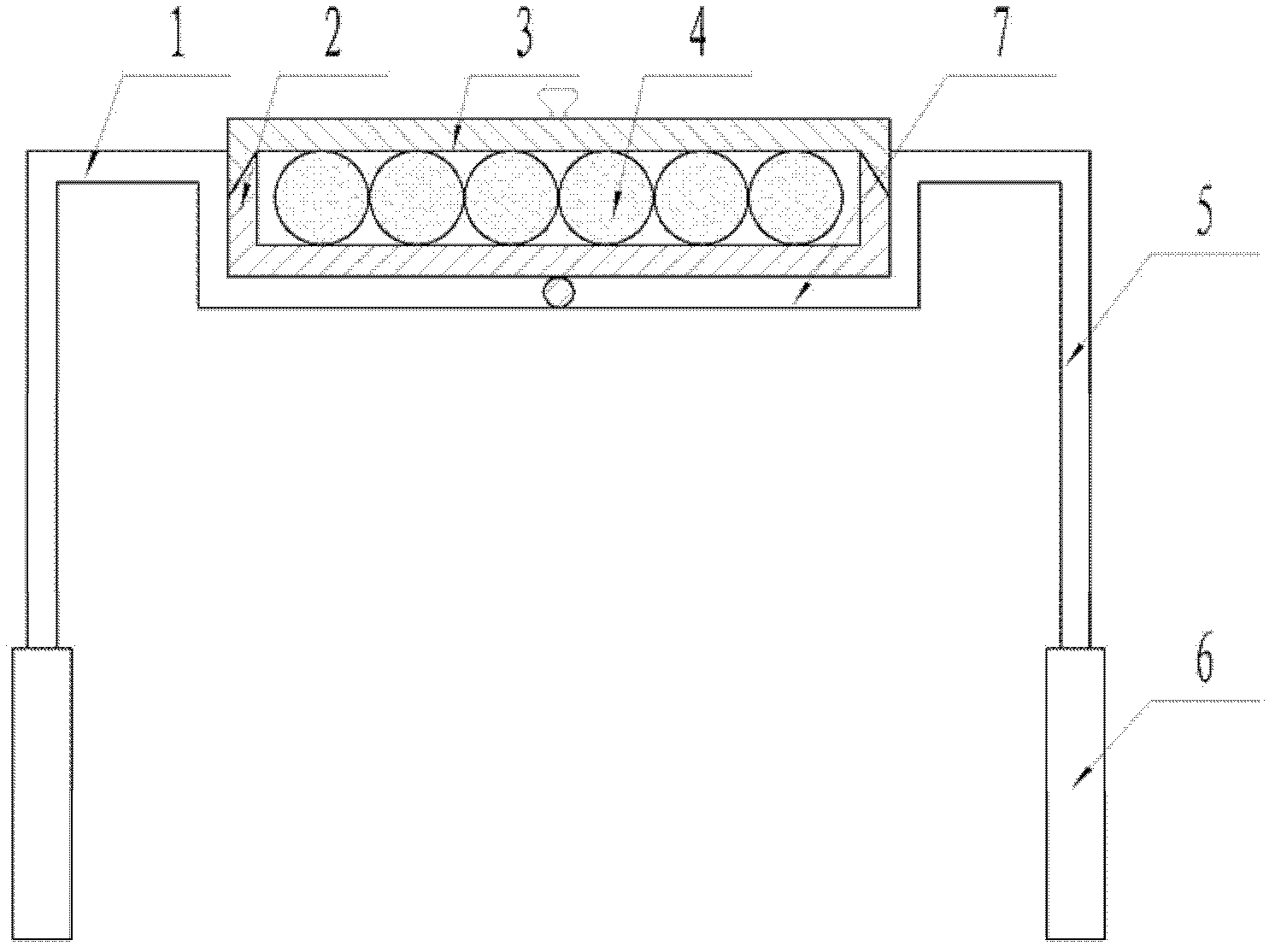

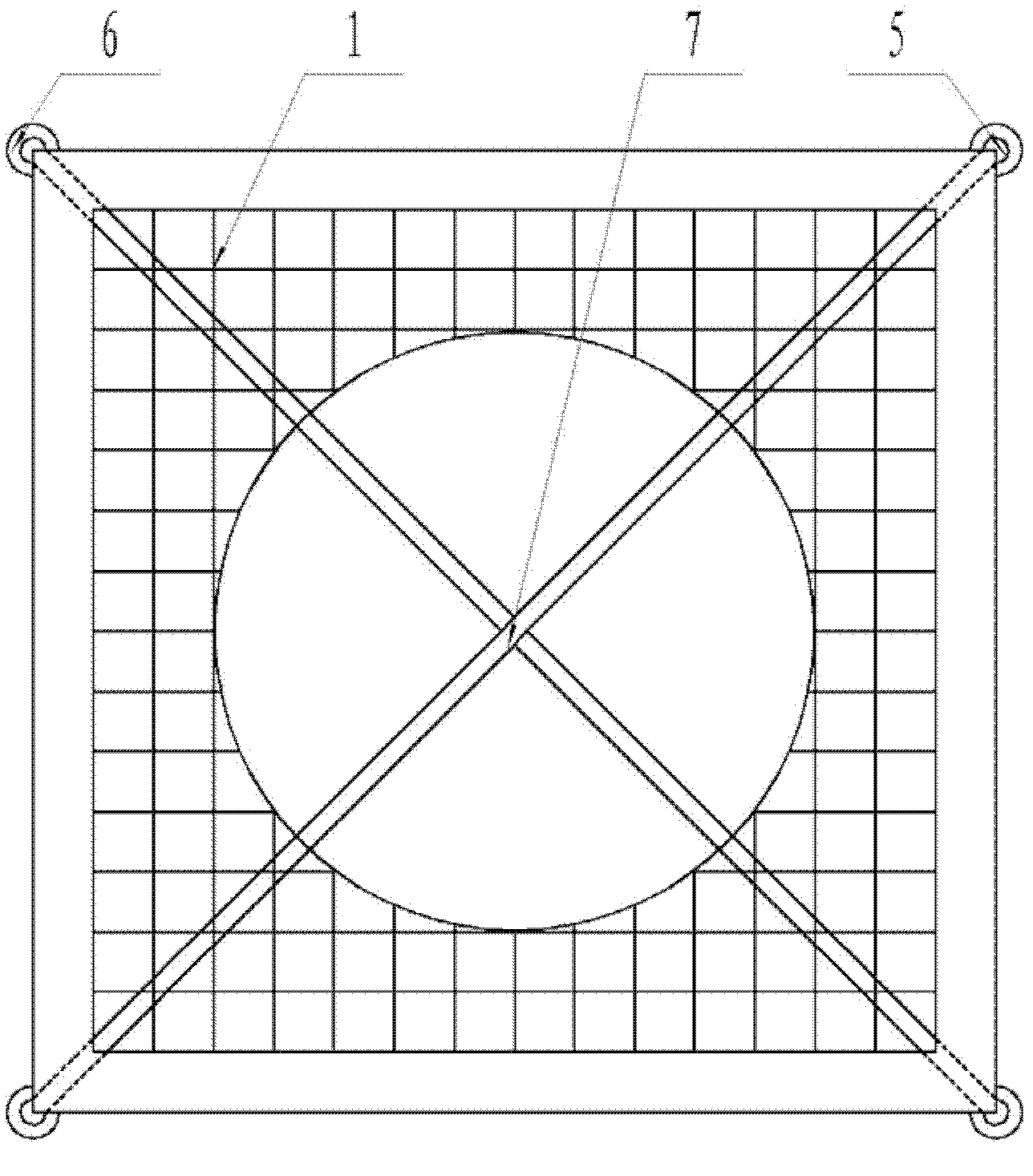

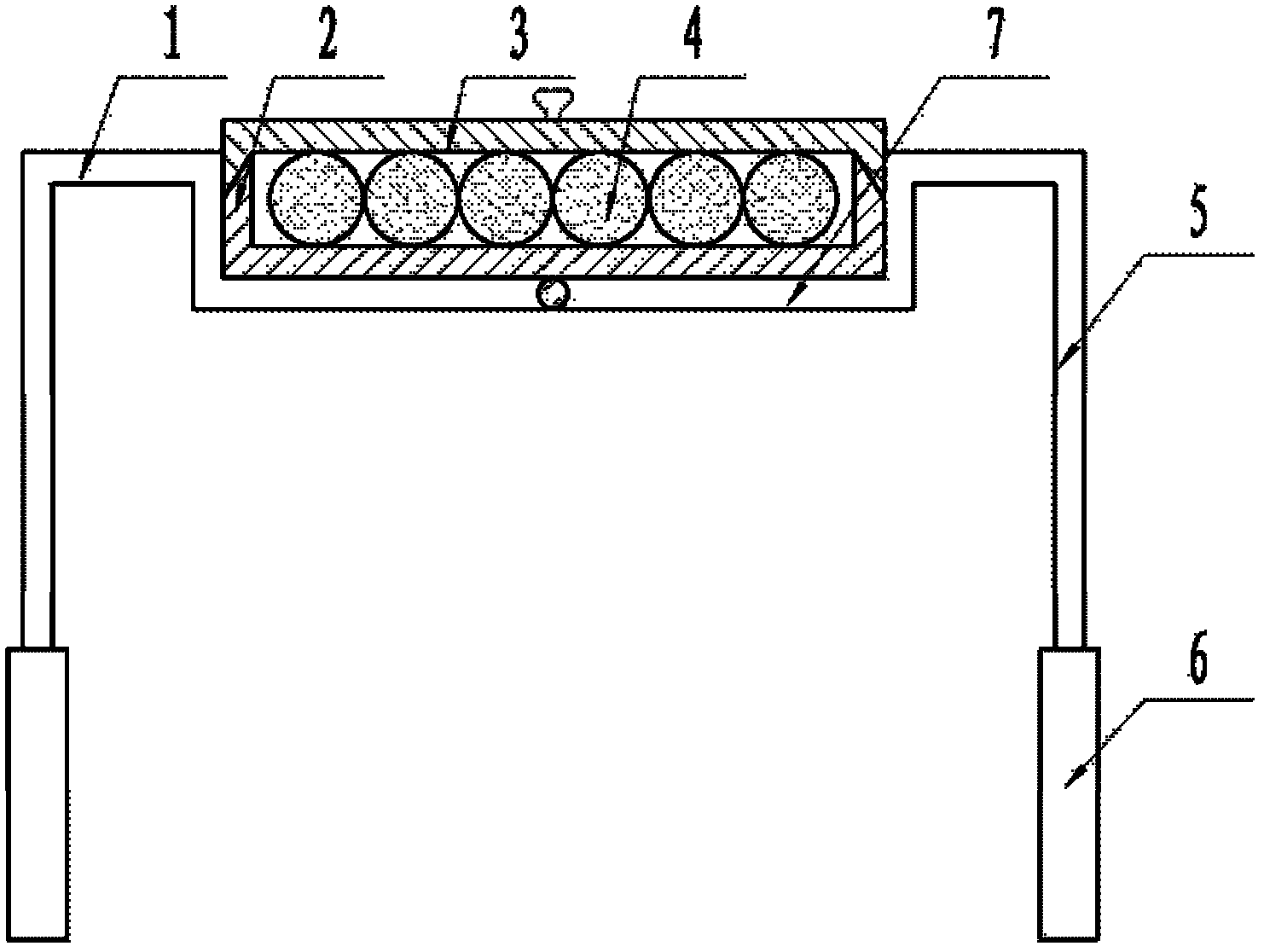

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: Add 150ml of water into a 500ml beaker, turn on the electric furnace to the second gear, and heat until the water boils.

[0020] Insulated appliance Boiling time

[0021] Asbestos mesh 6 minutes

[0022] Insulation 4 minutes

Embodiment 2

[0023] Embodiment two: heating on the heat insulation device, the electric furnace is opened to the second gear, and when the explosion-proof dish 2 turns red, the electric furnace is closed, and the water can continue to heat up by utilizing the waste heat of the sand insulation layer 4; according to the situation, the electric furnace can be opened again, Repeat the previous process until the water boils, which takes no more than 5 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com