A kind of heat penetration process of s32750 duplex stainless steel

A technology of duplex stainless steel and pipe penetration, which is applied in the field of heat penetration pipe technology, can solve the problems of uneven wall surface and core structure, easy cracking strength of heat penetration pipe, and difficult coordination of dual phase structure, etc. The effects of small particle size, improved strength and toughness, and uniform distribution of the two phases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

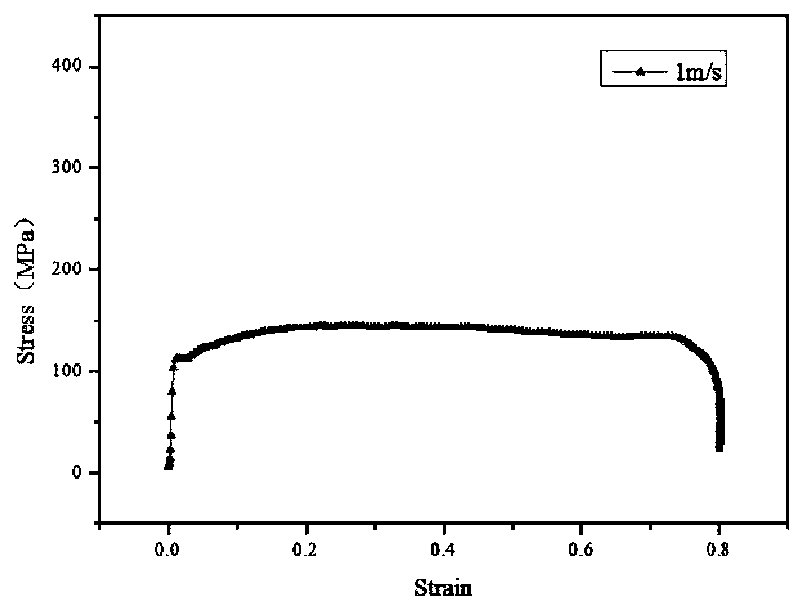

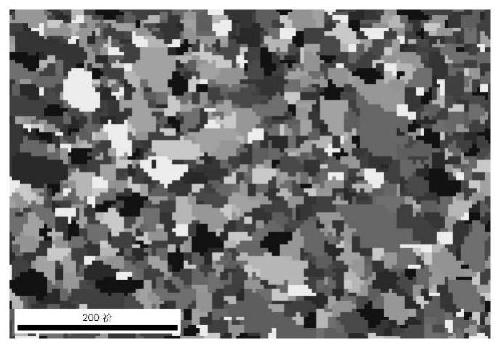

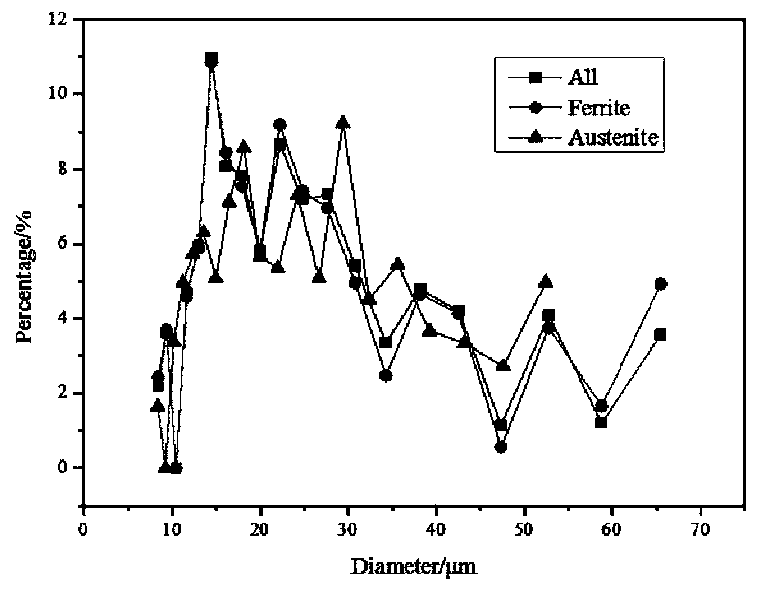

[0022] Heat the S32750 duplex stainless steel bar to 1250°C (this temperature is the solid solution temperature) and keep it warm for 60 minutes, and heat through the pipe at a temperature of 1050°C at a rate of 1m / s. The analysis results of the curve and deformed tissue are as follows: Figure 1-4 See Table 1 for grain size and two-phase ratio data.

Embodiment 2

[0055] The S32750 duplex stainless steel bar was processed with the same processing technology and parameters as in Comparative Example 14, the only difference being that the pipe penetration temperature was 950°C, and the grain size and two-phase ratio data are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com