TiAl3/Al2O3 composite powder as well as preparation method and application thereof

A composite powder and powder technology, which is applied in the field of titanium alloy high-temperature protective coating preparation, can solve the problems of high coating brittleness, fast coating degradation, and easy cracks, etc., to achieve uniform distribution of two phases, easy control of components, and easy operation. The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

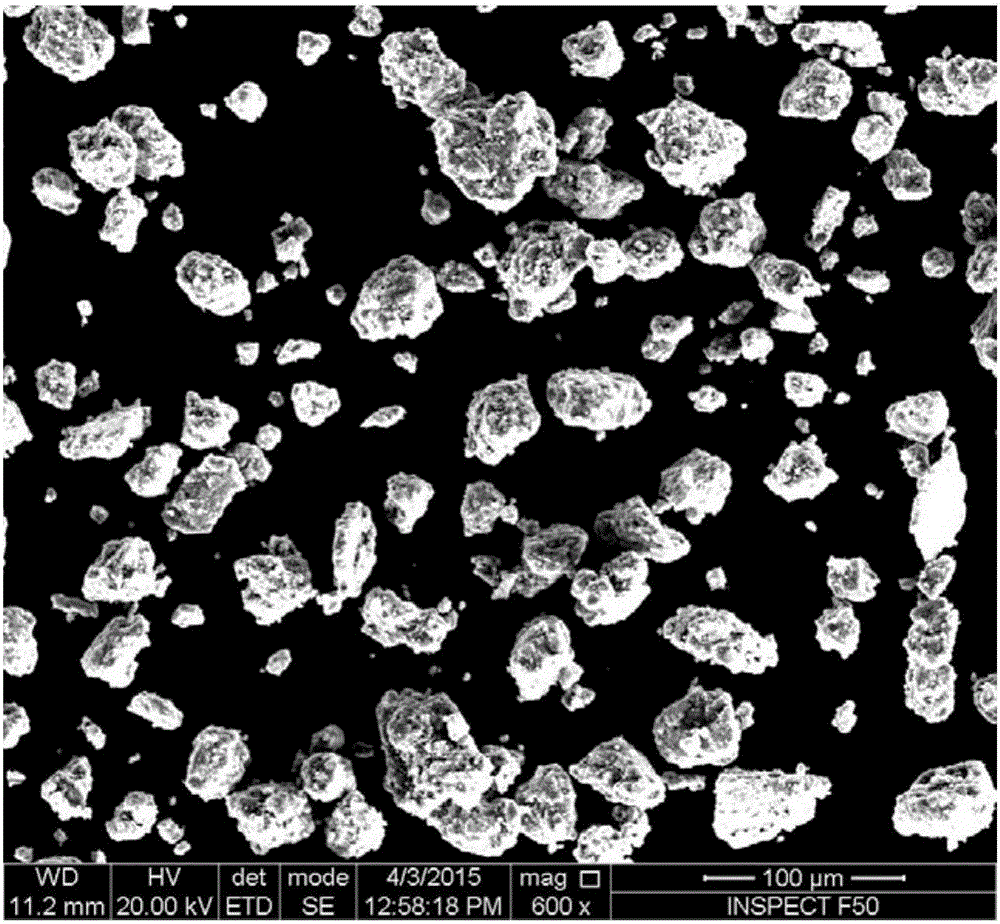

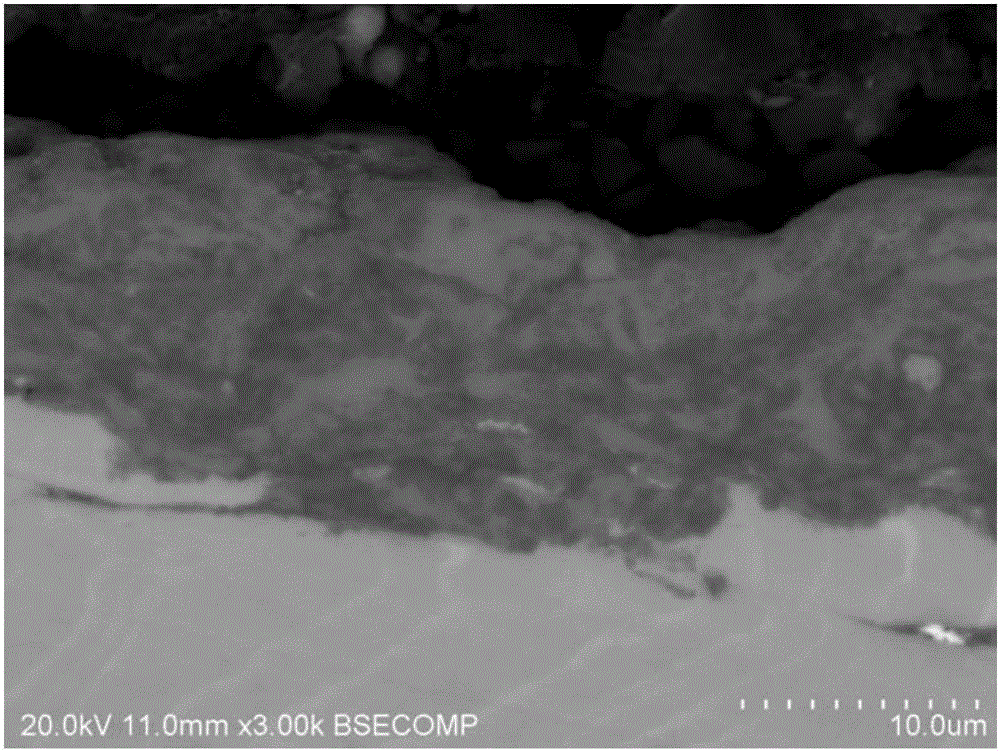

[0037] Pure Al powder with a particle size of 5-30 μm and nano-TiO 2 The powders were mixed at a mass ratio of 3:1 and then high-energy ball milled for 2 hours, and the powder after high-energy ball milling was heat-treated at 650°C for 10 hours to prepare TiAl 3 / Al 2 o 3 Composite powder is prepared by depositing composite powder on γ-TiAl matrix alloy with cold spraying equipment. The operating temperature is 500°C, the operating pressure is 1.8MPa, the coating thickness is 20μm, and the two phases in the composite coating are evenly distributed.

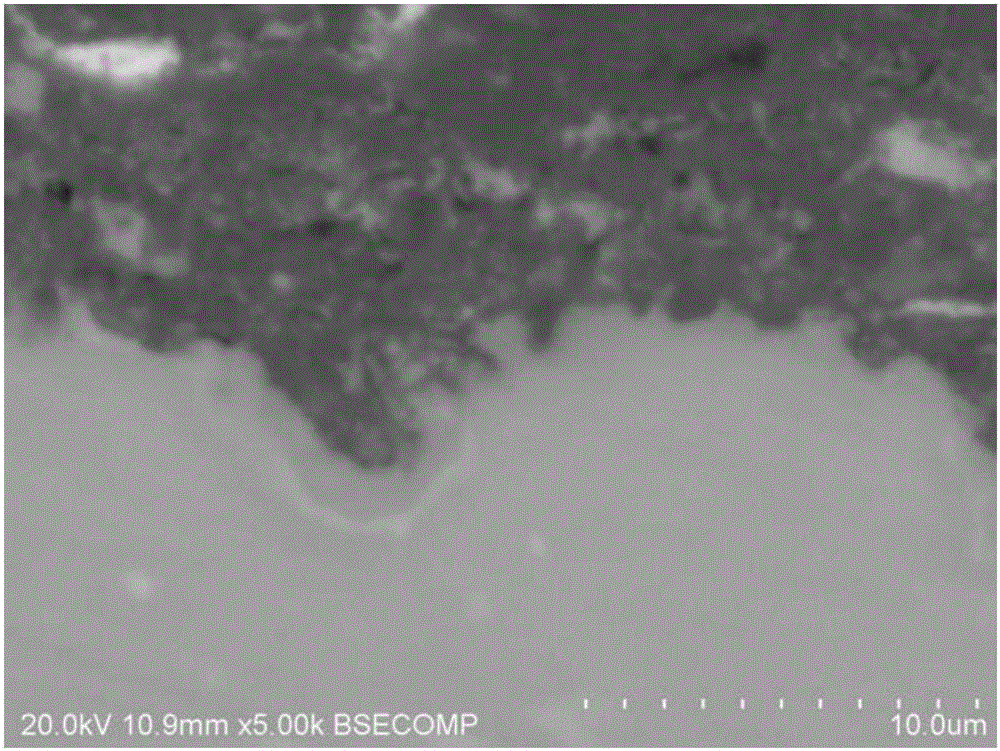

[0038] Such as figure 1 As shown, the particle size of the composite powder is in the range of 30-80 μm. Such as figure 2 As shown, the thickness of the composite coating is about 20 μm, and it is well combined with the substrate. Such as image 3 As shown, the interdiffusion between the composite coating and the substrate is significantly weakened after high temperature oxidation. Experimental results show that the coati...

Embodiment 2

[0040] Pure Al powder with a particle size of 5-30 μm and nano-TiO 2 The powders were mixed at a mass ratio of 2:1 and then high-energy ball milled for 1 h, and the powder after high-energy ball milling was heat-treated at 750 °C for 10 h to prepare TiAl 3 / Al 2 o 3 Composite powder, the composite powder prepared by depositing on the γ-TiAl matrix alloy with cold spraying equipment, the operating temperature is 600°C, the operating pressure is 2.0MPa, and the coating thickness is 30μm. Experimental results show that the coating has good high temperature oxidation resistance. The performance index of this example is: the weight gain of the coating is less than 2.5mg / cm after isothermal oxidation at 900°C for 500h 2 .

Embodiment 3

[0042] Pure Al powder with a particle size of 5-30 μm and nano-TiO 2 The powders were mixed at a mass ratio of 1:1 and then high-energy ball milled for 2 hours, and the powder after high-energy ball milling was heat-treated at 850°C for 10 hours to prepare TiAl 3 / Al 2 o 3 Composite powder, composite powder prepared by depositing on Ti-22Al-26Nb matrix alloy with cold spraying equipment, operating temperature 500°C, operating pressure 1.8MPa, coating thickness 10μm. Experimental results show that the coating has good high temperature oxidation resistance. The performance index of this example is: the weight gain of the coating is less than 2.0mg / cm after cyclic oxidation at 900°C for 100 times 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com