Thermal bridge suppression structure for equipment installation

A technology for installing thermal bridges and equipment, which is applied in the field of aircraft thermal structure connection, can solve problems that affect the reliability of electronic equipment inside the equipment, and the temperature rise of the equipment shell, so as to reduce heat transfer, reduce equipment temperature, and suppress thermal bridges Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

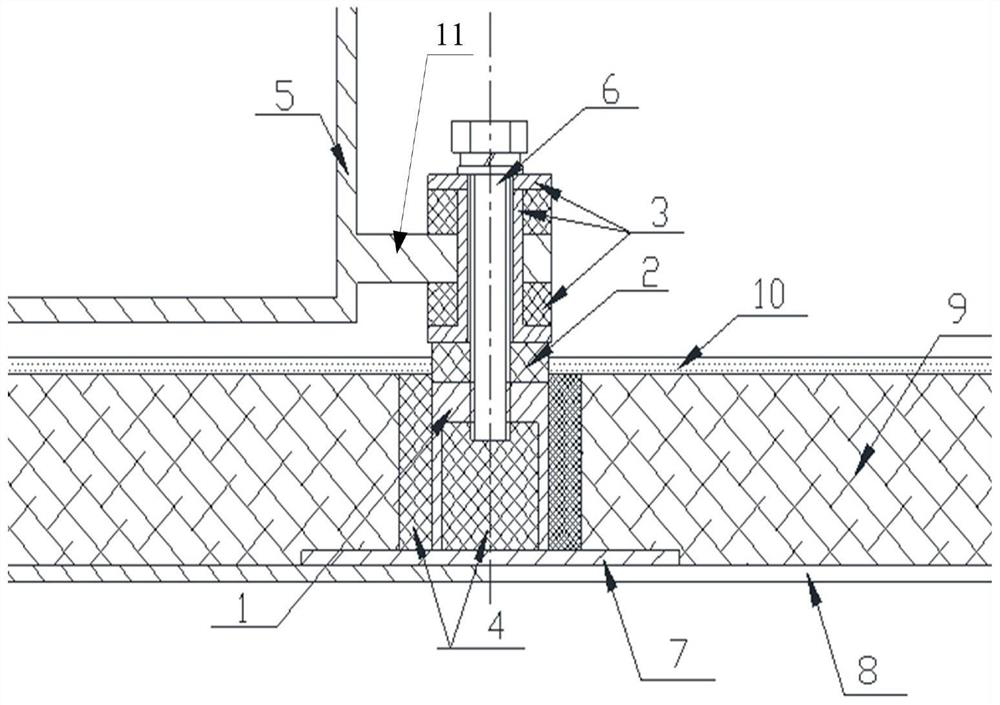

[0011] The present invention will be described in detail below in conjunction with specific examples and accompanying drawings.

[0012] The present invention as figure 1 As shown, an equipment installation thermal bridge suppression structure is provided. The equipment is installed in the air through the adapter tab 11 provided on the equipment housing 5. The adapter tab 11 is connected to the top of the mounting foot 1 through the connecting screw 6. The installation foot 1 is installed inside the thermal protection structure of the equipment compartment shell, and the bottom of the mounting leg 1 is connected to the equipment compartment shell 8 through an adapter gasket. The mounting leg 1 is a thin-walled hollow structure, and pyrolytic Material 4.

[0013] The invention reduces the heat transfer area passing through the heat bridge and the total heat transfer amount passing through the heat bridge through the mounting feet of the hollow structure. The heat transferred ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com