Thermal protection method of porous medium jetting support plate leading edge nose cone

A technology for injecting struts and porous media, which is applied in combustion methods, lighting and heating equipment, combustion chambers, etc., can solve problems such as high stagnation temperature, damage to injection struts, engine flameout, etc., and achieve rapid and stable combustion, Easy to ignite and burn, enhance the effect of fuel blending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

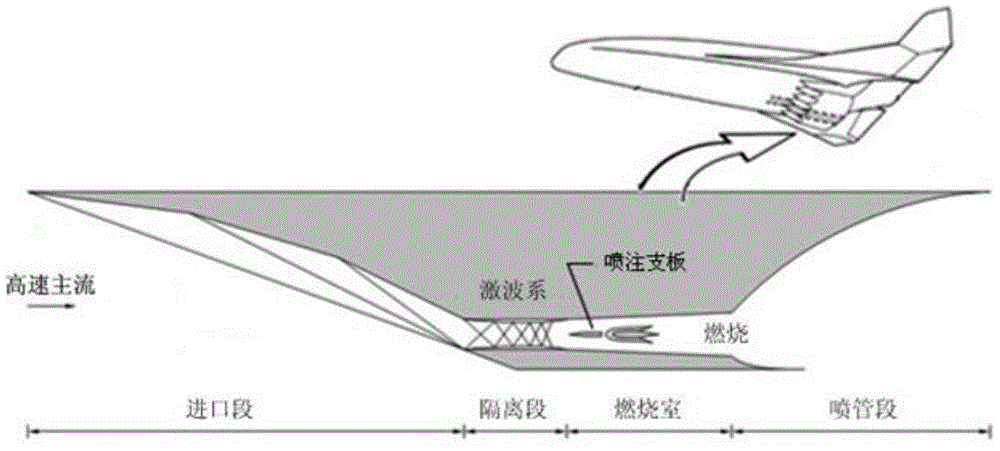

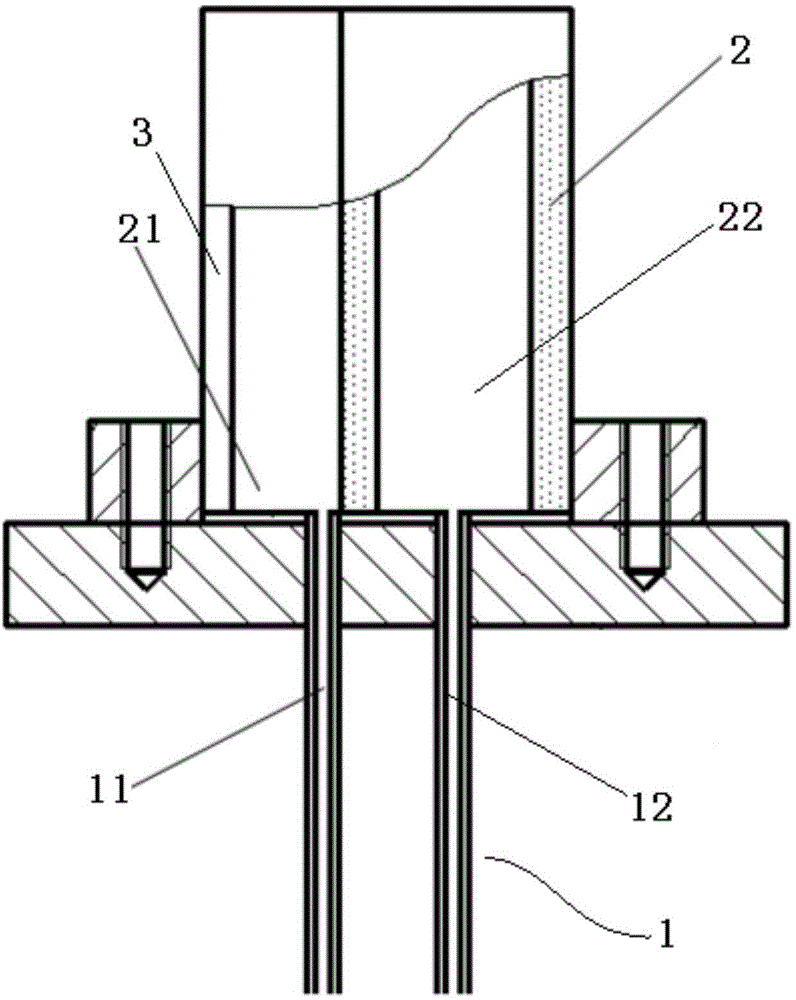

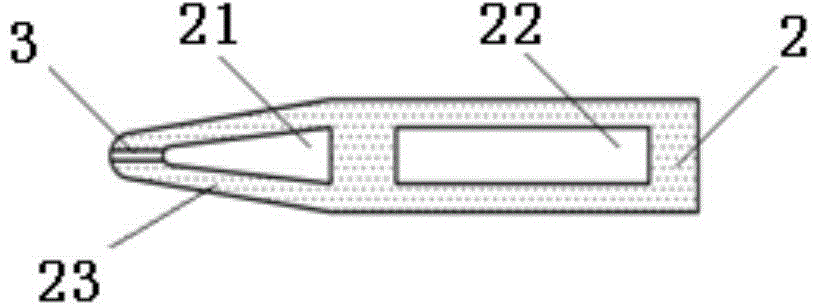

[0021] Such as figure 1 , figure 2 As shown, the fuel connected to the injection branch plate 2 by the fuel pipe 1 is controlled by the pump carried by the super-combustion engine itself and the valve arranged on the fuel channel. After reaching a certain pressure, it enters the injection branch plate 2 through the fuel pipe 1 , mixed with the high-speed air behind the shock wave system in the combustion chamber and then burned, the generated gas is ejected backward to provide power. The shape of the porous medium material used in the injection support plate 2 and the injection support plate 2 in the present invention is basically the same as that of the prior art, and the difference is that the structure, cooling method and oil injection method of the injection support plate 2 are used in the present invention. Improvements on. The difference bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com