Micro-Channel Regeneratively Cooled Micro-Combustor

A micro-combustion chamber, regenerative cooling technology, applied in the field of aero-engines, to achieve the effect of reducing weight, improving combustion efficiency, and good ignition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

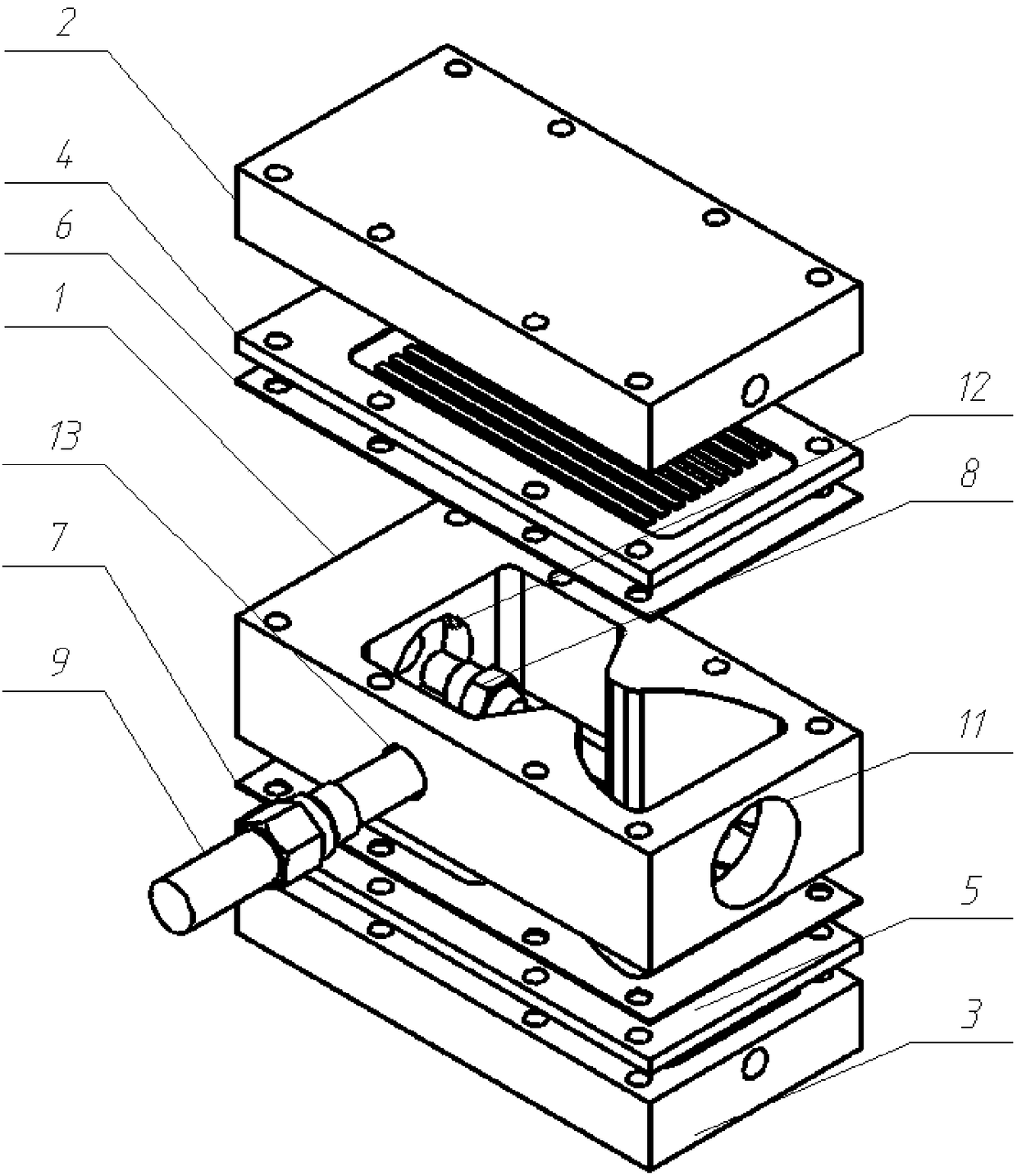

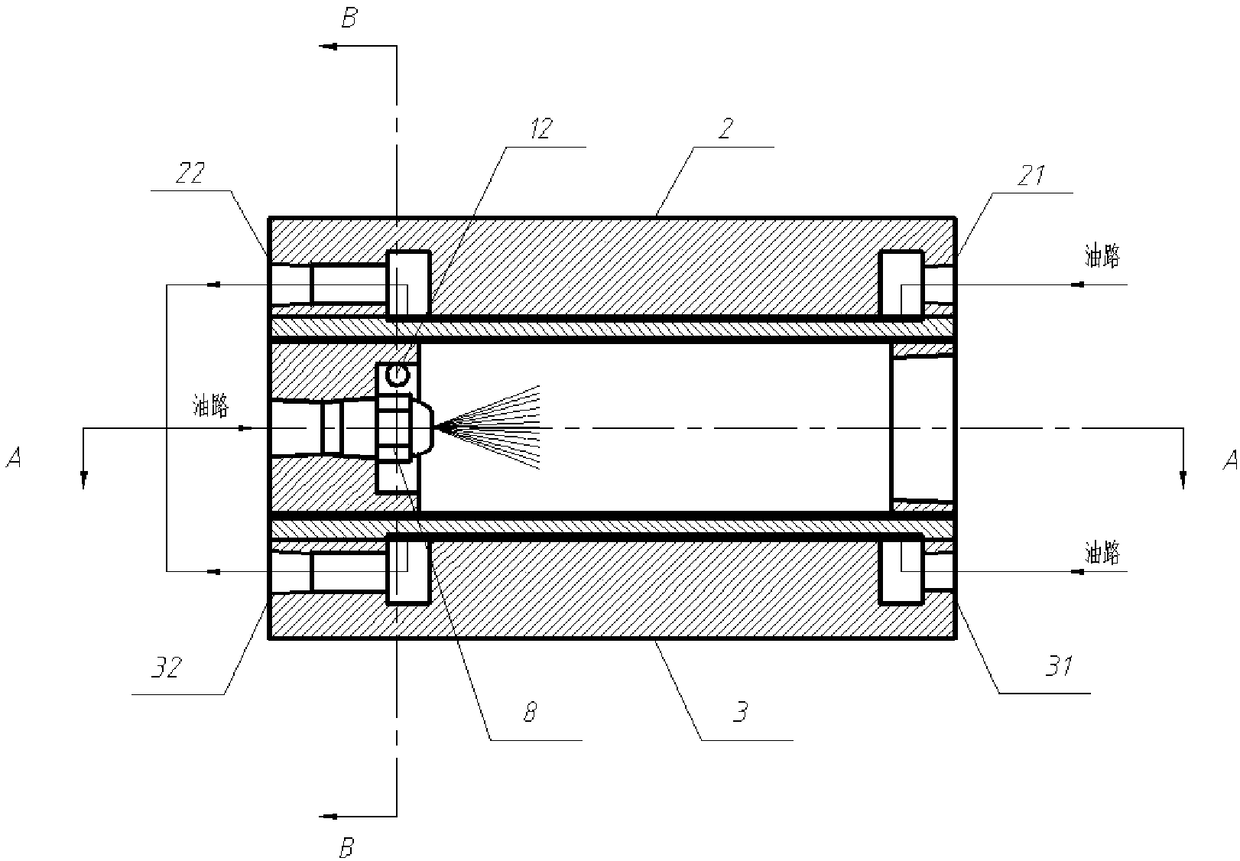

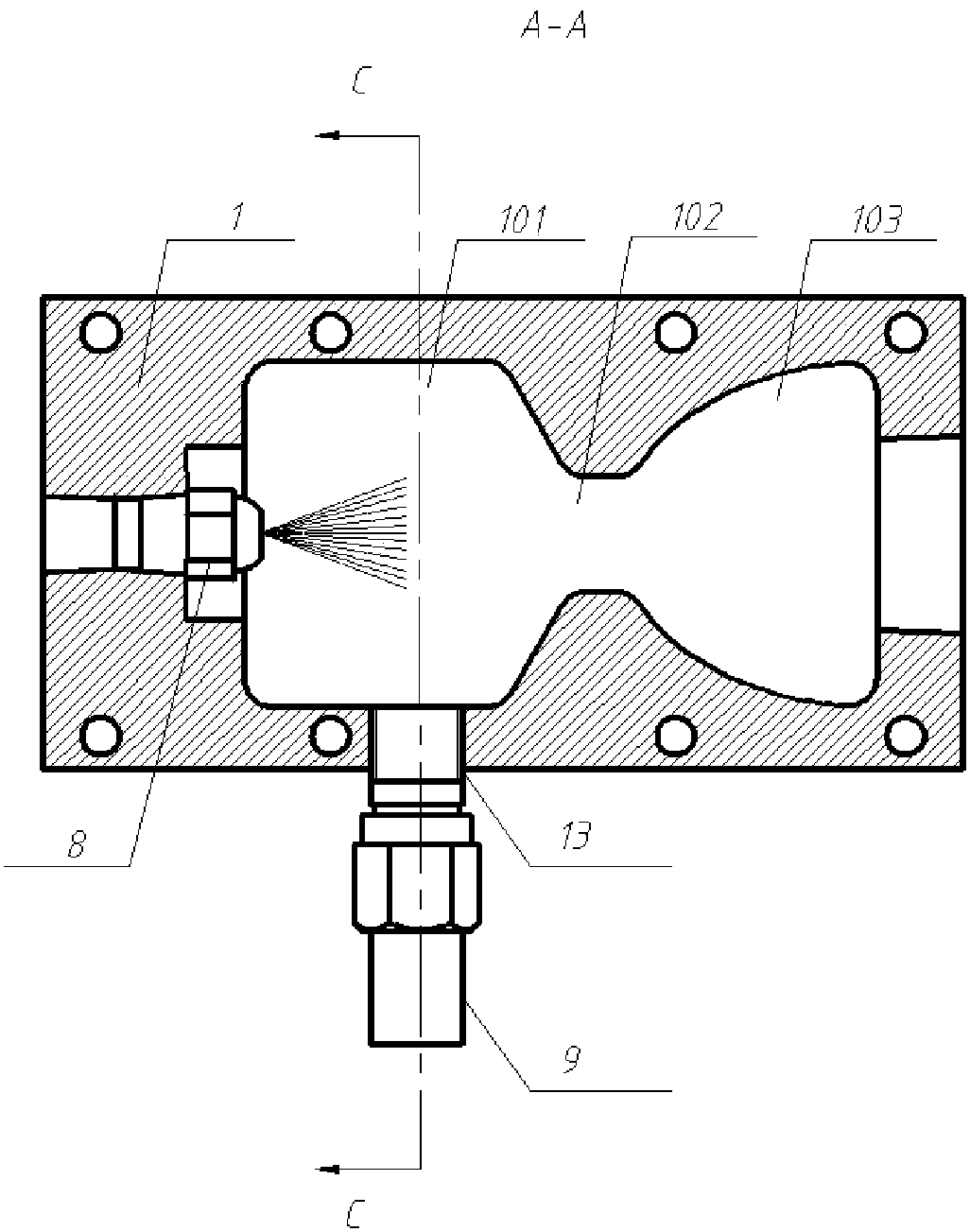

[0024] See figure 1 with figure 2 , A micro-combustion chamber with micro-channel regenerative cooling, such as figure 1 As shown, it is composed of the combustion chamber 1 and its upper and lower intermediate pads 6, 7, microchannel plates 4, 5, and top cover plates 2, 3 by stacking and combining, the combustion chamber 1, the middle pad The plates 6, 7, and the microchannel plates 4, 5 form a closed combustion chamber. The front end of the combustion chamber 1 is provided with a fuel nozzle 8, the rear end is an exhaust outlet 11, one side wall is provided with an air inlet 12, and the other side is provided There is a connection port 13 for the igniter 9; the top cover plates 2, 3 are provided with fuel inlets 21, 31 and outlets 22, 32 respectively; the microchannel plates 4, 5 contain 10-20 microchannels arranged in parallel and equally spaced. Channel 41. When assembling, stack the top cover plate 2, the microchannel plate 4, the middle backing plate 6, and the combustio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com