Lower spraying laminar flow cooling device

A laminar cooling device and cooling device technology, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of reducing the edge of the strip, uneven cooling distribution, and high water consumption of the device. consumption, avoid water waste, ensure the effect of the shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

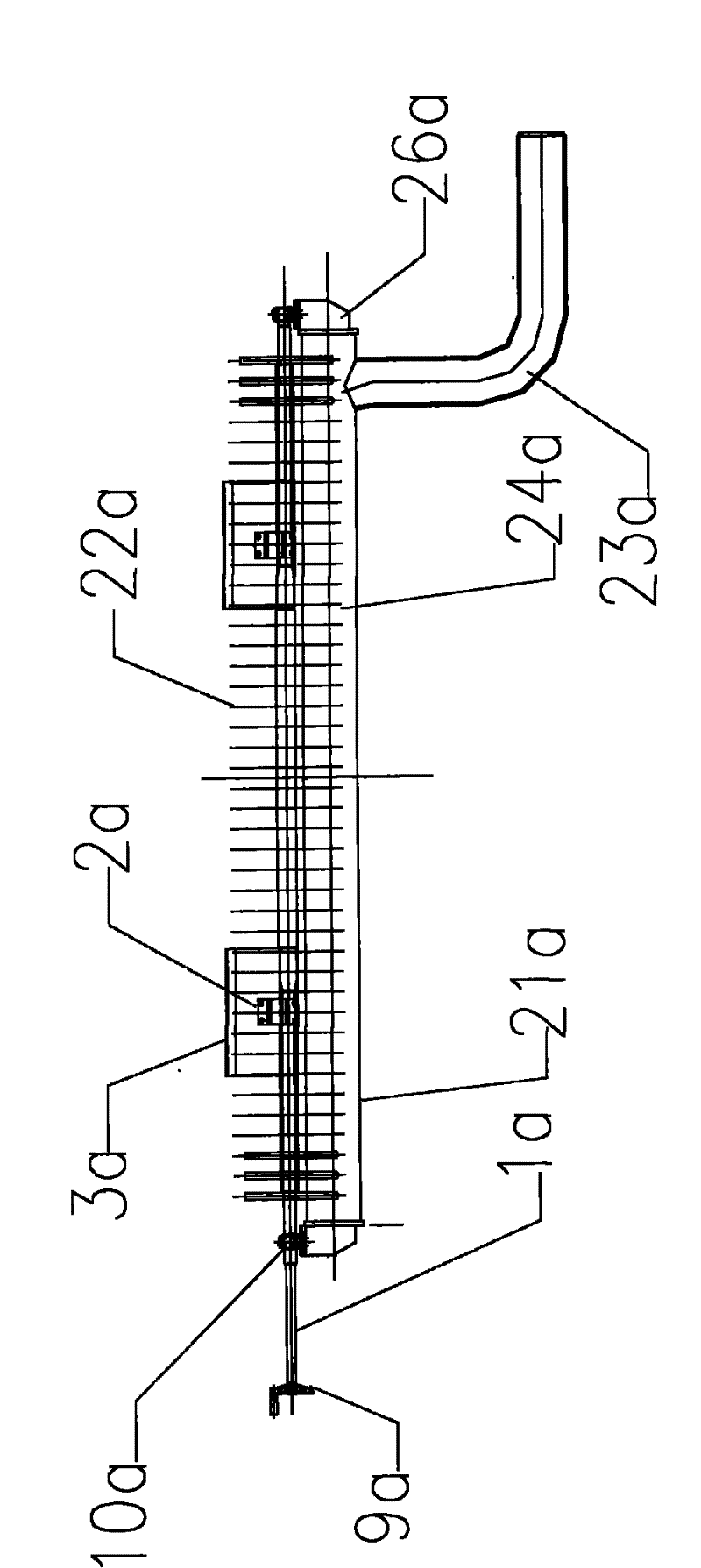

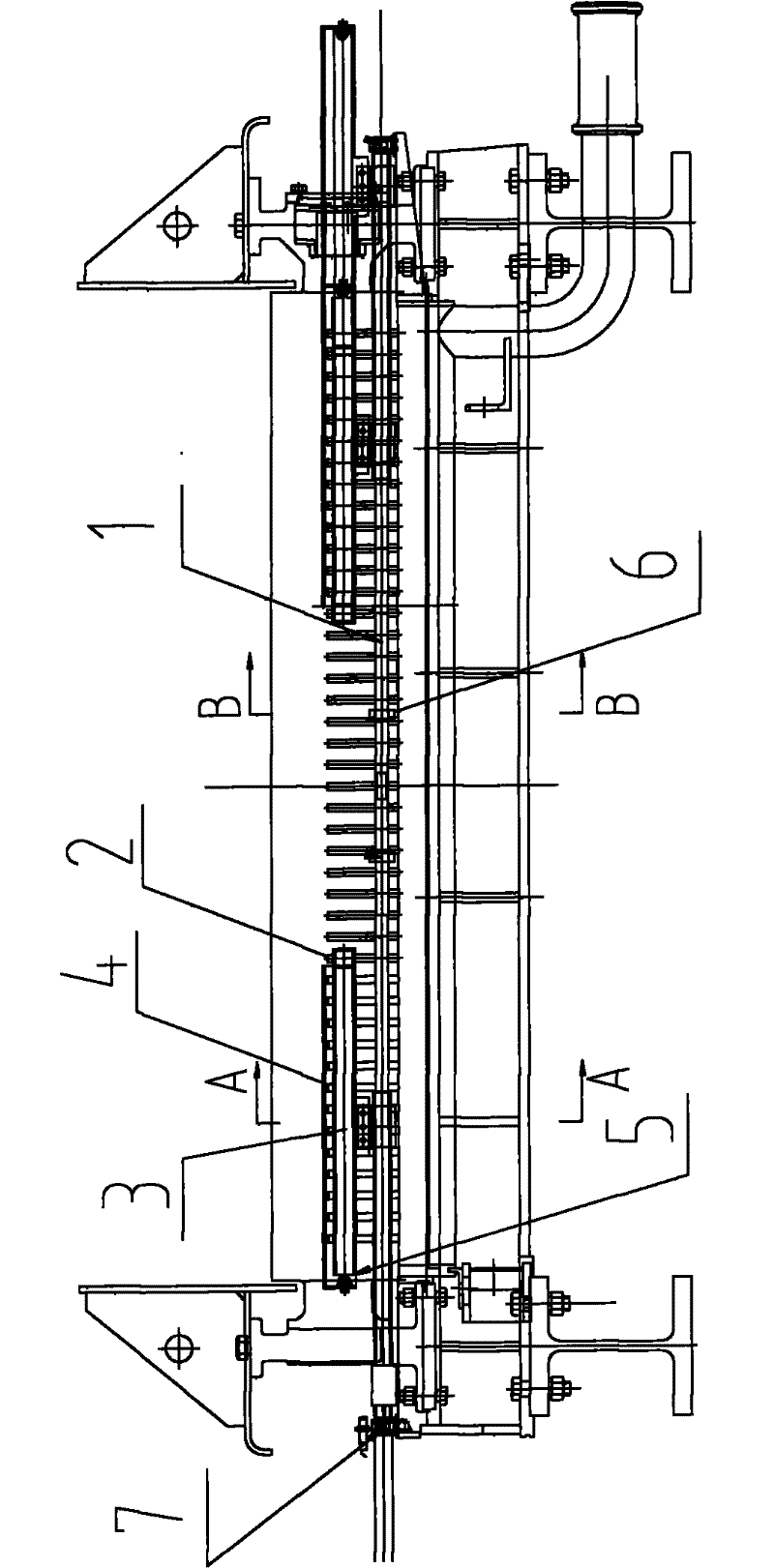

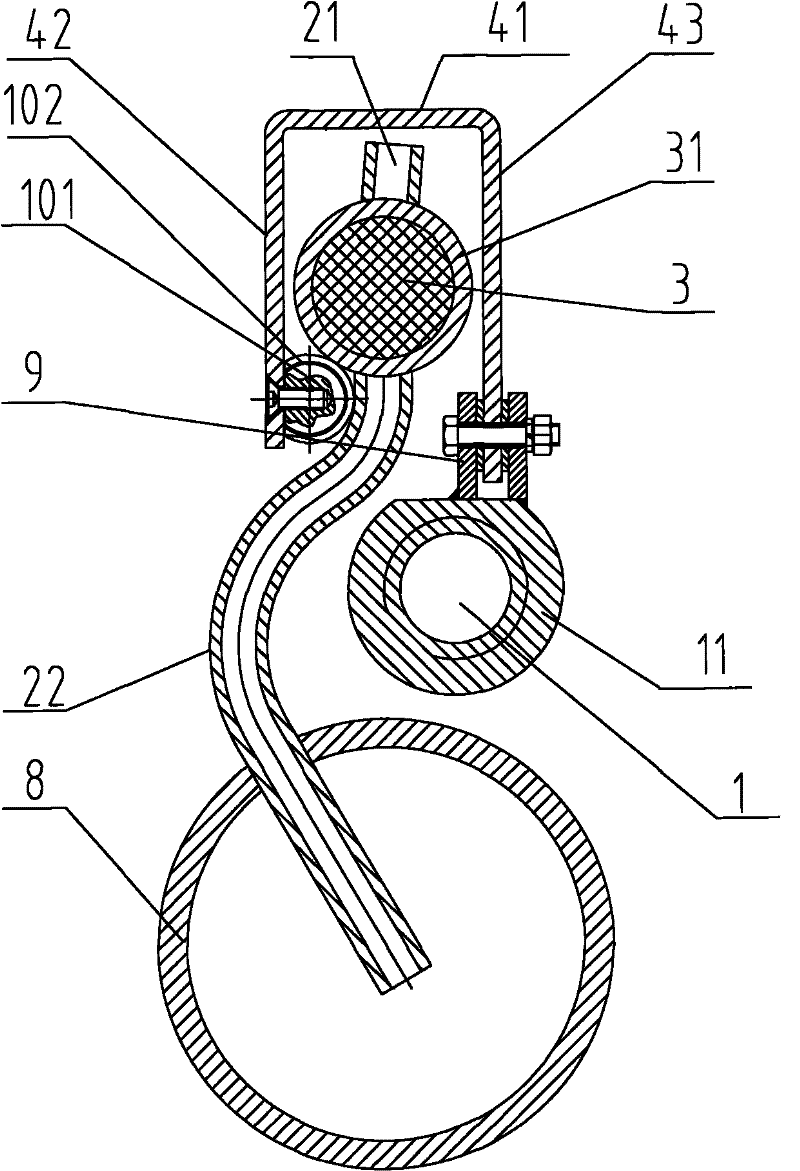

[0051] In this example will combine Figure 2-Figure 5 A preferred embodiment of the present invention is introduced.

[0052] The down spray laminar flow cooling device in the present embodiment comprises several groups of down spray devices, each group of down spray devices such as figure 2 and image 3 The shown includes: a header 8 fixedly arranged along the running direction of the vertical strip; a number of gooseneck nozzles 2 are evenly distributed on the header 8 along the axial direction of the header, and the gooseneck nozzles 2 are connected to the header 8; Two plunger pipes 31 are respectively fixedly arranged above the left and right ends of the manifold 8, and the two plunger pipes 31 run through a plurality of gooseneck nozzles 2 evenly distributed at both ends of the manifold 8 respectively, and the gooseneck nozzles 2 are sprayed on respectively. 21 and the lower nozzle pipe 22, the plunger pipe 31 is connected with the upper nozzle 21 and the lower nozzl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com