Preparation method of biphasic calcium phosphate composite powder synthesized by high-temperature solid-state reaction

A high-temperature solid-state reaction, biphasic calcium phosphate technology, applied in the direction of prosthesis, tissue regeneration, medical science, etc., can solve the problem of inability to effectively control the grain size and crystallinity of HA and β-TCP, unsuitable for mass production, very difficult Difficult two-phase structure and other problems, to achieve the effect of low raw material cost, controllable grain size and crystallinity, and uniform distribution of two phases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

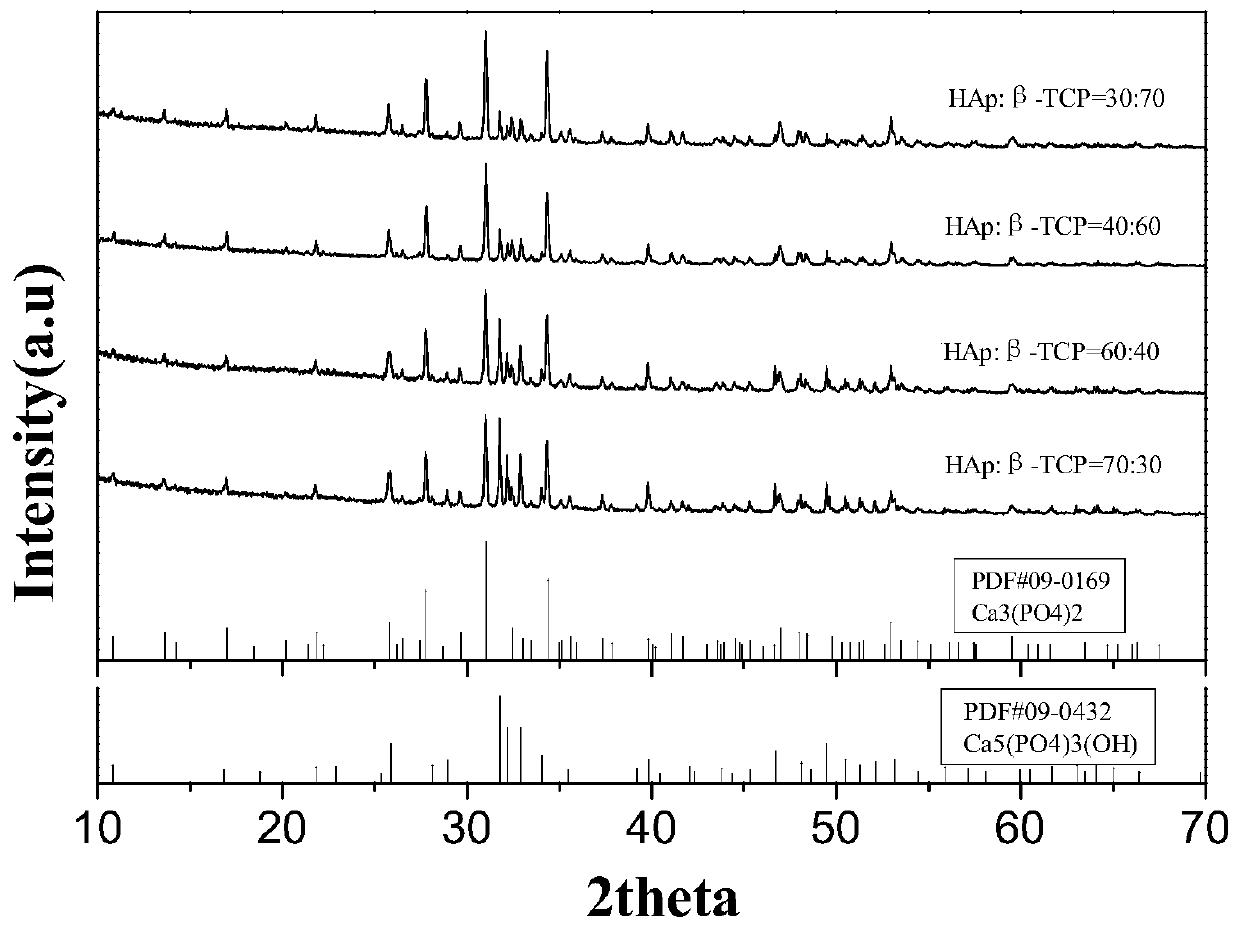

Embodiment 1

[0055] BCP (99wt% β-TCP+1wt% HA)

[0056] Weigh 200.78g calcium carbonate and 688.36g dibasic calcium phosphate dihydrate respectively, add 250ml ethanol and ball mill for 25h, the mass ratio of raw material and ball milling medium is 1:4, the ball mill speed is 450rpm to obtain a uniform mixed slurry, and then dry and crush. Place the dried and crushed mixed powder in a corundum crucible, and move it into a muffle furnace for calcination. When the temperature is raised to 700℃, the deionized water is introduced at a rate of 0.2ml / min, and it is calcined at 900℃ for 5 hours. After the furnace is cooled down, the desired product is obtained. X-ray diffraction (XRD) and scanning electron microscopy (SEM) analysis results show that the product is BCP (99wt%β-TCP+1wt%HA) composite powder with a grain size of 0.1-2μm and a crystallinity of more than 75%.

Embodiment 2

[0058] BCP (1wt% β-TCP+99wt% HA)

[0059] Weigh 266.2g calcium carbonate and 688.4g dibasic calcium phosphate dihydrate, the mass ratio of raw material and ball milling medium is 1:4, add 500ml deionized water and ball mill for 18h, the speed of the ball mill is 350rpm to obtain a uniform mixed slurry, and then dry Shattered. Place the dried and crushed mixed powder into the device for calcination. When the temperature is raised to 700°C, deionized water is introduced at a rate of 1ml / min, and finally the temperature is raised to 1200°C and kept for 3h, and the temperature is reduced to 800 at a rate of 5°C / min. Stop passing the deionized water after temperature, and obtain the required BCP (1wt% β-TCP+99wt% HA) composite powder after natural cooling. XRD and SEM analysis results show that the product has a crystal grain size of 2-15 μm and a crystallinity of over 85%.

Embodiment 3

[0061] BCP (10wt% β-TCP+90wt% HA)

[0062] Weigh 391.15g calcium carbonate and 1036.50g dibasic calcium phosphate dihydrate, the mass ratio of raw material and ball milling medium is 1:3, add 520ml deionized water and ethanol mixed ball mill solvent and ball mill for 4h, the ball mill speed is 350rpm, to obtain a uniform mixed slurry Material, and then dried and crushed. Place the dried and crushed mixed powder in the device for calcination. When the temperature is raised to 700°C, deionized water is introduced at a rate of 3ml / min, and finally the temperature is raised to 1150°C and kept for 8h, and the temperature is reduced to 800 at a rate of 4°C / min. Stop passing in deionized water after ℃, and obtain the required BCP (10wt% β-TCP+90wt% HA) composite powder after natural cooling. XRD and SEM analysis results show that the crystal grain size of the product is 10-27 μm, and the crystallinity is about 80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com