Film cooling system with ejector and method

A technology of film cooling and ejector, which is applied in space vehicle heat protection devices, aerospace safety/emergency devices, aircraft parts, etc. It can solve the problems of simple structure and achieve the effect of increasing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

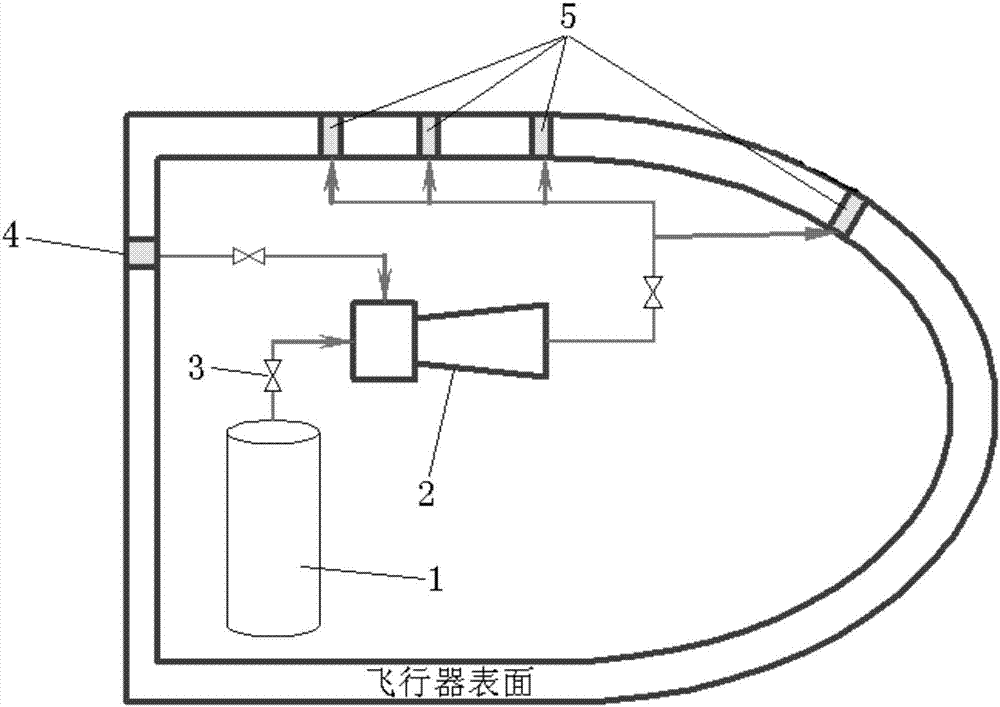

Embodiment 1

[0022] Such as figure 1 As shown, this embodiment provides an ejector-containing film cooling system carrying a gaseous coolant, which includes a coolant storage container 1 and an ejector 2 . Wherein, the coolant storage container 1 stores gaseous coolant, and the coolant storage container 1 is arranged inside the hypersonic aircraft. The coolant storage container 1 is connected to the high-pressure inlet of the ejector 2 through the pipeline and the regulating valve 3, and the low-pressure inlet of the ejector 2 is connected to the suction hole 4 on the surface of the aircraft through the pipeline. The outlet of the ejector 2 is connected with several film cooling microholes 5 on the surface of the aircraft through pipelines.

[0023] In a preferred embodiment, the position of the suction hole 4 is not limited, and the position on the surface of the aircraft with a lower atmospheric temperature is preferred.

[0024] In a preferred embodiment, the position of the film cool...

Embodiment 2

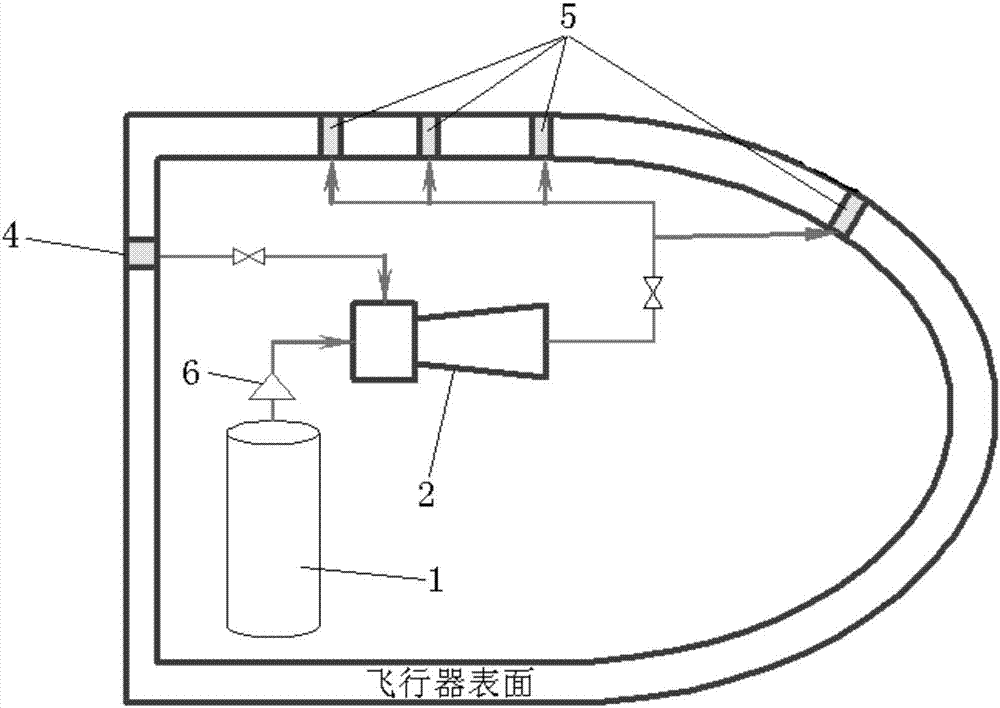

[0031] Such as figure 2 As shown, this embodiment provides an ejector-containing film cooling system carrying a liquid coolant, which includes a coolant storage container 1 and an ejector 2 . Wherein, liquid coolant is stored in the coolant storage container 1, and the coolant storage container 1 is arranged inside the hypersonic aircraft. The coolant storage container 1 is connected to the high-pressure inlet of the ejector 2 through a pipeline and a booster pump 6, and the low-pressure inlet of the ejector 2 is connected to the suction hole 4 on the surface of the aircraft through a pipeline. The outlet of the ejector 2 is connected with several film cooling microholes 5 on the surface of the aircraft through pipelines.

[0032] In a preferred embodiment, the position of the suction hole 4 is not limited, and the position on the surface of the aircraft with a lower atmospheric temperature is preferred.

[0033] In a preferred embodiment, the position of the film cooling m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com